Investigating Vibration Acceleration of a Segmented Piezoelectric Ciliary-Like Body Beam for a Tactile Feedback Device

Abstract

1. Introduction

2. Principle

3. Analysis for Forced Vibration Excited by Piezoelectric Sheets

Forced Vibration Analysis of a Touch Beam

4. Results Analysis for the Dynamic Characteristic

4.1. Analysis for the Forced Response

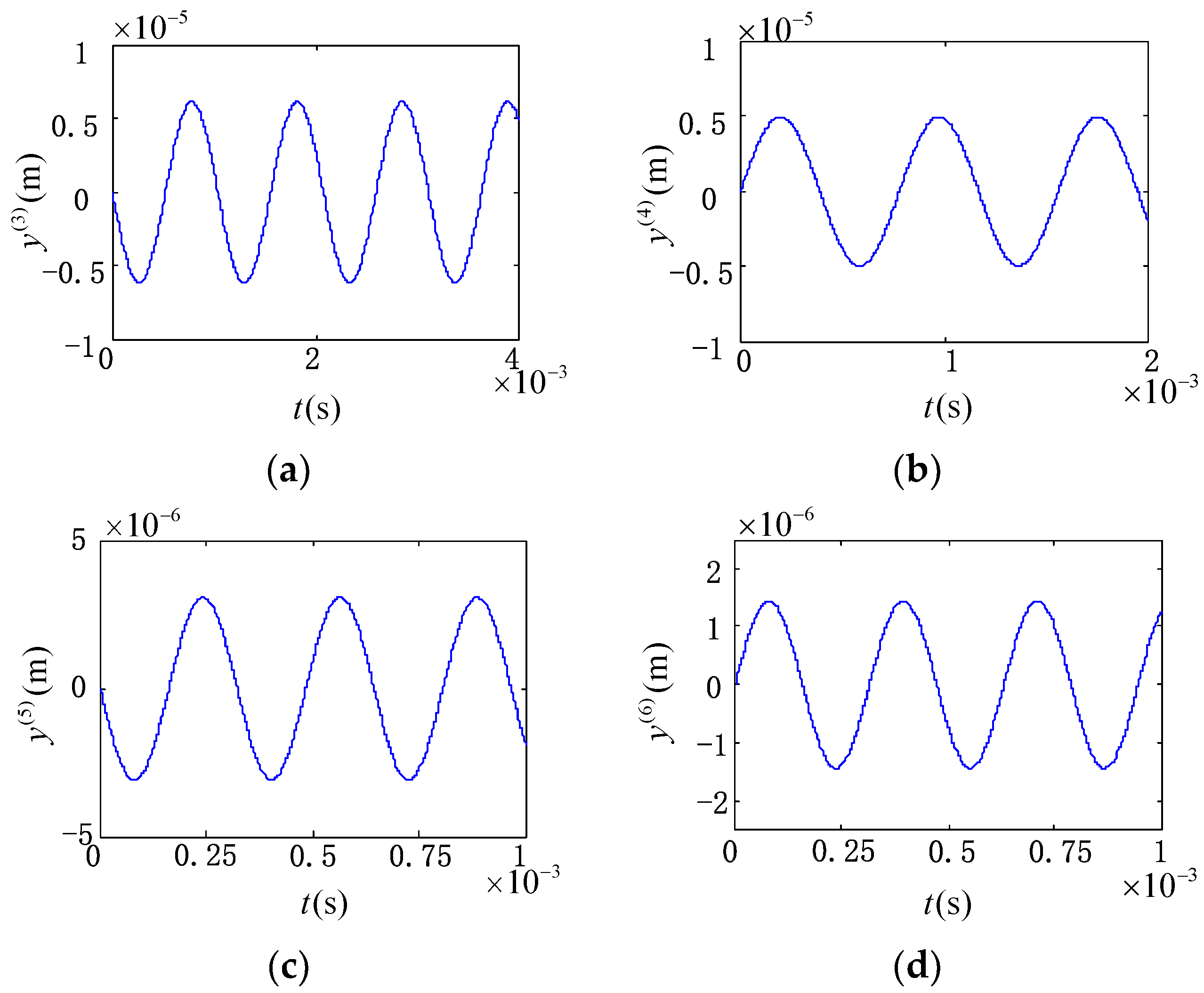

- As the order of vibration increases, the resonant frequency increases and the total amplitude decreases. The 6th order amplitude of the cantilever touch beam is 1.44 × 10−6 m. The peak number of the vibration touch beam increases with increasing excitation frequency. The wavelength of one cycle is shortened, so the vibration number of the ciliary-like body keeping the same direction in one cycle is changing less. The subject will feel the touch beam friction change is more when the finger touches and moves along the beam in one direction.

- The amplitude of the vibration of the ciliary-like body touch beam at different positions during vibration is also different, and it is distributed in a sinusoidal manner. The feeling of the changing friction of the touch beam is more obvious when the vibration amplitude is larger, and the friction changes of the touch beam are weaker in the place where the vibration amplitude is smaller.

- We took the peak values of excitation voltage of 100 V, 150 V, and 200 V as calculation examples. As the value of the excitation voltage increases, the amplitude of the forced response gradually increases, and the larger the excitation frequency, the smaller the amplitude increase. It can be seen from the curves that when the excitation frequency is at the sixth-order natural frequency, the excitation voltage is increased from 100 V to 200 V, and the vibration amplitude is changed from 1.44 × 10−6 m to 2.62 × 10−6 m. More importantly, it can be speculated that increasing the excitation voltage can make the tactile change of the cantilever touch beam easier to perceive.

- The effect of choosing piezoelectric sheets of different thicknesses on the forced response is verified by bringing in piezoelectric sheets with thicknesses of 0.3 mm, 0.4 mm, and 0.5 mm. As the thickness hp decreases, the vibration amplitude of the cantilever touch beam gradually increases. The larger the excitation frequency, the smaller the amplitude increases. For increasing the displacement of forced vibration to improve the sensitivity of touch sensation, we can use the thinner piezoelectric sheets as an excitation element.

- Investigating the influence of the material properties of the touch beam substrate on the vibration amplitude of the forced response, especially the elastic modulus E, can provide a basis for selecting materials during design. We chose the elastic modulus of the touch beam as a research subject and analyze the effect of the three materials of brass, phosphor bronze, and spring steel, respectively, on the forced response. As the elastic modulus increases, the forced response of the cantilever touch beam gradually decreases. Therefore, the material of the touch beam substrate with the higher elastic modulus would reduce the forced response displacement to a greater extent.

- In addition, the piezoelectric constant that measures the quality of the piezoelectric material is also an index that affects the forced response performance. The piezoelectric constant e31 was changed so that e31 takes values of 2.0 c/m2, 2.5 c/m2, and 3.0 c/m2, respectively. As the piezoelectric constant of the piezoelectric element increases, the response amplitude of the cantilever touch beam gradually increases. It can be seen from the image that when the excitation frequency is at the sixth-order natural frequency, the piezoelectric constant is increased from 2.0 to 3.0, and the vibration amplitude increases from 1.44 × 10−6 m to 2.37 × 10−6 m, and the variation is also obvious. We recommend using a high-quality piezoelectric material with a large piezoelectric constant to enhance the perceptibility of the touch beam.

4.2. Analysis for Frequency Domain Response of Touch Beams

- The touch beam has a significantly increased amplitude of the forced response when the excitation frequency is close to its natural frequencies, and the magnitude of the forced response of the touch beam becomes small when it is far from the natural frequency of the touch beam itself. Therefore, the touch beam needs to operate at its resonance frequency to be effective. As the order of the natural frequency increases, the displacement response of forced vibration will gradually decrease, and the displacement response of the sixth order decreases to about one-sixth of that of the third order. However, the frequency of the sixth order is 24,221 Hz, which is beyond the sound range that humans can recognize and so will not make the subject uncomfortable due to noise, showing that this excitation frequency is more suitable as a working frequency.

- With the increase of excitation voltage and piezoelectric constant, the displacement of the forced response of the touch beam gradually increases. Within the interval of resonance, especially, the increase values of the forced response are more significant. However, with the increase of the elasticity modulus, the modal stiffness increases, and therefore the displacement of forced response gradually decreases. Within the intervals of resonance, the decrease values of the forced response caused by the elasticity modulus are more significant. In addition, increasing the modal damping ratio can reduce the displacement of forced response in the resonance intervals significantly. However, out of the resonance intervals, this kind of influence on forced response is not obvious.

4.3. The Active Average Acceleration of the Ciliary-Like Body Structure

- As the excitation frequency increases, the vibration acceleration of the cantilever touch beam ciliary-like body gradually increases, and the slope of the curve gradually increases. When the excitation frequency is increased from 10,000 Hz to 20,000 Hz, the vibration acceleration of the ciliary-like body is increased by about 45,000 m/s2, and the excitation frequency is the 6-order natural frequency of 24,221 Hz. The maximum vibration acceleration of the ciliary-like body is 69,324 m/s2.

- The vibration acceleration of the ciliary-like body is linearly positively correlated with the amplitude of the excitation voltage. When the excitation voltage is 100 V, the vibration acceleration of the ciliary-like body is 69,324 m/s2. When the excitation voltage is 200 V, the vibration acceleration doubles to 13,8648 m/s2.

- The vibration acceleration of the ciliary-like body is linearly positively correlated with the piezoelectric constant of the piezoelectric piece. When the piezoelectric constant is 3.0 c/m2, the vibration acceleration is 10,864 m/s2.

- The vibration acceleration of the ciliary-like body changes in different positions of the touch beam. As the position coordinates increase, the vibration acceleration exhibits a pulsating cycle change. The second peak at the left is 69,324 m/s2, and the acceleration at some points is zero.

5. Experimental Analysis

- Fix the ciliary-like body touch beam to the bracket by the cantilever beam and tighten the screws on one side, so the other side is free.

- The driving signal was supplied by an arbitrary signal generator. We then used the driving signal, which was modulated by the HFVA-42 power amplifier, to drive the touch beam. The voltage was adjusted to ~100 V and the signal frequency adjusted to the sixth-order natural frequency which was ~24,000 Hz.

- There existed some error between the theoretical calculation and the experiment, so the frequency was fine-tuned between 20,000 Hz and 24,000 Hz, while continuously touching and feeling the changing state of the surface of the touch beam until it could be clearly felt that the touch beam became smooth. After debugging, the touch beam was obviously smooth when the experimental prototype was excited at the frequency of ~23,200 Hz.

- The laser vibrometer was mounted vertically to measure the cantilever touch beam from directly above, and the measurement data was transmitted through the acquisition card to the supporting software of the computer. On the left and right touch beam segments of the piezoelectric sheets, point-by-point measurement was performed from left to right. The waveform data displayed by the computer’s companion software eZ-Analyst was continuously observed. The average amplitude of the real-time waveform of the measurement points was recorded.

- The amplitude is larger when the excitation voltage is 200 V, but the positions of the five larger vibration amplitude points under the two voltage excitations are basically the same, so increasing the excitation voltage will not change the position of the touch beam peak and valley.

- Overall, the amplitude of vibration shapes from the experiment is slightly larger than the theoretical calculation, and meanwhile the measured position of each peak and trough has a certain deviation from their theoretical values. However, the deviation is relatively small and completely acceptable, in addition the trend of consistency does not change under the two voltages.

- The maximum deviation of the 200 V excitation voltage is 9 mm, which is slightly larger than that of the 100 V excitation voltage of 8 mm. The two experimental curves are basically in accordance with the theoretical calculation. The experimental deviation value increases slightly with the increase of the excitation voltage.

6. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhao, L.; Liu, Y.; Ma, Z. Research progress of tactile reproduction technology. J. Comput. 2018, 30, 4–25. [Google Scholar]

- Dahiya, R.S.; Metta, G.; Valle, M.; Sandini, G. Tactile sensing—From humans to humanoids. IEEE Trans. Robot. 2009, 26, 1–10. [Google Scholar] [CrossRef]

- Cai, G.; Wang, J.; Qian, K.; Chen, J.; Li, S.; Lee, P.S. Extremely stretchable strain sensors based on conductive self-healing dynamic cross-links hydrogels for human-motion detection. Adv. Sci. 2016, 4, 1600190. [Google Scholar] [CrossRef] [PubMed]

- Toshio, W.; Shigehisa, F. A method for controlling tactile sensation of surface roughness using ultrasonic vibration. IEEE Int. Conf. Robot. Autornation 1995, 1, 1134–1139. [Google Scholar]

- M’Boungui, G.; Lemaire-Semail, B.; Frédéric, G. Piezoelectric actuator for a force-feedback application: Preliminary evaluation. In Proceedings of the 3rd Joint EuroHaptics Conference Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems, Salt Lake City, UT, USA, 18–20 March 2009; p. 85. [Google Scholar]

- Casset, F.; Danel, J.S.; Chappaz, C.; Yoan, C. Low voltage actuated plate for haptic applications with PZT thin-film. In Proceedings of the Transducers & Eurosensors Xxvii: The International Conference on Solid-state Sensors IEEE, Barcelona, Spain, 16–20 June 2013. [Google Scholar]

- Sari, G.; Akgul, M.B.; Kirisken, B.; Ak, A.F.; Akis, A.A. An experimental study of a piezoelectrically actuated touch screen. In Proceedings of the International Conference on Mechanical & Aerospace Engineering IEEE, Prague, Czech Republic, 5 May 2017; pp. 753–758. [Google Scholar]

- Takasaki, M.; Fujii, Y.; Kotani, H.; Mizuno, T.; Nara, T. Proposal of tele-touch using active type SAW tactile display. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots & Systems, Daejeon, Korea, 9–14 October 2016; pp. 1032–1037. [Google Scholar]

- Giraud, F.; Amberg, M.; Lemaire-Semail, B.; Casiez, G. Design of a transparent tactile stimulator. In Proceedings of the 2012 IEEE Haptics Symposium, Vancouver, BC, Canada, 4–7 March 2012; pp. 485–489. [Google Scholar]

- Giraud, F.; Amberg, M.; Lemaire-Semail, B. Design and control of a haptic knob. Sens. Actuators A 2013, 196, 78–85. [Google Scholar] [CrossRef]

- Chen, Y.M.; Tsai, M.C.; Wang, S.H. Sliding position detection of touchscreen with piezoelectric cantilever. In Proceedings of the IEEE International Conference on Networking Sensing and Control, Taipei, Taiwan, 9–11 April 2015; pp. 236–240. [Google Scholar]

- Saleem, M.K.; Yilmaz, C.; Basdogan, C. Psychophysical evaluation of change in friction on an ultrasonically-actuated touchscreen. IEEE Trans. Haptics 2018, 11, 599–610. [Google Scholar] [CrossRef] [PubMed]

- Hayward, V.; Cruz-hern, J.M. Tactile display device using distributed lateral skin stretch. In Proceedings of the ASME International Mechanical Engineering Congress & Exposition, Portland, OR, USA, 15–19 November 2020; pp. 1309–1314. [Google Scholar]

- Ikei, Y.; Shiratori, M. Texture explorer: A tactile and force display for virtual textures. In Proceedings of the Symposium on Haptic Interfaces for Virtual Environment & Teleoperator Systems IEEE, Orlando, FL, USA, 24–25 March 2002; pp. 327–334. [Google Scholar]

- Ino, S.; Homma, T.; Izumi, T. Psychophysical measurement of multiple tactile sensations using a broadband vibrotactile display. In Proceedings of the International Symposium on Universal Communication, Osaka, Japan, 15–16 December 2008; pp. 274–280. [Google Scholar]

- Gi-Hun, Y.; Woosub, L.; Sungchul, K. Development of vibrotactile pedestal with multiple actuators and application of haptic illusions for information delivery. IEEE Trans. Ind. Inform. 2019, 15, 591–598. [Google Scholar]

- Hoshi, T. 2A2-B04 visualization of pressure distribution on airborne ultrasonic tactile display using viscous fluid (tactile and force sensation (2)). Robot. Mechatron. Lect. Lect. Summ. 2015, 1–3. [Google Scholar]

- Xing, J.; Li, H.; Liu, D. Anisotropic vibration tactile model and human factor analysis for a piezoelectric tactile feedback device. Micromachines 2019, 10, 448. [Google Scholar] [CrossRef] [PubMed]

- Xing, J.; Liu, D. Free vibration analysis for a tactile feedback device of a piezoelectric ciliary body beam. In Iranian Journal of Science & Technology Transactions of Mechanical Engineering; Springer: Berlin, Germany, 2019. [Google Scholar]

- Liu, D. Structural Design and Dynamic Analysis of Piezoelectric Haptic Feedback Actuator. Ph.D. Thesis, Yanshan University, Qinhuangdao, China, 2018. [Google Scholar]

| Length L | Thickness H | Width W | Elastic Modulus E | Density |

|---|---|---|---|---|

| 0.1 m | 5 mm | 5 mm | 105 GPa | 8500 kg/m3 |

| Length lp | Thickness Hp | Width Wp | Elastic Modulus Ep | Density ρp | Piezoelectric Constant e31 |

|---|---|---|---|---|---|

| 10 mm | 0.3 mm | 5 mm | 76.5 GPa | 7500 kg/m3 | 2.0 c/m2 |

| Test Point | ① | ② | ③ | ④ | ⑤ |

|---|---|---|---|---|---|

| Position coordinates (mm) | 13.25 | 29.25 | 47.25 | 74.70 | 90.75 |

| Average amplitude (m) | 1.24 × 10−6 | 1.24 × 10−6 | 1.24 × 10−6 | 1.23 × 10−6 | 1.25 × 10−6 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xing, J.; Li, H.; Howard, I. Investigating Vibration Acceleration of a Segmented Piezoelectric Ciliary-Like Body Beam for a Tactile Feedback Device. Appl. Sci. 2020, 10, 5362. https://doi.org/10.3390/app10155362

Xing J, Li H, Howard I. Investigating Vibration Acceleration of a Segmented Piezoelectric Ciliary-Like Body Beam for a Tactile Feedback Device. Applied Sciences. 2020; 10(15):5362. https://doi.org/10.3390/app10155362

Chicago/Turabian StyleXing, Jichun, Huajun Li, and Ian Howard. 2020. "Investigating Vibration Acceleration of a Segmented Piezoelectric Ciliary-Like Body Beam for a Tactile Feedback Device" Applied Sciences 10, no. 15: 5362. https://doi.org/10.3390/app10155362

APA StyleXing, J., Li, H., & Howard, I. (2020). Investigating Vibration Acceleration of a Segmented Piezoelectric Ciliary-Like Body Beam for a Tactile Feedback Device. Applied Sciences, 10(15), 5362. https://doi.org/10.3390/app10155362