Evaluation of Shrimp Waste Valorization Combining Computer-Aided Simulation and Numerical Descriptive Inherent Safety Technique (NuDIST)

Abstract

:1. Introduction

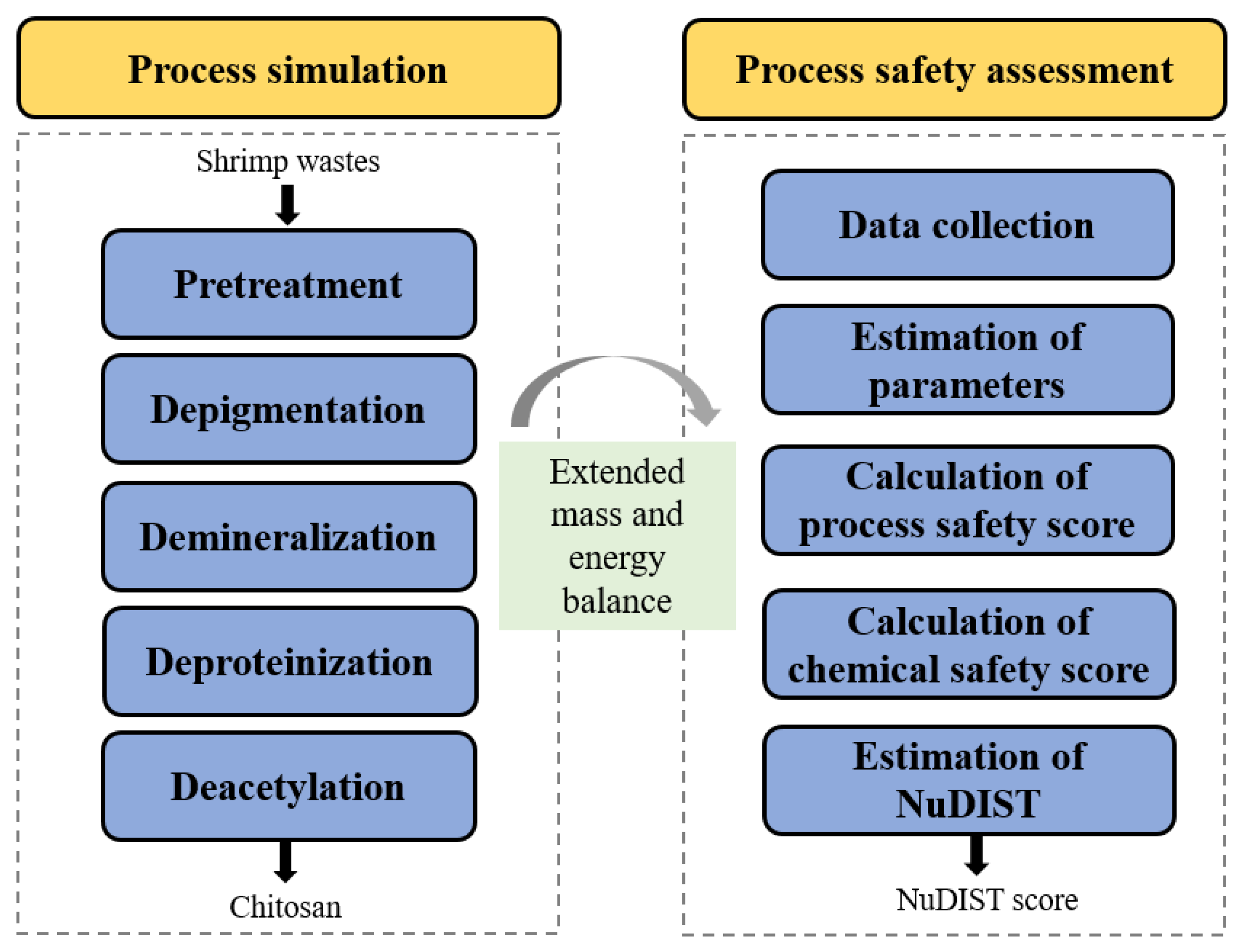

2. Methodology

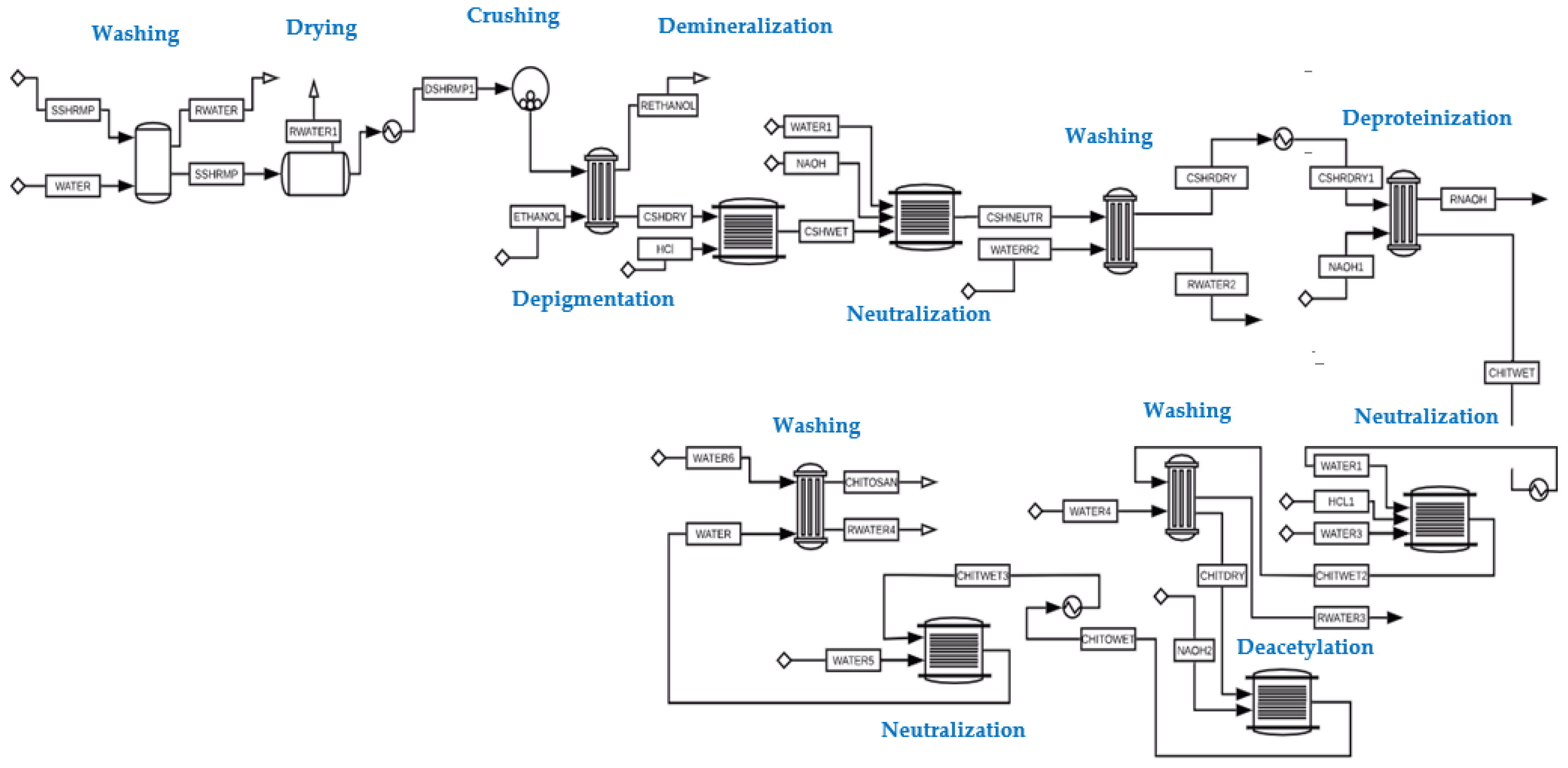

2.1. Process Description

- Pretreatment

- Depigmentation

- Demineralization

- Deproteinization

- Deacetylation

Gathering of Process Data from Computer-Aided Simulation

2.2. Process Safety Assessment

| Temperature (ST) | (5) | |

| (6) | ||

| Pressure (SP) | (7) | |

| Heat of reaction (HR) | (8) | |

| (9) |

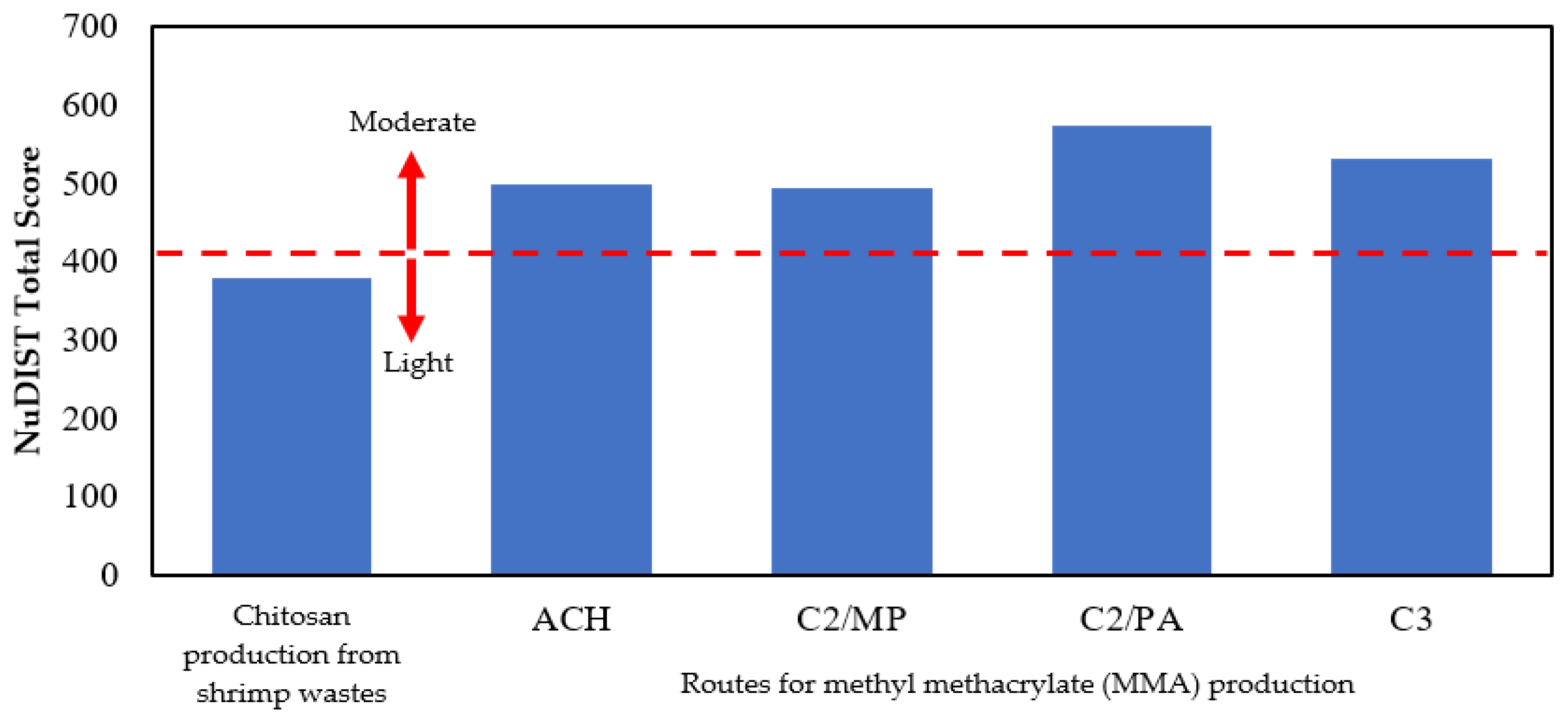

3. Results and Discussion

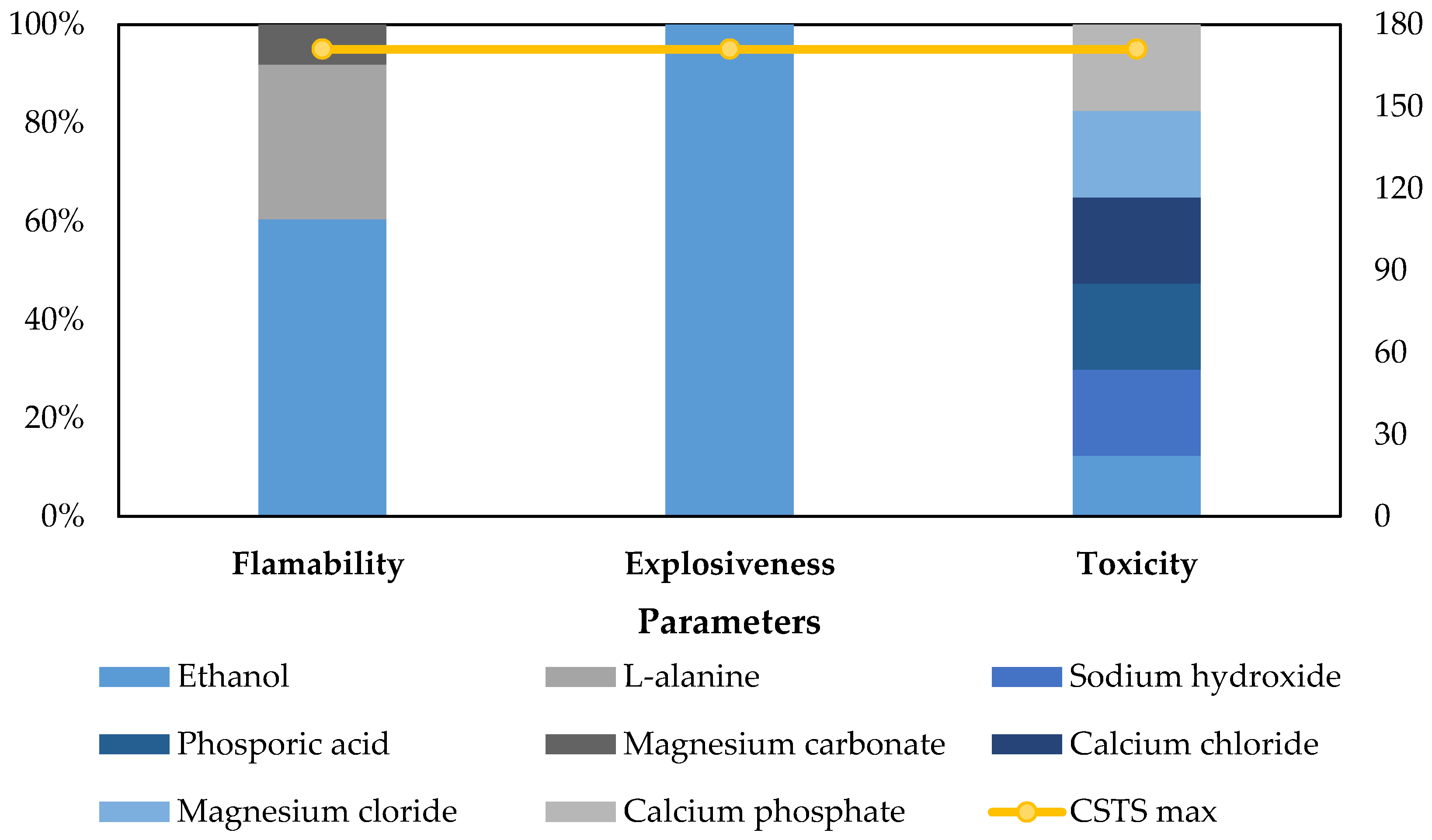

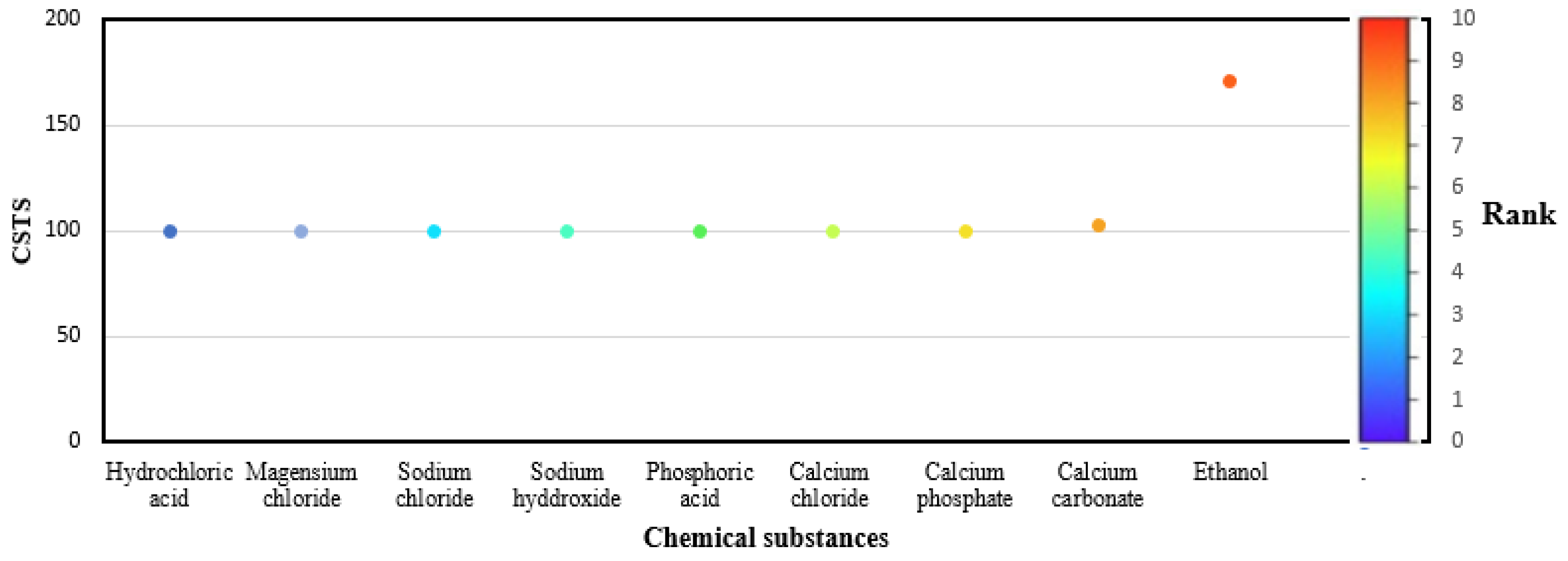

3.1. Chemical Safety Assessment

3.2. Process Safety Assessment

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Chemical Substance | Stage(s) of the Process | SFL | SEXP | STOX |

|---|---|---|---|---|

| Astaxanthin | Pretreatment and depigmentation | 0.037 | - | - |

| Calcium carbonate | Pretreatment and depigmentation | 3.13 | - | 99.74 |

| Calcium chloride | Pretreatment and depigmentation | - | - | 99.75 |

| Magnesium carbonate | Pretreatment and depigmentation | 9.38 | - | - |

| L-alanine | Pretreatment, depigmentation, demineralization, and deproteinization | 36.74 | - | - |

| Magnesium chloride | Demineralization | - | - | 99.75 |

| Calcium phosphate | Demineralization | - | - | 99.75 |

| Hydrochloric acid | Demineralization, neutralization, and deproteinization | - | - | 99.74 |

| Glucosamine | Pretreatment, neutralization, depigmentation, neutralization, demineralization, and deproteinization | 3.20 | - | - |

| Phenylalanine | Pretreatment, depigmentation, demineralization, and deproteinization | 0.66 | - | - |

| Phosphoric acid | Demineralization and neutralization | - | - | 99.75 |

| Lysine | Pretreatment, depigmentation, demineralization, and neutralization | 0.88 | - | - |

| Ethanol | Depigmentation | 70.44 | 0.82 | 99.39 |

| Sodium chloride | Demineralization, deproteinization, and deacetylation | - | - | 99.74 |

| Sodium hydroxide | Neutralization, deproteinization, and deacetylation | - | - | 99.75 |

References

- Cahú, T.B.; Santos, S.D.; Mendes, A.; Córdula, C.R.; Chavante, S.F.; Carvalho, L.B.; Nader, H.B.; Bezerra, R.S. Recovery of protein, chitin, carotenoids and glycosaminoglycans from Pacific white shrimp (Litopenaeus vannamei) processing waste. Process Biochem. 2012, 47, 570–577. [Google Scholar] [CrossRef] [Green Version]

- Hamed, I.; Ozogul, F.; Regenstein, J. Industrial applications of crustacean by-products (chitin, chitosan, and chitooligosaccharides): A review. Trends Food Sci. Technol. 2016, 48, 40–50. [Google Scholar] [CrossRef]

- Cabarcas, M.; Marimon, W.; Miranda, M. Diseño de un proceso económico y competitivo para la extracción de quitina y producción de quitosano a partir de exoesqueletos de camarón. Doctoral Dissertation, Universidad de Cartagena, Cartagena, Colombia, 2011. [Google Scholar]

- Elieh-Ali-Komi, D.; Hamblin, M. Chitin and Chitosan: Production and Application of Versatile Biomedical Nanomaterials. Int. J. Adv. Res. 2016, 4, 411–427. [Google Scholar]

- Srinivasan, H.; Velayutham, K.; Ravichandran, R. Chitin and chitosan preparation from shrimp shells Penaeus monodon and its human ovarian cancer cell line, PA-1. Int. J. Biol. Macromol. 2018, 107, 662–667. [Google Scholar] [CrossRef]

- Cogollo-Herrera, K.; Bonfante-Álvarez, H.; de Ávila-Montiel, G.; Herrera Barros, A.; González-Delgado, Á.D. Techno-economic Sensitivity Analysis of Large Scale Chitosan Production Process from Shrimp Shell Wastes. Chem. Eng. Trans. 2018, 70, 2179–2184. [Google Scholar]

- Islam, S. Production of chitin and chitosan from shrimp shell wastes. J. Bangladesh Agric. Univ. 2016, 14, 253–259. [Google Scholar] [CrossRef] [Green Version]

- Nouri, M.; Khodaivan, F.; Razavi, S.; Mousav, M. Improvement of chitosan production from Persian Gulf shrimp waste by response surface methodology. Food Hydrocoll. 2016, 59, 50–58. [Google Scholar] [CrossRef]

- Kishimoto, Y.; Yoshida, H.; Kondo, K. Potential Anti-Atherosclerotic Properties of Astaxanthin. Mar. Drugs 2016, 14, 35. [Google Scholar] [CrossRef] [PubMed]

- Torres-carvajal, L.K.; González, Á.D.; Francisco, U.; Santander, D.P. Astaxanthin Production from Haematococcus pluvialis: Effects of Light Wavelength and Salinity. Contemp. Eng. Sci. 2017, 10, 1739–1746. [Google Scholar] [CrossRef]

- Kockmann, N.; Thenée, P.; Fleischer-Trebes, C.; Laudadio, G.; Noel, T. Safety assessment in development and operation of modular continuous-flow processes. React. Chem. Eng. 2017, 2, 258–280. [Google Scholar] [CrossRef]

- Javad, M.; Mohammadi, H.; Reniers, G.; Pouyakian, M. Exploring inherent process safety indicators and approaches for their estimation: A systematic review. J. Loss Prev. Process Ind. 2018, 52, 66–80. [Google Scholar]

- Gerbec, M. Supporting organizational learning by comparing activities and outcomes of the safety-management system. J. Loss Prev. Process Ind. 2013, 26, 1113–1127. [Google Scholar] [CrossRef]

- Ahmad, S.I.; Hashim, H.; Hassim, M.H. Numerical Descriptive Inherent Safety Technique (NuDIST) for inherent safety assessment in petrochemical industry. Process Saf. Environ. Prot. 2014, 92, 379–389. [Google Scholar] [CrossRef]

- Ahmad, S.I.; Hashim, H.; Hassim, M.H.; Abdul, Z. Inherent Safety Assessment of Biodiesel Production: Flammability Parameter. Proced. Eng. 2016, 148, 1177–1183. [Google Scholar] [CrossRef] [Green Version]

- Mabrouk, A.; Erdocia, X.; Alriols, M.G.; Labidi, J. Economic analysis of a biorefinery process for catechol production from lignin. J. Clean. Prod. 2018, 198, 133–142. [Google Scholar] [CrossRef]

- Han, W.; Fang, J.; Liu, Z.; Tang, J. Techno-economic evaluation of a combined bioprocess for fermentative hydrogen production from food waste. Bioresour. Technol. 2016, 202, 107–112. [Google Scholar] [CrossRef]

- Ahmad, S.I.; Yunus, N.A.; Hashim, H.; Rashid, R. Inherent safety assessment of solvent alternatives for palm oil recovery. Chem. Eng. Trans. 2019, 72, 49–54. [Google Scholar]

- Ahmad, S.I.; Hashim, H.; Hassim, M. Inherent Safety Assessment Technique for Preliminary Design Stage. Chem. Eng. Trans. 2017, 56, 1345–1350. [Google Scholar] [CrossRef]

- Aristizábal-Marulanda, V.; Poveda-Giraldo, J.A.; Cardona Alzate, C.A. Comparison of furfural and biogas production using pentoses as platform. Sci. Total Environ. 2020, 728, 138841. [Google Scholar] [CrossRef]

- Meramo-Hurtado, S.; Alarcón-Suesca, C.; González-Delgado, Á.D. Exergetic sensibility analysis and environmental evaluation of chitosan production from shrimp exoskeleton in Colombia. J. Clean. Prod. 2020, 248. [Google Scholar] [CrossRef]

- Trung, T.S.; Phuong, P.T.D. Bioactive compounds from by-products of shrimp processing industry in Vietnam. J. Food Drug Anal. 2012, 20, 194–197. [Google Scholar]

- Gómez-Ríos, D.; Barrera-Zapata, R.; Ríos-Estepa, R. Comparison of process technologies for chitosan production from shrimp shell waste: A techno-economic approach using Aspen Plus®. Food Bioprod. Process. 2017, 103, 49–57. [Google Scholar] [CrossRef]

- Razi Parjikolaei, B.; Errico, M.; Bahij El-Houri, R.; Mantell, C.; Fretté, X.C.; Christensen, K.V. Process design and economic evaluation of green extraction methods for recovery of astaxanthin from shrimp waste. Chem. Eng. Res. Des. 2017, 117, 73–82. [Google Scholar] [CrossRef]

- Luzi, F.; Puglia, D.; Sarasini, F.; Tirillò, J.; Maffei, G.; Zuorro, A.; Torre, L. Valorization and extraction of cellulose nanocrystals from north african grass: Ampelodesmos mauritanicus (diss). Carbohydr. Polym. 2019, 209, 328–337. [Google Scholar] [CrossRef] [PubMed]

- Maffei, G.; Bracciale, M.P.; Broggi, A.; Zuorro, A.; Santarelli, M.L.; Lavecchia, R. Effect of an enzymatic treatment with cellulase and mannanase on the structural properties of nannochloropsis microalgae. Bioresour. Technol. 2018, 249, 592–598. [Google Scholar] [CrossRef]

- Sudarni, D.H.A.; Handogo, R. Process Safety Index in Chemical Process. Int. Semin. Sci. Technol. 2016, 10–13. [Google Scholar] [CrossRef] [Green Version]

| Chemical Processes | Process Simulation | NuDIST Technique | Reference |

|---|---|---|---|

| Methyl methacrylate manufacturing | + | [14] | |

| Biodiesel production | + | [15] | |

| Catechol production from lignin | + | [16] | |

| Fermentative hydrogen production from food waste | + | [17] | |

| Palm oil recovery | + | [18] | |

| Hydrodealkylation process | + | [19] | |

| Furfural and biogas production using pentoses | + | [20] | |

| Production of chitosan from shrimp wastes | + | + | This work |

| Stage | Reactions | Source |

|---|---|---|

| Deacetylation | [23] | |

| Demineralization | [21,23] | |

| Deproteinization | [23] |

| Stream Name | SSHRIMP | RWATER1 | ETHANOL | RETHANOL | CSHDRY |

| Mass Flow Rate (kg/h) | 6602.0 | 6502.4 | 27,714.0 | 27,850.8 | 6365.3 |

| Mass composition (wt.) | |||||

| METHY-01 | 0.0640 | 0.0009 | 0.0000 | 0.0000 | 0.0000 |

| ASTAX-01 | 0.0041 | 0.0000 | 0.0000 | 0.0011 | 0.0000 |

| CALCI-01 | 0.0513 | 0.0000 | 0.0000 | 0.0000 | 0.0588 |

| CALCI-02 | 0.1290 | 0.0000 | 0.0000 | 0.0000 | 0.1478 |

| SODIU-01 | 0.0262 | 0.0000 | 0.0000 | 0.0000 | 0.0300 |

| MAGNE-01 | 0.0152 | 0.0000 | 0.0000 | 0.0000 | 0.0174 |

| L-ALA-01 | 0.0645 | 0.0000 | 0.0000 | 0.0000 | 0.0739 |

| CARBO-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| MAGNE-02 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| CALCI-03 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| HYDRO-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| D-N-A-01 | 0.3000 | 0.0000 | 0.0000 | 0.0038 | 0.3269 |

| L-GLU-01 | 0.1113 | 0.0000 | 0.0000 | 0.0000 | 0.1275 |

| L-PHE-01 | 0.0420 | 0.0000 | 0.0000 | 0.0000 | 0.0481 |

| ORTHO-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| METHI-01 | 0.0377 | 0.0000 | 0.0000 | 0.0000 | 0.0432 |

| LYSIN-01 | 0.1103 | 0.0000 | 0.0000 | 0.0000 | 0.1264 |

| WATER | 0.0446 | 0.9990 | 0.1500 | 0.1493 | 0.0000 |

| ETHAN-01 | 0.0000 | 0.0000 | 0.8500 | 0.8458 | 0.0000 |

| SODIU-02 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| SODIU-03 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| CHITOSAN | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| SODIU-04 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| Stream Name | CHITIWET2 | RWATER3 | CHITOWET | CHITWET4 | RWATER4 |

| Mass Flow Rate (kg/h) | 141,921.3 | 197,886.0 | 100,789.0 | 401,939.0 | 489,905.4 |

| Mass composition (wt.) | |||||

| METHY-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| ASTAX-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| CALCI-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| CALCI-02 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| SODIU-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| MAGNE-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| L-ALA-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| CARBO-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| MAGNE-02 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| CALCI-03 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| HYDRO-01 | 0.0066 | 0.0047 | 0.0000 | 0.0039 | 0.0033 |

| D-N-A-01 | 0.0145 | 0.0018 | 0.0000 | 0.0000 | 0.0000 |

| L-GLU-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| L-PHE-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| ORTHO-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| METHI-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| LYSIN-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| WATER | 0.9743 | 0.9902 | 0.9643 | 0.9852 | 0.9908 |

| ETHAN-01 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 |

| SODIU-02 | 0.0000 | 0.0000 | 0.0156 | 0.0000 | 0.0000 |

| SODIU-03 | 0.0046 | 0.0033 | 0.0000 | 0.0057 | 0.0050 |

| CHITOSAN | 0.0000 | 0.0000 | 0.0138 | 0.0035 | 3.0E-06 |

| SODIU-04 | 0.0000 | 0.0000 | 0.0063 | 0.0016 | 0.0013 |

| Safety Parameters Per Stage | HR Score | Temperature Score | Pressure Score |

|---|---|---|---|

| Deacetylation | 99.90 | 0.3826 | 0.8163 |

| Demineralization | 100.00 | ||

| Deproteinization | 8.10 | ||

| Total | 208.00 | 0.3826 | 0.8163 |

| Total safety score of the process (PSTS)max | 209.20 | ||

| NuDIST Score | 380.20 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuorro, A.; Cassiani-Cassiani, D.; Meza-González, D.A.; Moreno-Sader, K.A.; González-Delgado, Á.D. Evaluation of Shrimp Waste Valorization Combining Computer-Aided Simulation and Numerical Descriptive Inherent Safety Technique (NuDIST). Appl. Sci. 2020, 10, 5339. https://doi.org/10.3390/app10155339

Zuorro A, Cassiani-Cassiani D, Meza-González DA, Moreno-Sader KA, González-Delgado ÁD. Evaluation of Shrimp Waste Valorization Combining Computer-Aided Simulation and Numerical Descriptive Inherent Safety Technique (NuDIST). Applied Sciences. 2020; 10(15):5339. https://doi.org/10.3390/app10155339

Chicago/Turabian StyleZuorro, Antonio, Daylisney Cassiani-Cassiani, Demmy A. Meza-González, Kariana Andrea Moreno-Sader, and Ángel Darío González-Delgado. 2020. "Evaluation of Shrimp Waste Valorization Combining Computer-Aided Simulation and Numerical Descriptive Inherent Safety Technique (NuDIST)" Applied Sciences 10, no. 15: 5339. https://doi.org/10.3390/app10155339

APA StyleZuorro, A., Cassiani-Cassiani, D., Meza-González, D. A., Moreno-Sader, K. A., & González-Delgado, Á. D. (2020). Evaluation of Shrimp Waste Valorization Combining Computer-Aided Simulation and Numerical Descriptive Inherent Safety Technique (NuDIST). Applied Sciences, 10(15), 5339. https://doi.org/10.3390/app10155339