An SVM-Based Scheme for Automatic Identification of Architectural Line Features and Cracks

Abstract

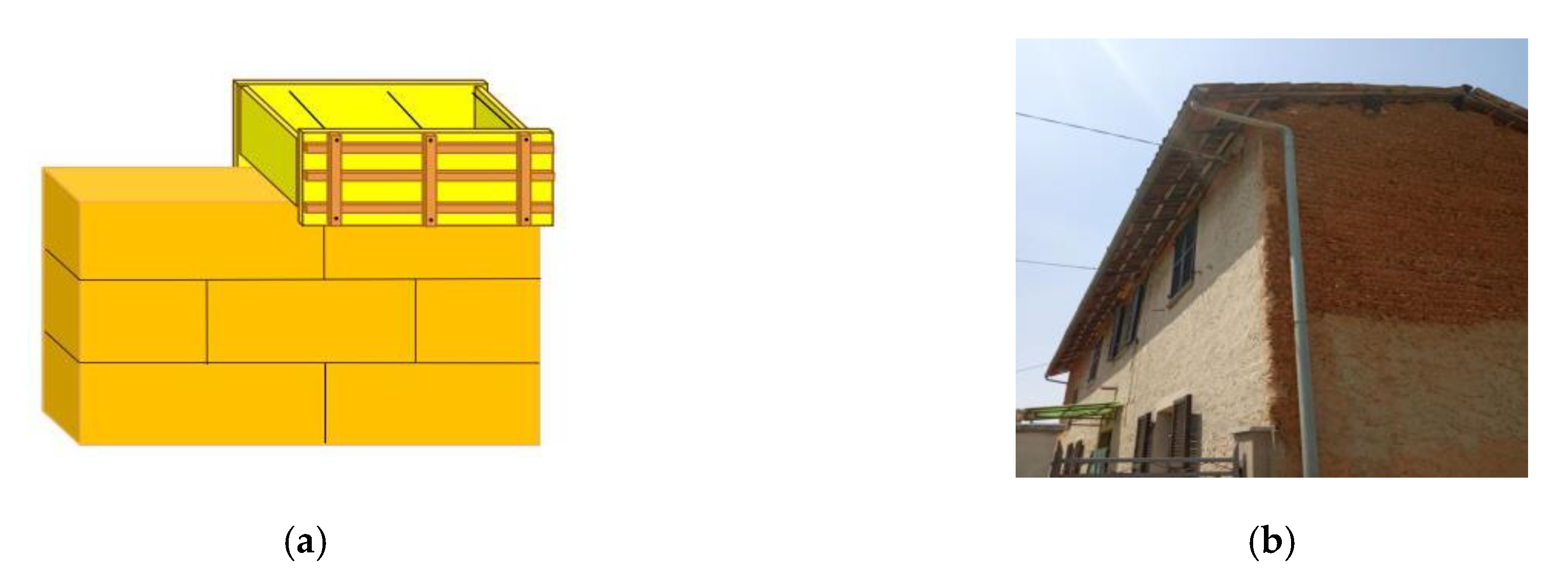

:1. Introduction

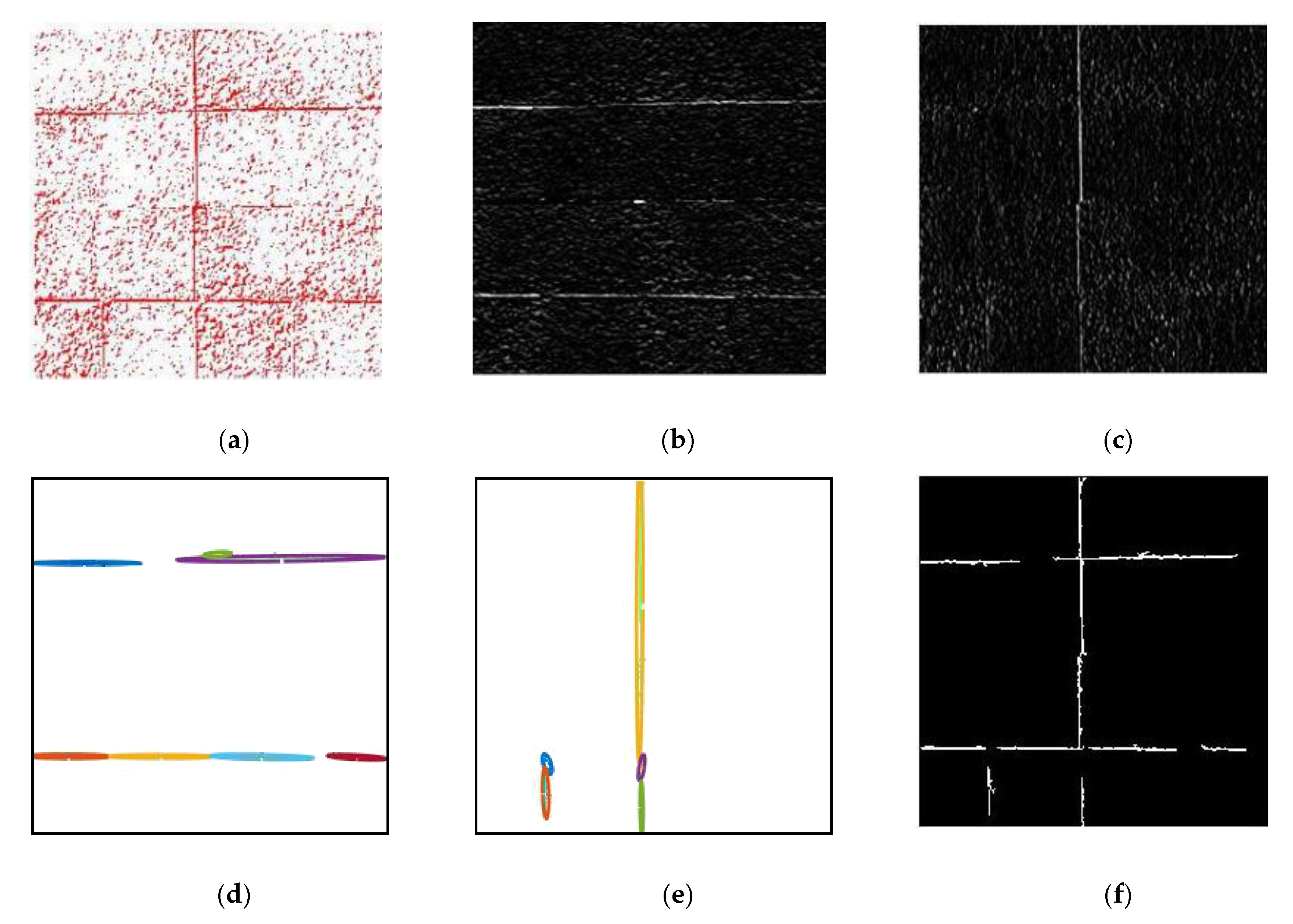

2. Developed Methodology

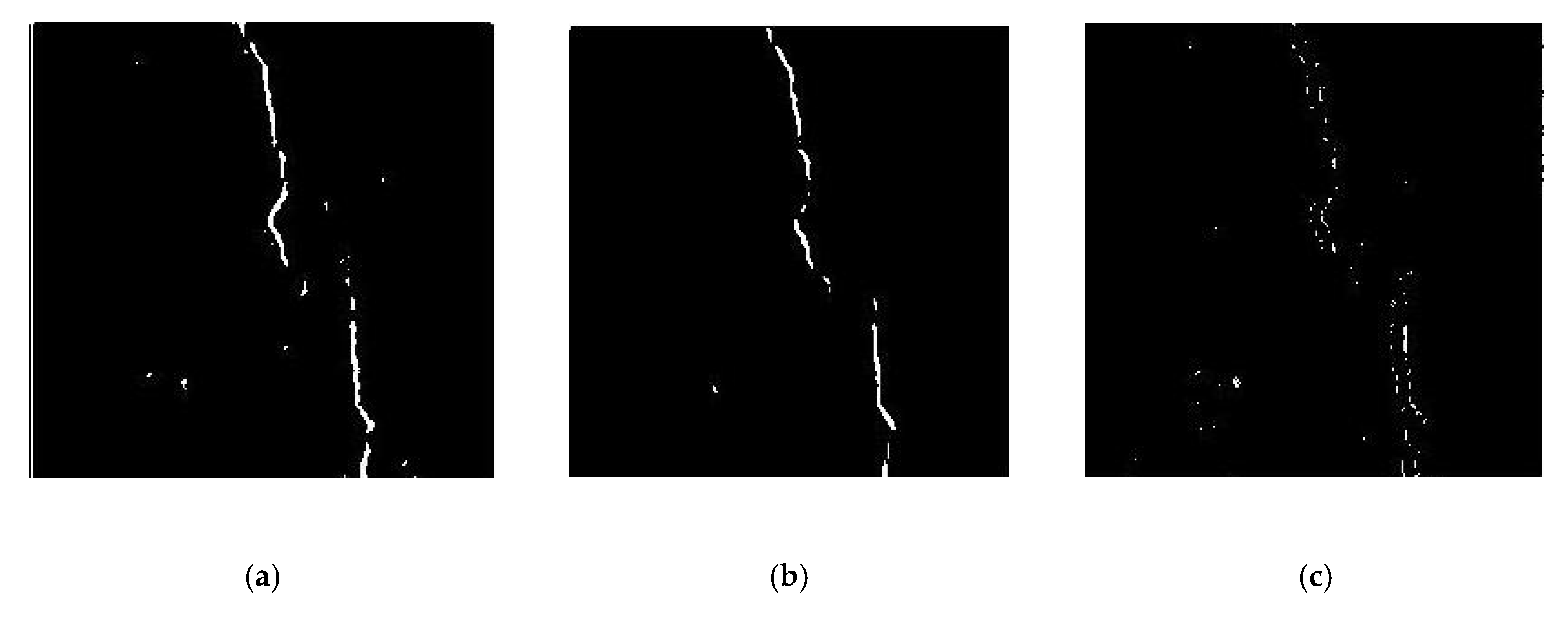

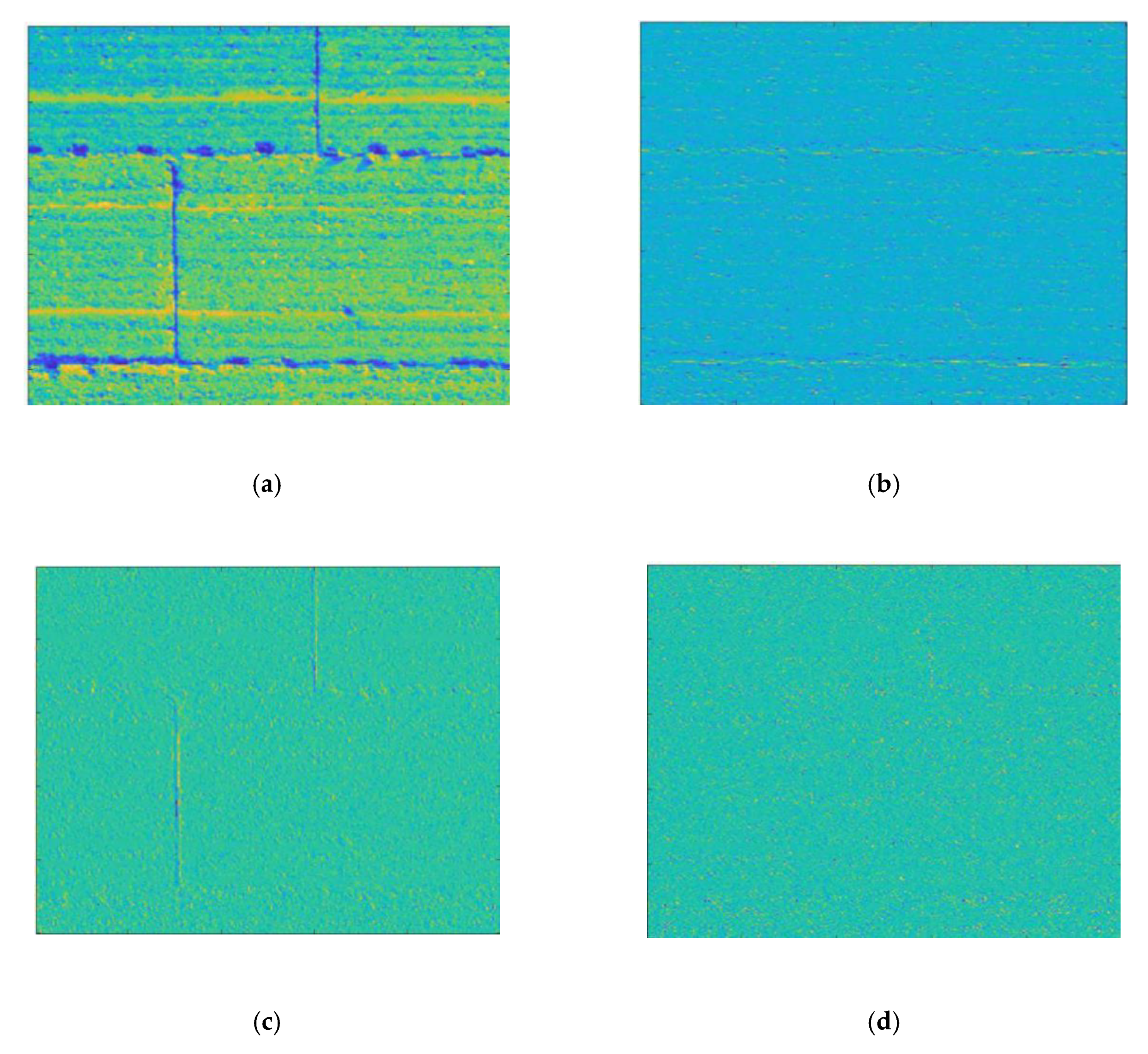

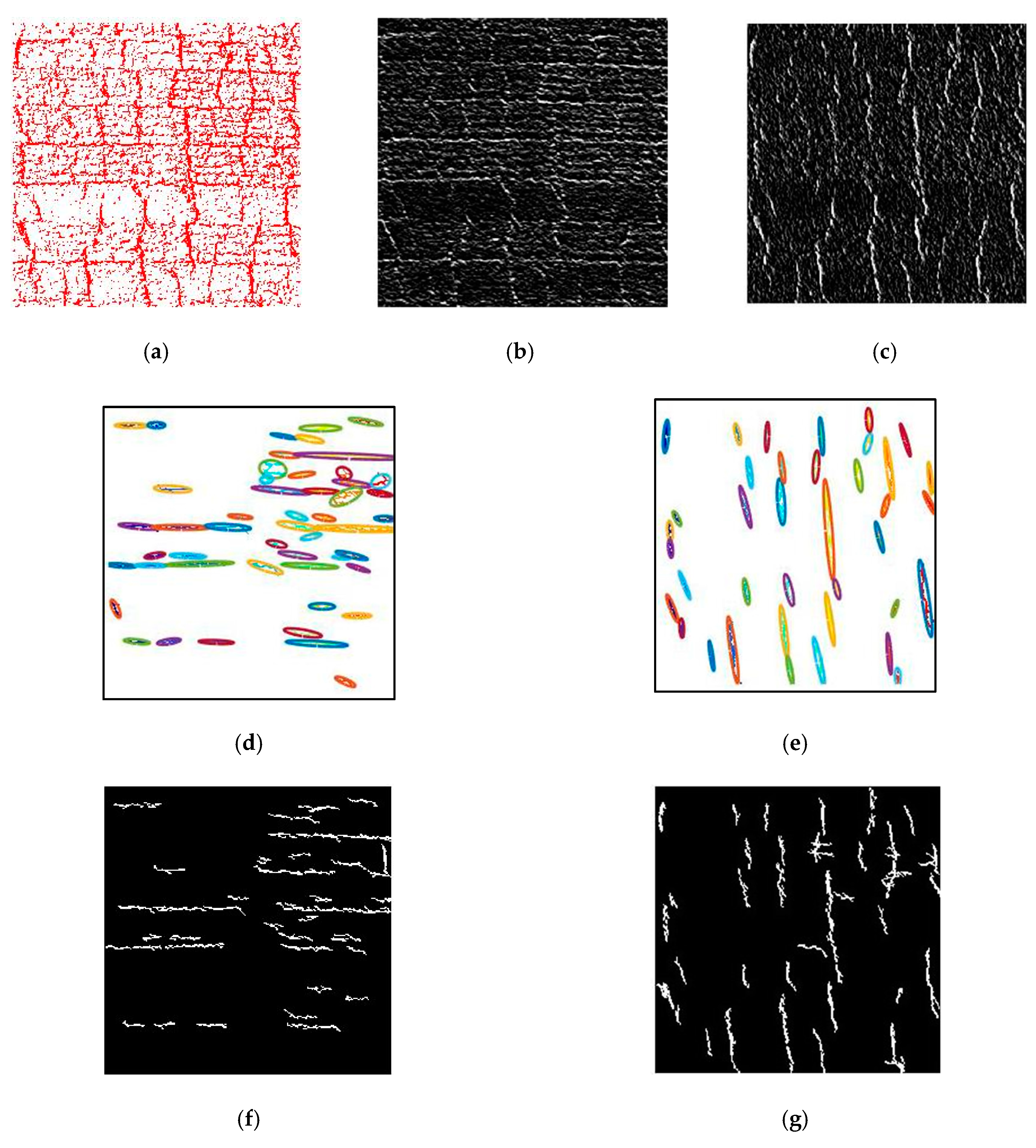

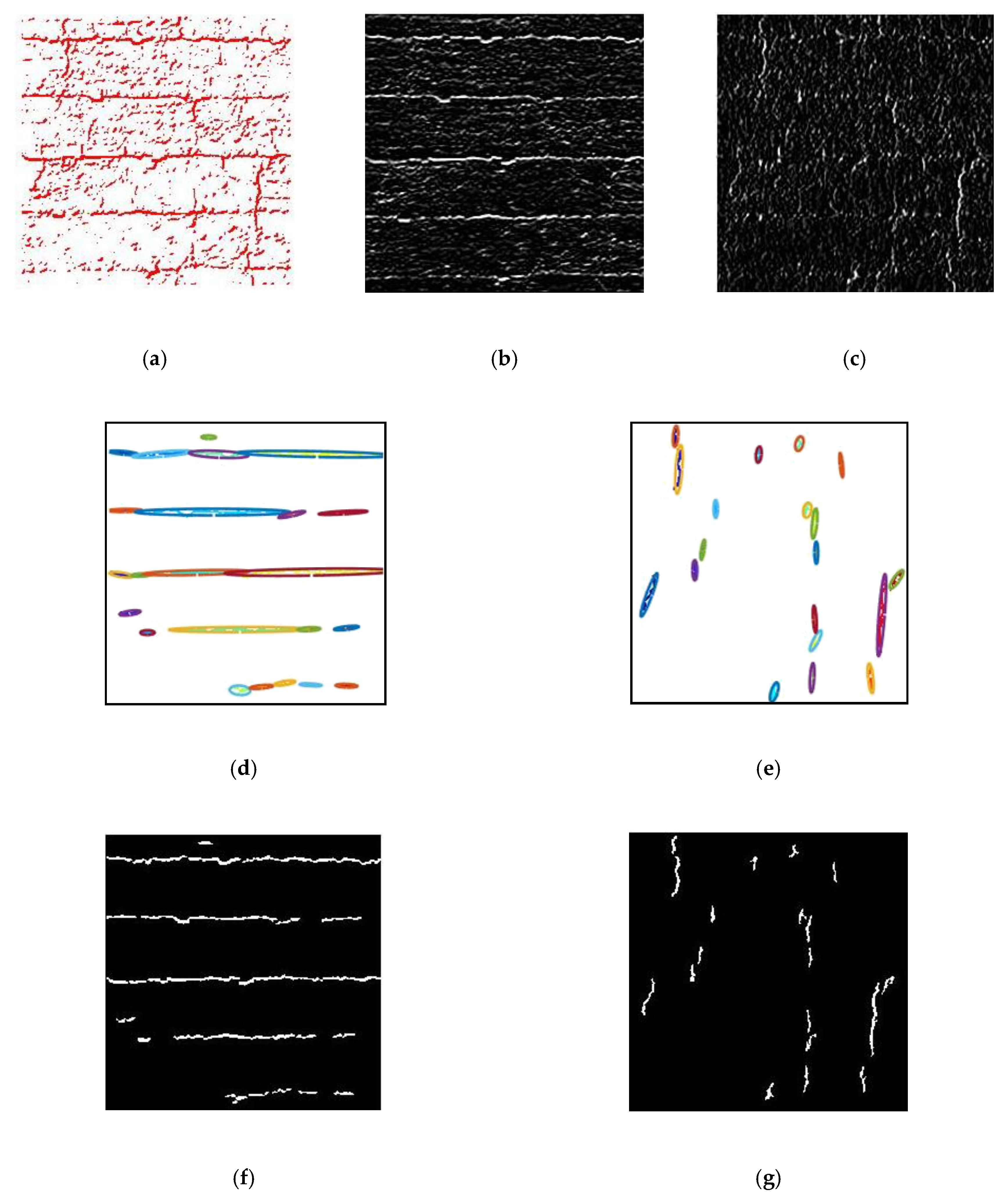

2.1. Constructing Edge Maps

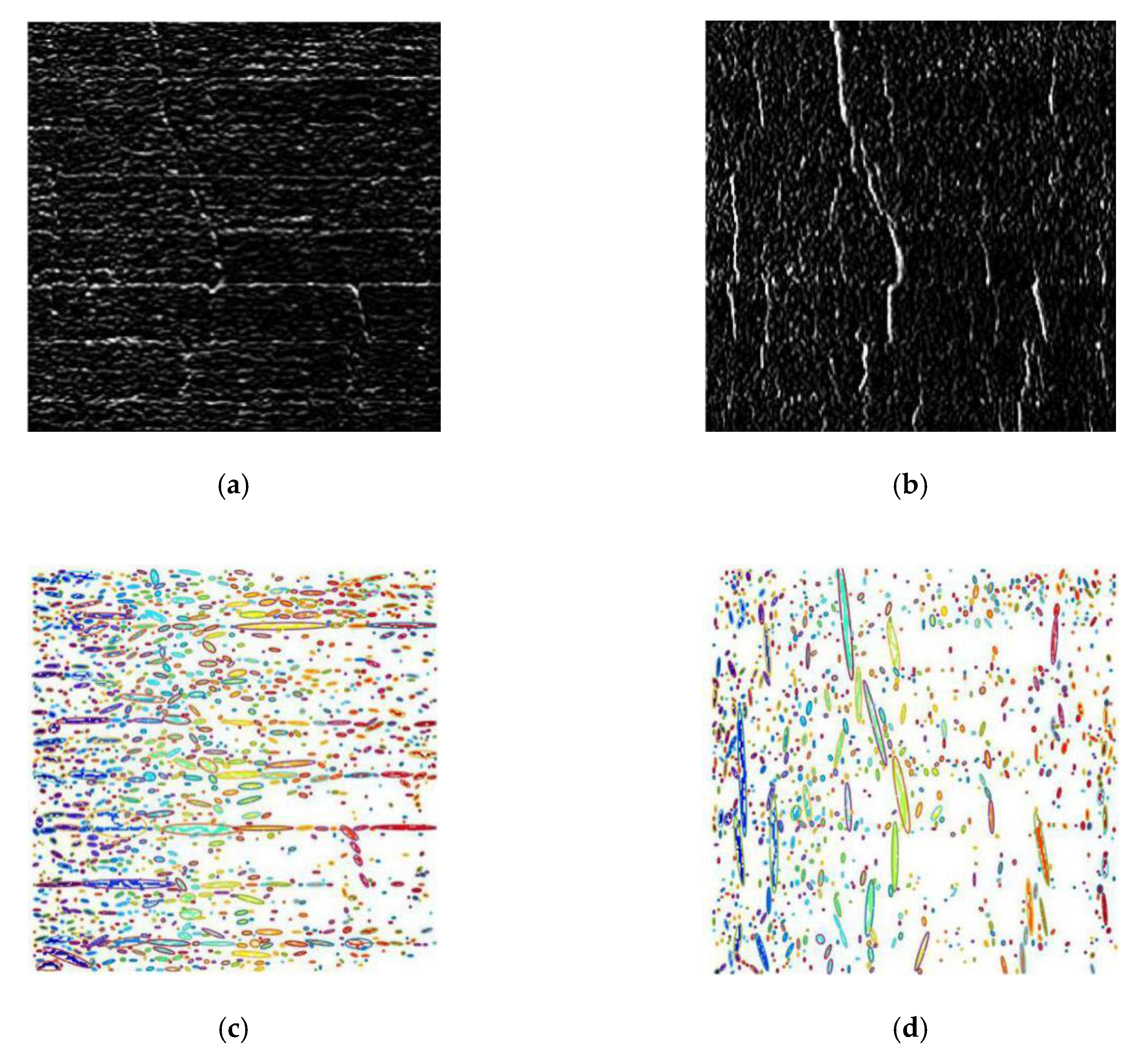

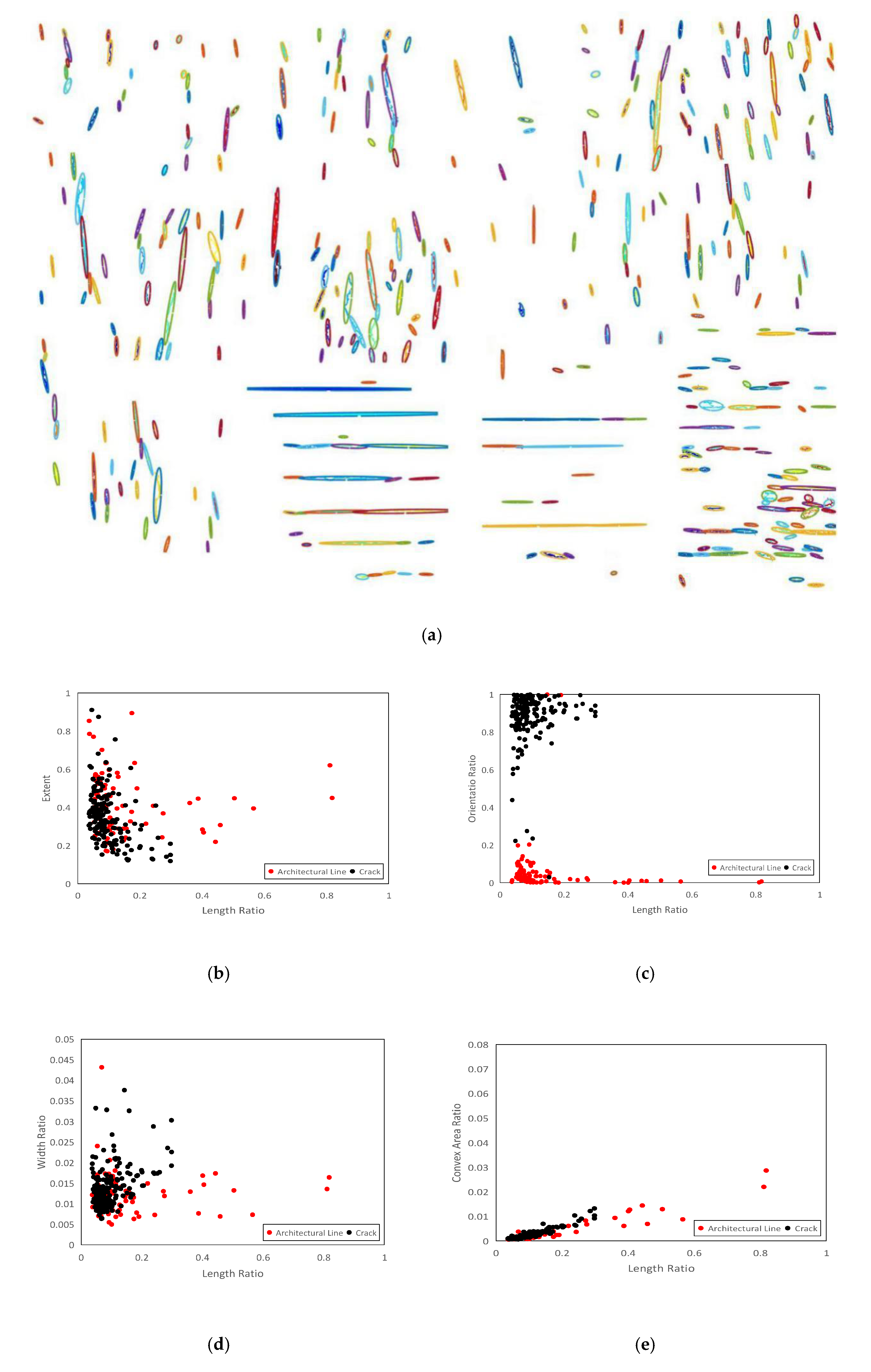

2.2. Connected Component Analysis

2.3. SVM-Based Classification Scheme

2.4. Map Generation

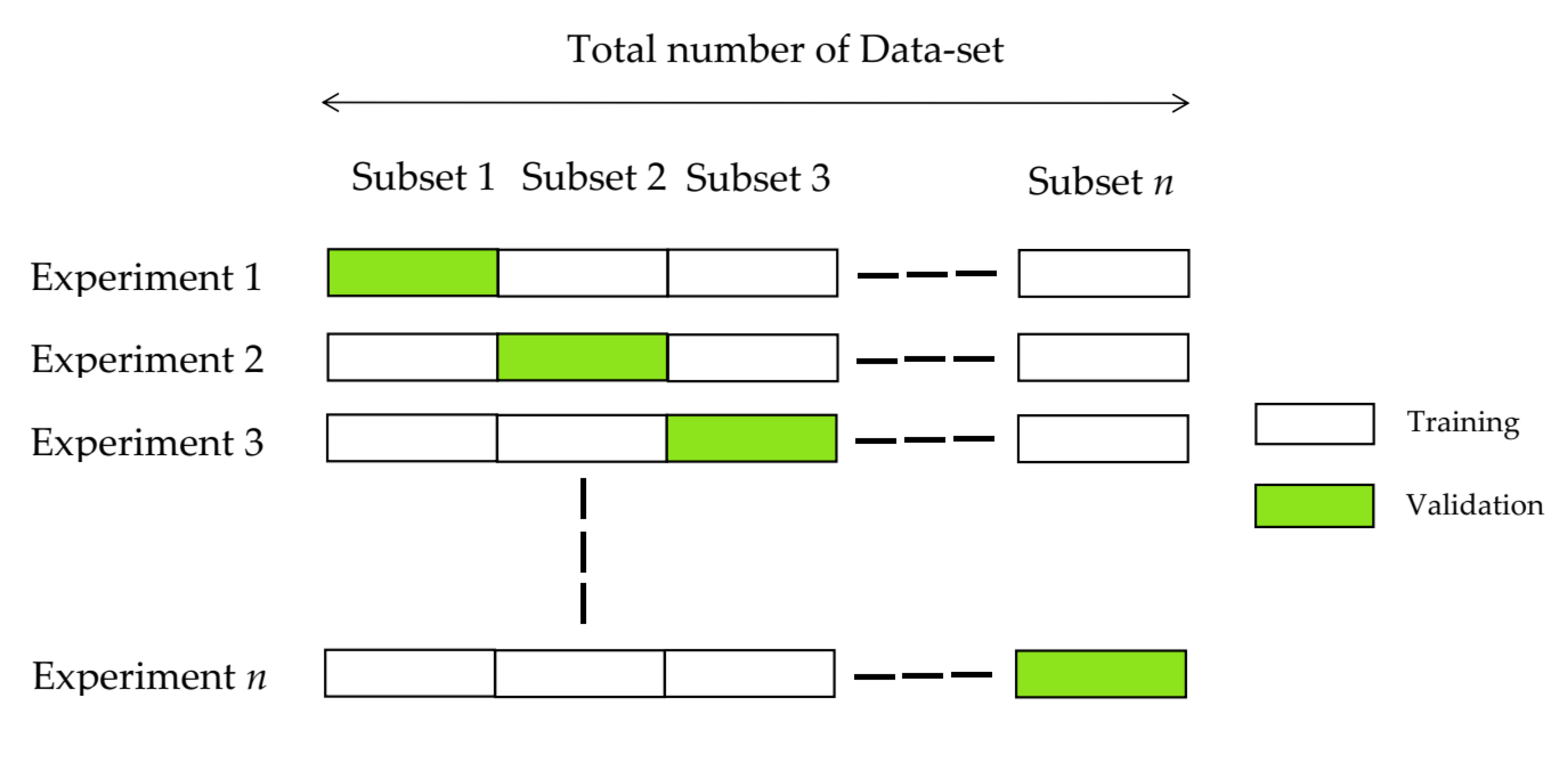

3. Model Evaluation

- -

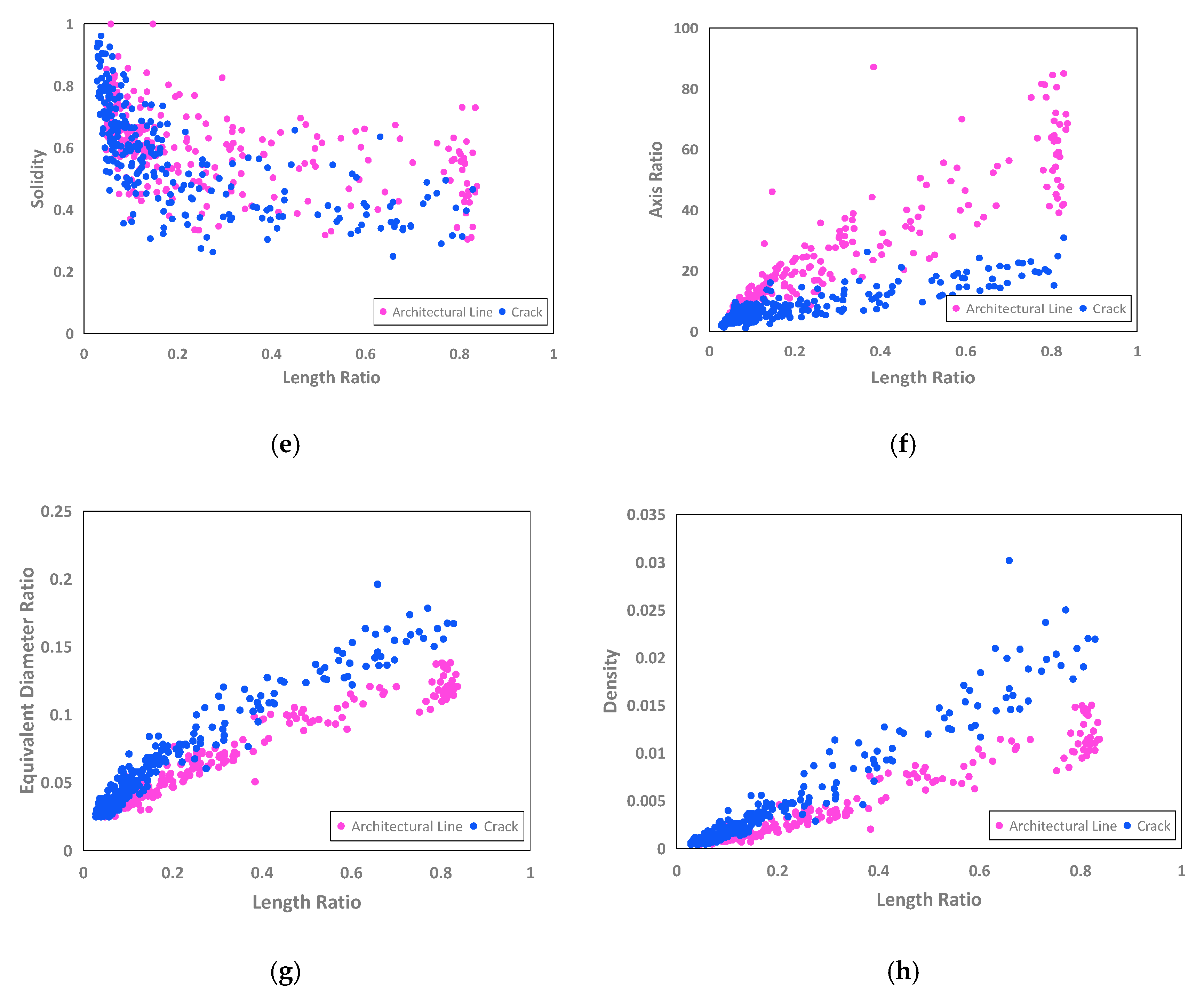

- For a specific orientation, the boundary value of the axis length ratio, the maximum value of the axis length ratio for an equivalent ellipse to be considered as a crack, increases with an increase in crack length. This highlights the high accuracy of the model in the identification of severe and thin cracks for any directions rather than horizontal and vertical ones, which can be indications of structural crack initiation.

- -

- When orientation approaches horizontal and vertical directions, the boundary value of axis length ratio decreases for a specific length of the feature. This justifies the accuracy of the developed model in detecting the presence of very thin architectural lines left on the walls due to the construction technology of rammed earth buildings. On the other hand, this confirms the ability of the model to detect severe cracks in horizontal and vertical directions.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Broberg, P. Surface crack detection in welds using thermography. NDT E Int. 2013, 57, 69–73. [Google Scholar] [CrossRef]

- Sinha, S.K.; Fieguth, P.W. Automated detection of cracks in buried concrete pipe images. Autom. Constr. 2006, 15, 58–72. [Google Scholar] [CrossRef]

- Merazi-Meksen, T.; Boudraa, M.; Boudraa, B. Mathematical morphology for TOFD image analysis and automatic crack detection. Ultrasonics 2014, 54, 1642–1648. [Google Scholar] [CrossRef] [PubMed]

- Jahanshahi, M.R.; Masri, S.F. Adaptive vision-based crack detection using 3D scene reconstruction for condition assessment of structures. Autom. Constr. 2012, 22, 567–576. [Google Scholar] [CrossRef]

- Wang, P.; Huang, H. Comparison analysis on present image-based crack detection methods in concrete structures. In Proceedings of the 2010 3rd International Congress on Image and Signal Processing (CISP2010), Yantai, China, 16–18 October 2010; pp. 2530–2533. [Google Scholar]

- Alam, S.Y.; Loukili, A.; Grondin, F.; Roziere, E. Use of the digital image correlation and acoustic emission technique to study the effect of structural size on cracking of reinforced concrete. Eng. Fract. Mech. 2015, 143, 17–31. [Google Scholar] [CrossRef]

- Brooks, W.S.; Lamb, D.A.; Irvine, S.J. IR reflectance imaging for crystalline Si solar cell crack detection. IEEE J. Photovolt. 2015, 5, 1271–1275. [Google Scholar] [CrossRef]

- Iliopoulos, S.; Aggelis, D.G.; Pyl, L.; Vantomme, J.; Van Marcke, P.; Coppens, E.; Areias, L. Detection and evaluation of cracks in the concrete buffer of the Belgian Nuclear Waste container using combined NDT techniques. Constr. Build. Mater. 2015, 78, 369–378. [Google Scholar] [CrossRef]

- Hamrat, M.; Boulekbache, B.; Chemrouk, M.; Amziane, S. Flexural cracking behavior of normal strength, high strength and high strength fiber concrete beams, using Digital Image Correlation technique. Constr. Build. Mater. 2016, 106, 678–692. [Google Scholar] [CrossRef]

- Merazi-Meksen, T.; Boudra, B.; Drai, R.; Boudraa, M. Automatic crack detection and characterization during ultrasonic inspection. J. Nondestr. Eval. 2010, 29, 169–174. [Google Scholar] [CrossRef]

- Vidal, M.; Ostra, M.; Imaz, N.; Garcı´a-Lecina, E.; Ubide, C. Analysis of SEM digital images to quantify crack network pattern area in chromium electrodeposits. Surf. Coat. Technol. 2016, 285, 289–297. [Google Scholar] [CrossRef]

- Wolf, J.; Pirskawetz, S.; Zang, A. Detection of crack propagation in concrete with embedded ultrasonic sensors. Eng. Fract. Mech. 2015, 146, 161–171. [Google Scholar] [CrossRef]

- Dhital, D.; Lee, J.R. A fully non-contact ultrasonic propagation imaging system for closed surface crack evaluation. Exp. Mech. 2012, 52, 1111–1122. [Google Scholar] [CrossRef]

- Li, X.; Jiang, H.; Yin, G. Detection of surface crack defects on ferrite magnetic tile. NDT E Int. 2014, 62, 6–13. [Google Scholar] [CrossRef]

- Guo, X.; Vavilov, V. Crack detection in aluminum parts by using ultrasound-excited infrared thermography. Infrared Phys. Technol. 2013, 61, 149–156. [Google Scholar] [CrossRef]

- Fujita, Y.; Hamamoto, Y. A robust automatic crack detection method from noisy concrete surfaces. Mach. Vis. Appl. 2011, 22, 245–254. [Google Scholar] [CrossRef]

- Glud, J.A.; Dulieu-Barton, J.M.; Thomsen, O.T.; Overgaard, L.C.T. Automated counting of off-axis tunnelling cracksusing digital image processing. Compos. Sci. Technol. 2016, 125, 80–89. [Google Scholar] [CrossRef] [Green Version]

- Talab, A.M.A.; Huang, Z.; Xi, F.; HaiMing, L. Detection crack in image using Otsu method and multiple filtering in image processing techniques. Optik–Int. J. Light Electron Opt. 2016, 127, 1030–1033. [Google Scholar] [CrossRef]

- Agarwal, S.; Singh, D. An adaptive statistical approach for non-destructive underline crack detection of ceramic tiles using millimetre wave imaging radar for industrial application. IEEE Sens. J. 2015, 15, 7036–7044. [Google Scholar] [CrossRef]

- Gunkel, C.; Stepper, A.; Müller, A.C.; Müller, C.H. Micro crack detection with Dijkstra’s shortest path algorithm. Mach. Vis. Appl. 2012, 23, 589–601. [Google Scholar] [CrossRef]

- Xu, C.; Xie, J.; Chen, G. Weiping Huang, An infrared thermal image processing framework based on superpixel algorithm to detect cracks on metal surface. Infrared Phys. Technol. 2014, 67, 266–272. [Google Scholar] [CrossRef]

- Anwar, S.A.; Abdullah, M.Z. Micro-crack detection of multicrystalline solar cells featuring an improved anisotropic diffusion filter and image segmentation technique. EURASIP J. Image Video Process. 2014, 1, 15. [Google Scholar] [CrossRef] [Green Version]

- Heideklang, R.; Shokouhi, P. Multi-sensor image fusion at signal level for improved near-surface crack detection. NDT E Int. 2015, 71, 16–22. [Google Scholar] [CrossRef]

- Rodríguez-Martín, M.; Lagüela, S.; González-Aguileraa, D.; Martinezb, J. Prediction of depth model for cracks in steel using infrared thermography. Infrared Phys Technol. 2015, 71, 592–600. [Google Scholar] [CrossRef]

- Yiyang, Z. The design of glass crack detection system based on image preprocessing technology. In Proceedings of the 2014 IEEE 7th Joint International Information Technology and Artificial Intelligence Conference, Chongqing, China, 20–21 December 2014; pp. 39–42. [Google Scholar]

- Yamaguchi, T.; Hashimoto, S. Fast crack detection method for large-size concrete surface images using percolationbased image processing. Mach. Vis. Appl. 2010, 21, 787–809. [Google Scholar] [CrossRef]

- Nazaryan, N.; Campana, C.; Moslehpour, S.; Shetty, D. Application of a He–Ne infrared laser source for detection of geometrical dimensions of cracks and scratches on finished surfaces of metals. Opt. Lasers Eng. 2013, 51, 1360–1367. [Google Scholar] [CrossRef]

- Chen, X.; Michaels, J.E.; Lee, S.J.; Michaels, T.E. Load-differential imaging for detection and localization of fatigue cracks using Lamb waves. NDT E Int. 2012, 51, 142–149. [Google Scholar] [CrossRef]

- Kabir, S. Imaging-based detection of AAR induced mapcrack damage in concrete structure. NDT E Int. 2010, 43, 461–469. [Google Scholar] [CrossRef]

- Adhikari, R.S.; Moselhi, O.; Bagchi, A. Image-based retrieval of concrete crack properties for bridge inspection. Autom. Constr. 2014, 39, 180–194. [Google Scholar] [CrossRef]

- Haralick, R.M.; Shapiro, L.G. Computer and Robot Vision, Volume I; Addison-Wesley: Boston, MA, USA, 1992; pp. 28–48. [Google Scholar]

- Christianini, N.; Shawe-Taylor, J.C. An Introduction to Support Vector Machines and Other Kernel-Based Learning Methods; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Otsu, N. A threshold selection method from gray-level histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.C.; Chiu, C.C. Texture construction edge detection algorithm. Appl. Sci. 2019, 9, 897. [Google Scholar] [CrossRef] [Green Version]

- Parker, J.R. Algorithms for Image Processing and Computer Vision; Wiley: New York, NY, USA, 1997. [Google Scholar]

- Bachman, N.; Beckenstein, F. Wavelet Analysis; Springer: New York, NY, USA, 2000. [Google Scholar]

- Canny, J. A computational approach to edge detection. IEEE Trans. Pattern Anal. Mach. Intell. 1986, 6, 679–698. [Google Scholar] [CrossRef]

- Prewitt, J.M.S. Object enhancement and extraction. In Picture Processing and Psychopictorics; Lipkin, B., Rosenfeld, A., Eds.; Academic Press: New York, NY, USA, 1970; pp. 15–19. [Google Scholar]

- Marr, D.; Hildreth, E. Theory of edge detection. Proc. R. Soc. Lond. Ser. B Biol. Sci. 1980, 207, 187–217. [Google Scholar]

- Mohan, A.; Poobal, S. Crack detection using image processing: A critical review and analysis. Alex. Eng. J. 2018, 57, 787–798. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, L. Classification of fruits using computer vision and a multiclass support vector machine. Sensors 2012, 12, 12489–12505. [Google Scholar] [CrossRef] [PubMed]

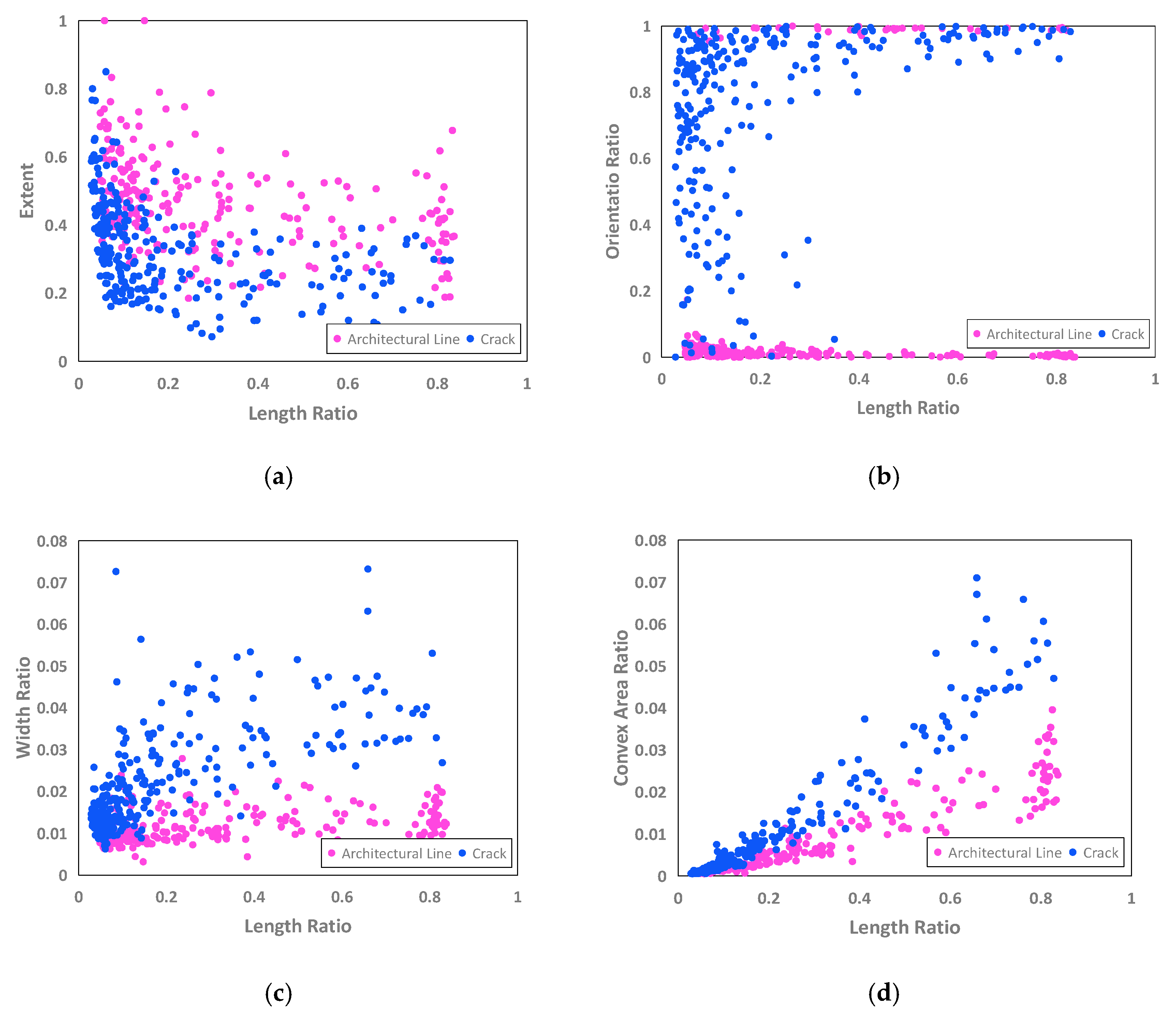

| Area | Number of Pixels |

|---|---|

| Density | Ratio of pixels in the region to pixels in total image |

| Major axis length | Length (in pixels) of the major axis of the equivalent ellipse |

| Minor axis length | Length (in pixels) of the minor axis of the equivalent ellipse |

| Length ratio | Ratio of the major axis length to 256√2 |

| Width ratio | Ratio of the minor axis length to 256√2 |

| Axis length ratio | Ratio of Major Axis Length to Minor axis length |

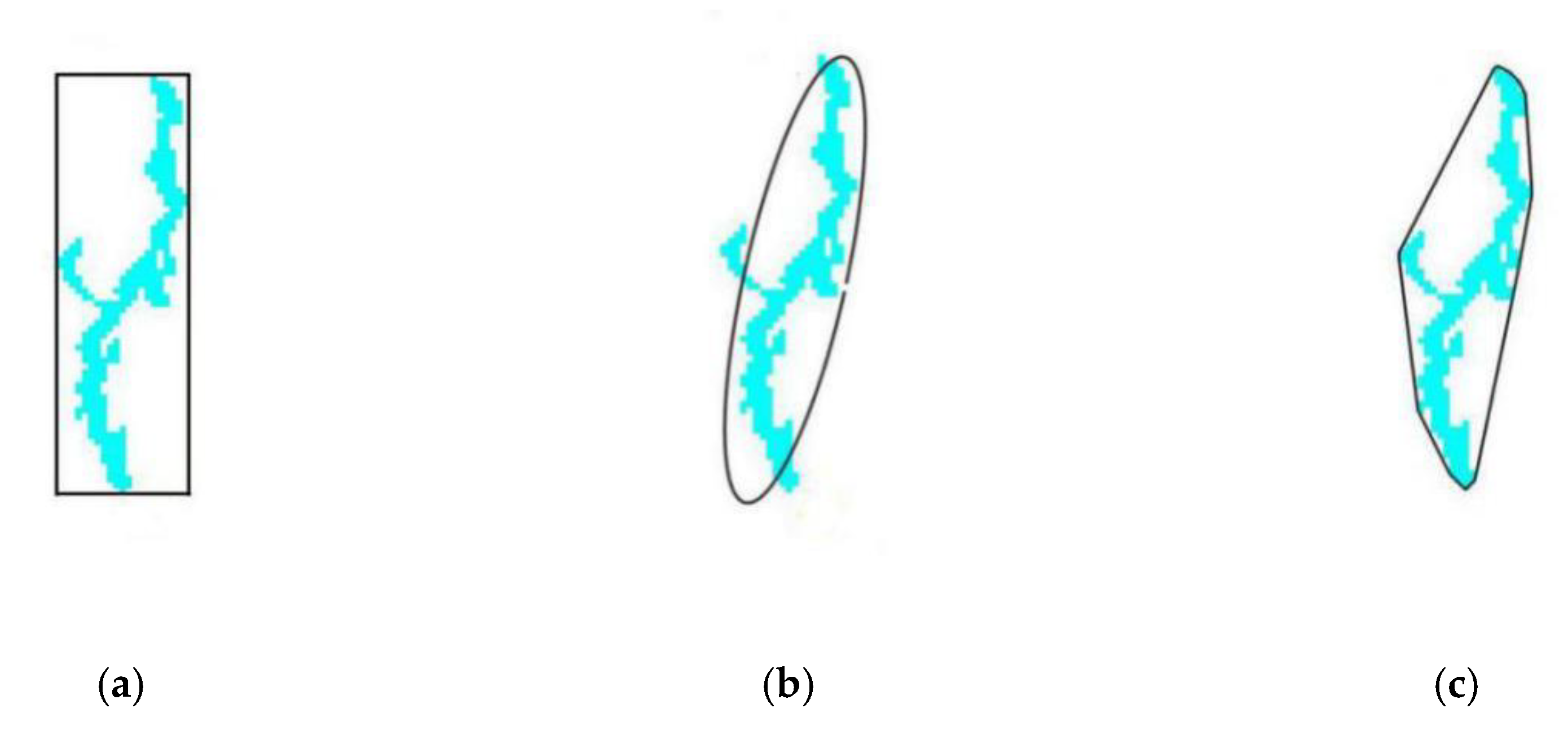

| Orientation | Absolute value of the angle between the x-axis and the major axis of the ellipse, ranging from 0 degrees to 90 degrees (Figure 3b). |

| Orientation ratio | Ratio of orientation to 90 degrees |

| Convex area | Number of pixels in convex Image (Figure 8c) |

| Convex area ratio | Ratio of pixels in convex area to pixels in total image |

| Equivalent diameter | Diameter of an equivalent circle with the same area as the region |

| Equivalent diameter ratio | Ratio of Equivalent diameter to 256 |

| Extent | Ratio of pixels in the region to pixels in the total bounding box |

| Solidity | Ratio of area to convex area |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeighami Moghaddam, M.; Umili, G.; Messina, V.; Bonetto, S.; Ferrero, A.M.; Bollini, G.; Gandreau, D. An SVM-Based Scheme for Automatic Identification of Architectural Line Features and Cracks. Appl. Sci. 2020, 10, 5077. https://doi.org/10.3390/app10155077

Zeighami Moghaddam M, Umili G, Messina V, Bonetto S, Ferrero AM, Bollini G, Gandreau D. An SVM-Based Scheme for Automatic Identification of Architectural Line Features and Cracks. Applied Sciences. 2020; 10(15):5077. https://doi.org/10.3390/app10155077

Chicago/Turabian StyleZeighami Moghaddam, Mahshid, Gessica Umili, Vito Messina, Sabrina Bonetto, Anna Maria Ferrero, Gaia Bollini, and David Gandreau. 2020. "An SVM-Based Scheme for Automatic Identification of Architectural Line Features and Cracks" Applied Sciences 10, no. 15: 5077. https://doi.org/10.3390/app10155077

APA StyleZeighami Moghaddam, M., Umili, G., Messina, V., Bonetto, S., Ferrero, A. M., Bollini, G., & Gandreau, D. (2020). An SVM-Based Scheme for Automatic Identification of Architectural Line Features and Cracks. Applied Sciences, 10(15), 5077. https://doi.org/10.3390/app10155077