Automatic Supervisory Controller for Deadlock Control in Reconfigurable Manufacturing Systems with Dynamic Changes

Abstract

:1. Introduction

- Mass customization manufacturing can use the proposed approach to address its difficulties. For example, by trying to make products available rapidly to consumers, a high quality production of a wide variety of products can be maintained and achieve low costs in line with standard products.

- Lean productivity concept can also use the proposed approach to enable a company to implement an RMS in order to improve the exploitation of the part of the resources for various family products and to minimize waste from the idle resource of an RMS.

- Agile manufacturing can use the proposed approach to facilitate rapid products changeovers, rapid introduction of new products and unattended operation.

- Flexible manufacturing systems can use the proposed approach to increase response to a variety of customers and markets. Moreover, scalability to the desired volume of products and convertibility to current systems, machines, robots, and controls are increased in accordance with the new production requirements.

2. Preliminaries

2.1. S3PR NET

- 1.

- the subnet created by Y = PA ∪ {p0} ∪ T is an S2P;

- 2.

- PR ≠ ∅ and (PA ∪ {p0}) ∩ PR = ∅, where PR is called a set of resource places;

- 3.

- PC = PA ∪ {p0} ∪ PR, F ⊆ (PC × T) ∪ (T × PC) is flow relations;

- 4.

- ••(p0) ∩ PR = (p0)•• ∩ PR ≠ ∅;

- 5.

- ∀p ∈ PA, ∀t ∈ •p, ∀t′ ∈ p•, rp ∈ PR, •t ∩ PR = t′• ∩ PR = {rp};

- 6.

- ∀r ∈ PR, ••r ∩ PA = r•• ∩ PA ≠ ∅ and •r ∩ r• ≠ ∅;

- 1.

- An S2PR is an S3PR;

- 1.

- Let Ni = ({p0i} ∪ PAi ∪ PRi, Ti, Fi), i = {1, 2}, be two S3PRs such that ({p01} ∪ PA1) ∩ ({p02} ∪ PA2) = ∅, PR1 ∩ PR2 = PD, PA1 ∩ PA2 ≠ PD, and T1 ∩ T2 ≠ ∅; then, the net N = ({p0} ∪ PA ∪ PR, T, F) is an S3PR resulting from the integration of N1 and N2 by the set of common PD (denoted as N1N2) and expressed as: (1) p0 = {p01} ∪ {p02}, (2) PA = PA1 ∪ PA2, (3) PR = PR1 ∪ PR2, (4) T = T1 ∪ T2, and (5) F = F1 ∪ F2.

- ∀i ∈ {1,2}, ∀p ∈ PAi ∪ {p0i}, Mo(p) = Mio (p).

- ∀i ∈ {1,2}, ∀r ∈PRiPD, Mo(r) = Mio (r).

- ∀i ∈ {1,2}, ∀r ∈ PD, Mo(p) = max {M1o (r), M2o (r)}.

2.2. Reconfigurable S3PR Net

- 1.

- For all rr ∈ , rr = {L, R, φ, •φ, φ•};

- 2.

- L = (PCL, TL, FL, WL, MoL, KL) is called the left-hand side;

- 3.

- R = (PCR, TR, FR, WR, MoR, KR) is called the right-hand side;

- 4.

- φ ⊆ (PCL × PCR) ∪ (TL × TR) is said to be an interface transfer relation of r that relates places of L to places of R and transitions of L to transitions of R, PCL φ ⊆ PCR, φPCR ⊆ PCL, TLφ ⊆ TR, and φTR ⊆ PL;

- 5.

- •φ ⊆ φ is said to be an input interface transfer relation, expressed as •φ = {({L.pi}, {R.pi})} or {({L.ti}, {R. ti})}, and L.* or R.* means to input nodes “*” in L or R;

- 6.

- φ• ⊆ φ is named output interface transfer relation, φ• = {({L.pj}, {R.pj})} or {({L.tj}, {R.tj})}, and L.* or R.* means to output nodes “*” in L or R;

- 7.

- for all rri, rrj ∈ (i ≠ j), ξ (Li) ∩ ξ (Lj) ≠ ∅, a rewriting must be guaranteed without overlap; moreover, the order of rri, rrj does not impact the result of the rewriting.

- 1.

- Transition firing: If Arcs labeled with t can fire in the net (N1, M1), leading to (N2, M2): (N1, M1) (N2, M2) ⇔ (N1 = N2 and M1[M2 in N1).

- 2.

- Configuration changing: Arcs labeled with r = {L, R, φ, •φ, φ•} from state (N1, M1) to state (N2, M2) if there is ξ: L → N1 so that, ∀a ∉ ξ(L) and b ∈ L if

- 2.1.

- a ∈ •ξ(b) ⇒ b ∈ •φ and a ∈ ξ(b)• ⇒ b ∈ φ•.

- 2.2.

- N1 = (PC1, T1, F1, W1, M1, K1) and N2 = (PC2, T2, F2, W2, M2, K2) holds the following: PC2 = PC1 − ξ(PC1L) + PC1R and T2 = T1 − ξ(T1L) + T1R. Note that −(+) means deleting(inserting) places or transitions from (to) N1 and the places name of PC1R and T1R inserted into N1 must be different to prevent clashes.

| Algorithm 1:Reconfiguration procedures for S3PR net |

| Input: An S3PR net (No, Mo) Output: A reconfigurable S3PR net (NR, MRo) Initialization:Generate dynamic configurations = {rr1, rr2, rr3, …, rrm} k=0. Step 1: while ≠ ∅ do k = k+1 1.1. Build rrk = {Lk, Rk, φk, •φk, φk•}. 1.2. Build Lk = (PCLk, TLk, FLk, WLk, MLko, KLk). 1.3. Build Rk = (PCRk, TRk, FRk, WRk, MRko, KRk). 1.4. Build •φk and φk•. 1.5. Build ξk: Nk-1 → Nk. 1.6. Apply rewriting rule rrk: Nk Nk−1. 1.7. Update the flow relation Fk as follows: end while Step 2: Output a reconfigurable S3PR net (NR, MRo) Step 3: End |

3. Deadlock Prevention Policy for Reconfigurable S3PR Net Based on Siphons

| Algorithm 2:Deadlock prevention algorithm for reconfigurable S3PR net based on siphon control |

| Input: An S3PR net (No, Mo) Output: A controlled reconfigurable S3PR net (NRC, MRCo). Initialization: Generate dynamic configurations = {rr1, rr2, rr3, …, rrm} k=0, PV = ∅, TV = ∅, FV = ∅, (NRC, MRCo) = ∅. Step 1: while ≠ ∅ do k=k+1 1.1. Build (Nk, Mko) by using Algorithm 1. 1.2. Compute minimal siphons for (Nk, Mko). 1.3. for each S ∈ do if VS• •S, then a. Add S to (; ). b. c. . d. PV := PV ∪ {Vs} e. TV := TV ∪ {t\t ∈ •VS ∪ VS•}. f. FV := FV ∪ ((PV × TV) ∪ (TV × PV)) elseIf VS• ⊆ •S and , then Add S to (; ). end if end for 1.4. (NRC, MRCo) := (Nk, Mko) ‖ (Vk, MVko) 1.5. = \CR. /* CR is covered rrk*/ end while Step 2: Output a controlled reconfigurable S3PR net (NRC, MRCo). Step 3: End |

4. Behavioral and Quantitative Analysis of Reconfigurable S3PR Net

4.1. Liveness

4.2. Boundedness

4.3. Reversibility

4.4. Computational Complexity

4.5. GPENSIM Code and Validation

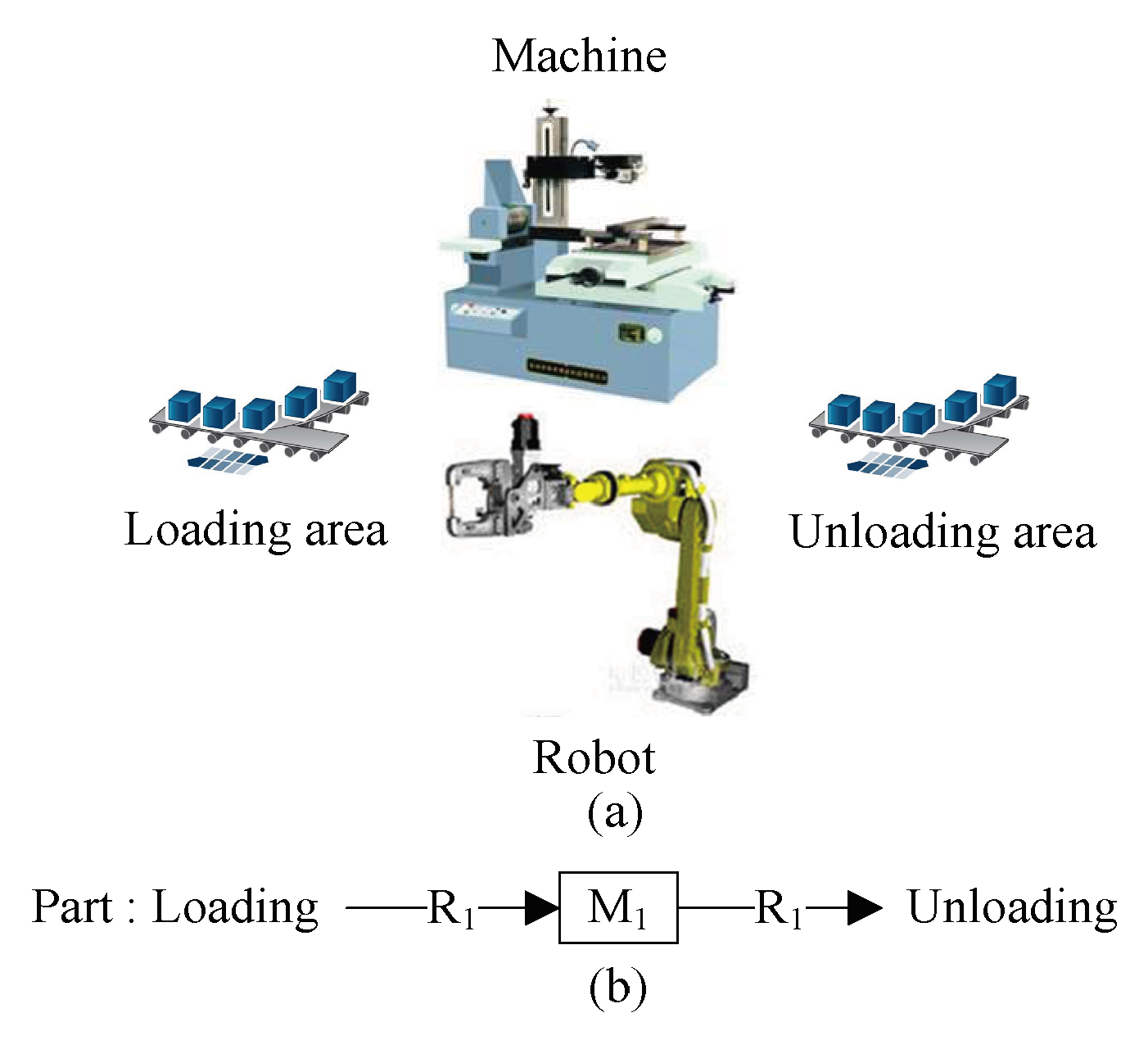

5. Numerical Example

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hu, Y.; Ma, Z.; Li, Z. Design of Supervisors for Active Diagnosis in Discrete Event Systems. IEEE Trans. Autom. Control 2020. [Google Scholar] [CrossRef]

- Wang, D.; Wang, X.; Li, Z. Nonblocking Supervisory Control of State-Tree Structures with Conditional-Preemption Matrices. IEEE Trans. Ind. Inform. 2019, 16, 3744–3766. [Google Scholar] [CrossRef]

- Mehrabi, M.G.; Ulsoy, A.G.; Koren, Y. Reconfigurable manufacturing systems: Key to future manufacturing. J. Intell. Manuf. 2000, 11, 403–419. [Google Scholar] [CrossRef]

- Katz, R. Design principles of reconfigurable machines. Int. J. Adv. Manuf. Technol. 2007, 34, 430–439. [Google Scholar] [CrossRef]

- Patel, R.; Gojiya, A.; Deb, D. Failure Reconfiguration of Pumps in Two Reservoirs Connected to Overhead Tank. In Innovations in Infrastructure; Springer: Berlin/Heidelberg, Germany, 2019; pp. 81–92. [Google Scholar]

- Kaid, H.; Al-Ahmari, A.; Li, Z.; Davidrajuh, R. Single controller-based colored Petri nets for deadlock control in automated manufacturing systems. Processes 2020, 8, 21. [Google Scholar] [CrossRef] [Green Version]

- Kaid, H.; Al-Ahmari, A.; Li, Z.; Davidrajuh, R. Intelligent colored token Petri nets for modeling, control, and validation of dynamic changes in reconfigurable manufacturing systems. Processes 2020, 8, 358. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Zhou, M. Deadlock Resolution in Automated Manufacturing Systems: A Novel Petri Net Approach; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Zan, X.; Wu, Z.; Guo, C.; Yu, Z. A Pareto-based genetic algorithm for multi-objective scheduling of automated manufacturing systems. Adv. Mech. Eng. 2020, 12, 1687814019885294. [Google Scholar] [CrossRef]

- Li, L.; Basile, F.; Li, Z. An approach to improve permissiveness of supervisors for GMECs in time Petri net systems. IEEE Trans. Autom. Control 2019, 65, 237–251. [Google Scholar] [CrossRef]

- Liu, Y.; Cai, K.; Li, Z. On scalable supervisory control of multi-agent discrete-event systems. Automatica 2019, 108, 108460. [Google Scholar] [CrossRef] [Green Version]

- Chen, Q.; Yin, L.; Wu, N.; El-Meligy, M.A.; Sharaf, M.A.F.; Li, Z. Diagnosability of vector discrete-event systems using predicates. IEEE Access 2019, 7, 147143–147155. [Google Scholar] [CrossRef]

- Kaid, H.; Al-Ahmari, A.; Nasr, E.A.; Al-Shayea, A.; Kamrani, A.K.; Noman, M.A.; Mahmoud, H.A. Petri Net Model Based on Neural Network for Deadlock Control and Fault Detection and Treatment in Automated Manufacturing Systems. IEEE Access 2020, 8, 103219–103235. [Google Scholar] [CrossRef]

- Zhao, M. An integrated control method for designing non-blocking supervisors using Petri nets. Adv. Mech. Eng. 2017, 9, 1687814017700829. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Khalgui, M.; Mosbahi, O. Design of a maximally permissive liveness-enforcing Petri net supervisor for flexible manufacturing systems. Autom. Sci. Eng. IEEE Trans. 2011, 8, 374–393. [Google Scholar] [CrossRef]

- Al-Ahmari, A.; Kaid, H.; Li, Z.; Davidrajuh, R. Strict Minimal Siphon-Based Colored Petri Net Supervisor Synthesis for Automated Manufacturing Systems with Unreliable Resources. IEEE Access 2020. [Google Scholar] [CrossRef]

- Kaid, H.; Al-Ahmari, A.; El-Tamimi, A.M.; Abouel Nasr, E.; Li, Z. Design and implementation of deadlock control for automated manufacturing systems. South Afr. J. Ind. Eng. 2019, 30, 1–23. [Google Scholar] [CrossRef] [Green Version]

- Chao, D.Y. Improvement of suboptimal siphon-and FBM-based control model of a well-known S3PR. IEEE Trans. Autom. Sci. Eng. 2011, 8, 404–411. [Google Scholar] [CrossRef]

- Ghaffari, A.; Rezg, N.; Xie, X. Design of a live and maximally permissive Petri net controller using the theory of regions. IEEE Trans. Robot. Autom. 2003, 19, 137–141. [Google Scholar] [CrossRef]

- Uzam, M. The use of the Petri net reduction approach for an optimal deadlock prevention policy for flexible manufacturing systems. Int. J. Adv. Manuf. Technol. 2004, 23, 204–219. [Google Scholar] [CrossRef]

- Sun, D.; Chen, Y.; El-Meligy, M.A.; Sharaf, M.A.F.; Wu, N.; Li, Z. On algebraic identification of critical states for deadlock control in automated manufacturing systems modeled with Petri nets. IEEE Access 2019, 7, 121332–121349. [Google Scholar] [CrossRef]

- Nasr, E.A.; El-Tamimi, A.M.; Al-Ahmari, A.; Kaid, H. Comparison and Evaluation of Deadlock Prevention Methods for Different Size Automated Manufacturing Systems. Math. Probl. Eng. 2015, 501, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Tilbury, D.M. Deadlock-free resource allocation control for a reconfigurable manufacturing system with serial and parallel configuration. IEEE Trans. Syst. ManCybern. Part C (Appl. Rev.) 2007, 37, 1373–1381. [Google Scholar] [CrossRef]

- Li, J.; Dai, X.; Meng, Z. Automatic reconfiguration of petri net controllers for reconfigurable manufacturing systems with an improved net rewriting system-based approach. IEEE Trans. Autom. Sci. Eng. 2009, 6, 156–167. [Google Scholar] [CrossRef]

- Wu, N.; Zhou, M. Intelligent token Petri nets for modelling and control of reconfigurable automated manufacturing systems with dynamical changes. Trans. Inst. Meas. Control 2011, 33, 9–29. [Google Scholar]

- Sampath, R.; Darabi, H.; Buy, U.; Liu, J. Control reconfiguration of discrete event systems with dynamic control specifications. IEEE Trans. Autom. Sci. Eng. 2008, 5, 84–100. [Google Scholar] [CrossRef]

- Dumitrache, I.; Caramihai, S.; Stanescu, A. Intelligent agent-based control systems in manufacturing. In Proceedings of the 2000 IEEE International Symposium on Intelligent Control. Held jointly with the 8th IEEE Mediterranean Conference on Control and Automation (Cat. No. 00CH37147), Rio Patras, Greece, 19–19 July 2000; pp. 369–374. [Google Scholar]

- Ohashi, K.; Shin, K.G. Model-based control for reconfigurable manufacturing systems. In Proceedings of the 2001 ICRA. IEEE International Conference on Robotics and Automation (Cat. No. 01CH37164), Seoul, Korea, 21–26 May 2001; pp. 553–558. [Google Scholar]

- Kalita, D.; Khargonekar, P.P. Formal verification for analysis and design of logic controllers for reconfigurable machining systems. IEEE Trans. Robot. Autom. 2002, 18, 463–474. [Google Scholar] [CrossRef]

- Almeida, E.E.; Luntz, J.E.; Tilbury, D.M. Event-condition-action systems for reconfigurable logic control. IEEE Trans. Autom. Sci. Eng. 2007, 4, 167–181. [Google Scholar] [CrossRef]

- Zhang, L.; Rodrigues, B. Modelling reconfigurable manufacturing systems with coloured timed Petri nets. Int. J. Prod. Res. 2009, 47, 4569–4591. [Google Scholar] [CrossRef]

- Kahloul, L.; Bourekkache, S.; Djouani, K.; Chaoui, A.; Kazar, O. Using high level Petri nets in the modelling, simulation and verification of reconfigurable manufacturing systems. Int. J. Softw. Eng. Knowl. Eng. 2014, 24, 419–443. [Google Scholar] [CrossRef]

- Yu, Z.; Guo, F.; Ouyang, J.; Zhou, L. Object-oriented Petri nets and π-calculus-based modeling and analysis of reconfigurable manufacturing systems. Adv. Mech. Eng. 2016, 8, 1687814016677698. [Google Scholar] [CrossRef] [Green Version]

- Llorens, M.; Oliver, J. Structural and dynamic changes in concurrent systems: Reconfigurable Petri nets. IEEE Trans. Comput. 2004, 53, 1147–1158. [Google Scholar] [CrossRef]

- Li, J.; Dai, X.; Meng, Z. Improved net rewriting systems-based rapid reconfiguration of Petri net logic controllers. In Proceedings of the 31st Annual Conference of IEEE Industrial Electronics Society, Raleigh, NC, USA, 6–10 November 2005. [Google Scholar]

- da Silva, R.M.; Benítez-Pina, I.F.; Blos, M.F.; Santos Filho, D.J.; Miyagi, P.E. Modeling of reconfigurable distributed manufacturing control systems. IFAC-Pap. 2015, 48, 1284–1289. [Google Scholar] [CrossRef]

- Berthomieu, B.; Ribet, P.-O.; Vernadat, F. The tool TINA–construction of abstract state spaces for Petri nets and time Petri nets. Int. J. Prod. Res. 2004, 42, 2741–2756. [Google Scholar] [CrossRef]

- Bonet, P.; Catalina, M.L.; Puigjaner, R. A Petri Net tool for performance modeling. In Proceedings of the 23rd Latin American Conference on Informatics (CLEI 2007), San Jose, Costa Rica, October 2007. [Google Scholar]

- Badouel, E.; Llorens, M.; Oliver, J. Modeling concurrent systems: Reconfigurable nets. In Proceedings of the PDPTA, Las Vegas, NV, USA, 23–26 June 2003; pp. 1568–1574. [Google Scholar]

- Yamalidou, K.; Moody, J.; Lemmon, M.; Antsaklis, P. Feedback control of Petri nets based on place invariants. Automatica 1996, 32, 15–28. [Google Scholar] [CrossRef]

- Moody, J.O.; Antsaklis, P.J. Supervisory Control of Discrete Event Systems Using Petri Nets; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 8. [Google Scholar]

- Davidrajuh, R. Modeling Discrete-Event Systems with GPenSIM: An Introduction; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Ezpeleta, J.; Colom, J.M.; Martinez, J. A Petri net based deadlock prevention policy for flexible manufacturing systems. IEEE Trans. Robot. Autom. 1995, 11, 173–184. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Zhou, M. Elementary siphons of Petri nets and their application to deadlock prevention in flexible manufacturing systems. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2004, 34, 38–51. [Google Scholar] [CrossRef]

- Piroddi, L.; Cordone, R.; Fumagalli, I. Selective siphon control for deadlock prevention in Petri nets. IEEE Trans. Syst. Man Cybern. Part A: Syst. Hum. 2008, 38, 1337–1348. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Zhou, M. Behaviorally optimal and structurally simple liveness-enforcing supervisors of flexible manufacturing systems. IEEE Trans. Syst. Man Cybern. Part A Syst. Hum. 2012, 42, 615–629. [Google Scholar] [CrossRef]

| Performance | Ezpeleta et al. [43] | Li and Zhou [44] | Kaid et al. [6] | The Proposed Method |

|---|---|---|---|---|

| M1 utilization (%) | 29.05 | 29.05 | 29.60 | 29.05 |

| M2 utilization (%) | 29.61 | 29.61 | 30.50 | 29.61 |

| R1 utilization (%) | 48.04 | 48.04 | 47.56 | 48.04 |

| Throughput (parts) | 34 | 34 | 34 | 34 |

| Throughput time (min/part) | 14.12 | 14.12 | 14.12 | 14.12 |

| Parameter | Configuration | |||

|---|---|---|---|---|

| An Initial S3PR Net | Removal of an Old Machine | Addition of a New Product | Rework | |

| No. of monitors | 5 | 3 | 5 | 10 |

| No. of arcs | 21 | 12 | 26 | 48 |

| Liveness | Live | Live | Live | Live |

| Boundedness | Bounded | Bounded | Bounded | Bounded |

| Reversibility | Reversible | Reversible | Reversible | Reversible |

| Configuration | i | Siphon | •VSi | VSi• | MRCo (Vsi) |

|---|---|---|---|---|---|

| An initial S3PR net | 1 | S1 | t7,t13 | t1,t9 | 5 |

| 2 | S2 | t4,t5,t13 | t1,t11 | 2 | |

| 3 | S3 | t7,t13 | t1,t9 | 4 | |

| 4 | S4 | t7,t11 | t1,t9 | 3 | |

| 5 | S5 | t4,t13 | t2,t11 | 1 | |

| Removal of an old machine | 1 | S1 | t4,t13 | t1,t9 | 1 |

| 2 | S2 | t7,t11 | t4,t9 | 3 | |

| 3 | S3 | t7,t13 | t1,t9 | 4 | |

| Addition of a new product | 1 | S1 | t11,t17 | t10,t15 | 1 |

| 2 | S2 | t4,t13,t17 | t1,t10,t15 | 2 | |

| 3 | S3 | t4,t13 | t1,t9 | 1 | |

| 4 | S4 | t7,t11,t17 | t4,t9,t15 | 3 | |

| 5 | S5 | t7,t13,t17 | t1,t9,t15 | 4 | |

| Rework | 1 | S1 | t7 | t6,t19 | 1 |

| 2 | S2 | t20 | t6 | 2 | |

| 3 | S3 | t6,t20 | t7 | 1 | |

| 4 | S4 | t7,t11,t17 | t4,t9,t15,t19 | 3 | |

| 5 | S5 | t7,t13,t17 | t1,t9,t15,t19 | 4 | |

| 6 | S6 | t11,t17,t20 | t4,t9,t15 | 4 | |

| 7 | S7 | t13,t17,t20 | t1,t9,t15 | 5 | |

| 8 | S8 | t11,t17 | t8,t15 | 1 | |

| 9 | S9 | t4,t13,t17 | t1,t10,t15 | 2 | |

| 10 | S10 | t4,t13 | t1,t9 | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaid, H.; Al-Ahmari, A.; Li, Z.; Davidrajuh, R. Automatic Supervisory Controller for Deadlock Control in Reconfigurable Manufacturing Systems with Dynamic Changes. Appl. Sci. 2020, 10, 5270. https://doi.org/10.3390/app10155270

Kaid H, Al-Ahmari A, Li Z, Davidrajuh R. Automatic Supervisory Controller for Deadlock Control in Reconfigurable Manufacturing Systems with Dynamic Changes. Applied Sciences. 2020; 10(15):5270. https://doi.org/10.3390/app10155270

Chicago/Turabian StyleKaid, Husam, Abdulrahman Al-Ahmari, Zhiwu Li, and Reggie Davidrajuh. 2020. "Automatic Supervisory Controller for Deadlock Control in Reconfigurable Manufacturing Systems with Dynamic Changes" Applied Sciences 10, no. 15: 5270. https://doi.org/10.3390/app10155270