Numerical Simulation of Cavitation Erosion Aggressiveness Induced by Unsteady Cloud Cavitation

Abstract

1. Introduction

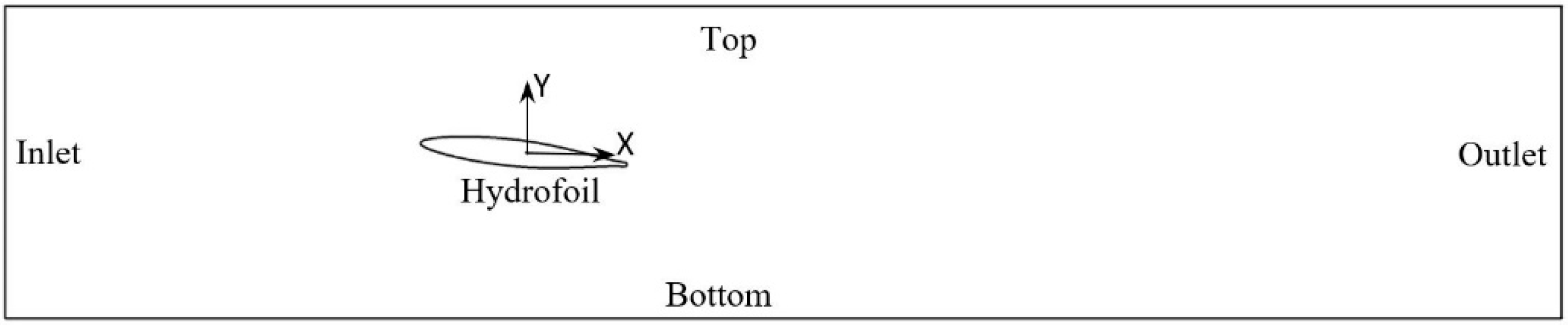

2. Experiment Description and Numerical Model

2.1. Experiment Description

2.2. Numerical Model

2.3. Cavitation Erosion Model

3. Results

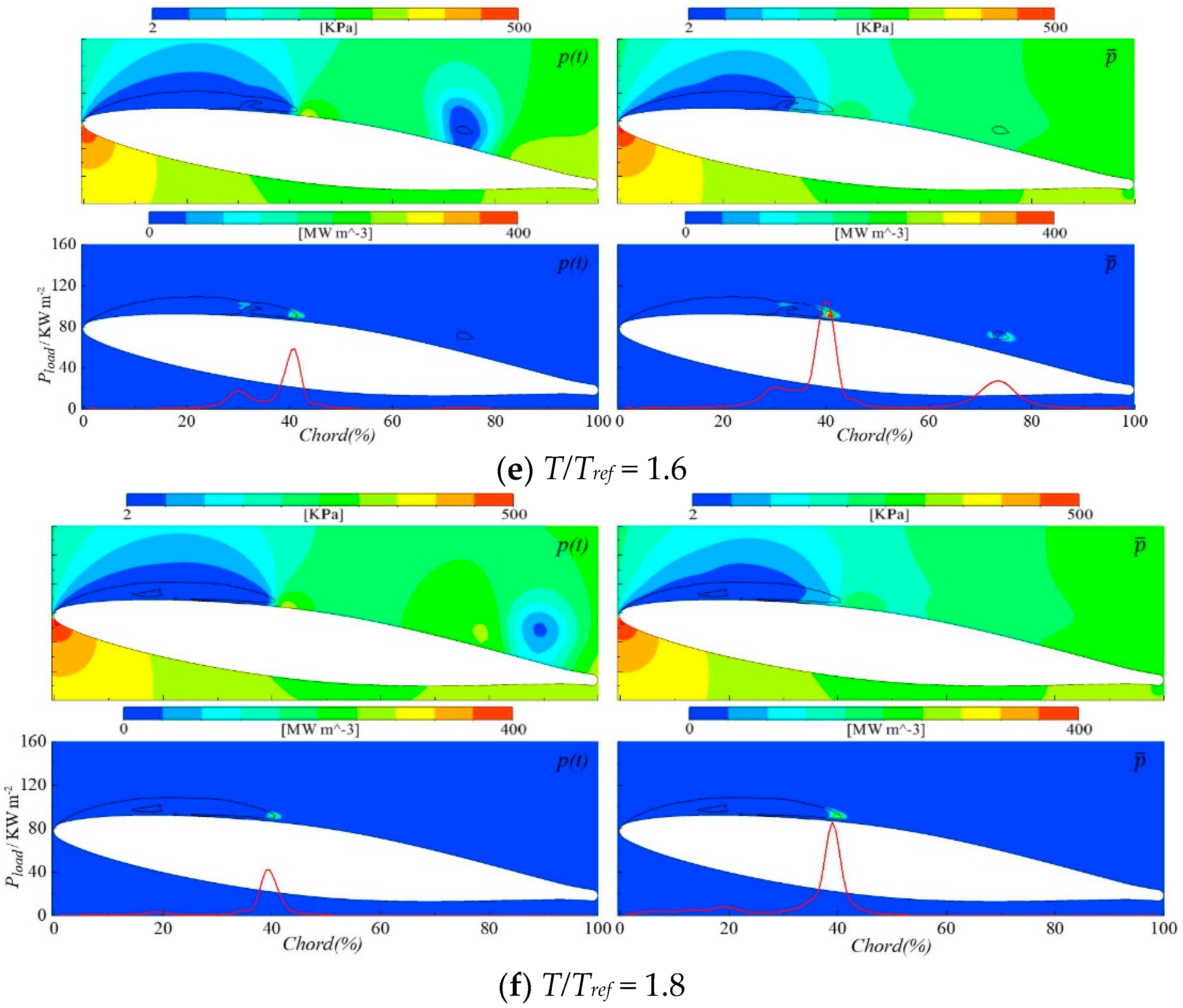

3.1. Influence of Driving Pressure Definition

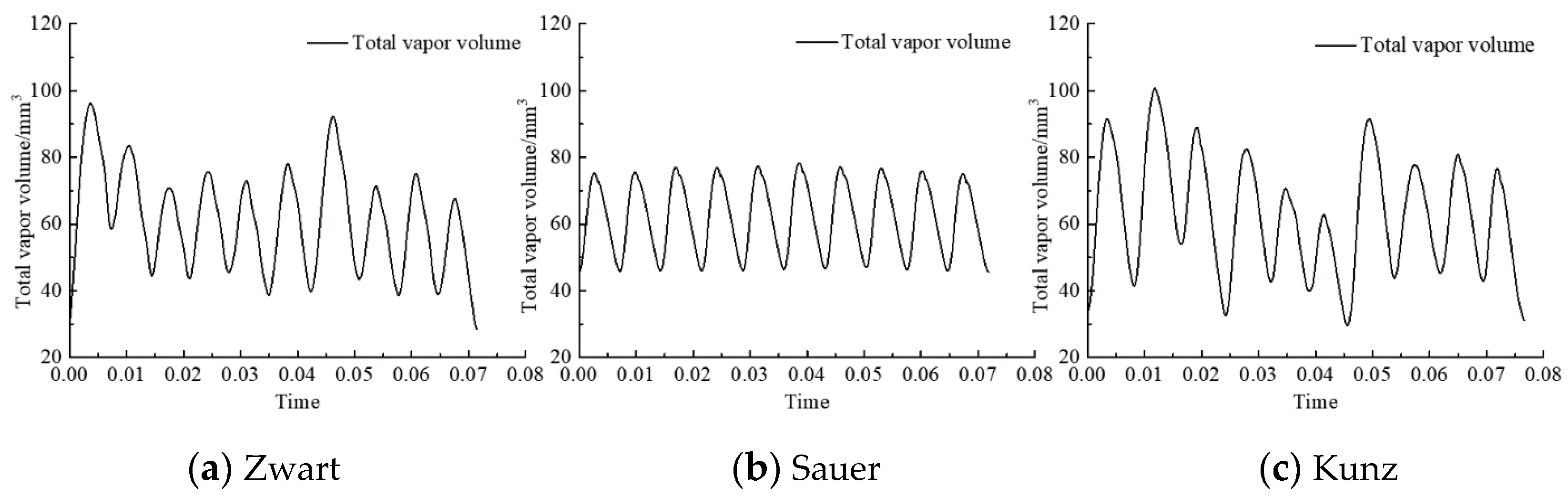

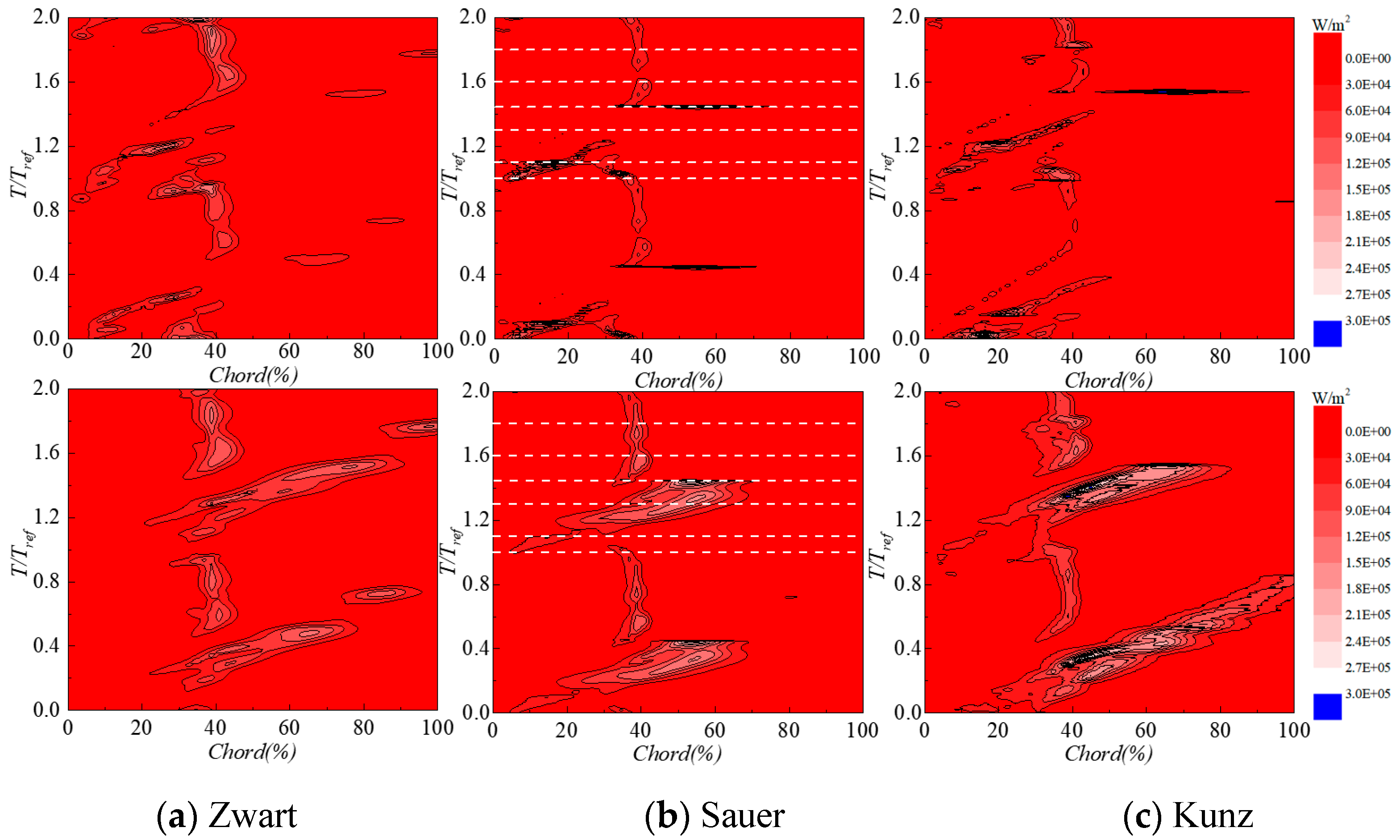

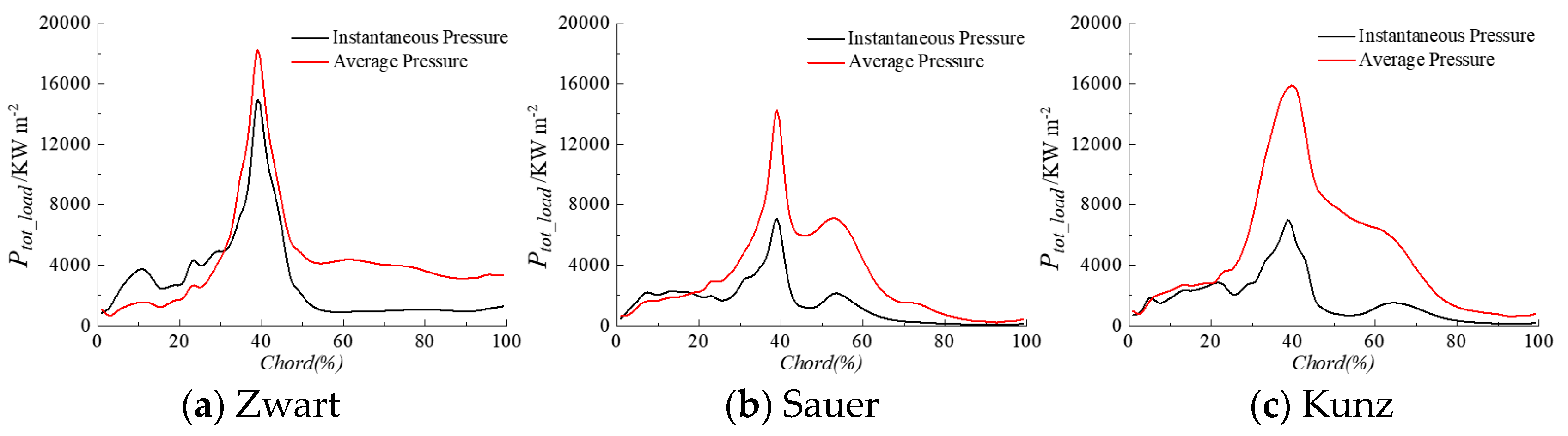

3.2. Influence of Cavitation Model

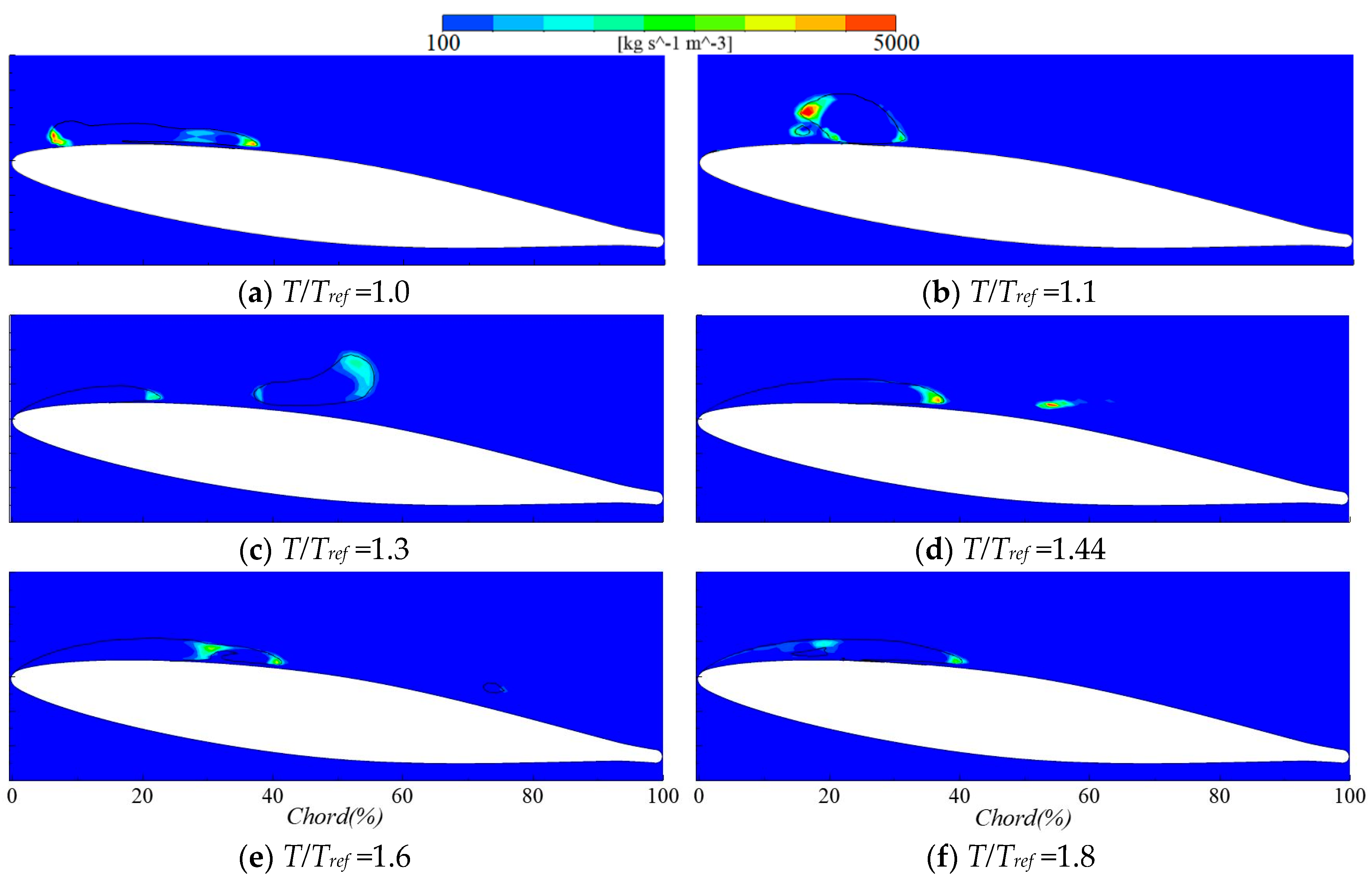

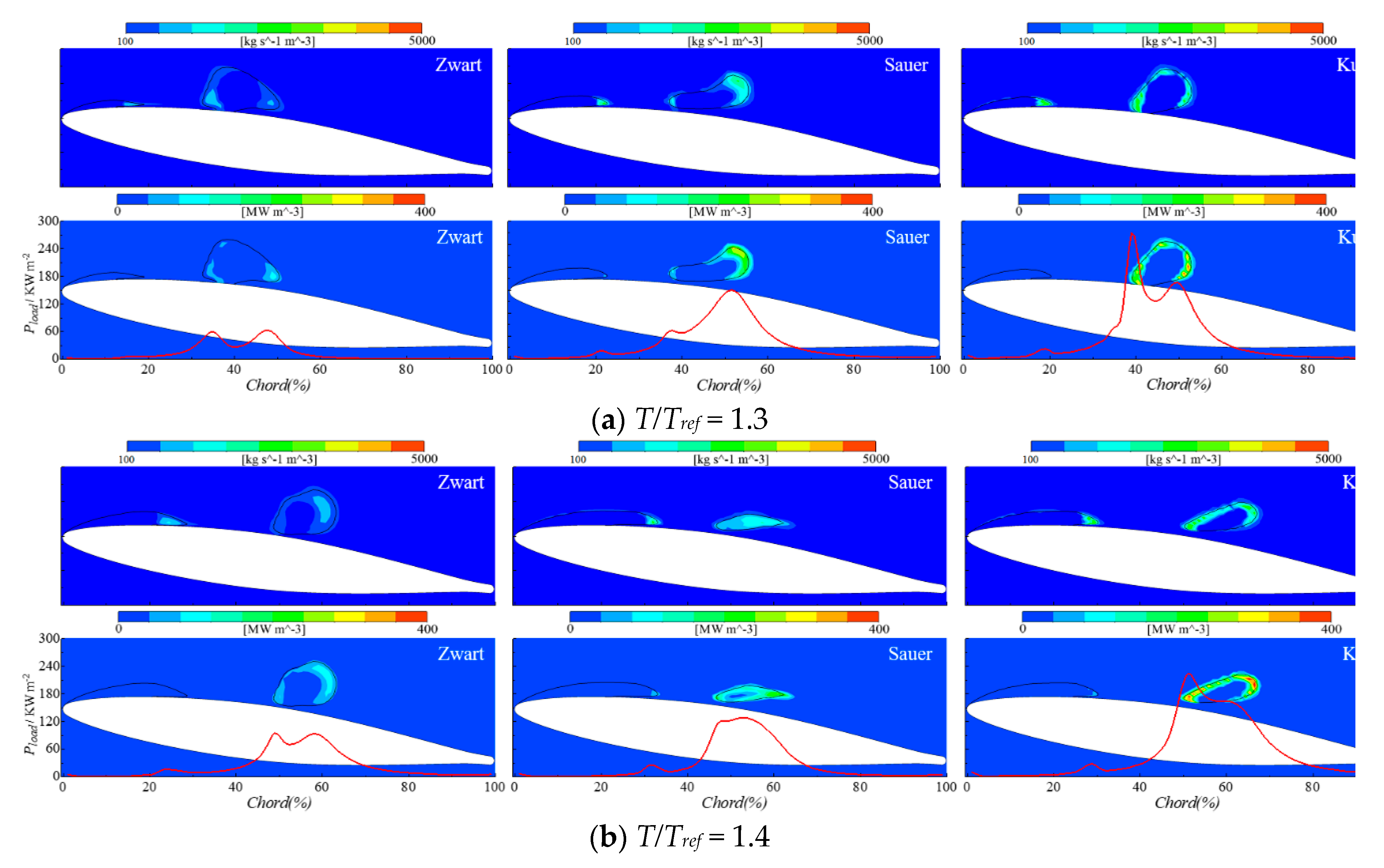

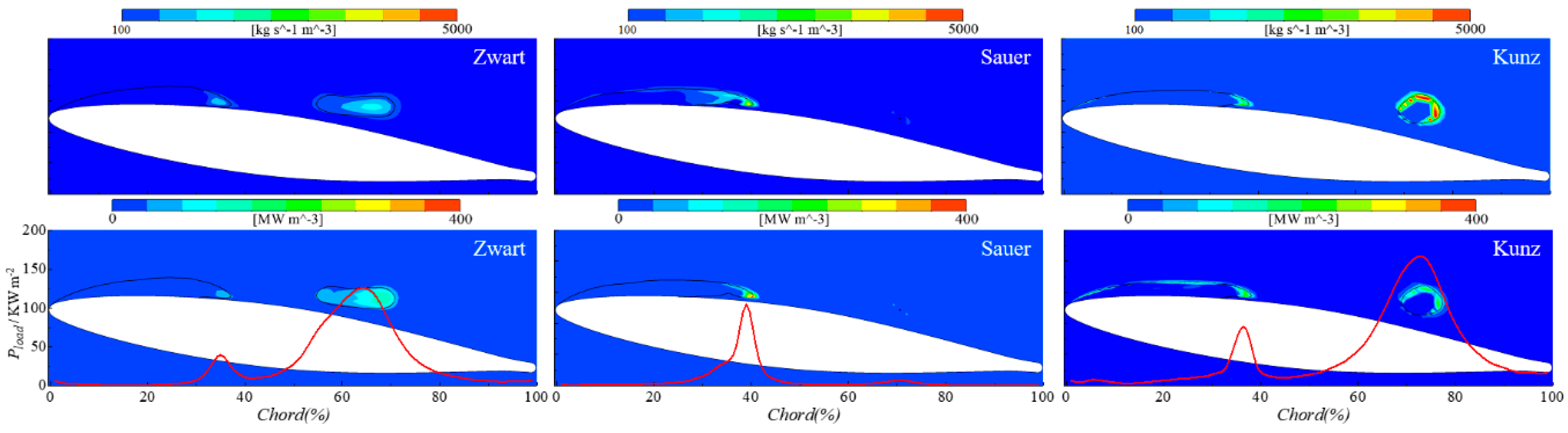

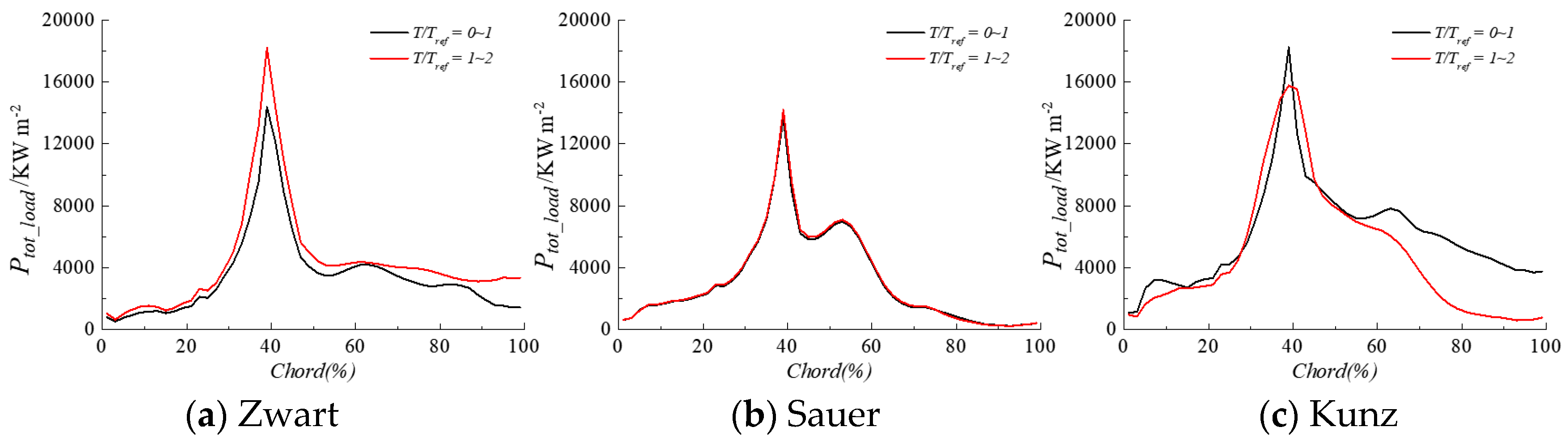

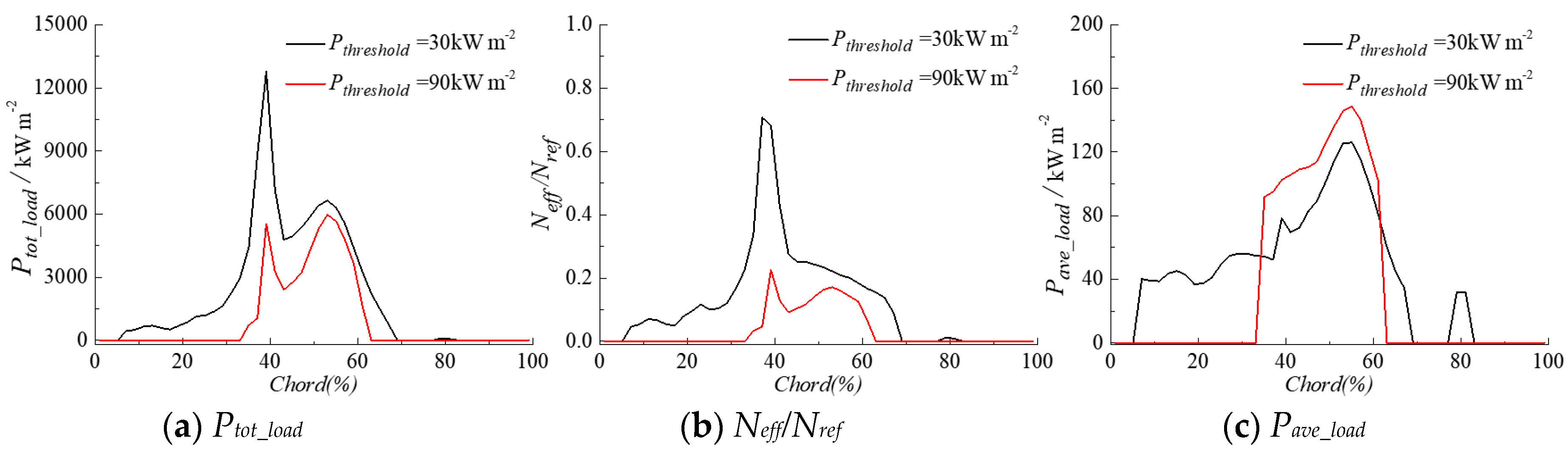

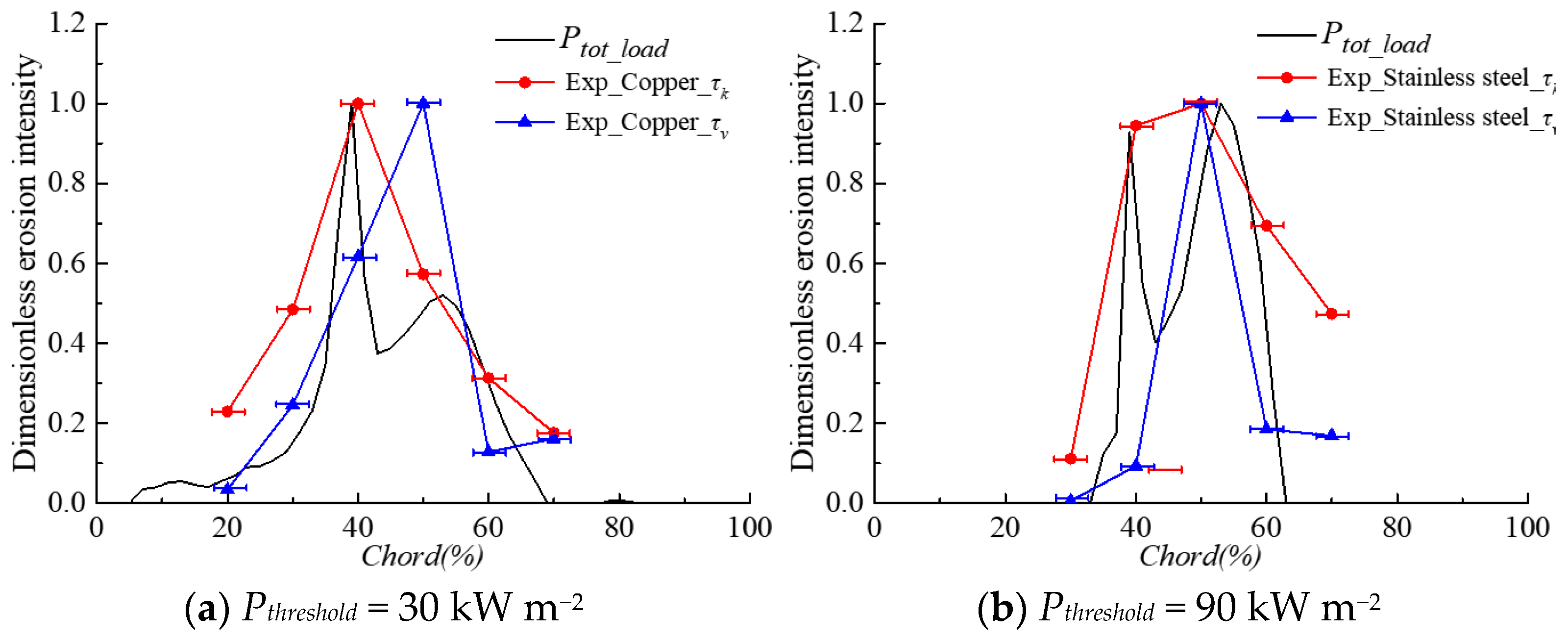

3.3. The Mechanism of Cavitation Erosion

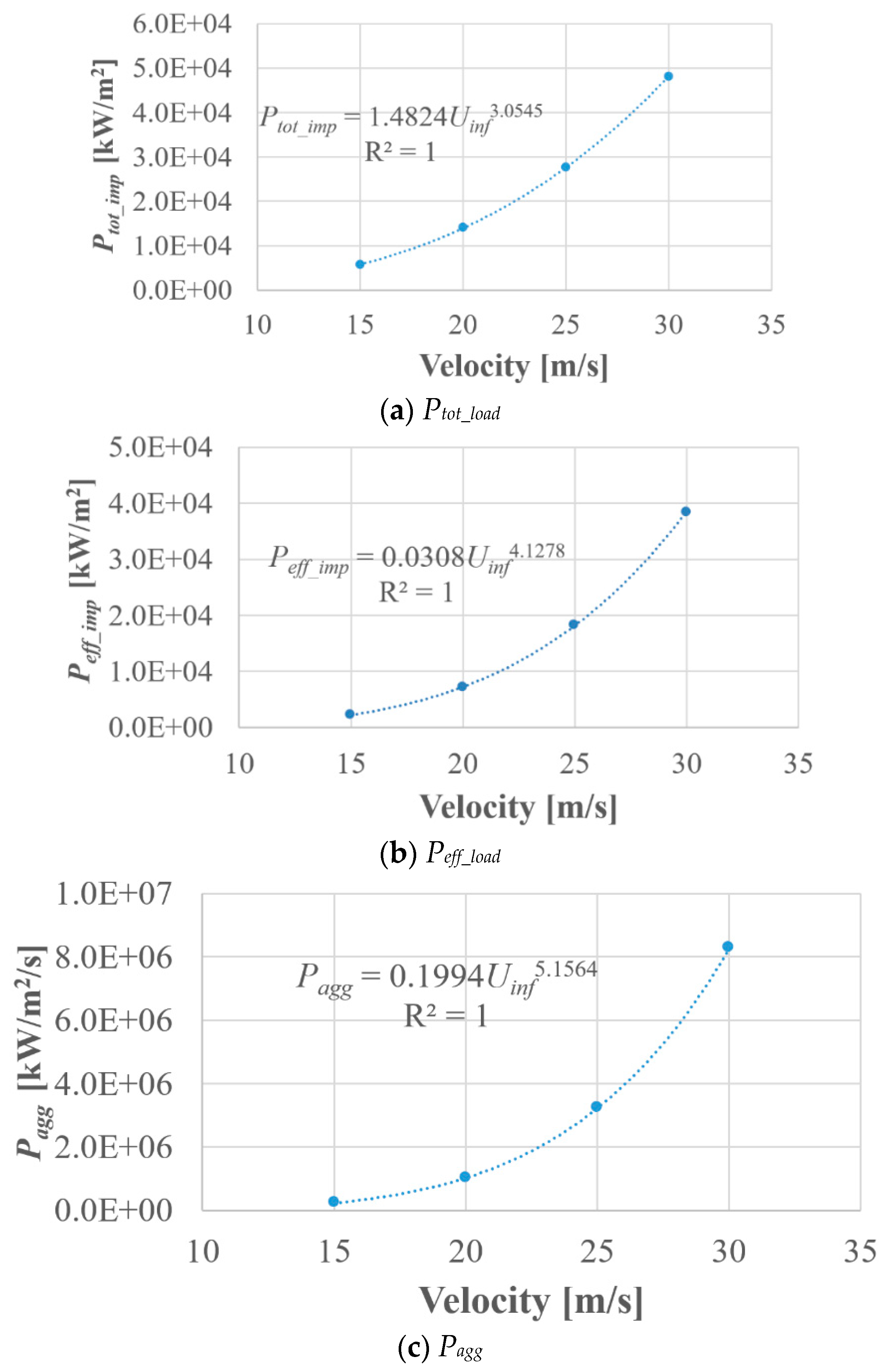

3.4. Free Stream Velocity Effects

4. Conclusions

- The selection of the driving pressure to estimate the power of the cavity collapse has a significant effect on the space-time distribution of the cavitation aggressiveness on the hydrofoil surface. The use of the average pressure gives more similar results to the experiment than the use of the instantaneous pressure.

- The cavitation model influences significantly the power loaded on the hydrofoil surface both in terms of magnitude and spatial distribution along the chord. For the cases considered in the present study, the Sauer model performs better than the Kunz and Zwart ones.

- Two main erosion mechanisms have been predicted that are in good agreement with experimental observations. One is induced by the high frequency of low-intensity collapses taking place at the closure region of the main sheet cavity attached to the hydrofoil surface. The other one is induced by the low frequency and high intensity collapses of the shed cloud cavities.

- Power laws have been obtained that permit the calculation of the erosive cavitation intensity as a function of the flow velocity by taking into account the collapse efficiency and the shedding frequency. More specifically, the effective power load law grows with an exponent of 4, and the erosion aggressiveness per unit time grows with an exponent of 5.

Author Contributions

Funding

Conflicts of Interest

References

- Kim, K.H.; Chahine, G.; Franc, J.P.; Karimi, A. Advanced Experimental and Numerical Techniques for Cavitation Erosion Prediction; Springer: New York, NY, USA, 2014. [Google Scholar]

- Li, Z.R. Assessment of cavitation erosion with a multiphase Reynolds-Averaged Navier-Stokes method. Ph.D. Thesis, Delft University of Technology, Wageningen, The Netherlands, 2012. [Google Scholar]

- Hsiao, C.T.; Jayaprakash, A.; Kapahi, A.; Choi, J.K.; Chahine, G.L. Modelling of material pitting from cavitation bubble collapse. J. Fluid Mech. 2014, 755, 142–175. [Google Scholar] [CrossRef]

- Fivel, M.; Franc, J.P.; Chandra Roy, S. Towards numerical prediction of cavitation erosion. Interface Focus 2015, 5, 20150013. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.C.; Franc, J.P.; Pellone, C.; Fivel, M. Determination of cavitation load spectra–Part 1: Static finite element approach. Wear 2015, 344, 110–119. [Google Scholar] [CrossRef]

- Roy, S.C.; Franc, J.P.; Pellone, C.; Fivel, M. Determination of cavitation load spectra–Part 2: Dynamic finite element approach. Wear 2015, 344, 120–129. [Google Scholar] [CrossRef]

- Joshi, S.; Franc, J.P.; Ghigliotti, G.; Fivel, M. SPH modelling of a cavitation bubble collapse near an elasto-visco-plastic material. J. Mech. Phys. Solids. 2019, 125, 420–439. [Google Scholar] [CrossRef]

- Joshi, S.; Franc, J.P.; Ghigliotti, G.; Fivel, M. Bubble collapse induced cavitation erosion: Plastic strain and energy dissipation investigations. J. Mech. Phys. Solids. 2020, 134, 103749. [Google Scholar] [CrossRef]

- Ochiai, N.; Iga, Y.; Nohmi, M.; Ikohagi, T. Numerical prediction of cavitation erosion intensity in cavitating flows around a Clark Y 11.7% hydrofoil. J. Fluid Sci. Tech. 2010, 5, 416–431. [Google Scholar] [CrossRef]

- Wang, H.; Zhu, B. Numerical prediction of impact force in cavitating flows. Trans. ASME J. Fluids Eng. 2010, 132, 101301. [Google Scholar] [CrossRef]

- Eskilsson, C.; Bensow, R.E.; Kinnas, S. Estimation of cavitation erosion intensity using CFD: Numerical comparison of three different methods. In Proceedings of the 4th International Symposium on Marine Propulsors, Austin, TX, USA, 31 May–4 June 2015. [Google Scholar]

- Schnerr, G.H.; Sezal, I.H.; Schmidt, S.J. Numerical Investigation of Three-Dimensional Cloud Cavitation with Special Emphasis on Collapse Induced Shock Dynamics. Phys. Fluids. 2008, 20, 040703. [Google Scholar] [CrossRef]

- Mihatsch, M.S.; Schmidt, S.J.; Adams, N.A. Cavitation erosion prediction based on analysis of flow dynamics and impact load spectra. Phys. Fluids. 2015, 20, 103302. [Google Scholar] [CrossRef]

- Blume, M.; Skoda, R. 3D flow simulation of a circular leading edge hydrofoil and assessment of cavitation erosion by the statistical evaluation of void collapses and cavitation structures. Wear 2019, 428, 457–469. [Google Scholar] [CrossRef]

- Nohmi, M.; Ikohagi, T.; Iga, Y. Numerical Prediction Method of Cavitation Erosion. In Proceedings of the ASME 2008 Fluids Engineering Division Summer, Jacksonville, FL, USA, 10–14 August 2008. [Google Scholar]

- Li, Z.R.; Pourquie, M.; van Terwisga, T. Assessment of cavitation erosion with a URANS method. Trans. ASME J. Fluids Eng. 2014, 136, 041101. [Google Scholar] [CrossRef]

- Fortes-Patella, R.; Reboud, J.L.; Briancon-Marjollet, L. A phenomenological and numerical model for scaling the flow agressiveness in cavitation erosion. In Proceedings of the EROCAV Workshop, Val de Reuil, France, May 2004. [Google Scholar]

- Patella, R.F.; Archer, A.; Flageul, C. Numerical and experimental investigations on cavitation erosion. In Proceeding of the 26th IAHR Symposium on Hydraulic Machinery and Systems, Beijing, China, 19–23 August 2012. [Google Scholar]

- Koukouvinis, P.; Bergeles, G.; Gavaises, M. A cavitation aggressiveness index within the Reynolds averaged Navier Stokes methodology for cavitating flows. J. Hydrodyn. 2015, 27, 579–586. [Google Scholar] [CrossRef][Green Version]

- Ponkratov, D.; Caldas, A. Prediction of Cavitation Erosion by Detached Eddy Simulation (DES) and its Validation against Model and Ship Scale Results. In Proceeding of the 4th International Symposium on Marine Propulsors, Austin, TX, USA, 31 May–4 June 2015. [Google Scholar]

- Dular, M.; Coutier-Delgosha, O. Numerical modelling of cavitation erosion. Int. J. Numer. Methods Fluids. 2009, 61, 1388–1410. [Google Scholar] [CrossRef]

- Peters, A.; Sagar, H.; Lantermann, U.; el Moctar, O. Numerical modelling and prediction of cavitation erosion. Wear 2015, 338, 189–201. [Google Scholar] [CrossRef]

- Carrat, J.B.; Fortes-Patella, R.; Franc, J.P. Assessment of cavitating flow aggressiveness on a hydrofoil: Experimental and numerical approaches. In Proceedings of the ASME 2017 Fluids Engineering Division Summer Meeting, Waikoloa, HI, USA, 30 July–3 August 2017. [Google Scholar]

- Leclercq, C.; Archer, A.; Fortes-Patella, R.; Cerru, F. Numerical cavitation intensity on a hydrofoil for 3D homogeneous unsteady viscous flows. Int. J. Fluid Mach. Syst. 2017, 10, 254–263. [Google Scholar] [CrossRef]

- Melissaris, T.; Bulten, N.; van Terwisga, T.J.C. On Cavitation Aggressiveness and Cavitation Erosion on Marine Propellers using a URANS Method. In Proceeding of the 10th International Symposium on Cavitation, Baltimore, MD, USA, 14–16 May 2018. [Google Scholar]

- Schenke, S.; van Terwisga, T.J. An energy conservative method to predict the erosive aggressiveness of collapsing cavitating structures and cavitating flows from numerical simulations. Int. J. Multiph. Flow 2019, 111, 200–218. [Google Scholar] [CrossRef]

- Melissaris, T.; Bulten, N.; van Terwisga, T.J. On the Applicability of Cavitation Erosion Risk Models With a URANS Solver. Trans. ASME J. Fluids Eng. 2019, 141, 101104. [Google Scholar] [CrossRef]

- Leclercq, C. Simulation numérique du chargement mécanique en paroi généré par les écoulements cavitants, pour application à l’usure par cavitation des pompes centrifuges. Ph.D. Thesis, Université Grenoble Alpes, Grenoble Alpes, France, 2017. [Google Scholar]

- Escaler, X.; Farhat, M.; Egusquiza, E.; Avellan, F. Dynamics and intensity of erosive partial cavitation. Trans. ASME J. Fluids Eng. 2007, 129, 886–893. [Google Scholar] [CrossRef]

- Couty, P. Physical investigation of cavitation vortex collapse. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 2002. [Google Scholar]

- Geng, L.; Escaler, X. Assessment of RANS turbulence models and Zwart cavitation model empirical coefficients for the simulation of unsteady cloud cavitation. Eng. Appl. Comp. Fluid Mech. 2020, 14, 151–167. [Google Scholar] [CrossRef]

- Coutier-Delgosha, O.; Fortes-Patella, R.; Reboud, J.L. Evaluation of the turbulence model influence on the numerical simulations of unsteady cavitation. Trans. ASME J. Fluids Eng. 2003, 125, 38–45. [Google Scholar] [CrossRef]

- Zwart, P.J.; Gerber, A.G.; Belamri, T. A Two-Phase Flow Model for Predicting Cavitation Dynamics. In Proceedings of the International Conference on Multiphase Flow, Yokohama, Japan, 30 May–4 June 2004. [Google Scholar]

- Schnerr, G.H.; Sauer, J. 2001 Physical and Numerical Modeling of Unsteady Cavitation Dynamics. In Proceedings of the 4th International Conference on Multiphase Flow, New Orleans, LA, USA, 27 May–1 June 2001. [Google Scholar]

- Kunz, R.F.; Boger, D.A.; Stinebring, D.R.; Chyczewski, T.S.; Lindau, J.W.; Gibeling, H.J.; Venkateswaran, S.; Govindan, T.R. A Preconditioned Navier-Stokes Method for Two-Phase Flows with Application to Cavitation Prediction. Comput. Fluids 2000, 29, 849–875. [Google Scholar] [CrossRef]

- Leclercq, C.; Archer, A.; Fortes-Patella, R. 2016 Numerical investigations on cavitation intensity for 3d homogeneous unsteady viscous flows. In Proceeding of the 28th IAHR Symposium on Hydraulic Machinery and Systems, Grenoble, France, 4–8 July 2016. [Google Scholar]

- Asnaghi, A.; Feymark, A.; Bensow, R.E. Numerical investigation of the impact of computational resolution on shedding cavity structures. Int. J. Multiph. Flow 2018, 107, 33–50. [Google Scholar] [CrossRef]

- Lu, N.X.; Bensow, R.E.; Bark, G. Indicators of erosive cavitation in numerical simulations. In Proceeding of the 7th international workshop on ship hydrodynamics, Shanghai, China, 16–19 September 2011. [Google Scholar]

- Fortes-Patella, R.; Challier, G.; Reboud, J.L.; Archer, A. Energy Balance in Cavitation Erosion: From Bubble Collapse to Indentation of Material Surface. Trans. ASME J. Fluids Eng. 2013, 135, 011303. [Google Scholar] [CrossRef]

- Bachert, B.; Dular, M.; Baumgarten, S.; Ludwig, G.; Stoffel, B. Experimental investigations concerning erosive aggressiveness of cavitation at different test configurations. In Proceedings of the ASME Heat Transfer/Fluids Engineering Summer Conference, Westin Charlotte, NC, USA, 11–15 July 2004. [Google Scholar]

- Dular, M.; Sirok, B.; Stoffel, B. Influence of gas content in water and flow velocity on cavitation erosion aggressiveness. Stroj. Vestn. J. Mech E. 2005, 51, 132–145. [Google Scholar]

| α [°] | l/c [–] | Uinf [m/s] | σ [-] | f [Hz] | St [-] |

|---|---|---|---|---|---|

| 6 | 40 | 15 | 1.55 | 96.1 | 0.26 |

| 6 | 40 | 20 | 1.58 | 132.8 | 0.27 |

| 6 | 40 | 25 | 1.60 | 175.5 | 0.28 |

| 6 | 40 | 30 | 1.62 | 225.8 | 0.30 |

| Model | (P < Pv) | (P > Pv) |

|---|---|---|

| Zwart | ||

| Sauer | ||

| Kunz |

| Uinf [m/s] | Time Step [s] | σexp | σ CFD | fexp [s−1] | fCFD [s−1] | fdev [%] |

|---|---|---|---|---|---|---|

| 15 | 0.00004 | 1.55 | 1.55 | 96.1 | 106 | 10.3 |

| 20 | 0.00003 | 1.58 | 1.55 | 132.8 | 139 | 4.7 |

| 25 | 0.000024 | 1.60 | 1.55 | 175.5 | 177 | 0.8 |

| 30 | 0.00002 | 1.62 | 1.55 | 225.8 | 216 | −4.3 |

| Uinf [m/s] | Ptot_load [kW m−2] | P∞ [Pa] | Pg0 [Pa] | ηcollapse [%] | Peff_load_ [kW m−2] | fCFD [s−1] | Pagg [kW m−2 s−1] |

|---|---|---|---|---|---|---|---|

| 15 | 5792 | 176,026 | 1500 | 38.0 | 2202 | 106 | 233,385 |

| 20 | 13,963 | 311,380 | 1500 | 51.7 | 7222 | 139 | 1,003,915 |

| 25 | 27,711 | 485,406 | 1500 | 65.7 | 18,216 | 177 | 3,224,249 |

| 30 | 48,033 | 698,105 | 1500 | 80.0 | 38,421 | 216 | 8,298,901 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, L.; Chen, J.; De La Torre, O.; Escaler, X. Numerical Simulation of Cavitation Erosion Aggressiveness Induced by Unsteady Cloud Cavitation. Appl. Sci. 2020, 10, 5184. https://doi.org/10.3390/app10155184

Geng L, Chen J, De La Torre O, Escaler X. Numerical Simulation of Cavitation Erosion Aggressiveness Induced by Unsteady Cloud Cavitation. Applied Sciences. 2020; 10(15):5184. https://doi.org/10.3390/app10155184

Chicago/Turabian StyleGeng, Linlin, Jian Chen, Oscar De La Torre, and Xavier Escaler. 2020. "Numerical Simulation of Cavitation Erosion Aggressiveness Induced by Unsteady Cloud Cavitation" Applied Sciences 10, no. 15: 5184. https://doi.org/10.3390/app10155184

APA StyleGeng, L., Chen, J., De La Torre, O., & Escaler, X. (2020). Numerical Simulation of Cavitation Erosion Aggressiveness Induced by Unsteady Cloud Cavitation. Applied Sciences, 10(15), 5184. https://doi.org/10.3390/app10155184