Abstract

Roof sliding and instability along the coal wall usually occur in the working face at large mining heights during the process of the first weighting, which causes roof cutting and support crushing. A mechanical model consists of the main roof, immediate roof, and support based on the nonlinear characteristics of the failure and instability of the immediate roof under the abutment pressure, which we constructed to study the step sinking of the main roof, as well as to assign the reasonable value of the support resistance during the first weighting. The instability mechanism of the system was studied by the catastrophe theory and the principle of energy conservation. A conclusion was drawn that the combined cantilever beam structure for the immediate roof will form with the increase of the mining height, and the instability of the immediate roof causes the catastrophic instability of the system. The system instability was found to be related to the stiffness ratio K, material parameters, the load Q, and the first weighting interval of the main roof by analyzing the necessary and sufficient conditions for system instability. The influence degree of each parameter on the stiffness ratio K was as follows: elastic modulus E > support stiffness k1 > cross-section area a > immediate roof thickness H. The calculation equations of support resistance and subsidence of roof step were obtained. The method of judging the roof instability using catastrophe theory was proved as reasonable on the basis of the monitoring example of no. 12401 working face in Shendong mining area, China. On this basis, a reasonable value of support resistance was further calculated, and the working face was maintained safely when the support resistance exceeded 19,232 kN.

1. Introduction

Shallow coal seams are widely distributed in the northwestern territory of China, which is characterized by shallow burial depth, thin bedrock, and an overlying thick and loose sand layer [1]. The mining height of coal seam is increasing, reaching a maximum of 8.8m at present with the continuous improvement of fully mechanized mining degrees, which makes the goaf space formed by coal seam mining increase constantly. The original main roof is broken into a cantilever beam structure with the increasing of goaf space, which forms a new immediate roof, and increases the thickness of the immediate roof. As a result, a new main roof is formed in the upper rock stratum and a cantilever beam–masonry beam structure is formed, which makes the strata behavior violent and the dynamic load phenomenon obvious [2,3]. The strata behavior is the most violent and difficult to control during the first weighting. Roof sliding and instability along the coal wall usually occurs, resulting in support crushing or water/sand burst, which brings many security risks to coal mining. Therefore, it is of great significance to study the relationship between the support and the surrounding rock during the first weighting of working face, as well as to analyze the mechanical mechanism and key disaster-causing factors of the main roof step sinking along the coal wall then to provide the determination method of the support resistance, which has an important role in ensuring the safety of the working face.

Many scholars have already done much work on the characteristics of mine pressure and the relationship between support and surrounding rock in working face with large mining height by various methods. Ju et al. [4,5,6] found that the breaking of the upper sub-key strata of the working face will cause the break of the lower sub-key strata, with the interval of step and the intensity of weighting in working face being changed alternately. Zhao et al. [7] found that the structure instability of the cracked roof rock beam depends on the interaction between the vertical load and the horizontal thrust. Wang et al. [8] established three kinds of mechanical models in the mining field—these being symmetrical pressure-arch, stepped pressure-arch, and rotating-squeezed pressure-arch—and derived the instability criterion of each pressure-arch structure. Szurgacz and Brodny [9,10] developed an effective method for determining the position (geometry) of the support section during the operation process and analyzed the influence of dynamic load on the work parameters of a powered roof support’s hydraulic leg via tests. The research results were conducive to the safe and efficient mining of coal. Yang and Liu [11] pointed out that mining intensity, single roof structure, easy sliding, and instability were the main reasons for the violent appearance of strata behavior. Huang and Zhou [12,13] proposed the definition of the equivalent immediate roof of large mining height and analyzed the pressure characteristics of the oblique step voussior beam structure of the working face, giving the support resistance of the working face without slipping and instability. Pang et al. [14] proposed the cantilever beam + masonry beam structure and stability control technology for ultra-height mining height working face on the basis of 8.0m ultra-height mining height mining practice. Xing et al. [15] established a fracture mechanical model of key roof and derived the theoretical calculation formula for the fracture step of key roof and support resistance. Sun et al. [16] proposed a new model to describe the movement and subsidence of the inner burden during shallow coal seam mining. Feng et al. [17] found that the mining height had an exponential function relationship with the average first weighting interval and had a binomial functional relationship with average periodic weighting interval. Chinese scholars focused on the characteristics of roof breaking, pressure mechanism, and the adaptability of the support during the first weighting. Huang et al. [18] analyzed the roof control effect and working resistance overrun percentage and put forward an inversion method for working resistance optimization. Zhao et al. [19] established the calculation method for determining the dynamic load factor when the slipping instability of main roof structure occurs. Wang and Wang [20] pointed out that the increase of height to length ratio of key block causes the increase of the rotation angle required for the hinged structure to reach equilibrium. This usually results in sliding and instability of the main roof. The cut down of the entire thickness of the overlying strata along the working face is a dynamic evolutionary process during the first weighting of main roof [21]. Yang [22] derived the formulae for breaking convergence of the main roof and built the criterion of step convergence after the main roof breaking during the first weighting by initial post-buckling theory and the cusp catastrophic model. Zuo et al. [23] analyzed the blasting mechanism of shallow depth mining face with a large cutting height by fracture mechanics and calculated the initial fracturing distance of main roof after blasting.

The research on the immediate roof started earlier. Scholars mainly studied the bearing, deformation, and failure characteristics during the weighting process of the immediate roof. Qian et al. [24,25,26] pointed out that the relationship between the support resistance and the amount of roof subsidence was caused by the action of the support and the immediate roof under a given deformation of the main roof. Gong and Jin [27] carried out the in situ measurement and the simulation experiment on the structural characteristics of roofs with large mining height, dividing the immediate roof into three types and finding that the stability control of the type III immediate roof mainly considers the thickness, location, and engineering mechanical characteristics of the key layer of the immediate roof. Du and Bai [28] divided the immediate roof into two types and found that the instability of the type II immediate roof usually causes periodic weighting on the working face. Yuan et al. [29] found that the key strata in immediate roof (KSIF) controls the caving of its upper immediate roof strata and has a direct dynamic impact on its lower strata when the KSIF breaks. Yang et al. [30,31,32] gave a method to determine the range of the immediate roof and deduced the calculation equation of roof pressure on the basis of the principle of conservation of energy. Liu et al. [33] found that a relative thick immediate roof tends to form a stable voussoir beam, while a relative thin immediate roof tends to form a cantilever beam. Their research mainly focused on the failure characteristics of the immediate roof and the determination of the support resistance, which is less involved in the role of the immediate roof in the relationship between the support and surrounding rocks and the fracture and instability mechanism of the immediate roof.

At present, the main research methods of roof instability include numerical simulation, elastic plastic theory, elastic damage theory, and catastrophe theory. As a new subject, the theory of catastrophe theory has been widely applied, not only in the field of rock system instability, but also in the field of coal and rock system instability. Wang et al. [34] analyzed the mutation instability rules of the room mining residual pillars in the shallow depth seam. Xu et al. [35] deduced the expression of the limit thickness of the goaf roof under the filling body by building the cusp catastrophe model. Mu et al. [36] revealed that the stability of layered rock mass was controlled by the external force, the modulus of the elasticity, the severity of rock mass, the inter layer shear stress, and the geometry based on the cusp catastrophe theory. Xu et al. [37,38] established the cusp catastrophe model on the basis of the energy theory, pointing out that the instability of the support system was caused by the incompatibility of energy release. The results showed that the catastrophe theory can explain the nonlinear dynamic characteristics of the instability of a coal–rock system. The deformation of the immediate roof accumulates elastic energy under the load of the overlying rock layer, and when the energy accumulates to a certain extent, it will be released instantly, resulting in the step sinking of the main roof. The crushing of the support and the ribbing of the coal wall have obvious instantaneity and abruptness. Therefore, the catastrophe theory is introduced into the stability analysis and parameter calculation during the first weighting of the working face to solve the problem of sudden disaster in coal mining.

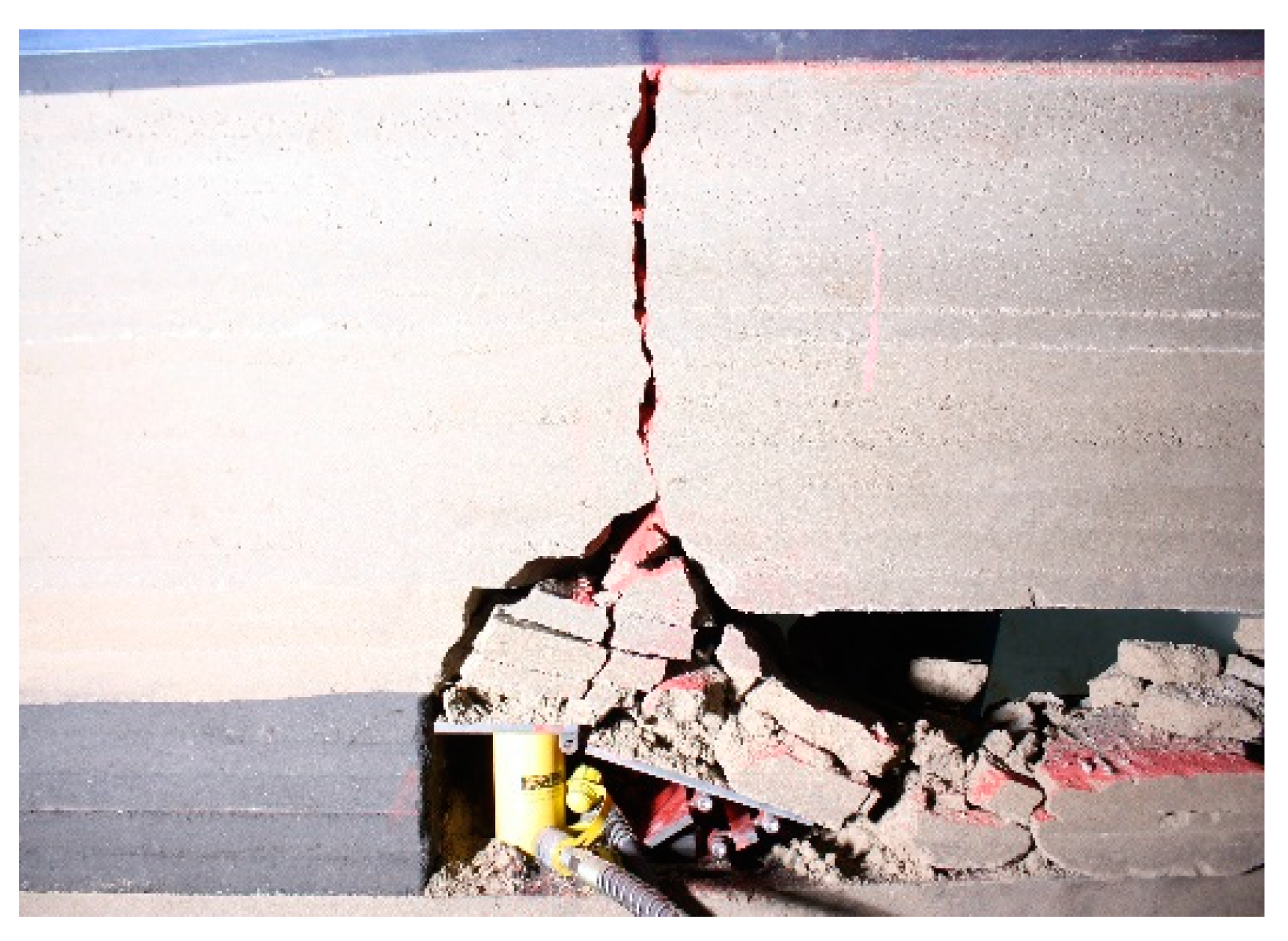

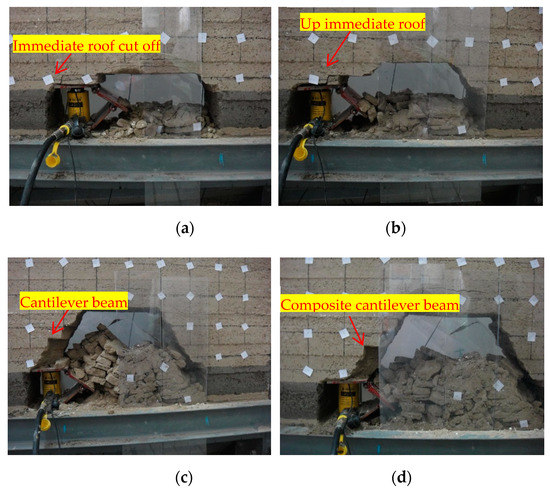

In the system of main roof-immediate roof-support, the deformation of the main roof is generally given, and the influence degree of the support on the main roof and the effect degree of the main roof on the support depend on the mechanical properties (stiffness) of the immediate roof medium and the yield ability of the support. The key point of roof control is the control of the immediate roof, and the role of immediate roof in the relationship between the support and surrounding rock is of vital importance [21,22,39]. According to the unstable collapse process and pressure characteristics of the main roof structure of large mining height, the main roof will break and rotate, compressing the immediate roof and support when the immediate roof and support system are not enough to support the main roof. When the deformation of the immediate roof rock exceeds its deformation critical value, the immediate roof will be crushed, and the main roof will slide along the coal wall, resulting in a wide range of roof cutting, support crushing, and step sinking (Figure 1) [40]. Therefore, the immediate roof rock mass controls the instability of the main roof, and the key point to control the large-scale pressure of the main roof is to control the instability of the immediate roof under the abutment pressure.

Figure 1.

The main roof is cut off and the immediate roof is crushed [40].

Therefore, the main objective of this study was to explore the general process and weighting characteristics of the main roof along the coal wall during the first weighting of large mining height in shallow coal seam, to analyze the mechanical mechanism of the main roof instability, to reveal the disaster-causing factors, and to explore the determination method of support resistance to ensure the stability of working face. In this study, according to the structural characteristics of the main roof cutting and instability along the coal wall during the first weighting, the system mechanical model consists of the main roof, immediate roof and support is established. This model is based on catastrophe theory and the energy conservation principle analysis method, as well as through considering the nonlinear characteristics of the failure and instability of the immediate roof. A new analysis method was proposed to study the mechanical mechanism of roof cutting along a coal wall during the first weighting. The instability process was analyzed theoretically, and the sufficient and necessary conditions for the sudden instability of the system were successfully obtained. The main influencing factors of the system catastrophe, such as stiffness ratio K, rock material parameters, external load Q, and weighting interval l are discussed. We also compared and analyzed the effects of elastic modulus E, support stiffness k1, cross-sectional area a, and immediate roof thickness H on the stiffness ratio K. After further derivation, the calculation equation of support resistance was obtained, and the main influencing factors of step sinking were analyzed. Finally, the rationality of the theoretical analysis results were verified by an engineering example, and the reasonable value of the support is given.

This paper is organized as follows: the structural characteristics and cutting process of the main roof during the first weighting in the working face of large mining height in the shallow coal seam are described in Section 2. A catastrophe theoretical analysis model consisting of main roof, immediate roof, and support is given in Section 3. The catastrophe instability condition of the immediate roof, the calculation method of the support resistance, and the step sinking are deduced by catastrophe theory in Section 4. Furthermore, the theoretical results are verified in Section 5. Conclusions are drawn in Section 6.

2. Analysis of First Weighting of Main Roof

2.1. Working Face Overview and Strata Behavior Monitoring

To analyze the roof structural characteristics of thin bedrock under thick loose layer during shallow coal seam mining, we took the no. 12401 panel of 5−2 coal seam in Shendong mining area as the engineering background. The length of working face was 260 m with a dip angle of 1–3°, and the average burial depth was 120 m. The thickness of the bedrock was 70 m on average. The thickness of the loose layer was 50 m on average. The thickness of the bedrock fluctuated in a small range. The roof was mostly mudstone, fine-grained sandstone, and siltstone, with an average compressive strength of 23.15 MPa. The floor was mainly siltstone, and the rock mass was complete with an average compressive strength of 26.35 MPa. The thickness of the coal seam was 7.1–17.35 m, with an average of 7.2 m, and the designed mining height was 7.0 m. The comprehensive histogram is shown in Table 1. The working face adopted 150 sets of ZY18000/32/70D electro-hydraulic control shield-type hydraulic supports. The measured first weighting interval of the main roof was about 54 m, and the average of periodic weighting interval was 15.8 m.

Table 1.

Lithology of the no. 12401 working face.

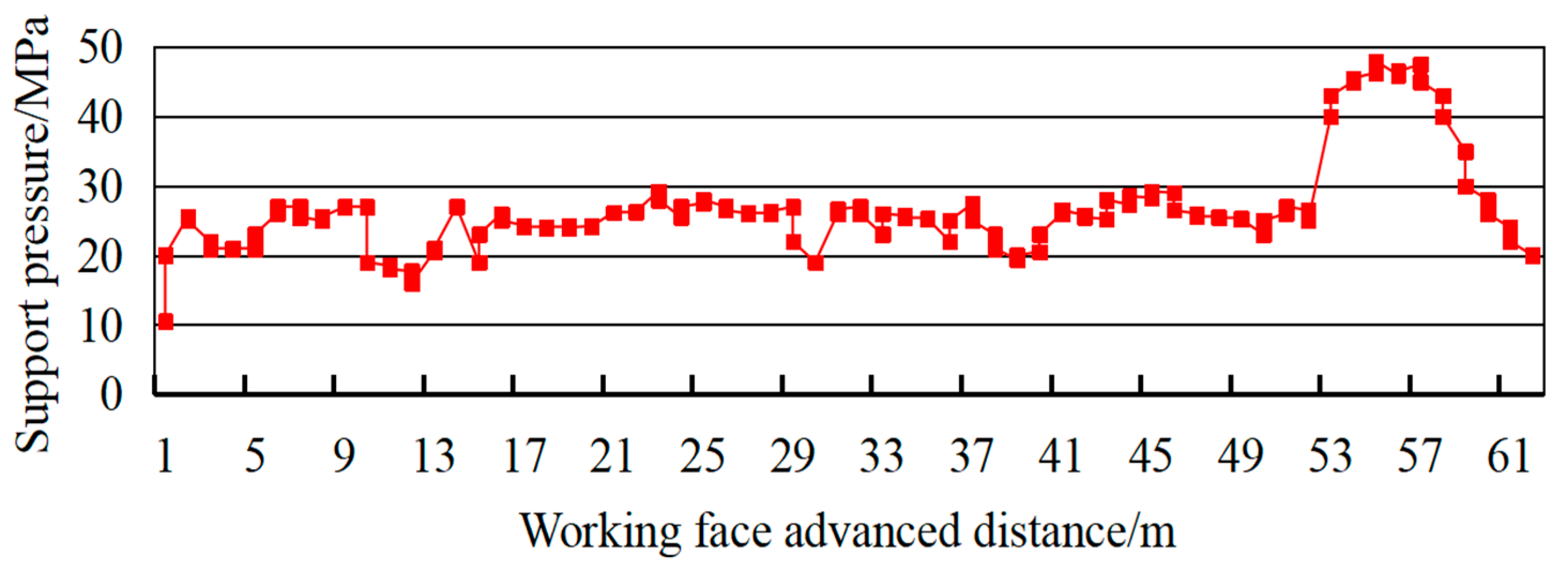

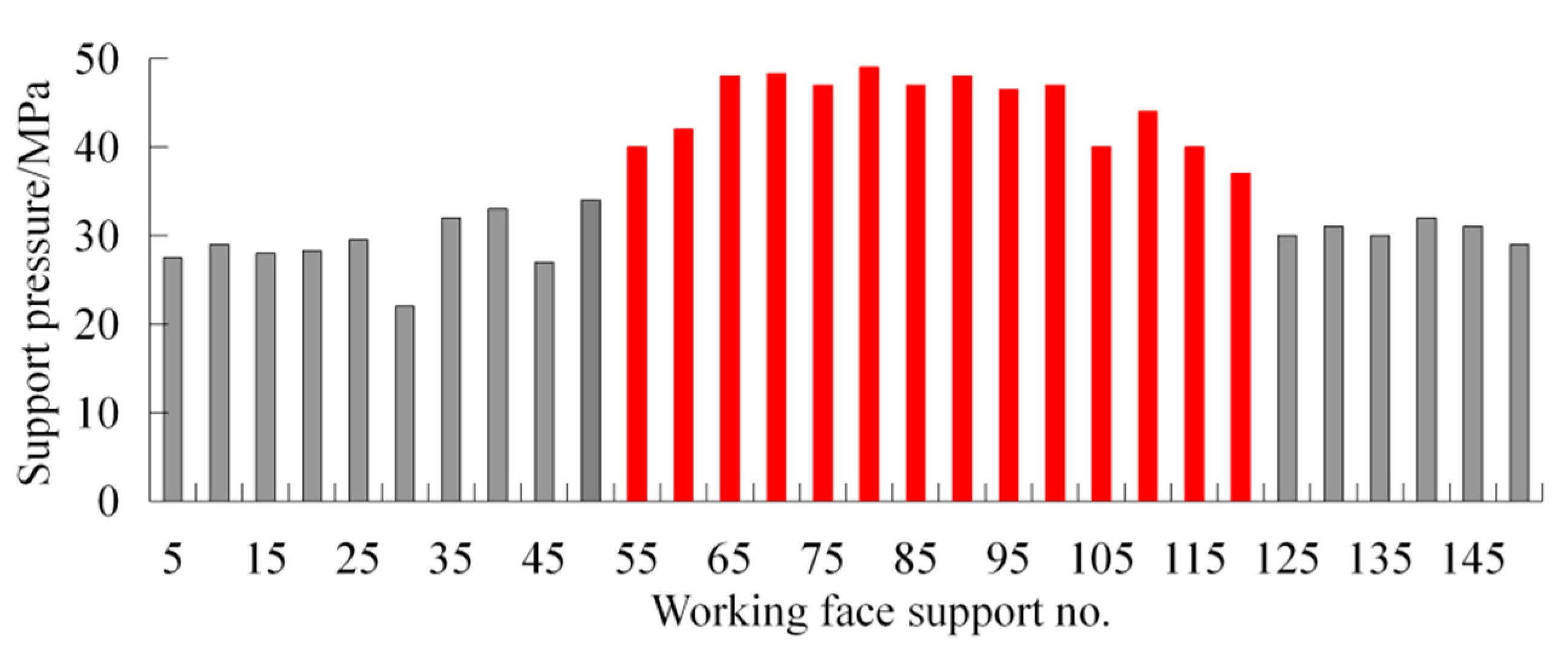

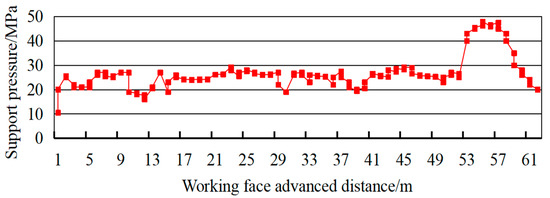

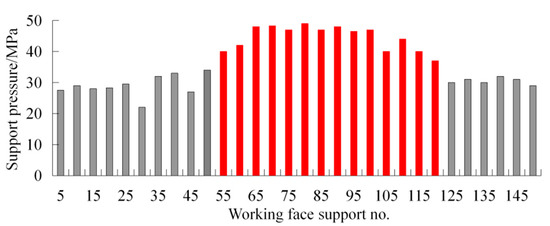

Figure 2 shows the monitoring curve of support resistance during the first weighting of working face, and Figure 3 shows the variation curve of working resistance of supports during the first weighting. The working resistance of the support was small and the change range was not large, most of which was 25.2–30.0 MPa, found by analyzing the curves in Figure 2 and Figure 3. The support resistance of no. 55–120 in the middle of the working face increased rapidly when the working face advanced about 53 m, and the maximum value reached 47.3 MPa (red area in Figure 4). There was frequent opening of the safety valve, rapid roof sinking, and great danger of support crushing. The rib fall of the coal wall was seriously cracked, and the average rib fall depth was 200–400 mm. After that, the weighting entered a continuous stage.

Figure 2.

First weighting curve of the no. 12401 working face.

Figure 3.

Distribution of support resistance during first weighting.

Figure 4.

Vertical and horizontal movement of ground cracks.

When the working face advanced about 60 m from the open-off cuts, there were obvious vertical and horizontal movement cracks on the surface, as shown in Figure 4. The subsidence was between 210 mm and 235 mm, and the average was 224 mm. The sinking amount was between 210 mm and 235 mm, with an average of 224 mm. The monitoring results showed that the roof damage caused by the first weighting directly affected the ground surface, and there were obvious step subsidence and dynamic load phenomenon in the process of weighting.

The measured first weighting interval of the main roof was about 54 m, which was larger than that of the general mining height. The support resistance increased sharply during first weighting, and the weighting in the middle of the working face was strong. The dynamic loading phenomenon was obvious, with the average dynamic load coefficient being 1.81. The roof moved violently, causing the safety valve of the support to open frequently, and there was great danger of support crushing. Therefore, it was necessary to analyze the applicability of the hydraulic support with a rated working resistance of 18,000 kN under the conditions of large mining height.

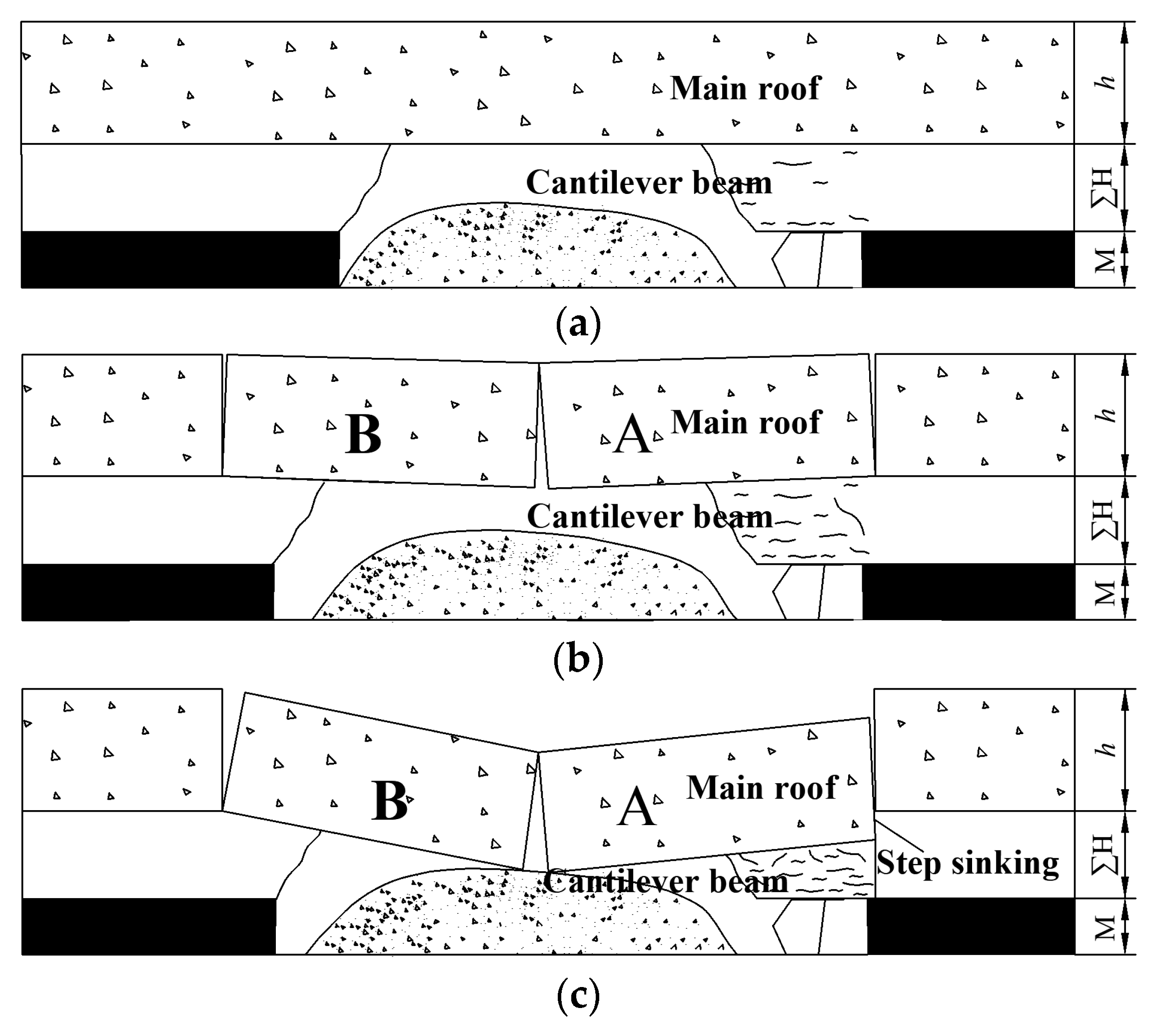

2.2. Characteristics of Roof First Weighting

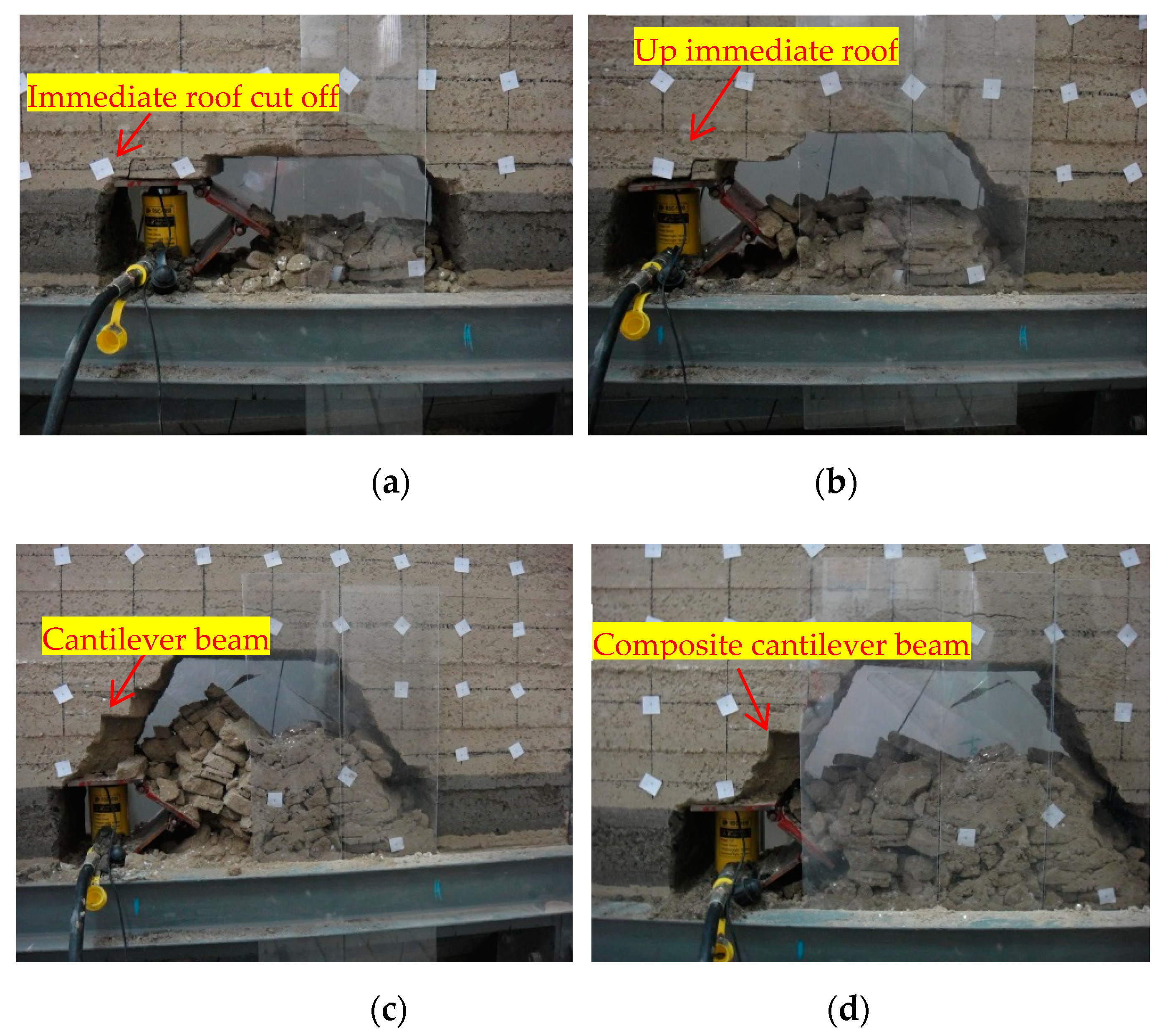

Figure 5 shows the first weighting process of working face under the condition of 7 m mining height of the shallow coal seam obtained from the similar material model test. The analysis of the simulation results showed that as the space of the goaf increased continuously with the advancement of the working face, the immediate roof had less filling to goaf (Figure 5a), causing the mining-induced fracture to extend continuously to the upper part of the goaf. The upper part of the original main roof formed the separation layer and working face pressure, and the previously broken rock mass could not form an articulated structure with the broken lower main roof, and thus the lower main roof formed a cantilever beam structure (Figure 5b). The upper rock layer broke continuously under the action of mining unloading with the advancement of the working face, and the thickness of the cantilever beam structure increased (Figure 5c) until the upper main roof formed a stable articulated structure due to rotation or sliding instability. In this process, a new immediate roof was formed, which was different from the original immediate roof, being composed of multiple layers of rock, as is shown in Figure 5d.

Figure 5.

Cantilever beam structure for first weighting of large mining height roof: (a) immediate roof cut off in front of support, (b) up immediate roof, (c) cantilever beam, (d) composite cantilever beam structure.

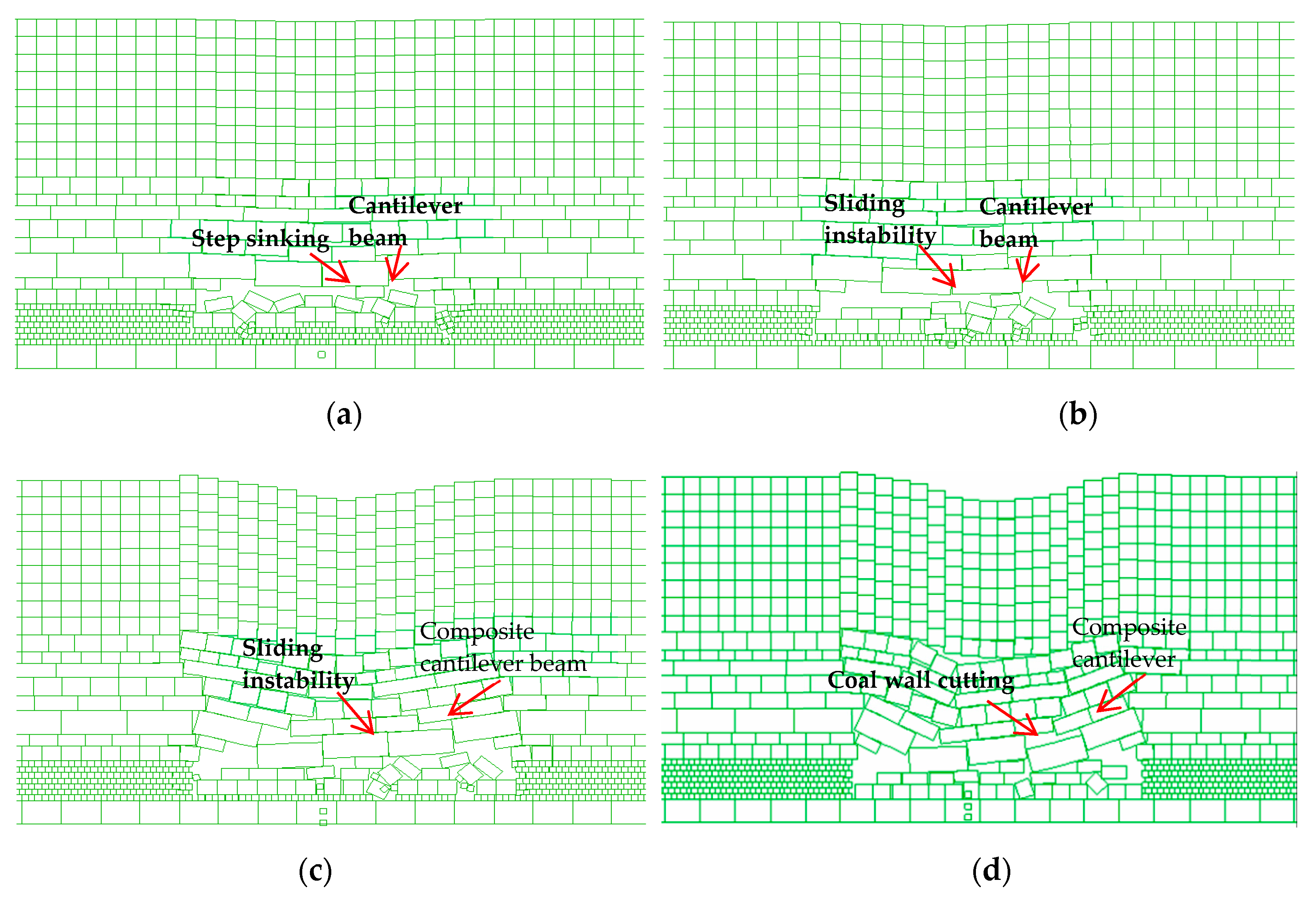

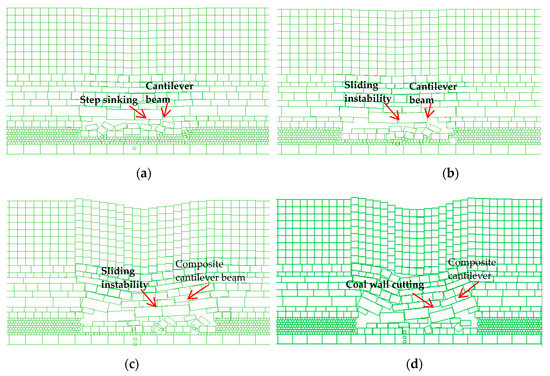

In order to analyze the characteristics of the first weighting in the shallow coal seam with large mining height, we constructed a numerical analysis model with a mining height of 4–7m [41,42,43]. The simulation results are shown in Figure 6, with there being different degrees of sliding instability and violent strata behavior in the working face of different mining heights. Similar to the physical simulation, the roof successively appeared as immediate roof (the mining height shown in Figure 6a is 4 m), cantilever beam structure (the mining height shown in Figure 6b is 5 m), and composite cantilever beam structure (the mining height in Figure 6c,d is 6 m and 6 m, respectively) with the increase of mining height. The space of the goaf was insufficient in terms of the increase of mining height, and thus the collapsed main roof could not form an articulated structure, continuing to collapse into the goaf until the goaf was filled to support the main roof. The collapsed main roof and the original immediate roof formed a new immediate roof of composite cantilever beam. In the process of the pressure of the upper main roof, the load formed by the sliding instability of the main roof along the coal wall acted on the immediate roof. In this process, the support and the immediate roof constituted a system that jointly bore the main roof loads. Considering the nonlinear deformation characteristics of the immediate roof, if the immediate roof broke under the pressure and lost its load-bearing effect, the force borne by the support would suddenly increase, wherein it would be easy to induce the roof cutting (Figure 6c,d). Therefore, the stability of the immediate roof plays an important role in the safety of the working face.

Figure 6.

First weighting of working face with 4–7 m mining height: (a) 4 m, advance 10 m each step, and L = 40 m first weighting; (b) 5 m, advance 10m each step, and L = 40 m first weighting; (c) 6 m, advance 10 m each step, and L = 50 m first weighting; (d) 7 m, advance 10 m each step, and L = 50 m first weighting.

3. Mechanical Models and Constitutive Relations

3.1. Mechanical Model Analysis

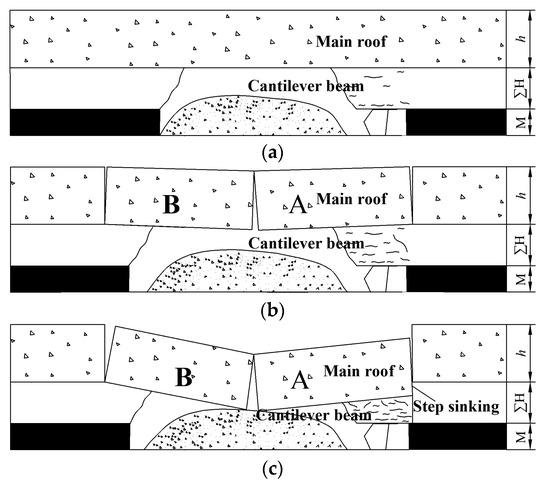

In the mining process, the sliding instability of the main roof was the biggest threat to the working face during the first weighting. The first weighting process is shown in Figure 7. The dead weight of the main roof and the load of overlying thick loose layer Q were transmitted to the immediate roof and support through the main roof, resulting in the compression deformation of the immediate roof and support (as shown in Figure 7b). If the system composed of the immediate roof and support could not form an effective support for the main roof, the main roof would rotate and deform to compress the immediate roof rock and support. The immediate roof would be crushed if the deformation increased to a certain critical value, causing the main roof to slide along the coal wall, and step sinking would occur at the main roof and the overlying thick loose layer (as shown in Figure 7c), resulting in coal mine accidents. Therefore, it was important to analyze the deformation and instability of the main roof immediate roof support system and provide measures to control the sliding instability of the coal wall when the main roof is broken and unstable, so that the main roof can rotate to the goaf for normal pressure.

Figure 7.

The structure of the main roof before and after the first weighting: (a) before breaking, (b) before instability, (c) roof step sinking.

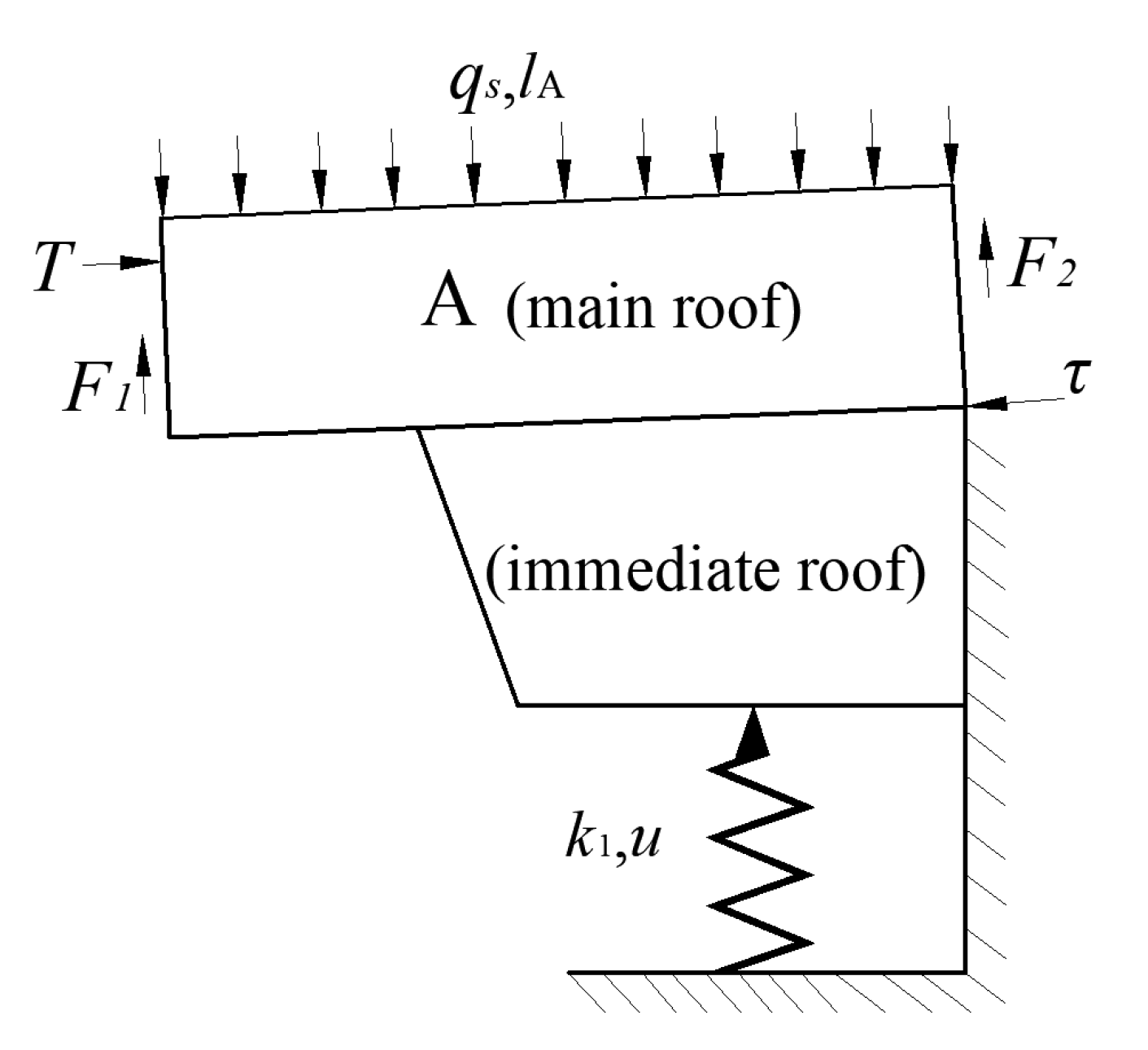

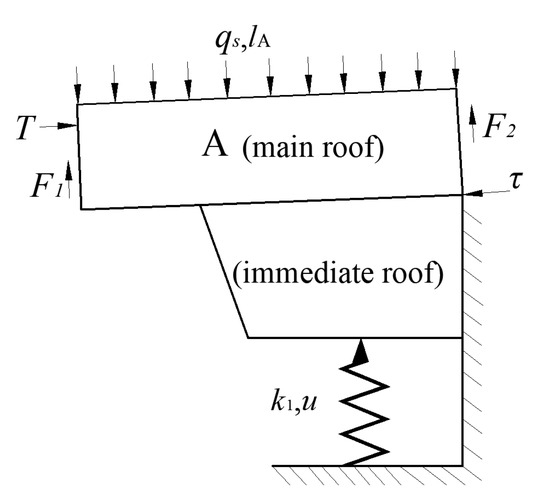

From the perspective of mechanical theory research, this paper studied the mechanical mechanism of the main roof sliding instability, establishing a mechanical system composed of the main roof, immediate roof, and support. Generally, the elastomer can be used to represent the support, and the immediate roof can be used as a variable medium. Because of the fracture at both ends of the main roof, it can be simplified as the hinged connection with the front and rear rock mass. During the process of the main roof sliding instability, the immediate roof and support bore the weight of the roof and the load of the loose layer Q, with the subsidence of the instability rock block A being set as Δh. As the subsidence of the main roof compressed the immediate roof and the support, the step sinking of the main roof was thus equal to the total displacement of the support and immediate roof. The coal gangue in the goaf was scattered, and thus the absorbed energy could be ignored. In the process of the main roof and follow-up rock block sinking, the gravitational potential energy decreased, the potential energy of the support and the immediate roof increased, and the friction of the hinge surface worked with energy conservation.

Combined with the above analysis, the mechanical analysis model was established, as shown in Figure 8, where qs is the weight of overlying loose layer and main roof, lA is the length of rock block A, u is the compression displacement of immediate roof rock mass, w is the compression displacement of support, a is the total displacement of the support-immediate roof, and k1 is the stiffness of support.

Figure 8.

Simplified mechanical mode l.

3.2. Constitutive Relationship of Immediate Roof Rock Mass

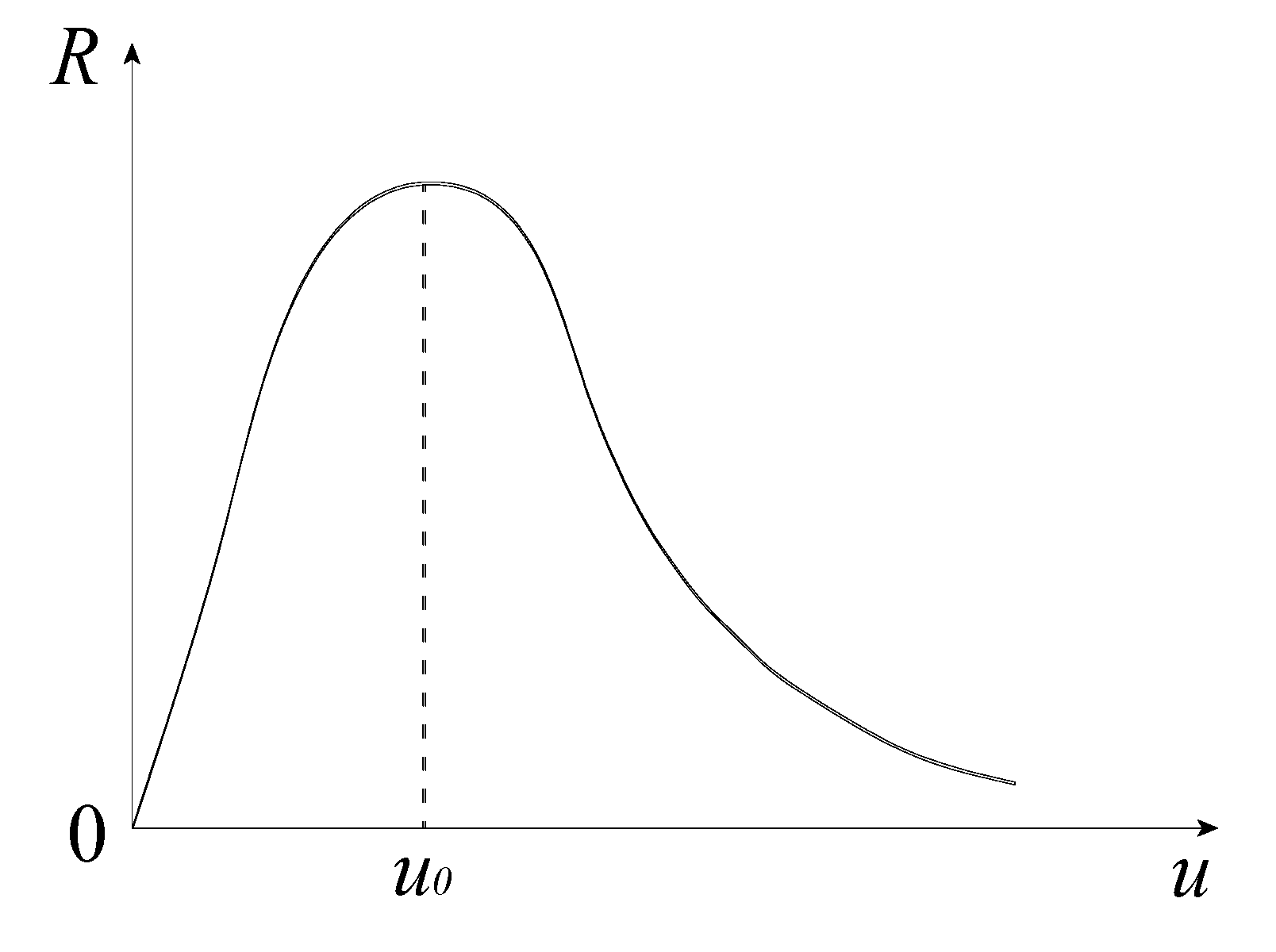

The constitutive relation of the immediate roof rock mass is a nonlinear relationship with a softening property [30,44]. The stress–strain relationship of rock materials is discussed in relevant literature [45,46], giving the relation between the stress σ and strain ε.

where E is the initial value of the elastic modulus, and the integral is the damage parameter that is related to the distribution density of defects in rock materials. When the defects in rock conform to Poisson distribution, the nonlinear constitutive relation can be expressed as

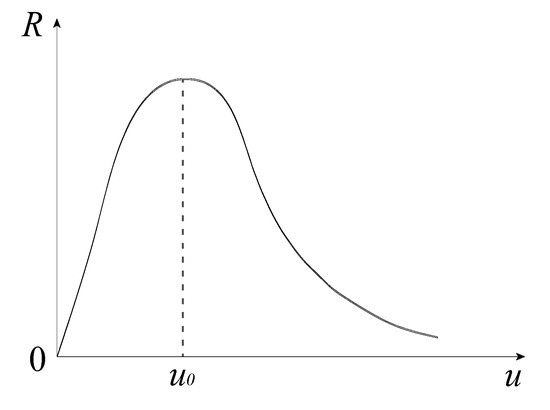

For the immediate roof rock mass with section A and height H, Equation (2) can be used as an expression of the relationship between the load R and deformation u (as shown in Figure 9)

where λ = EA/H is the initial stiffness of the rock mass and u0 is the strain value corresponding to the peak load. The nonlinear curve of Equation (3) has an inflection point at the strain u1 = 2u0, and the absolute value of the corresponding slope is λ1 = λe−2.

Figure 9.

Stress–strain curve of rocks.

4. Catastrophe Analysis of Immediate Roof Instability

4.1. System Potential Function

The total potential energy of the mechanical system composed of the main roof, immediate roof, and support can be expressed as

where WJ is the work done by external force Q, since gravity and friction work have the same path; the resultant force Q can be expressed as , where is the gravity of the main roof rock block, ; lA is the length of the broken block A; is the main roof height, m; is the main roof volume weight, kN/m3; and is the load of overlying thick loose layer. According to the calculation principle of Terzaghi earth pressure, the weight of load layer is , where ρ1g is the average volume weight of the load layer, kN/m3; φ is the internal friction angle of the load layer, °; and λz is the lateral stress ratio of the load layer, λz = 1-sinφ. is the friction caused by sliding instability, and the horizontal force on the rock contact hinge is , where is the maximum value of rock block rotating angle, is the friction coefficient between rock block and gangue, and i is the main roof rock block size. The main roof slipped and lost stability during the first weighting, which made it become a balance structure again after the roof cutting; therefore, it can be considered that the main roof was a horizontal structure. At this point , the friction shear stress on the contact hinge can be expressed as , kN [47,48].

According to the conservation of energy, the work done by the external force during the catastrophe instability of immediate roof can be expressed as

where is the step sinking of roof, m.

The strain energy of the immediate roof is , the compression capacity of support is w = a − u, and the elastic potential energy of the support is . Because the step sinking of the roof is equal to the total displacement of the support-immediate roof system, . Therefore, combining WJ, UZ, and US into (4), the total potential energy of the system can be expressed as

4.2. Catastrophe Analysis

Taking the compression displacement u of immediate roof rock mass as the state variable, according to the cusp catastrophe theory, obtaining of the equilibrium surface M can be expressed as

Then, the singular point set equation can be expressed as

The equilibrium surface M satisfies at the cusp, and the cusp equation can be obtained as

At the cusp,

It was found that the cusp was the inflection point of the constitutive curve of rock mass.

In order to transform the cusp catastrophe model to a standard form, we carried out a Taylor series expansion at the cusp, and the first three terms were truncated as

Introducing dimensionless parameters , and substitute u1 = 2u0, the above equation can be simplified to obtain the equation of equilibrium surface in the standard form of cusp catastrophe, which can be expressed as

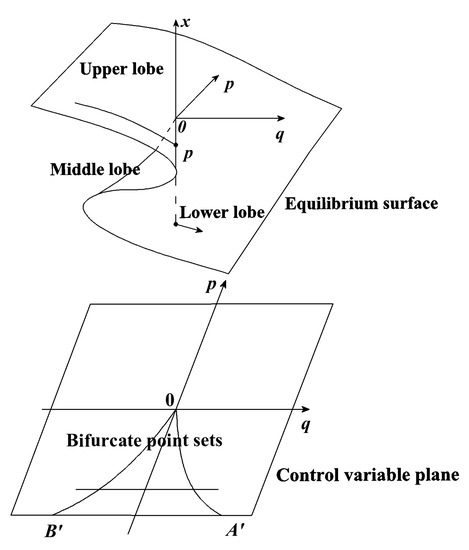

The parameter K is the ratio of the support stiffness to the slope of the constitutive relation curve of the immediate roof at the inflection point, which is called the stiffness ratio. ζ is the total displacement parameter, which is related to the total displacement of the support and the immediate roof. According to Equations (13) and (14), the control variables m and n of the system are related to the stiffness ratio K, the total displacement parameter ζ, the external load Q, and the first weighting interval l of the main roof.

The bifurcation set equation of cusp catastrophe with m and n as control parameters can be expressed as

The bifurcation set Equation (17) is the critical point of the system instability. Only when m ≤ 0 will the system cross the bifurcate set and cause a sudden jump of deformation, and thus m ≤ 0 is the necessary condition of the system instability. According to Equation (13), the stiffness ratio K must be less than or equal to 1, that is

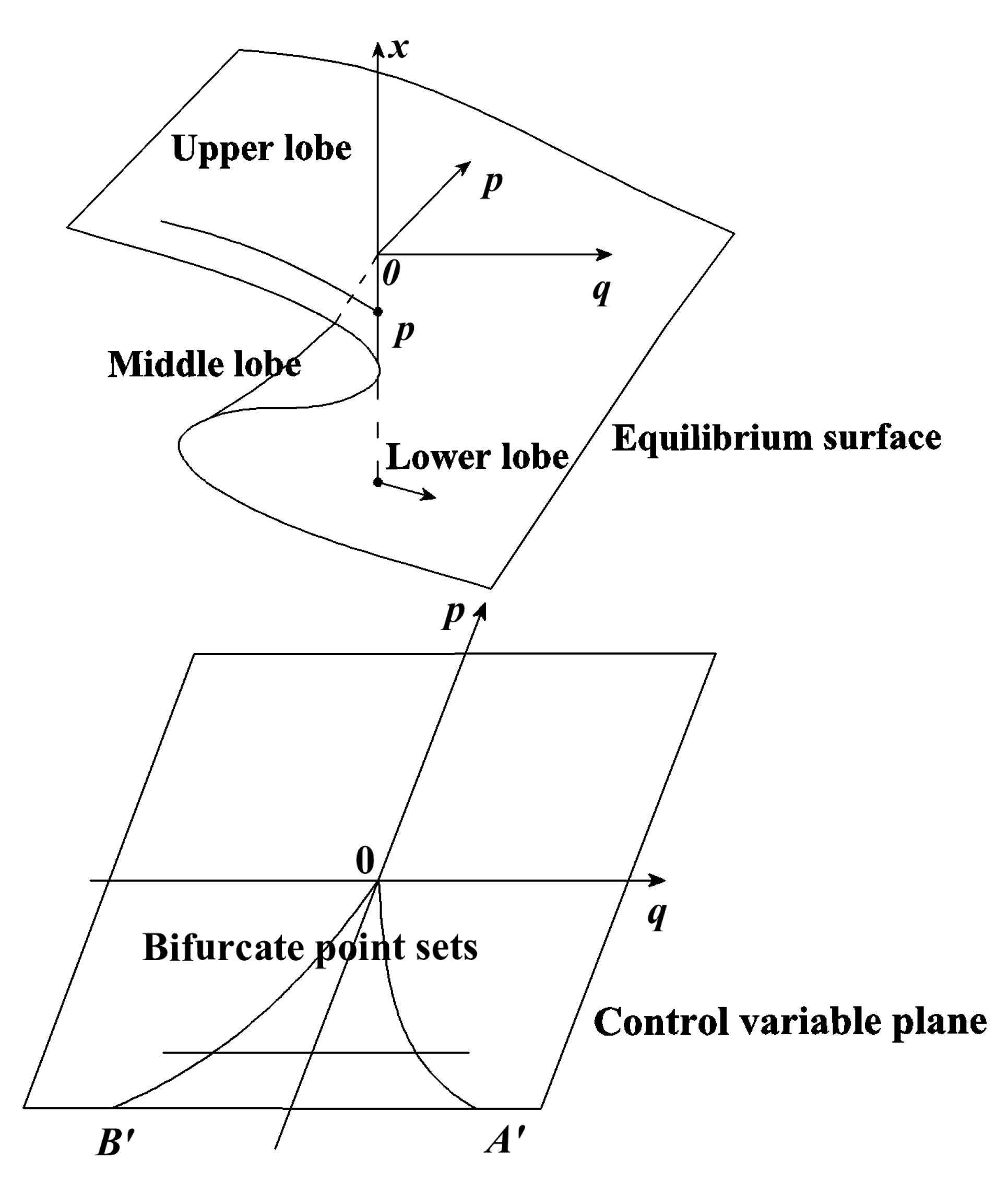

According to the catastrophe theory, only when m and n satisfy the bifurcation set Equation (17) will the system have a sudden jump in instability. Therefore, the bifurcation set equation is a sufficient condition for the sudden jump in instability of the system. According to the cusp catastrophe model in Figure 10, when the bifurcation set crossed from the right branch (n > 0) to the left branch (n < 0), the corresponding point was in an unstable state, and the state variable x was a sudden jump. The fracture instability occurred when the deformation value of the immediate roof increased instantly. The sufficient and necessary conditions for the catastrophic instability of the mechanical system were obtained from Equation (17), which can be expressed as

Figure 10.

The equilibrium surface and the control variable plane.

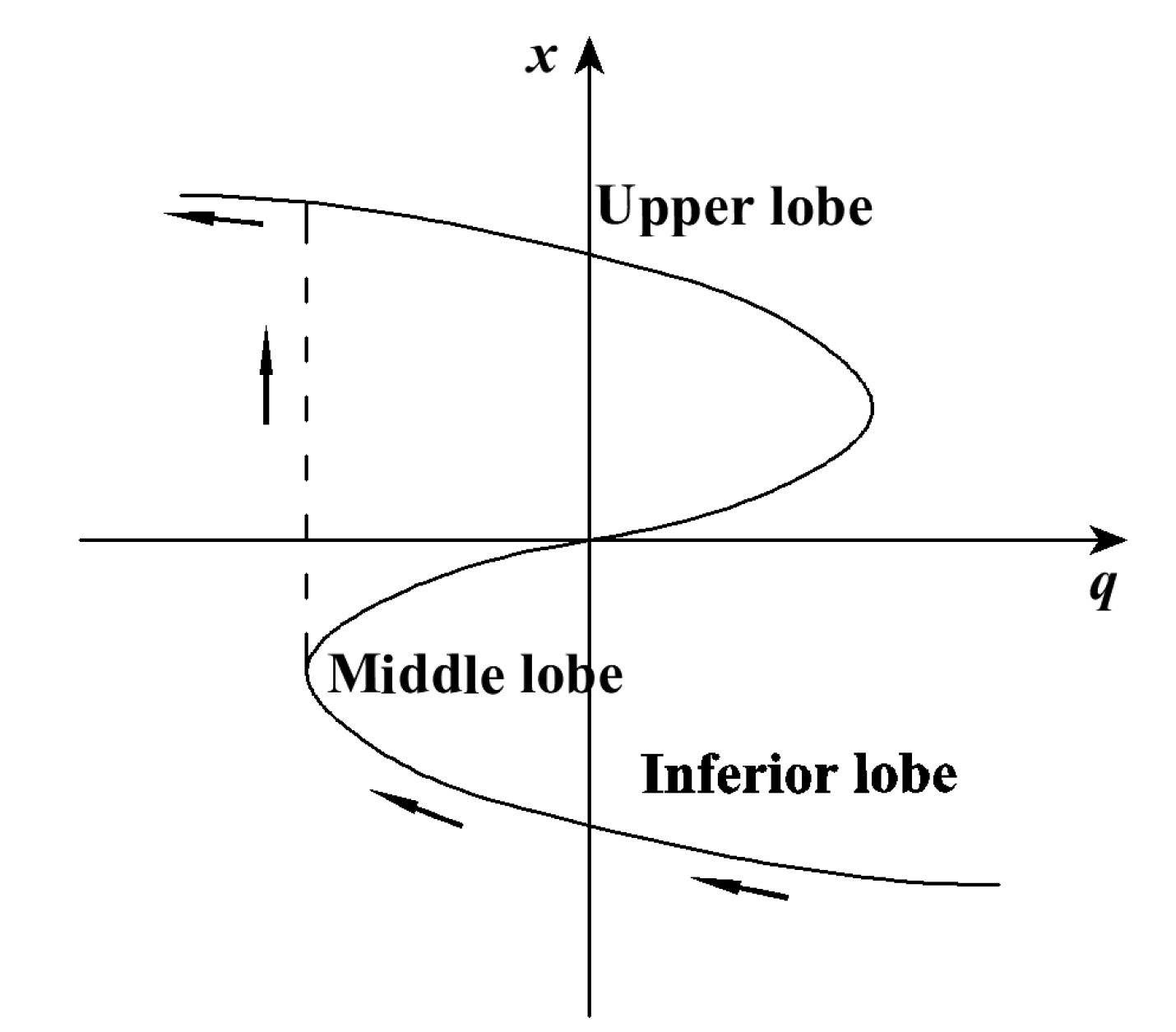

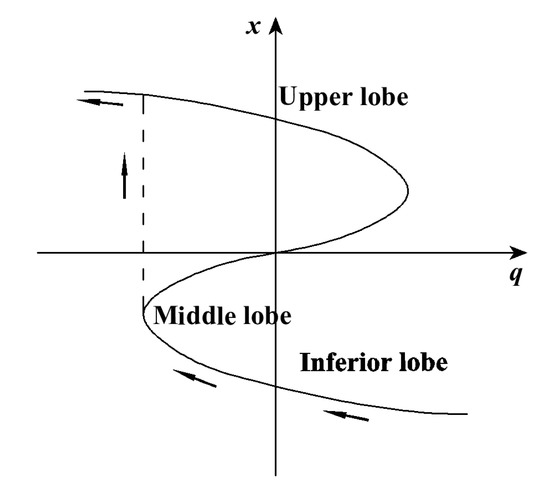

The lower lobe of the equilibrium surface in Figure 11 represents the accumulation process of system energy; at this time, the elastic potential energy increased gradually and the system was at the critical point of stable state. With the continuous mining work, the deformation of support and immediate roof rock increased gradually, and the compression displacement of immediate roof increased gradually, with the stress–strain curve developing to the critical state of the middle lobe. When the upper lobe was reached, the compression displacement of immediate roof u = 2u0 = u1, and the deformation increased suddenly and instantaneously, resulting in system instability, which led to the main roof cutting down along the coal wall, wherein the system reached a new equilibrium state. The whole process of the sudden jump deformation of the immediate roof was the catastrophic process of the system state.

Figure 11.

The state jump when leaping over the bifurcation point sets.

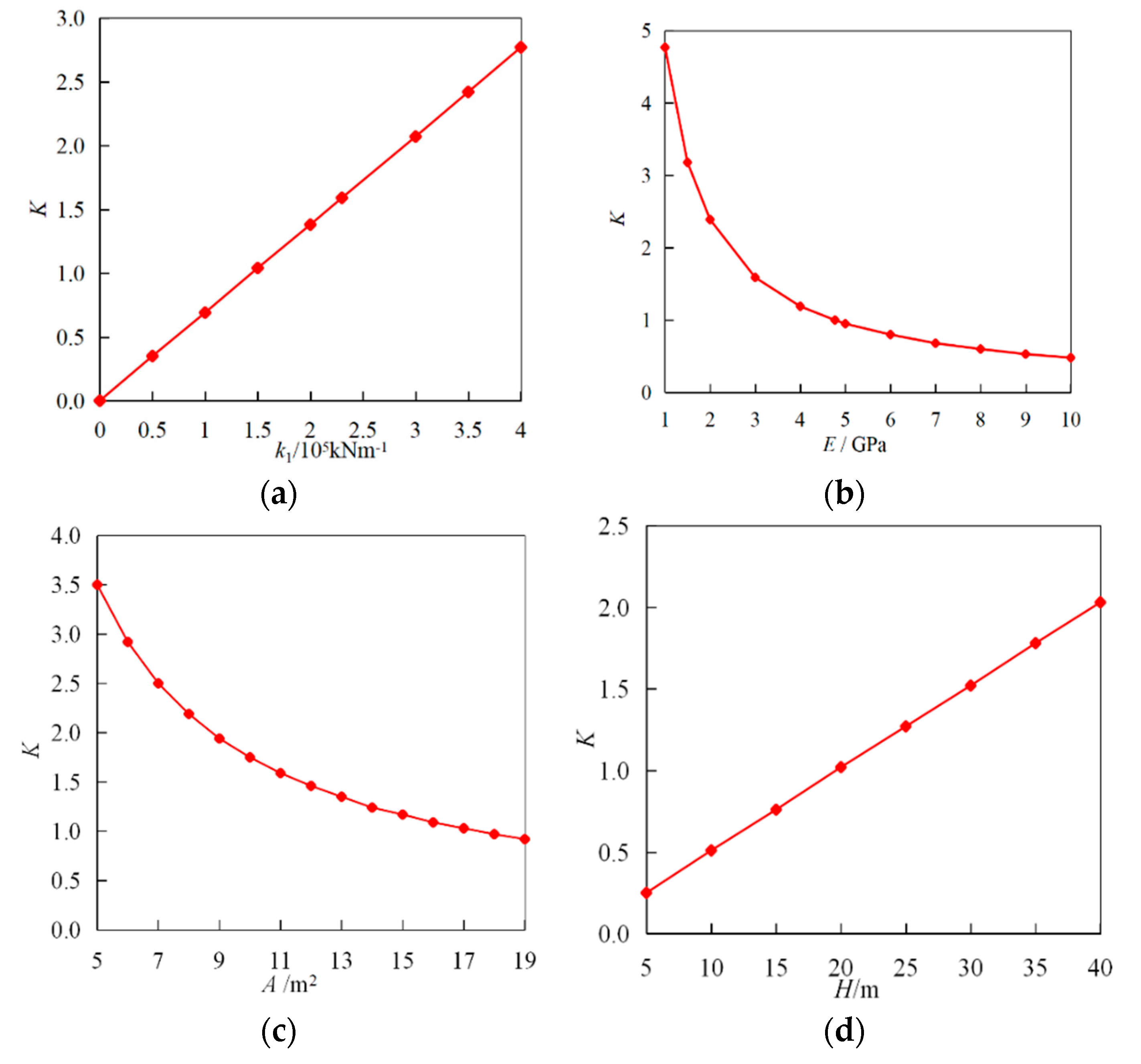

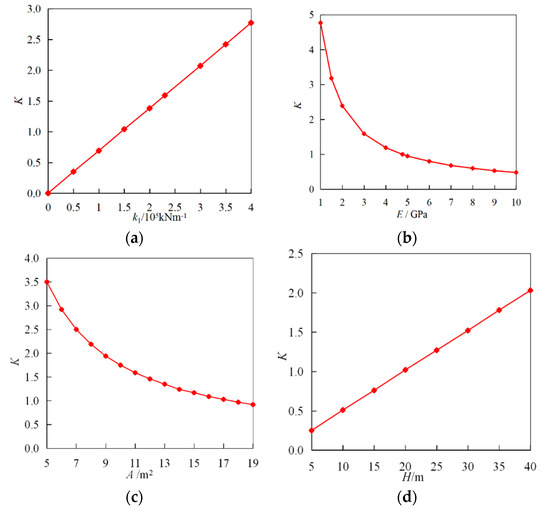

Since the parameter K was the ratio of the support stiffness k1 to the slope λ1 of the stress–strain curve of the immediate roof at the inflection point, and the stiffness ratio K was only related to the internal properties of the material, the internal characteristics of the material were therefore the necessary conditions for the system to have a catastrophic change. The main influence factors of the stiffness ratio K were analyzed by Equations (18) and (19). The influence of the support stiffness k1, the elastic modulus E, the immediate roof cross-sectional area A, and the immediate roof thickness on the stiffness ratio K are shown in Figure 12. It can be found from the curves that the stiffness ratio K was positively related to the support stiffness k1 and the immediate roof thickness, and was negatively related to the elastic modulus E and the immediate roof cross-sectional area A. The support resistance and the supporting capacity of the roof increased with the increase of the support stiffness k1, which was conducive to the stability of the roof and the system (Figure 12a). Therefore, increasing the support stiffness within a reasonable range played an important role in maintaining the stability of the roof. Because the immediate roof rock mass was composed of structural plane and joint fissures, the more complete the immediate roof, the greater the elastic modulus E and the stiffness λ1, and the more unstable the system (Figure 12b).

Figure 12.

Analysis of influence factors of stiffness ratio K.

In addition, the cross-sectional area A and thickness H of the immediate roof also had a great influence on the stiffness ratio. The immediate roof of the large mining height working face was composed of multiple layers of rock, which was thicker than the immediate roof of normal mining height. Because the stiffness ratio was directly proportional to the immediate roof thickness H, it was easy to induce the catastrophic instability of the working face, which was also the inducement of the roof cutting and sinking during the first weighting (Figure 12c). As the combined immediate roof was generally of inverted step structure, and the more the number of immediate roof layers, the greater the length, therefore, under the condition of large mining height, the increase of A played a positive role in ensuring the stability of working face (Figure 12d). Comparing the four curves, we found that the influence degree of each parameter on the stiffness ratio was elastic modulus E > support stiffness k1 > cross-sectional area A > immediate roof thickness H.

From the sufficient condition expression of the system catastrophe instability in Equation (19), we found that the system instability was also related to the external load Q and the length lA of the fracture block, i.e., the first weighting distances l. With the increase of load Q, the load on the system increased and the system stability decreased gradually. When the load reached a certain value, the catastrophe instability of the system occurred. The larger the first weighting distances l, the lower the system stability. When the first weighting interval exceeded a certain value, the sufficient conditions for the catastrophe instability were met, and the catastrophe instability of the system occurred. Therefore, the external load Q and the first weighting interval l were the external determinants of the system instability, which were large enough to change the stability of the system.

Through the analysis of the necessary and sufficient condition Equation (19), we found that the instability of the system was not only related to its internal characteristics (immediate roof elastic modulus E, thickness h, cross-sectional area A, stress–strain relationship and support stiffness k1), but also related to the deadweight of the main roof, the load of the overlying thick loose layer, and the weighting distance L. For the immediate roof, the stronger the strain softening property, the larger the elastic modulus E and corresponding λ1; the smaller the stiffness ratio K, the easier it was for the system lose stability. The larger the overburden load, the longer the first weighting interval of the main roof, and the easier it would be to cross the bifurcation point set, and therefore, the easier it would be for the system to lose stability.

The overlying thick loose sand layer in shallow coal seam made the load all act on the roof bedrock. During the advancement of the working face of large mining height, the main roof overlying load increased gradually, which would inevitably lead to the probability of catastrophe instability. In addition, when the support stiffness was certain, the influence of the support on the system stability and the load on the support were all determined by the mechanical properties and material parameters of the immediate roof. The lithology compositions and integrity of the immediate roof had a decisive influence on the occurrence of a catastrophe. Therefore, the catastrophe instability of the immediate roof determined the cut-off of the main roof.

4.3. Calculation of Step Sinking

When the system satisfied the necessary and sufficient conditions for catastrophe instability, we obtained three real roots of Equation (12). When crossing the set of bifurcation points, the state variable x would suddenly jump (Figure 10). The jump amount can be expressed as

The corresponding sudden jump compression of the immediate roof before and after system instability can be expressed as

It can be found from Equation (21) that the sudden jump was only related to the characteristics of the immediate roof and the stiffness ratio of support. The amount of sudden jump was determined by the properties of the materials in the system, and had nothing to do with other factors.

Taking m, n, Equations (13) and (14), and λ = EA/H into Equation (14), we can formulate the total displacement a during the sudden jump of deformation as

From and u1 = 2u0 (ξ takes the larger value), we can obtain

The total displacement of the system when the sudden jump occurs is the sinking value of the main roof, that is, ∆h = a, and thus the sinking value of the key block can be expressed as

In which ∆h is the step sinking value of the main roof when the catastrophe instability of immediate roof occurs, which is formed under the action of external conditions. From the constitutive relation curve of the rock in Figure 3, it can be found that the step sinking value was the allowable subsidence of the roof when the sliding instability occurs. If the step sinking value exceeded ∆h, the main roof would suddenly jump and lose stability, resulting in a large range of roof cutting and support crushing accidents. Therefore, the prediction of roof subsidence can be realized by calculating ∆h.

4.4. Calculation of Support Resistance

Before the sudden jump of the immediate roof, the compression displacement of the support is the difference between the displacement of the system and the immediate roof, and then the compression displacement of the support during the catastrophe instability can be expressed as

When the catastrophe occurs, the compression displacement of the support is the support-surrounding rock condition needed for the sudden jump. Combined with the bifurcation set Equation (14), which is the critical point of the system instability, when m ≤ 0, the system will cross the bifurcation to generate the sudden jump of deformation. Combined with Equation (18), the support stiffness value of the catastrophic instability of the system can be obtained as

Therefore, in order to keep the system stable without the sudden jump deformation of the immediate roof, the support stiffness k1 should be greater than , and the minimum support resistance required for system stability can be expressed as

Considering the support efficiency, the support resistance when the catastrophe instability occurs can be expressed as

where μ is the support efficiency of the support, equal to 0.9.

Through the interaction between the support and the main roof, the value of the minimum support resistance can be obtained to ensure the stability of the working face, which can be used as the basis for support selection.

5. Analysis of Influencing Factors and Engineering Example

5.1. Analysis of Influencing Factors

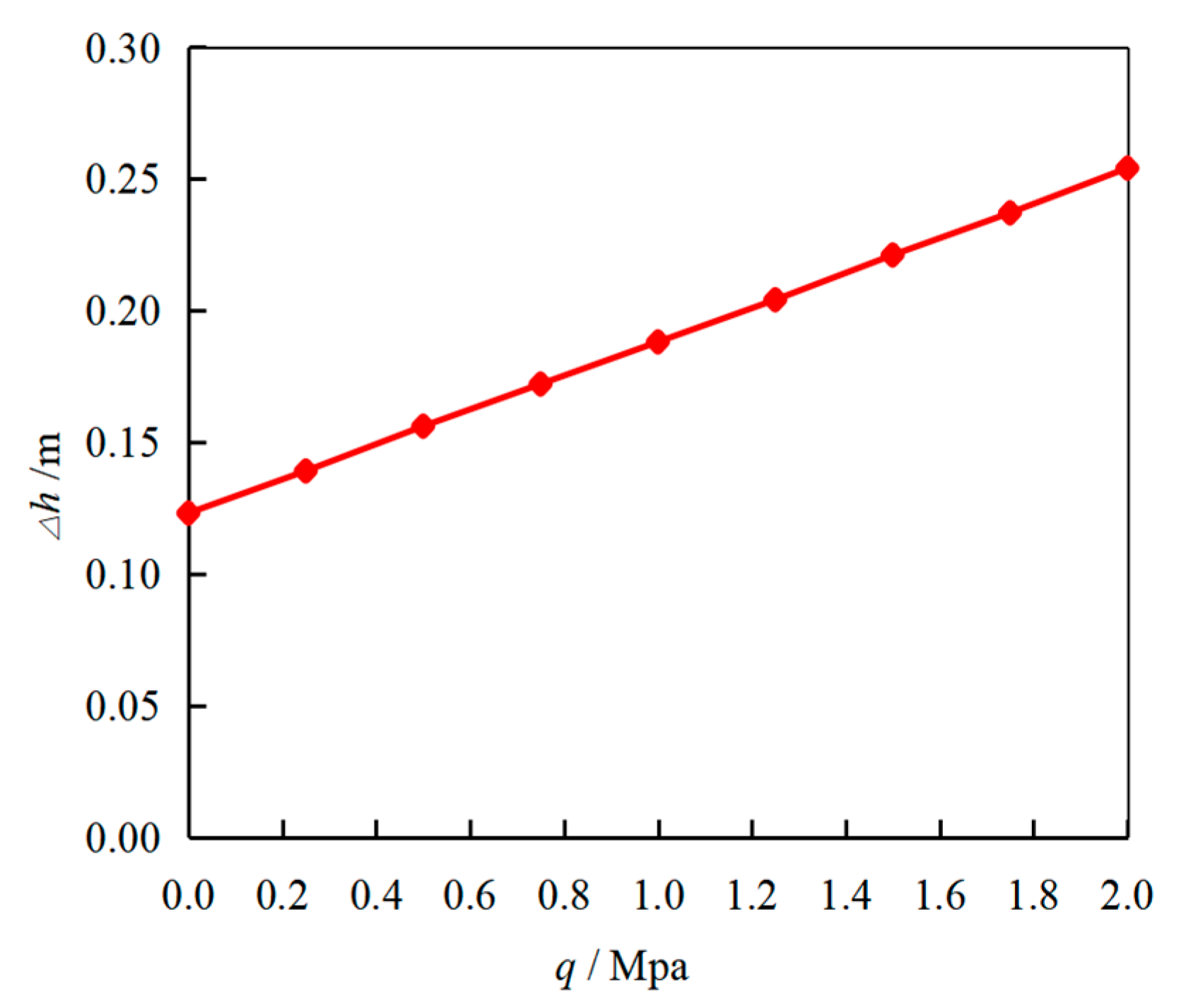

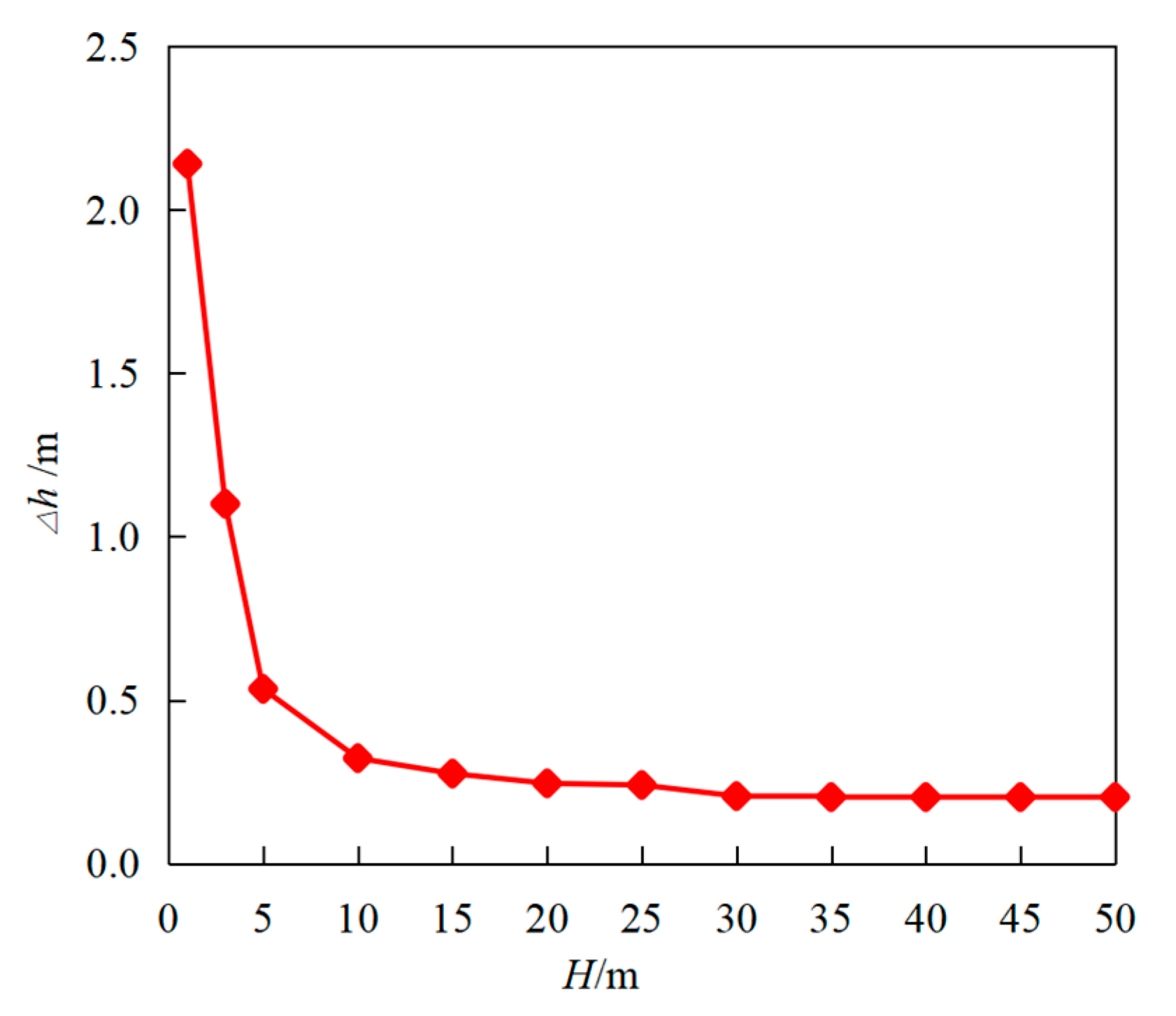

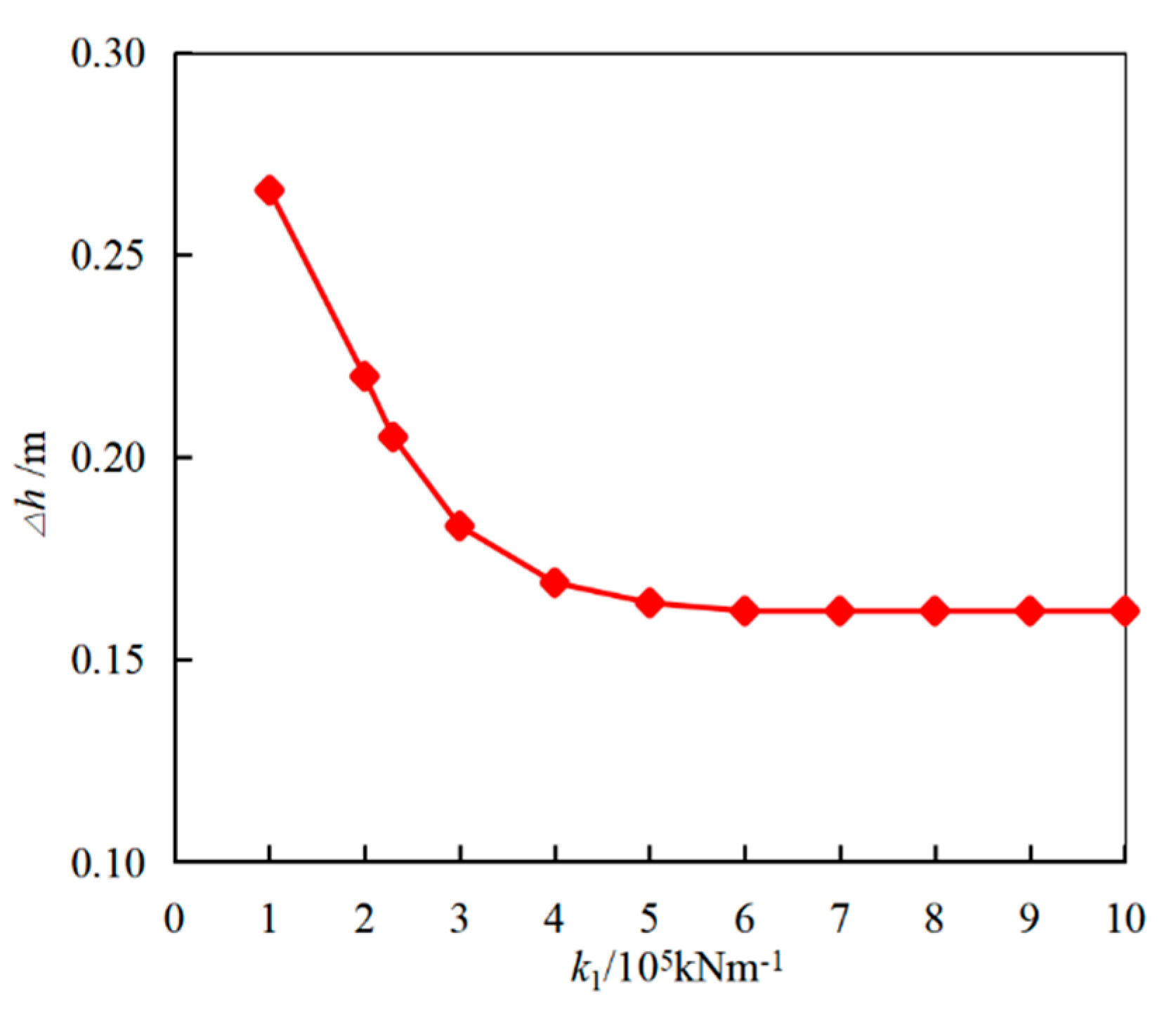

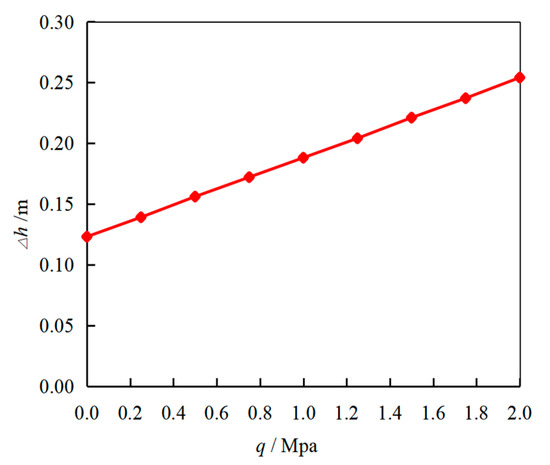

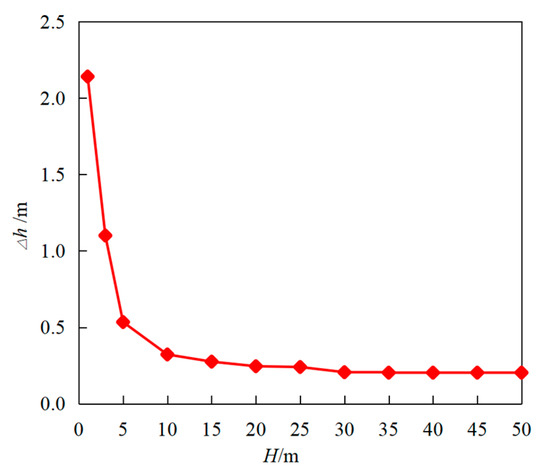

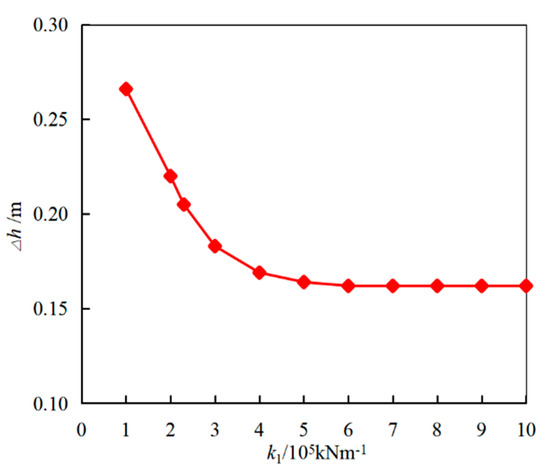

In order to deeply analyze the main influence factors of roof sinking ∆h (total displacement a) during the catastrophe instability of the system, we analyzed the main parameters, combined with the engineering geological conditions of the no. 12401 fully mechanized coal mining face in Shendong mining area. Figure 13, Figure 14 and Figure 15 show the corresponding roof subsidence curve when the overburden load q, the thickness H of the immediate roof, and the support stiffness k1 changed.

Figure 13.

The relationship between step sinking and overburden load.

Figure 14.

The relationship between step sinking and immediate roof thickness.

Figure 15.

The relationship between step sinking and support stiffness.

With the increase of external load q, the total displacement a of the roof increased linearly, indicating that the damage degree of system instability to the working face increased with the increase of the external load, as shown in Figure 13. It can be seen from Figure 14 and Figure 15 that the thickness H of the immediate roof and the support stiffness k1 were inversely proportional to the roof step sinking. With the increase of the thickness H of the immediate roof and the support stiffness k1, the step sinking of the roof decreased, which was conducive to the stability of the working face. When the support stiffness and the immediate roof thickness changed within a small range, the increase of the support stiffness had a greater effect on ∆h. When the support stiffness was close to or exceeded the immediate roof stiffness, the effect on the roof step sinking became smaller until it basically remained unchanged. Therefore, increasing the support stiffness (i.e., support resistance) in a certain range played a positive role in reducing the roof step sinking and ensuring the stability of the working face.

When the thickness of the immediate roof increased to a certain value, the step sinking value remained basically stable, indicating that the larger the thickness of the rock layer, the more stable the immediate roof, as the overlying rock layer could easily form a self-supporting structure, and the influence of mining action on the roof sinking would be reduced. By comparing the three parameters, we that the influence degree on step sinking was overburden load q > immediate roof thickness H > support stiffness k1.

5.2. Engineering Example

On the basis of the above research, we analyzed the catastrophe instability condition of no. 12401 working face in Shendong mining area, calculating its reasonable support resistance to verify the theoretical analysis results. According to Equation (19), the necessary and sufficient conditions for system instability can be determined when hj = 17.6 m, H = 31.3 m, φ′ = 31°, E = 3.8 GPa, LZ = 14 m, h1 = 50 m, lA = 30.4 m, k1 = 2.3 × 105 kN/m, q = 1.33 MPa, u0 = 35 mm, ρg = 22.3 kN/m3, ρ1g = 16.3 kN/m3, φ = 27°, i = 0.67, tanφ′ = 0.6, tanφ = 0.5, λz = 0.54.

Combined with the calculation equation of the thickness of an immediate roof rock stratum [3]

where ∑h is the thickness of an immediate roof rock stratum, m; M is the thickness of coal seam, 6.2 m; P is the recovery rate of the working face, 80%; and kp is the bulking coefficient of the immediate roof rock stratum, 1.15–1.30, 1.25 in this study.

According to Equation (29), the thickness of the immediate roof was 31.3 m. Combined with the mining conditions of no. 12401 working face, the thickness of the immediate roof was 31.3 m when the collapsed gangue filled the goaf. Therefore, in the process of collapse, the mudstone with a thickness of 5.86 m and the fine sandstone with a thickness of 4.72 m above the coal seam will be transformed into an immediate roof and enter the goaf, forming a combined cantilever beam structure.

(1) Calculation of main roof step sinking

At the time of the working face first weighting, the step sinking of the main roof was between 210 mm and 235 mm, with an average of 224 mm. The theoretical calculation results were close to the monitoring data of the step sinking, which proved the rationality of the theoretical analysis. However, there was also a difference of 0.021 m, indicating that the immediate roof had undergone a catastrophic instability, resulting in the step sinking of the main roof, which was consistent with the measured results.

(2) Judgment of system stability

Necessary conditions for catastrophic instability:

From λ= EA/L, , and substituted into Equation (22)

Analysis of sufficient conditions for catastrophic instability

It can be found from the calculation results of the catastrophe instability criterion that the mechanical system composed of the no. 12401 working face can meet the necessary and sufficient conditions of instability. Under the current support conditions, the catastrophic instability of the system is prone to occur and induce roof accidents. It can be found from the in-site monitoring that the roof had different degrees of step sinking with the average subsidence of 224 mm during the first weighting. The rib fall of coal wall is serious, which proves that the theoretical calculation is consistent with the actual situation. Therefore, it is necessary to adjust the external conditions, such as increasing the support resistance or improving the advance speed, in order to prevent the roof cutting along the coal wall.

(3) Reasonable calculation of support resistance

The support resistance of system instability can be determined by Equation (28)

The calculated support resistance required to ensure the stability of the system was greater than the rated support resistance of 18,000 kN, and thus it is necessary to increase the support resistance to prevent roof cutting accidents and ensure the safety of the working face.

6. Conclusions and Summary

In this paper, the structural characteristics and instability process of the first weighting in large mining height working face were analyzed through a physical experiment and a numerical simulation, performed in order to study roof sliding and instability along the coal wall during the first weighting in the working face with large mining height in shallow coal seam. An analysis model based on catastrophe theory was developed to study roof sliding and instability along the coal wall. The necessary and sufficient conditions of system instability were obtained, and the main factors affecting the system stability were analyzed. The influence of each parameter on the stiffness ratio K was discussed and compared. The calculation equations of support resistance and roof step sinking were obtained, and the mechanical mechanism and main influence factors of the main roof step sinking were analyzed. Combined with the monitoring example, the rationality of judging roof instability by catastrophe theory was verified, and the rationality of the support resistance selected in the working face was checked. The following conclusions can be drawn through analysis of the theoretical results.

- (1)

- The formation and weighting characteristics of composite cantilever beam structure of the first weighting in large mining height working face were analyzed through a physical test and a numerical simulation. The premise of working face stability was to ensure that the direct roof was not destroyed.

- (2)

- The sufficient and necessary conditions for system instability were obtained by analyzing the system model consisting of main roof, immediate roof, and support through catastrophe theory. The system instability was related not only to the stiffness ratio K and material parameters of the support and immediate roof, but also to the load Q and the first weighting interval of the main roof.

- (3)

- The influence degree of each parameter on the stiffness ratio K was as follows: elastic modulus E > support stiffness k1 > sectional area A > immediate roof thickness H. Increasing the support stiffness within a certain range had a positive effect on reducing the roof step sinking.

- (4)

- The main roof step sinking ∆h increased linearly with the external load q, and was inversely proportional to the thickness of immediate roof h and support stiffness k1. By comparing the three parameters, we found that the influence degree on step sinking was overburden load q > immediate roof thickness H > support stiffness k1.

- (5)

- The stability of no. 12401 working face was calculated and analyzed by the catastrophe theory, with the calculation results showing that the working face met the instability condition of the system, which was consistent with the monitoring results, and the support resistance should be greater than 19,232 kN to ensure the stability of the main roof.

Author Contributions

In this article, D.Y. and Z.C. put forward the study ideas, D.Y. designed the article structure and wrote the paper, D.Y. conducted the theoretical derivation and analyzed the data, D.Y. and Y.Z. collected and analyzed the data from mine site, and Y.Z. and Z.C. revised the English writing. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (grant no. 51704173 and 51674151), and the Key R&D projects of Shandong Province (grant no. 2019GSF111029), the Science and Technology program of colleges and universities in Shandong Province (grant no. J17KA203), the National Program on Key Basic Research Project (2018YFC1505300), and the Qingdao postdoctoral researcher application research project.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| Q | the weight of overlying loose layer and main roof; |

| lA | the length of rock block A; |

| u | the compression amount of immediate roof rock mass; |

| w | the compression amount of support; |

| a | the total displacement of support - immediate roof; |

| k1 | the rigidity of support; |

| E | the initial value of elastic modulus; |

| λ | the initial stiffness of the rock mass; |

| u0 | the corresponding strain value under peak load; |

| λ1 | the absolute value of corresponding slope; |

| WJ | the work done by external force Q; |

| QA | the gravity of the main roof rock block; |

| hj | the main roof height; |

| Ρg | the main roof volume weight; |

| Qs | the load of overlying thick loose layer, according to the calculation principle of Terzaghi earth pressure; |

| ρ1g | the average volume weight of the load layer; |

| Φ | the internal friction angle of the load layer; |

| λz | the lateral stress ratio of the load layer; |

| FC | the friction caused by sliding instability; |

| θ1max | the maximum value of rock block rotating angle; |

| tanφ′ | the friction coefficient between rock block and gangue; |

| i | the main roof rock block size; |

| △h | the step sinking of roof; |

| K | the ratio of the support stiffness and the slope of the constitutive relation curve of the immediate roof rock mass at the inflection point; |

| ζ | the total displacement parameter; |

| μ | the support efficiency of the support; |

| ∑h | the thickness of an immediate roof rock stratum; |

| M | the thickness of coal seam; |

| P | the recovery rate of the working face; |

| kp | the bulking coefficient of the immediate roof rock stratum. |

References

- Huang, Q.X. Study on Roof Structure and Ground Control in Shallow Seam Longwall Mining; China University of Mining and Technology Press: Xuzhou, China, 2010. [Google Scholar]

- Yan, S.H.; Yin, X.W.; Xu, H.J.; Xu, G.; Liu, Q.M.; Yu, L. Roof structure of short cantilever-articulated rock beam and calculation of support resistance in full-mechanized face with large mining height. J. China Coal Soc. 2011, 36, 1816–1820. [Google Scholar]

- Li, H.M.; Jiang, D.J.; Li, D.Y. Analysis of ground pressure and roof movement in fully-mechanized top coal caving with large mining height in ultra-thick seam. J. China Coal Soc. 2014, 39, 1956–1960. [Google Scholar]

- JU, J.F.; Xu, J.L.; Wang, Q.X. Cantilever structure moving type of key strata and its influence on ground pressure in large mining height workface. J. China Coal Soc. 2011, 36, 2115–2120. [Google Scholar]

- JU, J.F.; Xu, J.L. Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 7.0m height chocks. Int. J. Rock Mech. Min. Sci. 2013, 58, 46–54. [Google Scholar] [CrossRef]

- Li, Z.; Xu, J.L.; Yu, S.C.; Ju, J.F.; Xu, J.M. Mechanism and Prevention of a Chock Support Failure in the Longwall Top-Coal Caving Faces: A Case Study in Datong Coalfield, China. Int. J. Energ. 2018, 11, 288. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Wang, S.R.; Zou, Z.S.; Ge, L.L.; Cui, F. Instability characteristics of the cracked roof rock beam under shallow mining conditions. Int. J. Min. Sci. Technol. 2018, 28, 437–444. [Google Scholar] [CrossRef]

- Wang, S.R.; Wu, X.G.; Zhao, Y.H.; Hagan, P.; Cao, C. Evolution characteristics of composite pressure-arch in thin bedrock of overlying strata during shallow coal mining. Int. J. App. Mech. 2019, 11, 3. [Google Scholar] [CrossRef]

- Szurgacz, D.; Brodny, J. Analysis of the Influence of Dynamic Load on the Work Parameters of a Powered Roof Support’s Hydraulic Leg. Sustainability 2019, 11, 2570. [Google Scholar] [CrossRef]

- Szurgacz, D.; Brodny, J. Tests of Geometry of the Powered Roof Support Section. Energies 2019, 12, 3945. [Google Scholar] [CrossRef]

- Yang, J.Z.; Liu, Q.J. Analysis and measured of strata behavior law and mechanism of 8.8 m ultra-high minging. Coal Sci. Technol. 2020, 48, 69–74. [Google Scholar]

- Huang, Q.X.; Dong, B.; Chen, S.S. Determination of roof pressure law and support resistance in the mining face with super-large mining height in approximate shallow coal seam. J. Min. Saf. Eng. 2016, 5, 840–844. [Google Scholar]

- Zhou, J.L.; Huang, Q.X. Stability analysis of key stratum structures of large mining height longwall face in shallow coal seam. Chin. J. Rock Mech. Eng. 2019, 38, 1396–1407. [Google Scholar]

- Pang, Y.H.; Wang, G.F.; Zhang, J.H.; Liu, H.L. Overlying strata fracture structure and stability control technology for ultra large mining height working face. Coal Sci. Technol. 2017, 45, 50–55. [Google Scholar]

- Xing, P.W.; Song, X.M.; Fu, Y.P. A Study on the Roof Fracture Mechanism of Large Cutting Height Workface in Shallow Thick Coal Seam. Adv. Mater. Res. 2011, 347–353, 183–188. [Google Scholar] [CrossRef]

- Sun, Y.J.; Zuo, J.P.; Karakus, M.; Wang, J.T. Investigation of movement and damage of integral overburden during shallow coal seam mining. Int. J. Rock Mech. Min. Sci. 2019, 117, 63–75. [Google Scholar] [CrossRef]

- Feng, J.F.; Zhou, Y.; Zhang, K.Z.; Jiang, D.J.; Liu, C. The influence of mining height increase on weighting intervals in the fully-mechanized panels of Shendong coal field. J. Min. Saf. Eng. 2017, 34, 632–636 and 643. [Google Scholar]

- Huang, P.; Ju, F.; Jessu, K.; Xiao, M.; Guo, S. Optimization and Practice of Support Working Resistance in Fully-Mechanized Top Coal Caving in Shallow Thick Seam. Energies 2017, 10, 1406. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Wang, X.Z.; Zhou, J.L.; Li, Q.S.; Zhang, C. Influence of main roof thickness-span ratio on the initial cracking induced instability in fully mechanized longwall face. J. China Coal Soc. 2019, 44, 94–104. [Google Scholar]

- Wang, J.C.; Wang, Z.H. Stability of main roof structure during the first weighting in shallow high-intensity mining face with thin bedrock. J. Min. Saf. Eng. 2015, 32, 175–181. [Google Scholar]

- Wang, C.L.; Zhang, C.S.; Zhao, X.D.; Liao, L.; Zhang, S.L. Dynamic structural evolution of overlying strata during shallow coal seam longwall mining. Int. J. Rock Mech. Min. Sci. 2018, 203, 20–32. [Google Scholar] [CrossRef]

- Yang, Z.L. Stability of nearly horizontal roof strata in shallow seam longwall mining. Int. J. Rock Mech. Min. Sci. 2010, 47, 672–677. [Google Scholar] [CrossRef]

- Zuo, J.P.; Sun, Y.J.; Liu, W.G.; Hu, B. Mechanical analysis and blasting mechanism of main roof initial fracturing in shallow depth mining face with large cutting height. J. China Coal Soc. 2016, 41, 2165–2172. [Google Scholar]

- Qian, M.G. Review of the Theory and Practice of Strata Control Around Longwall Face in Recent 20 Years. J. China Univ. Min. Technol. 2000, 29, 1–4. [Google Scholar]

- Liu, C.Y.; Qian, M.G.; Cao, S.G.; Miao, X.X. Structural mechanics characteristics and stiffness of immediate roof for coal faces. J. China Univ. Min. Technol. 1997, 26, 20–23. [Google Scholar]

- GAO, F.; Qian, M.G.; Miao, X.X. Mechanical analysis of the immediate roof subjected to given deformation of the main roof. Chin. J. Rock Mech. Eng. 2000, 19, 145–148. [Google Scholar]

- Gong, P.L.; Jin, Z.M. Mechanical model study on roof control for fully-mechanized coal face with large mining height. Chin. J. Rock Mech. Eng. 2008, 27, 193–198. [Google Scholar]

- Du, F.; Bai, H.B. Mechanical analysis of immediate roof in fully mechanized top coal caving mining with thin bedrock. J. China Coal Soc. 2013, 38, 1331–1337. [Google Scholar]

- Yuan, Y.; Tu, S.H.; Zhang, X.G.; Li, B. Dynamic effect and control of key strata break of immediate roof in fully mechanized mining with large mining height. Shock Vib. 2015, 2015, 1–11. [Google Scholar]

- Yang, S.L.; Wang, Z.H.; Kong, D.Z.; Cheng, Z.B.; Song, G.F. Overlying strata failure process and support resistance determination in large mining height face. J. Min. Saf. Eng. 2016, 33, 199–207. [Google Scholar]

- Wang, J.C.; Yang, S.L.; Li, Y.; Wang, Z.H. A dynamic method to determine the supports capacity in longwall coal mining. Int. J. Surf. Min. Reclam. Environ. 2015, 29, 277–288. [Google Scholar] [CrossRef]

- Wang, J.C.; Yang, S.L.; Kong, D.Z. Failure mechanism and control technology of longwall coalface in large-cutting-height mining method. Int. J. Min. Sci. Technol. 2016, 26, 111–118. [Google Scholar] [CrossRef]

- Liu, C.; Li, H.M.; Hani, M.; Jiang, D.J.; Li, H.G.; Feng, J.F. Voussoir beam model for lower strong roof strata movement in longwall mining-Case study. J. Rock Mech. Geotech. Eng. 2017, 9, 1171–1176. [Google Scholar] [CrossRef]

- Wang, F.T.; Tu, S.H.; Li, Z.X.; Tu, H.S.; Chen, F. Mutation instability mechanism of the room mining residual pillars in the shallow depth seam. J. Min. Saf. Eng. 2012, 29, 770–775. [Google Scholar]

- Xu, H.; Wang, Y.M.; Wu, A.X.; Li, F.F.; Gao, W.H. A computational model of safe thickness of roof under filling body based on cusp catastrophe theory. Chin. J. Rock Mech. Eng. 2017, 36, 579–586. [Google Scholar]

- Mu, C.L.; Pei, X.J.; Lu, J.F.; Pei, Z.; Xi, C.H. Study on the instability criterion of layered rock mass failure based on the cusp catastrophe theory. J. China Coal Soc. 2017, 42, 1429–1435. [Google Scholar]

- Xu, X.D.; Zhou, Y.J.; Pang, S. Analysis of catastrophic instability of plastic supporting system in old goaf of gypsum mine. Chin. J. Rock Mech. Eng. 2018, 37, 129–136. [Google Scholar]

- Mu, C.L.; Pei, X.J.; Lu, J.F. Study on Catastrophe Instability of Support System in Gypsum Goaf Based on Energy Dissipation Theory. Adv. Civil Eng. 2018, 2018, 1–9. [Google Scholar]

- Liu, C.Y.; Qian, M.G.; Cao, S.G.; Miao, X.X. Influencing mechanism of immediate roof on the relation between support s in the workings and surrounding rocks. J. China Coal Soc. 1997, 22, 471–476. [Google Scholar]

- Yang, S.L.; Wang, J.C.; Yang, J.H. Physical analog simulation analysis and its mechanical explanation on dynamic load impact. J. China Coal Soc. 2017, 42, 335–343. [Google Scholar]

- Keilich, W. Numerical Modelling of Mining Subsidence, Subsidence and Valley Closure Using UDEC. Ph.D. Thesis, University of Wollongong, Wollongong, Australia, 2009; pp. 13–14. [Google Scholar]

- Kazerani, T.; Zhao, J. Micro mechanical parameters in bonded particle method for modelling of brittle material failure. Int. J. Numer. Anal. Methods Geomech. 2010, 34, 1877–1895. [Google Scholar] [CrossRef]

- Christianson, M.; Board, M.; Rigby, D. UDEC simulation of triaxial testingx of lithophysal tuff. In Proceedings of the 41st US Symposium on Rock Mechanics (USRMS), Golden, CO, USA, 17–21 June 2006. [Google Scholar]

- Kou, M.; Liu, X.; Tang, S.; Wang, Y. 3-D X-ray computed tomography on failure characteristics of rock-like materials under coupled hydro-mechanical loading. Theor. Appl. Fract. Mech. 2019, 104, 102396. [Google Scholar] [CrossRef]

- Tang, C.A.; Xu, X.H. A cusp catastrophic model of rock unstable failure. Chin. J. Rock Mech. Eng. 1990, 9, 100–107. [Google Scholar]

- Chen, Z.H.; Tang, C.A.; Fu, Y.F. Study on sudden jump of deformation in unstable failure of rocks. J. Eng. Geol. 1997, 5, 143–149. [Google Scholar]

- Huang, Q.X.; Qi, W.T.; Yang, C.L. Analysis of mechanism and form of main roof breaking during first weighting in longwall face. J. Xi’an Univ. Sci. Technol. 1999, 19, 193–197. [Google Scholar]

- Huang, Q.X. Structural analysis of main roof stability during first weighting in longwall face. Chin. J. Rock Mech. Eng. 1998, 17, 521–526. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).