Measurement of Wheel Radius in an Automated Guided Vehicle

Abstract

1. Introduction

2. Determination of the Vehicle Position and the Role of the Rolling Radius

2.1. Movement of a Wheeled Vehicle

2.2. Wheel and Its Properties

3. An Overview of Selected Measurement methods

3.1. Introduction

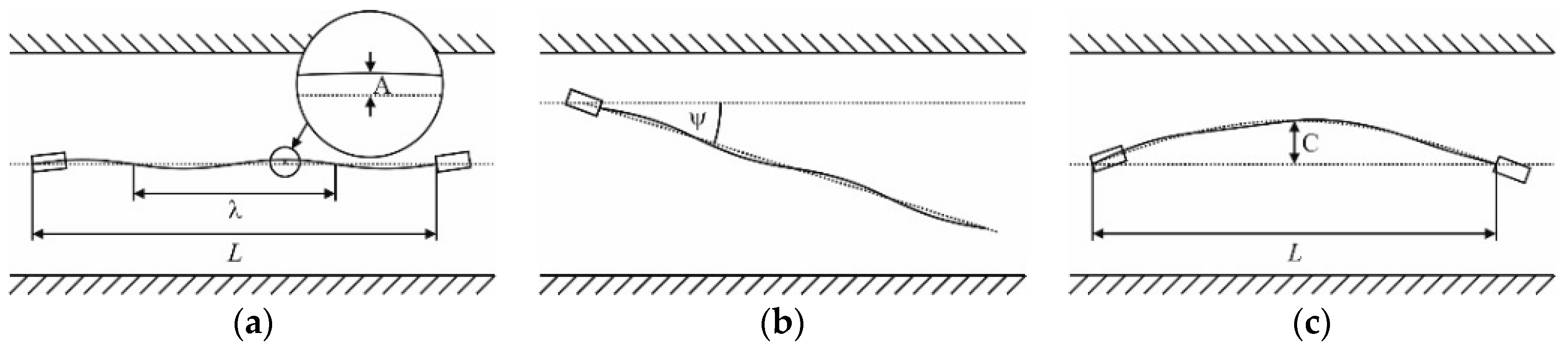

3.2. Methodology of Measurements in Curved Motion

3.3. Methodology of Measurements in Rectilinear Motion

3.4. Assessment of the Influence of Deviation from the Ideal Trajectory on the Value of the Rolling Radius

4. Research Outcomes and Their Analysis

4.1. Research Object

4.2. Research Results and Their Analysis

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Borenstein, J.; Feng, L. Measurement and correction of systematic odometry errors in mobile robots. IEEE Trans. Robot. Autom. 1996, 12, 869–880. [Google Scholar] [CrossRef]

- Chong, K.S.; Kleeman, L. Accurate odometry and error modelling for a mobile robot. In Proceedings of the IEEE International Conference on Robotics and Automation, Albuquerque, NM, USA, 25–25 April 1997. [Google Scholar] [CrossRef]

- Kelly, A. Linearized error propagation in odometry. Int. J. Robot. Res. 2004, 23, 179–218. [Google Scholar] [CrossRef]

- Epton, T.; Hoover, A. Improving odometry using a controlled point laser. Auton. Robot. 2012, 32, 165–172. [Google Scholar] [CrossRef]

- Lee, K.; Jung, C.; Chung, W. Accurate calibration of kinematic parameters for two wheel differential mobile robots. J. Mech. Sci. Technol. 2011, 25, 1603–1611. [Google Scholar] [CrossRef]

- Martinelli, A. The odometry error of a mobile robot with a synchronous drive system. IEEE Trans. Robot. Autom. 2002, 18, 399–405. [Google Scholar] [CrossRef]

- Jung, C.; Moon, C.; Jung, D.; Choi, J.; Chung, W. Design of test track for accurate calibration of two wheel differential mobile robots. Int. J. Precis. Eng. Manuf. 2014, 15, 53–61. [Google Scholar] [CrossRef]

- Kelly, A. Fast and easy systematic and stochastic odometry calibration. In Proceedings of the International Conference on Robots and Systems 2004 (IROS 2004), Sendai, Japan, 28 September–2 October 2004. [Google Scholar]

- Śmieszek, M.; Dobrzańska, M.; Dobrzański, P. Laser navigation applications for automated guided vehicles. Meas. Autom. Monit. 2015, 61, 503–506. [Google Scholar]

- Nguyen, V.; Gchter, S.; Martinelli, A.; Tomatis, N.; Siegwart, R. A comparison of line extraction algorithms using 2D range data for indoor mobile robotics. Auton. Robot. 2007, 23, 97–111. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, X. Prediction-based geometric feature extraction for 2D laser scanner. Robot. Auton. Syst. 2011, 59, 402–409. [Google Scholar] [CrossRef]

- Śmieszek, M.; Dobrzańska, M. Application of Kalman filter in navigation process of automated guided vehicles. Metrol. Meas. Syst. 2015, 22, 443–454. [Google Scholar] [CrossRef][Green Version]

- Kaniewski, P.; Gil, R.; Konatowski, S. Eestimation of UAV position with use of smoothing algorithms. Metrol. Meas. Syst. 2017, 24, 127–142. [Google Scholar] [CrossRef]

- Shen, K.; Selezneva, M.S.; Neusypin, K.A.; Proletarsky, A.V. Novel variable structure measurement system with intelligent components for flight vehicles. Metrol. Meas. Syst. 2017, 24, 347–356. [Google Scholar] [CrossRef]

- Dobrzańska, M.; Dobrzański, P.; Śmieszek, M.; Pawlus, P. Selection of Filtration Methods in the Analysis of Motion of Automated Guided Vehicle. Meas. Sci. Rev. 2016, 16, 183–189. [Google Scholar] [CrossRef]

- Meng, Q.; Bischoff, R. Odometry based pose determination and errors measurement for a mobile robot with two steerable drive wheels. J. Intell. Robot. Syst. 2005, 41, 263–282. [Google Scholar] [CrossRef]

- Ojeda, L.; Borenstein, J. Methods for the reduction of odometry errors in over-constrained mobile robots. Auton. Robot. 2004, 16, 273–286. [Google Scholar] [CrossRef]

- Song, X.; Seneviratne, L.; Althoefer, K. A vision based wheel slip estimation technique for mining vehicles. In Proceedings of the 2nd IFAC Workshop on Automation in Mining, Mineral and Metal Industry (IFACMMM), Vina del Mar, Chile, 14–16 October 2009. [Google Scholar]

- Antonelli, G.; Chiaverini, S. Linear estimation of the physical odometric parameters for differential-drive mobile robots. Auton. Robot. 2007, 23, 59–68. [Google Scholar] [CrossRef]

- Gutirrez, J.; Apostolopoulos, D.; Gordillo, J. Numerical comparison of steering geometries for robotic vehicles by modeling positioning error. Auton. Robot. 2007, 23, 147–159. [Google Scholar] [CrossRef]

- Doh, N.; Choset, H.; Chung, W. Relative localization using path odometry information. Auton. Robot. 2006, 21, 143–154. [Google Scholar] [CrossRef]

- Smieszek, M.; Dobrzanska, M.; Dobrzanski, P. The impact of load on the wheel rolling radius and slip in a small mobile platform. Auton. Robot. 2019, 43, 2095–2109. [Google Scholar] [CrossRef]

- Genta, G. Introduction to the Mechanics of Space Robots; Springer: New York, NY, USA, 2012; pp. 171–215. [Google Scholar]

- Jazar, R.N. Vehicle Dynamics Theory and Aplication; Springer: New York, NY, USA, 2008; pp. 98–161. [Google Scholar]

- Ellis, J.R. Vehicle Handling Dynamics; Wiley-Blackwell: London, UK, 1994; pp. 1–208. [Google Scholar]

- Sapietova, A.; Saga, M.; Kuric, I.; Vaclav, S. Application of optimization algorithms for robot systems designing. Int. J. Adv. Robot. Syst. 2018, 15, 1–10. [Google Scholar] [CrossRef]

| Force FN, N | Left Wheel | Right Wheel | ||

|---|---|---|---|---|

| r, m | σ × 10−6, m | r, m | σ × 10−6, m | |

| 790 | 0.10046 | 25.632 | 0.10030 | 23.935 |

| 1093 | 0.10049 | 25.103 | 0.10034 | 24.587 |

| 1376 | 0.10054 | 20.679 | 0.10041 | 18.644 |

| 1800 | 0.10058 | 37.081 | 0.10046 | 20.101 |

| Force FN (N) | 790 | 1093 | 1376 | 1800 |

|---|---|---|---|---|

| Left wheel | 0.000255 | 0.000250 | 0.000206 | 0.000369 |

| Right wheel | 0.000239 | 0.000245 | 0.000186 | 0.000200 |

| Additional Loading Force FN Over the Initial Value FN = 790 (N) | Radius of the Arc R (m) | Deviation from the Track to the Road L = 40 m (m) |

|---|---|---|

| 1010 | 503 | 1.59 |

| 2020 | 251 | 3.20 |

| 3030 | 168 | 4.84 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smieszek, M.; Dobrzanska, M.; Dobrzanski, P. Measurement of Wheel Radius in an Automated Guided Vehicle. Appl. Sci. 2020, 10, 5490. https://doi.org/10.3390/app10165490

Smieszek M, Dobrzanska M, Dobrzanski P. Measurement of Wheel Radius in an Automated Guided Vehicle. Applied Sciences. 2020; 10(16):5490. https://doi.org/10.3390/app10165490

Chicago/Turabian StyleSmieszek, Miroslaw, Magdalena Dobrzanska, and Pawel Dobrzanski. 2020. "Measurement of Wheel Radius in an Automated Guided Vehicle" Applied Sciences 10, no. 16: 5490. https://doi.org/10.3390/app10165490

APA StyleSmieszek, M., Dobrzanska, M., & Dobrzanski, P. (2020). Measurement of Wheel Radius in an Automated Guided Vehicle. Applied Sciences, 10(16), 5490. https://doi.org/10.3390/app10165490