Microstructure and Mechanical Property of Compact Graphite/6061Al Composite Prepared by Ultra-High Pressure Sintering

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Morphology of the Powder

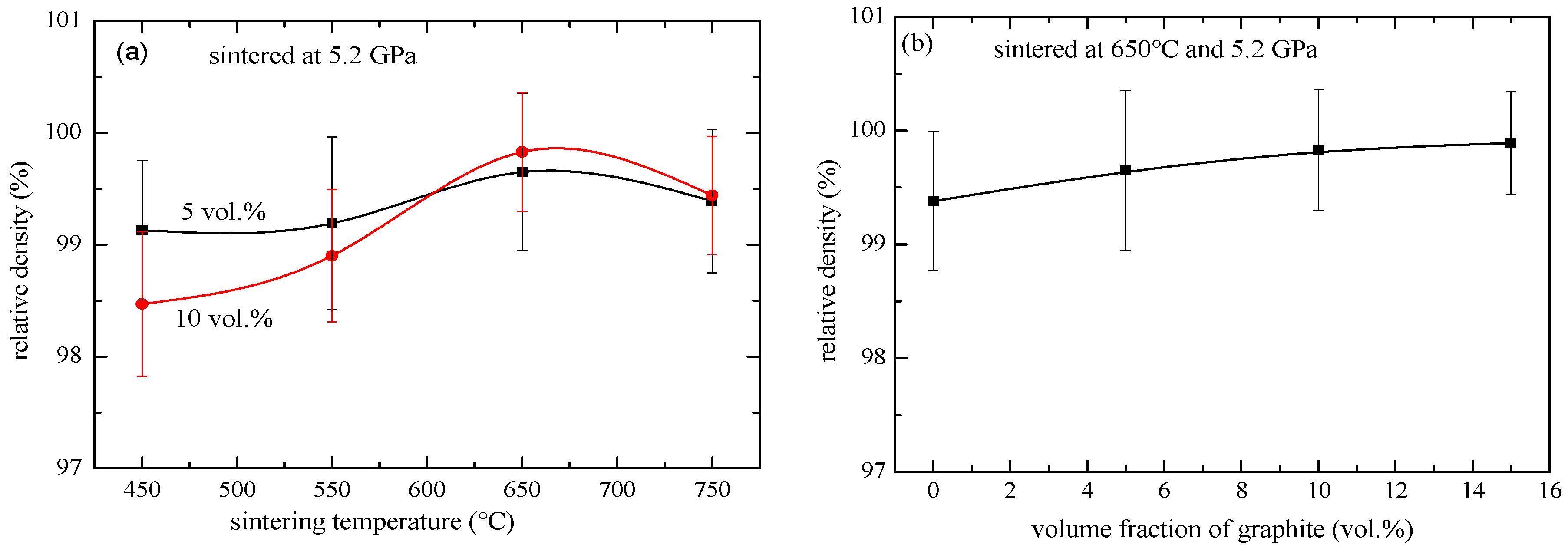

3.2. Microstructure, Relative Density and Phase Analysis of the G/6061Al Composite

3.3. Mechanical Properties of G/6061Al Composite

3.4. Wear Resistance of G/6061Al Composite

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Omrani, E.; Moghadam, A.D.; Menezes, P.L.; Rohatgi, P.K. Influences of graphite reinforcement on the tribological properties of self-lubricating aluminum matrix composites for green tribology, sustainability, and energy efficiency—A review. Int. J. Adv. Manuf. Technol. 2015, 83, 325–346. [Google Scholar] [CrossRef]

- Sharma, P.; Paliwal, K.; Garg, R.K.; Sharma, S.; Khanduja, D. A study on wear behaviour of Al/6101/graphite composites. J. Asian Ceram. Soc. 2017, 5, 42–48. [Google Scholar] [CrossRef] [Green Version]

- Fallahdoost, H.; Nouri, A.; Azimi, A. Dual functions of TiC nanoparticles on tribological performance of Al/graphite composites. J. Phys. Chem. Solids 2016, 93, 137–144. [Google Scholar] [CrossRef]

- Latief, F.; Sherif, E.-S.M. Effects of sintering temperature and graphite addition on the mechanical properties of aluminum. J. Ind. Eng. Chem. 2012, 18, 2129–2134. [Google Scholar] [CrossRef]

- Yolshina, L.A.; Muradymov, R.V.; Korsun, I.V.; Yakovlev, G.A.; Smirnov, S.V. Novel aluminum-graphene and aluminum-graphite metalliccomposite materials: Synthesis and properties. J. Alloy. Compd. 2016, 663, 449–459. [Google Scholar] [CrossRef]

- Alam, S.N.; Kumar, L. Mechanical properties of aluminium based metal matrix composites reinforced with graphite nanoplatelets. Mater. Sci. Eng. A 2016, 667, 16–32. [Google Scholar] [CrossRef]

- Durowoju, M.; Sadiku, E.; Diouf, S.; Shongwe, M.; Olubambi, P. Spark plasma sintering of graphite–aluminum powder reinforced with SiC/Si particles. Powder Technol. 2015, 284, 504–513. [Google Scholar] [CrossRef]

- Landry, K.; Kalogeropoulou, S.; Eustathopoulos, N. Wettability of carbon by aluminumand aluminum alloys. Mater. Sci. Eng. A 1998, 254, 99–111. [Google Scholar] [CrossRef]

- Seleman, M.M.E.-S.; Ahmed, M.; Ataia, S. Microstructure and mechanical properties of hot extruded 6016 aluminum alloy/graphite composites. J. Mater. Sci. Technol. 2018, 34, 1580–1591. [Google Scholar] [CrossRef]

- Deaquino-Lara, R.; Gutiérrez-Castañeda, E.; Estrada-Guel, I.; Hinojosa-Ruiz, G.; García-Sánchez, E.; Herrera-Ramírez, J.M.; Pérez-Bustamante, R.; Martínez-Sánchez, R. Structural characterization of aluminium alloy 7075-graphitecomposites fabricated by mechanical alloying and hot extrusion. Mater. Des. 2014, 53, 1104–1111. [Google Scholar] [CrossRef]

- Chen, J.-K.; Huang, I. Thermal properties of aluminum–graphite composites by powder metallurgy. Compos. Part B Eng. 2013, 44, 698–703. [Google Scholar] [CrossRef]

- Kurita, H.; Miyazaki, T.; Kawasaki, A.; Lu, Y.; Silvain, J. Interfacial microstructure of graphite flake reinforced aluminum matrixcomposites fabricated via hot pressing. Compos. Part A 2015, 73, 125–131. [Google Scholar] [CrossRef]

- Ningning, L.; Lei, X.; Changyun, L.; Youchao, W.; Guofa, M.; Erkuo, Y. Reach of the preparation, microstructure and properties of Gr/6061Al composites sintered by hot pressing sintering. Rare Met. Mater. Eng. 2019, 48, 1961–1968. [Google Scholar]

- Esmati, M.; Shari, H.; Raeissi, M.; Atrian, A.; Rajaee, A. Investigation into thermal expansion coefficient, thermal conductivityand thermal stability of Al-graphite composite prepared by powder metallurgy. J. Alloys Compd. 2019, 773, 503–510. [Google Scholar] [CrossRef]

- Tan, H.; Wang, S.; Cheng, J.; Zhu, S.; Yu, Y.; Qiao, Z.; Yang, J. Tribological properties of Al-20Si-5Fe-2Ni-Graphitesolid-lubricating composites. Tribol. Int. 2018, 121, 214–222. [Google Scholar] [CrossRef]

- Sahoo, B.; Kumar, R.; Joseph, J.; Sharma, A.; Paul, J. Preparation of aluminium 6063-graphite surface composites by anelectrical resistance heat assisted pressing technique. Surf. Coat. Technol. 2017, 309, 563–572. [Google Scholar] [CrossRef]

- Dolata-Grosz, A.; Śleziona, J.; Formanek, B. Structure and properties of aluminium cast compositesstrengthened by dispersion phases. J. Mater. Process. Technol. 2006, 175, 192–197. [Google Scholar] [CrossRef]

- Olmos, L.; Martin, C.; Bouvard, D. Sintering of mixtures of powders: Experiments and modelling. Powder Technol. 2009, 190, 134–140. [Google Scholar] [CrossRef]

- Hafizpour, H.R.; Simchi, A. Investigation on compressibility of Al–SiC composite powders. Powder Met. 2008, 51, 217–223. [Google Scholar] [CrossRef]

- Deaquino-Lara, R.; Estrada-Guel, I.; Hinojosa-Ruiz, G.; Flores-Campos, R.; Herrera-Ramirez, J.; Martínez-Sánchez, R. Synthesis of aluminum alloy 7075-graphite composites by milling processes and hot extrusion. J. Alloys Compd. 2011, 509, S284–S289. [Google Scholar] [CrossRef]

- Rong-de, L.; Xiu-sheng, C.; Ying-dong, Q.; Yao, X.; Run-xia, L.; Chan, T. Effect of super high pressure on crystal structure and microstructure of ZA27 alloy. Chin. J. Nonferrous Met. 2009, 9, 1570–1574. [Google Scholar]

- Solozhenko, V.L.; Kurakevych, O.O. Equation of state of aluminum carbide Al4C3. Solid State Commun. 2005, 133, 385–388. [Google Scholar] [CrossRef]

| Processing Parameters | Yield Strength Rp0.2 (MPa) | Tensile Strength Rm (MPa) |

|---|---|---|

| 5.2 GPa, 650 °C, 0 vol.% G | 293 | 338 |

| 5.2 GPa, 650 °C, 5 vol.%G | 142 | 183 |

| 35 MPa, 520 °C, 0 vol.% G | 81 | 179 |

| 35 MPa, 520 °C, 5 vol.% G | 74 | 77 |

| 6101Al, casting + T6 heat treatment [2] | - | 164 |

| 0 wt.% G/6016Al, sintering + hotextruding [9] | 75 | 106 |

| 5 wt.% G/6016Al, sintering + hot extruding [9] | 67 (Measured from the curve) | 97 (Measured from the curve) |

| 2 wt.% Graphene [5] | 48 | 94 |

| 2 wt.% Graphite [5] | 44 | 75.5 |

| Processing Parameters | UHP Sinteredat 5.2 GPa | HP Sinteredat 35 MPa and 520 °C | |||

|---|---|---|---|---|---|

| 450 °C | 550 °C | 650 °C | 750 °C | ||

| Friction coefficient | 0.484 | 0.483 | 0.595 | 0.544 | 0.455 |

| Wear rate (10−5 g/mm) | 12.45 | 17.92 | 0.97 | 0.15 | 133.89 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Wang, Y.; Xu, L.; Liu, Y.; Lu, N.; Mi, G. Microstructure and Mechanical Property of Compact Graphite/6061Al Composite Prepared by Ultra-High Pressure Sintering. Appl. Sci. 2020, 10, 5107. https://doi.org/10.3390/app10155107

Li C, Wang Y, Xu L, Liu Y, Lu N, Mi G. Microstructure and Mechanical Property of Compact Graphite/6061Al Composite Prepared by Ultra-High Pressure Sintering. Applied Sciences. 2020; 10(15):5107. https://doi.org/10.3390/app10155107

Chicago/Turabian StyleLi, Changyun, Yasong Wang, Lei Xu, Yang Liu, Ningning Lu, and Guofa Mi. 2020. "Microstructure and Mechanical Property of Compact Graphite/6061Al Composite Prepared by Ultra-High Pressure Sintering" Applied Sciences 10, no. 15: 5107. https://doi.org/10.3390/app10155107

APA StyleLi, C., Wang, Y., Xu, L., Liu, Y., Lu, N., & Mi, G. (2020). Microstructure and Mechanical Property of Compact Graphite/6061Al Composite Prepared by Ultra-High Pressure Sintering. Applied Sciences, 10(15), 5107. https://doi.org/10.3390/app10155107