1. Introduction

The combustion of liquid fuels is a process of high industrial importance. Even when the number of oil-burning furnaces is continuously reduced due to environment protection reasons, it still takes place in furnaces in central heating systems or industrial furnaces. It is also the main energy source for gas turbines and internal combustion engines.

The term heating oil is a general designation of, mostly, petroleum products used for thermal usage, with viscosities within the range from approximately 2.5 mPa s up to 360 mPa s (at 40 C). The effective and environmentally friendly heating of oil-burning requires disruption of the fuel volume into small drops, which is a task fulfilled by the device called the atomizer or nozzle.

There are a variety of nozzles used in practical applications, but the twin-fluid atomizers with internal mixing of fluids (IM-TFA ) have proven the capability to provide small drops with low energy consumption, even when spraying liquids of high viscosity, such as the marine diesel or heavy fuel oil [

1,

2,

3]. The low energy consumption is explained by the fact that the IM-TFA provides a high-quality spray without the need to pressurize the liquid to a level as pressure nozzles need (≈

MPa).

The typical application of IM-TFA is, except for combustion, the atomization of coke sludge slurries or liquid waste [

1,

3,

4,

5]. Other branches of industry where internal-mixing atomizers are commonly used are for example the pharmaceutical [

6] or food-processing industry, where IM-TFA are used for atomization of different Newtonian and non-Newtonian liquids—water—oil emulsions [

7,

8], and gelatinized native corn starch [

9]. Both the pharmaceutical and the food-processing industries also use spray-drying technology [

10,

11,

12]. The ability to produce fine spray suitable for fire-suppression purposes serves as an alternative to the systems based on environmentally unfriendly and health-threatening HALON gas [

13].

The work of IM-TFA is based on the creation of a two-phase flow inside the mixing chamber of the spraying device. The mixture flows through the mixing chamber until it reaches the discharge orifice [

14]. The mixture discharge is a process where the intense gas-to-liquid interaction takes place. Liquid is accelerated and the energy of the expanding gas is used to shatter the liquid volume into smaller structures (ligaments) and finally into drops [

1]. These processes are called primary and secondary liquid breakup.

The liquid-mixing and the two-phase flow development in the mixing chamber are the crucial processes of the IM-TFA work. The favourable internal flow pattern is an annular or wall-attached flow, leading to a stable liquid breakup and drops of uniform sizes [

15,

16]. The demand for efficient atomizer work requires a low gas consumption. A decrease of the gas content in the mixture supports the formation of slug or bubbly two-phase flow patterns, which downgrade the stability of the atomization and, consequently, the spray quality.

The mixing chamber flow pattern is the result of the viscous, gravitational, inertial forces and the surface tension equilibrium. The influence of individual forces on the flow in the mixing chamber can be described by the well-established dimensionless numbers—Weber (

), Froude (

), Ohnesorge (

) and Bond number (

). The two-phase flow pattern can be estimated by the two-phase flow maps which have been developed over past decades [

17,

18,

19]. Regardless of the flow map used, the correct usage of this two-phase flow pattern estimation method requires a sufficiently long mixing chamber to allow the flow pattern to develop. This condition is hard to sustain in a real atomizer design. We will show that the above-mentioned flow maps do not provide sufficient internal flow description to explain the atomizers’ behavior over the range of tested working conditions. An additional criterion, to estimate the internal Y-jet nozzle flow, was provided by [

20]. The authors investigated the fluid injection into the mixing chamber and linked the ratio of the fluid momentum to the observed internal flow pattern. This approach was also successfully applied to the modified design of an effervescent atomizer [

21,

22].

The proper fuel combustion requires a certain spray quality, in the meaning of the provided drop sizes spectrum. The low sensitivity of the spray parameters on the liquid viscosity is also the advantageous capability of the well-designed atomizer.

Several internal-mixing atomizer designs have been proposed and studied in detail in past decades [

12,

21,

23,

24,

25]. Unfortunately, there is a lack of papers oriented to the systematic comparison of different nozzles, which can help identify the key differences among nozzle types.

Some information can be found in [

3,

26], although these works are primarily oriented to the improvement of a specific atomizer type more than to the comparison of different nozzle designs. From recent research can be mentioned the work [

10], where the authors compare the performance of the different nozzle designs according to energy consumption. The performance comparison of the effervescent atomizer and the new type of internal-mixing atomizer, the ACLR nozzle, is provided in [

27,

28]. Here, the authors used statistical analysis to compare the spray quality of the two nozzle types.

The lack of published results oriented to the testing and comparison of different nozzle designs motivated us to perform experiments to answer the following questions: (1) What way nozzle design influences the fluid-mixing mechanism? (2) What is the effect of the fluid-mixing mechanism on the spray quality?

It is a known fact that the annular internal flow leads to good atomizer performance [

15]. The spray quality worsens rapidly when internal flow changes to the plug or slug regime [

10]. This fact contradicts to the requirement for efficient work, as the annular flow is usually linked with high gas content in the mixture.

Our present results document that even simple design difference between the OIG and OIL devices influences the internal flow significantly. We were able to achieve annular internal flow with the OIL device and good spray quality even with lowest gas consumption, while the performance of the OIG nozzle was poor at the same working regimes due to the plug/slug internal flows.

The influence of the mixing chamber design on internal flow and the spray quality is shown by the comparison of four atomizer types, some well-established and some experimental concepts. This research is a continuation of our previous work [

21], where the liquid disintegration process of the same nozzles was compared using high- speed camera.

The Y-jet atomizer (

Figure 1a), designed according to Mullinger and Chigier [

29], is a well-known nozzle design, used in several industrial applications Ferreira et al. [

3]. The internal flow of this device is created by injection of liquid into a high-speed gas stream. In contrast to this atomizer, the OIG and the OIL nozzles (

Figure 1b) use fluid-mixing at low velocities. Both atomizers have the same design of their mechanical parts. The different atomizer performances were achieved by switching of the inlet ports into an “outside-in-gas” (OIG) or “outside-in-liquid” (OIL) configuration. The effervescent atomizer designed by the Lefebvre [

30] represents the OIG configuration. As our previous work Mlkvik et al. [

21] revealed, the investigated OIL configuration proved that the injection port configuration has a significant influence on the performance of the atomizer. This was later confirmed by Zaremba et al. [

22]. The CFT (

Figure 1c) nozzle has a design inspired by several previous works Chin [

31], Ferreira M. Teixeira [

32], Tamaki N.and Shimizu [

33]. As opposed to the Y-jet nozzle, it is characterized by a low velocity of the internal flow. The mixing chamber is also significantly shorter than the mixing chamber of the OIG nozzle. This makes its design more compact and suitable for applications where a small atomizer body is required.

2. Experiment and Methods

The experiments were conducted on the test bench schematically drawn in

Figure 2. The pressurized vessel was used to drive the liquid into the atomizer and the liquid mass flow was controlled by a throttle valve. This approach was chosen to remove liquid flow variations caused by a pump. The air pressure in the mixing chamber was maintained by a pressure reduction valve. All the experiments were performed at air-conditioned room at temperature within the range 22–24

C with 40% (liq. 1) and 45% (liq. 2) aqueous maltodextrin solutions (

Table 1). Liquids were prepared at least 12 h before the tests and were stored in the same room, where the experiments were performed. Therefore, the room and the liquid temperatures were equalized. The physical properties of the maltodextrin solutions (

Table 1) were taken from [

10] and were measured at 25

C (

Table 1).

The atomizer working regimes were defined by

= 0.14 MPa and with GLR within the range from 2.5 to 20% (

Table 2,

Table 3,

Table 4 and

Table 5). We chose the inlet air pressure as an independent parameter because its contribution to the total energy balance dominates over the liquid inlet pressure [

1]. Therefore,

can be related to the potential energy of the atomization process. The GLR was chosen because it is commonly used, and easy to measure, dimensionless parameter. As we did not experimentally investigate the internal flows, we used three different two-phase flow maps to estimate the internal flow structure: [

17,

18,

19,

34].

The internal flows were further described by a set of dimensional (gas and liquid superficial velocities (

and

), characteristic length scale of the internal flow structures (

L)) and dimensionless criteria (Weber (We

mix), Bond (Bo

mix) and Froude (Fr

mix)). The void fraction at the discharge orifice (

) was estimated by a two-phase flow calculator [

35].

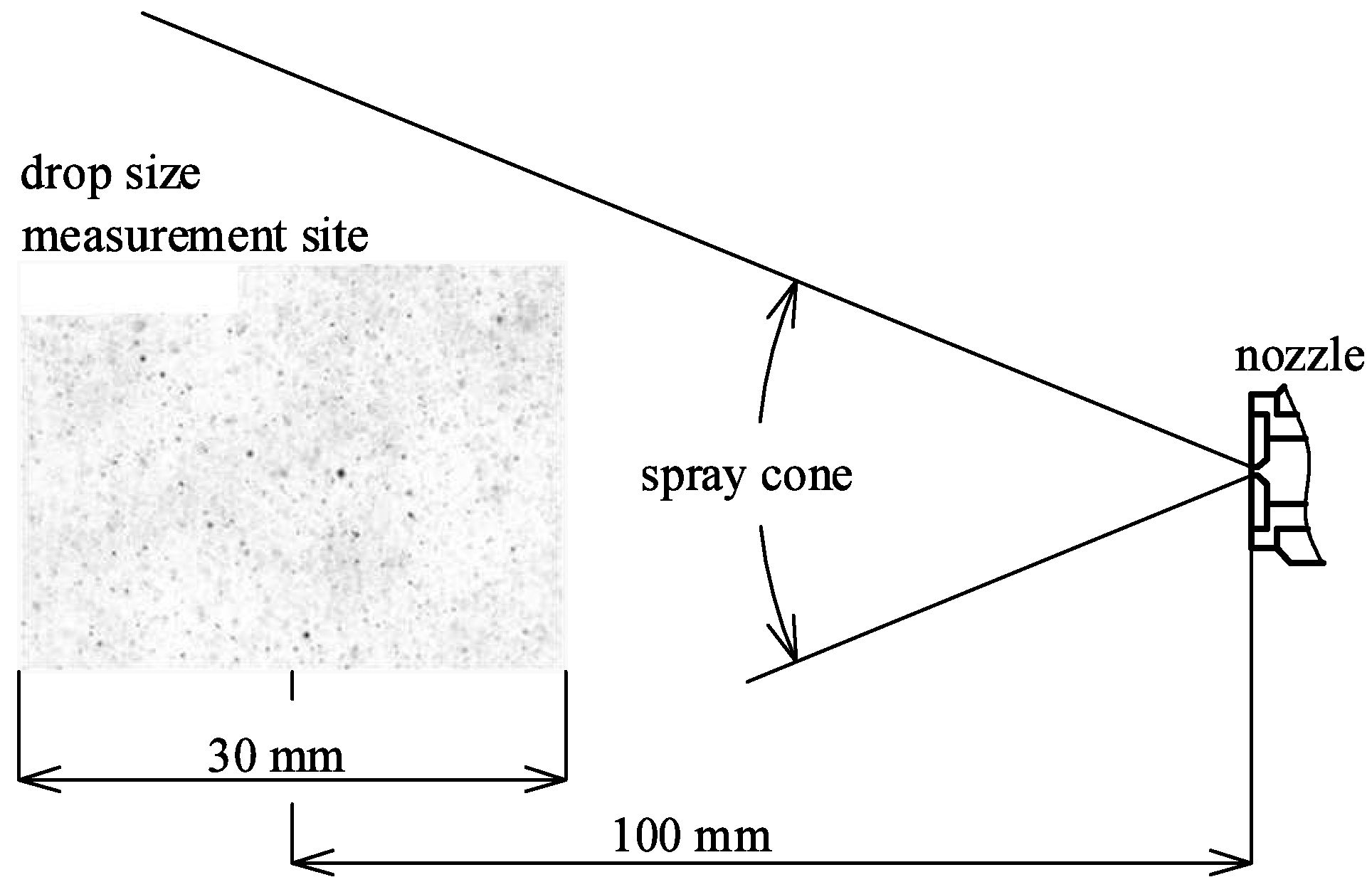

Instantaneous drop sizes (

) were measured by the laser diffraction system (Malvern Spraytec) at a distance 100 mm downstream to the discharge orifice. The measurement distance was theoretically estimated according to [

36]. The calculations were done by presumption that the liquid exits the atomizers in the form of a thin film. The input data of the calculations were taken from our previously published results [

21], which dealt with the observations of the liquid discharge in the close distance from the exit orifice. The longest theoretically estimated breakup distance was 40 mm for the Y-jet nozzle working with the more viscous liquid at GLR = 2.5%. The liquid breakup distance for the other nozzles was estimated within the range from 7 to 8 mm. The distance 100 mm between the nozzle and the drop size measurement site was, therefore, considered to be sufficient to avoid the presence of the ligaments. This consideration was further verified by direct observation of the spray pattern at the drop sizes measurement site by high-speed camera. The presence of the ligaments was not observed for any of the tested operating regimes of the nozzles, except for the ones where the nozzles did not atomize the liquid. The sample image of the spray pattern, as observed in the drop sizes measurement site, is shown in

Figure 3. The measurement frequency was 500 Hz and the measurement period was 25 s. The time-averaged Sauter mean diameters (

) were then estimated as the arithmetic means of the recorded 12,500 samples of

values.

The standard deviation (

) was used to measure the drop sizes variations of the measured dataset. As previously shown in Kleinhans et al. [

27], this method can identify the pulsations, but can lead to incorrect assumptions about the atomization process. To study the atomizers work, were involved two methods of the time-resolved analysis of the drop sizes. The first method was the conversion of the time-dependent data (

) into the Cumulative Distribution Function (CDF). This approach allowed us to analyze the whole range of the measured

and in this way to identify the spray pulsations. The second method, the FFT (Fast Fourier Transform) analysis, was used to identify the periodic behavior of the spray pulsations and to indirectly gain information about the two-phase flow in the atomizer mixing chamber. Similar analysis was, for the numerical simulation results, used in [

37].

The economy of the atomizer work was estimated in two ways. The atomization efficiency (

) and its sensitivity to the liquid viscosity are related to the process of liquid breakup and drops formation. The efficiency was calculated according to Jedelsky and Jicha [

1] as a ratio of the surface tension energy of drops in the spray (

), to the total energy (

) required to produce the spray (

).

3. Time-Averaged Spray Analysis

The unstable atomizer performance was characterized by the spray cone pulsations, followed by the formation of the various drop sizes. In this section, we analyze the uniformity of the size distributions of the generated drops by the standard deviation of the time-averaged

(denoted in

Figure 3 by the error bars).

The expected trend, an increase in drop sizes with reducing GLR, was observed for all the investigated cases. Also, was comparable for all the tested devices for GLR ≥ 10%. As atomization with low gas consumption is the key advantage of internal-mixing devices in comparison to their external mixing counterparts, we focused our further analysis on regimes with GLR ≤ 5%.

The OIL atomizer generally produced the smallest drops from among all the tested devices. It also atomized both liquids under the whole range of investigated GLRs. The drops with = 130 m were produced with the more viscous liquid at GLR = 2.5%. For liquid with lower viscosity the drops were smaller (75 m). Similar sensitivity of the to the liquid viscosity was, observed for all the GLRs with this atomizer. On the other hand, low pulsations for almost all the investigated regimes were typical for the OIL device. The only significant error bar (±26 m) is present for the GLR = 2.5% and liquid viscosity = 143 mPa s.

The OIG atomizer, however, has the same design as the previously mentioned device but provided considerably worse performance. It did not atomize the liq. 2 at GLR = 2.5%, and it produced

larger than 300

m at GLR = 5% with this liquid. For some applications, this can be considered, as unacceptable result. This device also shows sensitivity to

. It atomized the second, less viscous, liquid across the whole GLR range with acceptable drop sizes of 102 and 70

m at the GLR = 2.5 and 5% respectively. The

was not the only qualitative parameter which got worse when the OIG atomizer was used instead of its OIL counterpart. The error bars in

Figure 4, indicate that at low GLRs, the OIG device produced a spray with varying drop sizes, which can be related to the plug/slug internal two-phase flow pattern previously estimated in [

21]. The most intense pulsations were present when liquid liq. 2 was atomized, causing a very broad error bar at GLR = 5%.

The low sensitivity of the generated spray quality to the liquid viscosity (for the corresponding GLRs) was characteristic of the Y-jet atomizer. For GLR = 2.5%, the drops had sizes of 130 and 150 m for liq. 1 and liq. 2, respectively. At GLR = 5% the average drop size for both liquids was 80 m. The spray pulsations (characterized by the error bars) were most intense at lowest GLR and were comparable for both liquids ( 15 m). This is an important difference in comparison to the previously discussed devices, where spray pulsations intensity, as well as drop size, depended on liquid viscosity.

The last of the tested devices, the CFT atomizer, produced at low GLRs the spray with the largest drops among the set of the tested devices. As with the OIG device, the CFD nozzle did not atomize the more viscous liquid at GLR = 2.5%. The error bars of the indicates that the drops size spectrum was comparable for the two liquids, except for GLR = 2.5%, where the comparison could not be done.

The time-averaged analysis provided us with some spray quality comparisons. Increasing for low GLRs indicated unstable atomizer operation, but did not allow us to study the spray dynamic behavior. Accordingly, time-dependent analyses were used to study in detail drop size distributions and spray pulsations.

5. Atomization Efficiency

Although drop size is an important marker of spray quality, atomization efficiency is relevant for an evaluation of the energy consumption of the entire technological process (combustion, spray-drying and others). The relation of the atomization efficiency and spray quality is plotted in

Figure 13. It shows the known dependency of the

: smaller drops are produced with lower efficiency. The physical explanation of this trend can be found in previous works [

1,

10]. We will, therefore, focus only on the comparison of the nozzles.

Small drops (<60 m) were produced with efficiency from 0.03 to 0.06% by all the atomizers, regardless of the liquid used. This drop size range was related to high GLR regimes (GLR > 5%) where the spraying process was characterized by stable spray production. The significant difference in the atomization efficiency was found at lower GLRs, characterized by the production of larger drops. The differences among the atomizers is shown on two parameters: atomization efficiency and its sensitivity to liquid viscosity at low GLRs.

When the less viscous liquid was sprayed, the best overall results were observed for the OIL nozzle (

Figure 13). It reached 0.16% efficiency for the

= 75

m. The other atomizing devices reached this spray quality with much lower efficiencies— less than 0.1%.

The Y-jet atomizer was typified by the stable spray production, with efficiency comparable to the OIG and the CFT nozzles.

At low GLRs, the viscosity increase to 143 mPa s led to a less efficient spraying process for all the tested devices. The lowest efficiency was recorded with the OIG and the CFT nozzles. Both devices produced averaged drop sizes 100 m with 0.05%. The highest sensitivity of to liquid viscosity was shown by the OIL atomizer. However, at the lowest GLR with liq. 2, this device provided the smallest drops (135 m) with the highest efficiency (0.08%) among the tested atomizers; the relative decrease of the with liquid change was the most significant. On the other hand, when spraying the more viscous solution the Y-jet atomizer showed the lowest relative decrease of efficiency, which is in accordance with the fact that the spray stability of this device (for corresponding GLRs) was not significantly influenced by liquid physical properties.

7. Conclusions

We examined four atomizers, spraying two highly viscous liquids with a set of operating conditions to provide a comparison of their spraying abilities in order to define the advantages, disadvantages and potential applications for the spraying of liquid fuels. The comparison criteria were chosen to highlight the atomizers’ differences in two areas: spray quality and the efficiency of work.

The time-averaged was comparable for all the tested devices for GLR ≥ 10%. Also, the spray pulsations were weak, which led to small variations in drop size. Good spray quality was provided by high pressurized gas consumption, which led to low atomization efficiency for all the nozzles ( 0.06%).

An analysis of the time-resolved spray behavior documents that the nozzle designs based on the liquid injected to the gas stream (OIL and Y-jet atomizers) featured low spray pulsations, narrow drop size range and acceptable spraying efficiency. Their internal flows were characterized with wall-attached liquid stream even at low-GLR regimes.

Switching of the fluid injection ports from OIL to the OIG nozzle configuration led to internal flow with the presence of large gas and liquid structures, which caused local GLR fluctuations in the discharge orifice, along with spray pulsations. It resulted in large drops present in the spray, generated by the random discharge of the liquid that was not properly mixed with the pressurized air.

The OIL nozzle has shown to have a very good spraying ability in comparison to its OIG counterpart. It was caused by the fact that the injected liquid was immediately attached to the mixing chamber wall without a chance to interact with the gas core (as it did in the OIG atomizer). The simple design change influenced fluid-mixing mechanism so the annular flow was able to form even with low gas consumption. The working principle of the OIL nozzle differs from the original effervescent atomizer design (OIG) so much that it can be considered to be a separated atomizer type.

This device is characteristic by the stable operation and high efficiency when working with the liquid of constant viscosity. It is a good alternative of the currently used OIG nozzles which are often used for injection of fuel to the gas turbines or industrial furnaces.

The main advantage of the Y-jet atomizer was relative low sensitivity of the spray quality on the liquid viscosity. It provided stable performance with a narrow drop sizes spectrum and acceptable mean drop size. It is currently widely used in the industrial furnaces, but the observed behavior allows use of this nozzle in applications, where the liquid viscosity oscillates, such as spray-drying of the liquids in the food-processing industry.

The CFT nozzle, however, although giving the finest spray with the less viscous liquid at GLR = 20%, performed poorly in low gas consumption regimes and its usage potential at the atomization of the viscous fuel is low. Its potential lies in the other applications, where low gas consumption and high viscosity of the liquid are not required but the very fine spray is needed.

One interesting secondary finding is that for the OIG device the Golan and Stenning two-phase flow map predicted an annular flow for all of the tested working regimes which was not in accordance with the observed spray behavior, especially at low GLRS. The other tested flow map (Baker, Barnea) provided acceptable results, although the internal flow pattern estimation had to be supported by the additional dimensionless parameters to satisfactorily explain the OIG nozzle spray behavior.