Separation Process and Microstructure-Chemical Composition Relationship of Cenospheres from Lignite Fly Ash Produced from Coal-Fired Power Plant in Thailand

Abstract

1. Introduction

2. Materials and Methods

2.1. Cenospheres Separation

2.2. Fly Ash and Cenospheres Identification

3. Results and Discussion

3.1. Cenospheres Recovery Yield

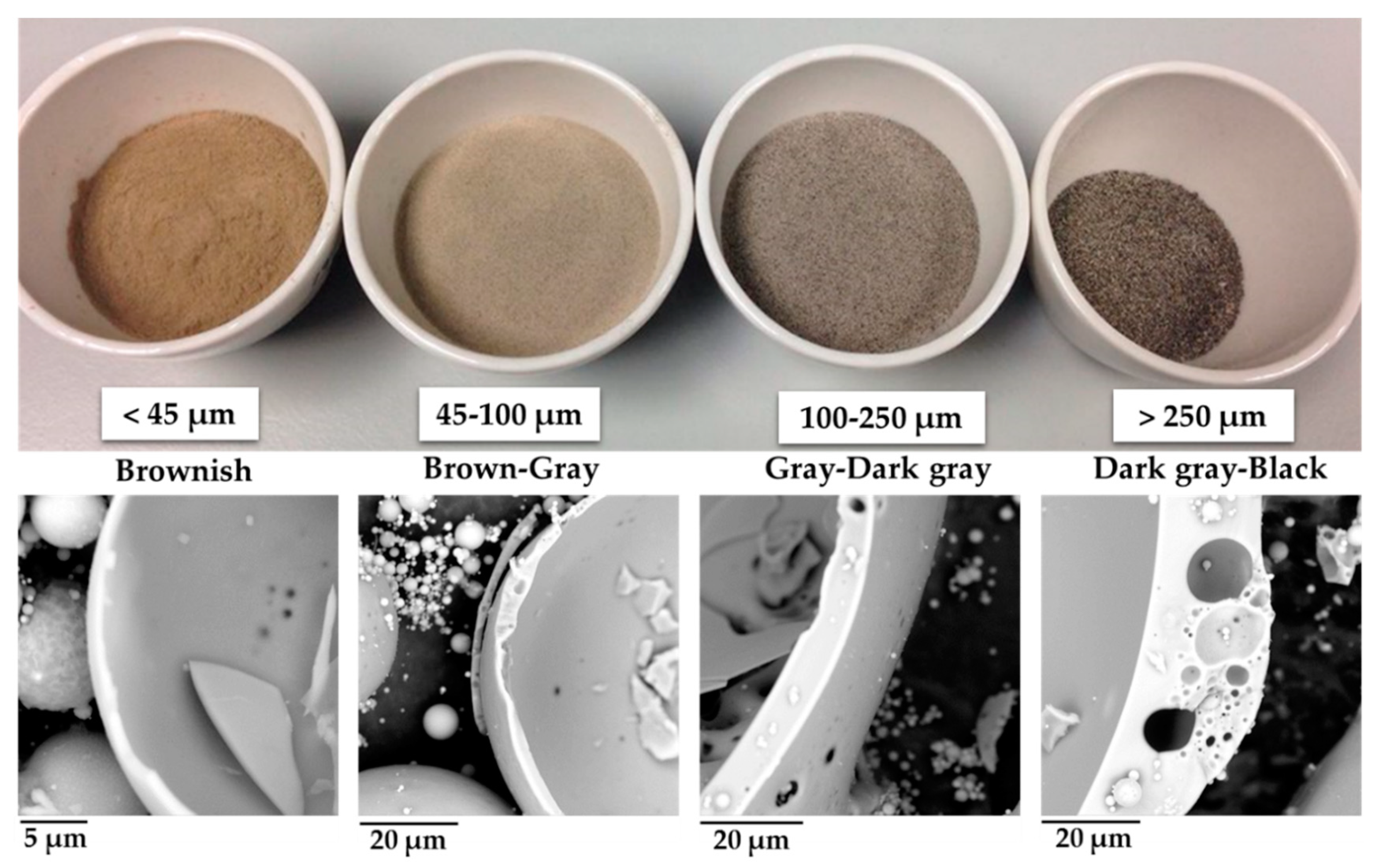

3.2. Physical Properties of Cenospheres

3.3. Morphologies of Cenospheres

3.4. Chemical Composition

) comparing to the smaller particles (

) comparing to the smaller particles ( ,

,  ) is probably due to a phenomenon observed in many studies; the SiO2 and Al2O3 contents reduced with increasing the particle size, while the extent of Al2O3 content reduction was measured in a very low amount with respect to the SiO2 content [13,34,50]. The small particles (<45–250 µm,

) is probably due to a phenomenon observed in many studies; the SiO2 and Al2O3 contents reduced with increasing the particle size, while the extent of Al2O3 content reduction was measured in a very low amount with respect to the SiO2 content [13,34,50]. The small particles (<45–250 µm,  ,

,  ,

,  ) having lower SiO2/Al2O3 ratio (~2.1–2.2) have a single-ring shell structure, whereas the larger cenospheres particles (>250 µm,

) having lower SiO2/Al2O3 ratio (~2.1–2.2) have a single-ring shell structure, whereas the larger cenospheres particles (>250 µm,  ) having higher SiO2/Al2O3 ratio (~2.3) have a porous wall shell structure, more likely in a network shell formed structure. An observation was reported on the relation between the SiO2/Al2O3 ratio and the shell structure for the cenospheres separated from Class F fly ash. A high SiO2/Al2O3 ratio (2.57) was found favorably to form small particles (<25 µm) with a spherical shape and the single-ring shell structure, while the relatively larger cenosphere particles (63–150 µm) with a network structure have a relatively lower SiO2/Al2O3 ratio (1.64–1.8) [16]. To this point of view, it is interesting to note herein that there is a significant variation in chemical composition and cenospheres yield across the power stations and fly ash sources. The chemistry in cenospheres is strongly governed by the process of ash cenospheres formation in the furnace. The chemical composition of the molten droplets associated with the temperature in the furnace considerably determined the particle size of cenospheres [16,69]. The formation of large particle size was attributed to a result of an increased Al content that increases viscosity of the molten droplets, in turn stabilizing them during the expansion, rather than exploding into small fragments [18]. Besides, the higher SiO2/Al2O3 ratio was suggested as an index parameter for a lower ash sintering temperature, favoring a ring structure [16,70].

) having higher SiO2/Al2O3 ratio (~2.3) have a porous wall shell structure, more likely in a network shell formed structure. An observation was reported on the relation between the SiO2/Al2O3 ratio and the shell structure for the cenospheres separated from Class F fly ash. A high SiO2/Al2O3 ratio (2.57) was found favorably to form small particles (<25 µm) with a spherical shape and the single-ring shell structure, while the relatively larger cenosphere particles (63–150 µm) with a network structure have a relatively lower SiO2/Al2O3 ratio (1.64–1.8) [16]. To this point of view, it is interesting to note herein that there is a significant variation in chemical composition and cenospheres yield across the power stations and fly ash sources. The chemistry in cenospheres is strongly governed by the process of ash cenospheres formation in the furnace. The chemical composition of the molten droplets associated with the temperature in the furnace considerably determined the particle size of cenospheres [16,69]. The formation of large particle size was attributed to a result of an increased Al content that increases viscosity of the molten droplets, in turn stabilizing them during the expansion, rather than exploding into small fragments [18]. Besides, the higher SiO2/Al2O3 ratio was suggested as an index parameter for a lower ash sintering temperature, favoring a ring structure [16,70].3.5. Phase Composition

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jinawath, S.; Thitianan, C. Production of Multiphase Plaster and Anhydrite from Mae Moh Flue-Gas Desulphurised Gypsum. Adv. Cem. Res. 2002, 14, 121–126. [Google Scholar] [CrossRef]

- Brigden, K.; Santillo, D.; Stringer, R. Hazardous Emissions from Thai Coal-Fired Power Plants: Toxic and Potentially Toxic Elements in Fly Ashes Collected from Mae Moh Thai Petrochemical Industry Coal-Fired Power Plants in Thailand, 2002; Greenpeace Research Laboratories, Department of Biological Sciences, University of Exeter: Exeter, UK, 2002. [Google Scholar]

- Jayaranjan, M.L.D.; Hullebusch, E.D.V.; Annachhatre, A.P. Reuse Options for Coal Fired Power Plant Bottom Ash and Fly Ash. Rev. Environ. Sci. Bio. Technol. 2014, 13, 467–486. [Google Scholar] [CrossRef]

- Punyawadee, V.; Ratana, P.; Winichaikule, N.; Satienperakul, K. Costs and Benefits of Flue Gas Desulfurization for Pollution Control at the Mae Moh Power Plant, Thailand. ASEAN Econ. Bull. 2008, 25, 99–112. [Google Scholar] [CrossRef]

- Tangtermsirikul, S. Development of fly ash usage in Thailand. Soc. Soc. Manag. Syst. Int. J. 2005, 1, 12. [Google Scholar]

- Tangtermsirikul, S.; Kaewkhluab, T.; Jitvutikrai, P. A Compressive Strength Model for Roller-Compacted Concrete with Fly Ash. Mag. Concr. Res. 2004, 56, 35–44. [Google Scholar] [CrossRef]

- Karasawa, A.; Suda, S.; Naito, H.; Fujiwara, H. Application of Fly Ash to Concrete Paving Block. In Proceedings of the 7th International Conference on Concrete Block Paving (PAVE AFRICA 2003), Sun City, South Africa, 12–15 October 2003. [Google Scholar]

- Ohenoja, K.; Pesonen, J.; Yliniemi, J.; Illikainen, M. Utilization of Fly Ashes from Fluidized Bed Combustion: A Review. Sustainability 2020, 12, 2988. [Google Scholar] [CrossRef]

- Sathonsaowaphak, A.; Chindaprasirt, P.; Pimraksa, K. Workability and Strength of Lignite Bottom Ash Geopolymer Mortar. J. Hazard. Mater. 2009, 168, 44–50. [Google Scholar] [CrossRef]

- Antoni Klarens, K.; Indranata, M.; Jamali, L.A.; Hardjito, D. The Use of Bottom Ash for Replacing Fine Aggregate in concrete Paving Blocks. In Proceedings of the MATEC Web of Conferences, Hong Kong, China, 1–3 July 2017; p. 1005. [Google Scholar]

- American Society for Testing and Materials. Standard Specification for Portland Cement. In ASTM C150/C150M-20; American Society for Testing and Materials: West Conshohocken, PA, USA, 2020. [Google Scholar]

- EGAT Sustainability Report. Available online: https://www.egat.co.th/en/images/sustainable-dev/csr-report/EGAT-CSR-Annual-2018-en/EGAT-CSR-2018.EN.pdf. (accessed on 1 May 2020).

- Vassilev, S.V.; Menendez, R.; Diaz-Somoano, M.; Martinez-Tarazona, M.R. Phase-Mineral and Chemical Composition of Coal Fly Ashes as a Basis for their Multicomponent Utilization. 2. Characterization of Ceramic Cenosphere and Salt Concentrates. Fuel 2004, 83, 585–603. [Google Scholar] [CrossRef]

- Fomenko, E.V.; Anshits, N.N.; Solovyov, L.A.; Mikhaylova, O.A.; Anshits, A.G. Composition and Morphology of Fly Ash Cenospheres Produced from the Combustion of Kuznetsk Coal. Energy Fuels 2013, 27, 5440–5448. [Google Scholar] [CrossRef]

- Li, Y.; Gao, X.; Wu, H. Ash Cenosphere from Solid Fuels Combustion. Part 2: Significant Role of Ash Cenosphere Fragmentation in Ash and Particulate Matter Formation. Energy Fuels 2013, 27, 822–829. [Google Scholar] [CrossRef]

- Ngu, L.-N.; Wu, H.; Zhang, D.-K. Characterization of Ash Cenospheres in Fly Ash from Australian Power Stations. Energy Fuels 2007, 21, 3437–3445. [Google Scholar] [CrossRef]

- Manocha, L.M.; Ram, K.A.; Manocha, S.M. Separation of Cenospheres from Fly Ashes by Floatation Method. Eurasian Chemtech. J. 2011, 12, 89–95. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A Review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Blanco, F.; García, P.; Mateos, P.; Ayala, J. Characteristics and Properties of Lightweight Concrete Mmanufactured with Cenospheres. Cem. Concr. Res. 2000, 30, 1715–1722. [Google Scholar] [CrossRef]

- Barbare, N.; Shukla, A.; Bose, A. Uptake and Loss of Water in a Cenosphere-Concrete Composite Material. Cem. Concr. Res. 2003, 33, 1681–1686. [Google Scholar] [CrossRef]

- McBride, S.P.; Shukla, A.; Bose, A. Processing and Characterization of a Lightweigth Concrete using Cenospheres. J. Mater. Sci. 2002, 37, 4217–4225. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, K.; Tang, Y.; Hu, C. Preparation of a Cenosphere Curing Agent and Its Application to Foam Concrete. Adv. Mater. Sci. Eng. 2019, 2019, 1–9. [Google Scholar] [CrossRef]

- Cardoso, R.; Shukla, A.; Bose, A. Effect of Particle Size and Surface Treatment on Constitutive Properties of Polyester-Cenosphere Composites. J. Mater. Sci. 2002, 37, 603–613. [Google Scholar] [CrossRef]

- Chalivendra, V.B.; Shukla, A.; Bose, A.; Parameswarn, V. Processing and Mechanical Characterization of Lightweight Polyurethane Composites. J. Mater. Sci. 2003, 38, 1631–1643. [Google Scholar] [CrossRef]

- Wasekar, P.A.; Kadam, P.G.; Mhaske, S.T. Effect of Cenosphere Concentration on the Mechanical, Thermal, Rheological and Morphological Properties of Nylon 6. J. Miner. Mater. Charact. Eng. 2012, 11, 807–812. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Van Erp, G.; Aravinthan, T.; Ghabraie, K. Evaluation of an Innovative Composite Railway Sleeper for a Narrow-Gauge Track under Static Load. J. Compos. Constr. 2018, 22, 1–13. [Google Scholar] [CrossRef]

- Tiwari, V.; Shukla, A.; Bose, A. Acoustic Properties of Cenosphere Reinforced Cement and Asphalt Concrete. Appl. Acoust. 2004, 65, 263–275. [Google Scholar] [CrossRef]

- Yoriya, S.; Intana, T.; Tepsri, P. Separation of Cenospheres from Lignite Fly Ash Using Acetone-Water Mixture. Appl. Sci. 2019, 9, 3792. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A. Formation Mechanism and Applications of Cenospheres: A Review. J. Mater. Sci. 2020, 55, 4539. [Google Scholar] [CrossRef]

- Sahu, P.K.; Mahanwar, P.A.; Bambole, V.A. Effect of Hollow Glass Microspheres and Cenospheres on Insulation Properties of Coatings. Pigment Resin Technol. 2013, 42, 223–230. [Google Scholar] [CrossRef]

- Joseph, K.V.; Francis, F.; Chacko, J.; Das, P.; Hebbar, G.S. Fly ash Cenosphere Waste Formation in Coal Fired Power Plants and Its Application as a Structural Material—A Review. Int. J. Eng. Res. Technol. 2013, 2, 1236–1260. [Google Scholar]

- Shao, Y.; Jia, D.; Zhou, Y.; Liu, B. Novel Method for Fabrication of Silicon Nitride/Silicon Oxynitride Composite Ceramic Foams using Fly Ash Cenosphere as a Pore-Forming Agent. J. Am. Ceram. Soc. 2008, 91, 3781–3785. [Google Scholar] [CrossRef]

- Gupta, N.W.E.; Mensah, P. Compression Properties of Syntactic Foams: Effect of Cenosphere Radius Ratio and Specimen Aspect Ratio. Compos. Part A Appl. Sci. Manuf. 2004, 35, 103–111. [Google Scholar] [CrossRef]

- Li, Y.; Gao, X.; Wu, H. Further Investigation into the Formation Mechanism of Ash Cenospheres from an Australian Coal-Fired Power Station. Energy Fuels 2013, 27, 811–815. [Google Scholar] [CrossRef]

- Hirajima, T.; Petrus, H.; Oosako, Y.; Nonaka, M.; Sasaki, K.; Ando, T. Recovery of Cenospheres from Coal Fly Ash using a Dry Separation Process: Separation Estimation and Potential Application. Int. J. Miner. Process. 2010, 95, 18–24. [Google Scholar] [CrossRef]

- Petrus, H.; Hirajima, T.; Oosako, Y.; Nonaka, M.; Sasaki, K.; Ando, T. Performance of Dry-Separation Processes in the Recovery of Cenospheres from Fly Ash and their Implementation in a Recovery Unit. Int. J. Miner. Process. 2011, 98, 15–23. [Google Scholar] [CrossRef]

- Sokol, E.; Maksimova, N.; Volkova, N.; Nigmatulina, E.; Frenkel, A. Hollow Silicate Microspheres from Fly Ashes of the Chelyabinsk Brown Coals (South Urals, Russia). Fuel Process. Technol. 2000, 67, 35–52. [Google Scholar] [CrossRef]

- Ramme, B.W.; Noegel, J.J.; Rohatgi, P.K. Separation of Cenospheres from Fly Ash. U.S. Patent No. 8,074,804, 13 December 2011. [Google Scholar]

- Kruger, R.; Toit, P. Recovery and Characterization of Cenospheres from South African Power Plants. In Proceedings of the Ninth International Ash Use Symposium, ACAA, Palo Alto, CA, USA, 3 January 1991; pp. 1–76. [Google Scholar]

- Kolay, P.K.; Singh, D.N. Physical Chemical, Mineralogical, and Thermal Properties of Cenospheres from an Ash Lagoon. Cem. Concr. Res. 2001, 31, 539–542. [Google Scholar] [CrossRef]

- Sarkar, A.; Rano, R.; Mishra, K.; Mazumder, A. Characterization of Cenospheres Collected from Ash-Pond of a Super Thermal Power Plant. Energy Sources Part A Recover. Util. Environ. Eff. 2007, 30, 271–283. [Google Scholar] [CrossRef]

- Drozhzhin, V.S.; Shpirt, M.Y.; Danilin, L.D.; Kuvaev, M.D.; Pikulin, I.V.; Potemkin, G.A. Formation Processes and Main Properties of Hollow Aluminosilicate Microspheres in Fly Ash from Thermal Power Stations. Solid Fuel Chem. 2008, 42, 107–119. [Google Scholar] [CrossRef]

- Fenelonov, V.B.; Mel’gunov, M.S.; Parmon, V.N. The Properties of Cenospheres and the Mechanism of their Formation during High-Temperature Coal Combustion at Thermal Power Plants. Kona Powder Part. J. 2010, 28, 189–208. [Google Scholar] [CrossRef]

- Kolay, P.K.; Bhusal, S. Recovery of Hollow Spherical Particles with Two Different Densities from Coal Fly Ash and their Characterization. Fuel 2014, 117, 118–124. [Google Scholar] [CrossRef]

- Żyrkowski, M.; Neto, R.C.; Santos, L.F.; Witkowski, K. Characterization of Fly-ash Cenospheres from Coal-Fired Power Plant Unit. Fuel 2016, 174, 49–53. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. In ASTM C618-12a; American Society for Testing and Materials: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Bachus, R.C.; Terzariol, M.; Pasten, C.; Chong, S.H.; Dai, S.; Cha, M.S.; Kim, S.; Jang, J.; Papadopoulos, E.; Roshankhah, S.; et al. Characterization and Engineering Properties of Dry and Ponded Class-F Fly Ash. J. Geotech. Geoenviron. Eng. 2019, 145, 4019003. [Google Scholar] [CrossRef]

- Ultrapyc: True Volume and Density Analyzer Operating Manual. Available online: http://eodg.atm.ox.ac.uk/eodg/equipment/Pycnometer_user_manual.pdf (accessed on 22 July 2020).

- Tepsri, P.; Chumphu, A.; Yoriya, S. High-Calcium Fly Ash Recovery from Wet-Stored Condition and its Properties. Mater. Res. Express 2018, 5, 115506. [Google Scholar] [CrossRef]

- Fomenko, E.V.; Anshits, N.N.; Vasilieva, N.G.; Mikhaylova, O.A.; Rogovenko, E.S.; Zhizhaev, A.M.; Anshits, A.G. Characterization of Fly ash Cenospheres Produced from the Combustion of Ekibastuz Coal. Energy Fuels 2015, 29, 5390–5403. [Google Scholar] [CrossRef]

- Anshits, N.; Mikhailova, O.; Salanov, A.; Anshits, A. Chemical Composition and Structure of the Shell of Fly Ash Non-Perforated Cenospheres Produced from the Combustion of the Kuznetsk Coal. Fuel 2010, 89, 1849–1862. [Google Scholar] [CrossRef]

- Kutchko, B.G.; Kim, A.G. Fly Ash Characterization by SEM–EDS. Fuel 2006, 85, 2537–2544. [Google Scholar] [CrossRef]

- Pintana, P.; Tippayawong, N.; Nuntaphun, A.; Thongchiew, P. Characterization of Slag from Combustion of Pulverized Lignite with High Calcium Content in Utility Boiler. Energy Explor. Exploit. 2014, 32, 471–482. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. Mineralogy of Combustion Wastes from Coal-Fired Power Stations. Fuel Process. Technol. 1996, 47, 261–280. [Google Scholar] [CrossRef]

- Hower, J.C.; Rathbone, R.F.; Robertson, J.D.; Peterson, G.; Trimble, A.S. Petrology, Mineralogy, and Chemistry of Magnetically-Separated Sized Fly Ash. Fuel 1999, 78, 197–203. [Google Scholar] [CrossRef]

- Anshits, N.N.; Fedorchak, M.A.; Fomenko, E.V.; Mazurova, E.V.; Anshits, A.G. Composition, Structure, and Formation Routes of Blocklike Ferrospheres Separated from Coal and Lignite Fly Ashes. Energy Fuels 2020, 34, 3743–3754. [Google Scholar] [CrossRef]

- McArthur, H.; Spalding, D. Engineering Materials Science: Properties, Uses, Degradation, Remediation, 1st ed.; Wookhead Publishing: Philadelphia, PA, USA, 2004. [Google Scholar]

- Molar Mass, Molecular Weight and Elemental Composition Calculator. Available online: https://www.webqc.org/mmcalc.php (accessed on 22 July 2020).

- Vassilev, S.V.; Eskenazy, G.M.; Vassileva, C.G. Behaviour of Elements and Minerals during Preparation and Combustion of the Pernik Coal, Bulgaria. Fuel Process. Technol. 2001, 72, 103–129. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Eskenazy, G.M.; Vassileva, C.G. Contents, Modes of Occurrence and Behavior of Chlorine and Bromine in Combustion Wastes from Coal-Fired Power Stations. Fuel 2000, 79, 923–937. [Google Scholar] [CrossRef]

- Zandi, M.; Russell, N.V. Design of a Leaching Test Framework for Coal Fly Ash Accounting for Environmental Conditions. Environ. Monit. Assess. 2007, 131, 509–526. [Google Scholar] [CrossRef]

- Leelarungroj, K.; Likitlersuang, S.; Chompoorat, T.; Janjaroen, D. Leaching Mechanisms of Heavy Metals from Fly Ash Stabilised Soils. Waste Manag. Res. 2018, 36, 616–623. [Google Scholar] [CrossRef]

- Hart, B.R.; Powell, M.A.; Fyfe, W.S.; Ratanasthien, B. Geochemistry and Mineralogy of Fly-Ash from the Mae Moh Lignite Deposit, Thailand. Energy Sources 2007, 17, 23–40. [Google Scholar] [CrossRef]

- Egemen, E.; Yurteri, C. Regulatory Leaching Tests for Fly Ash: A Case Study. Waste Manag. Res. 1996, 14, 43–50. [Google Scholar] [CrossRef]

- Baykal, G.; Saygili, A. A New Technique to Reduce the Radioactivity of Fly Ash Utilized in the Construction Industry. Fuel 2011, 90, 1612–1617. [Google Scholar] [CrossRef]

- Nisnevich, M.; Sirotin, G.; Schlesinger, T.; Eshel, Y. Radiological Safety Aspects of Utilizing Coal Ashes for Production of Lightweight Concrete. Fuel 2008, 87, 1610–1616. [Google Scholar] [CrossRef]

- Papaefthymiou, H.; Gouseti, O. Natural Radioactivity and Associated Radiation Hazards in Building Materials Used in Peloponnese, Greece. Radiat. Meas. 2008, 43, 1453–1457. [Google Scholar] [CrossRef]

- Vassilev, S.; Menendez, R.; Alvarez, D.; Diaz-Somoano, M.; Martinez-Tarazona, M. Phase-Mineral and Chemical Composition of Coal Fly Ashes as a Basis for their Multicomponent Utilization. 1. Characterization of Feed Coals and Fly Ashes. Fuel 2003, 82, 1793–1811. [Google Scholar] [CrossRef]

- Li, Y.; Wu, H. Ash Cnosphere from Solid Fuels Combustion. Part 1: An Investigation into its Formation Mechanism using Pyrite as a Model Fuel. Energy Fuels 2012, 26, 130–137. [Google Scholar] [CrossRef]

- Gupta, S.; Gupta, R.; Bryant, G.; Wall, T. The Effect of Potassium on the Fusibility of Coal Ashes with High Silica and Alumina Levels. Fuel 1998, 77, 1195–1201. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Karayigit, A.I.; Bulut, Y.; Alastuey, A.; Querol, X. Phase-Mineral and Chemical Composition of Fractions Separated from Composite Fly Ashes at the Soma Power Station, Turkey. Int. J. Coal Geol. 2005, 61, 65–85. [Google Scholar] [CrossRef]

- Fischer, R.X.; Schneider, H.; Schmucker, M. Crystal Structure of Al-Rich Mullite. Am. Miner. 1994, 79, 983–990. [Google Scholar]

| Item | Unit 12 |

|---|---|

| Density (g/cc) | 2.48 |

| %Free lime | 1.43 |

| %SO3 | 2.72 |

| Average particle size (D [4,3], μm) | 41.51 |

| Sample | Size Distribution (Wt.%) | |||||

|---|---|---|---|---|---|---|

| <1 µm | 1–10 µm | 10–50 µm | 50–100 µm | 100–250 µm | 250–500 µm | |

| Fresh fly ash | 8.13 | 32.66 | 33.08 | 14.33 | 10.89 | 0.91 |

| Method | Condition | Cenospheres Recovery (%) 1 |

|---|---|---|

| Sink-float method | Manual stirring | 1.43 |

| Ultrasonication | 1.52 | |

| Size sieving | 1.55 |

| Item | Size Range | |||

|---|---|---|---|---|

| <45 µm | 45–100 µm | 100–250 µm | >250 µm | |

| Weight fraction (wt.%) | 6.83 | 46.48 | 41.06 | 3.56 |

| Density (g/cm3) | 1.40 ± 0.01 | 0.76 ± 0.01 | 1.24 ± 0.04 | 1.93 ± 0.01 |

| Average size, D [4,3] (µm) | 25.9 | 46.9 | 93.7 | 229.2 |

| Item | Composition (Wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | SO3 | K2O | TiO2 | MnO | |

| Fly ash | 32.12 ± 0.29 | 13.82 ± 0.19 | 14.55 ± 0.27 | 24.49 ± 0.05 | 12.03 ± 0.26 | 2.31 ± 0.02 | 0.55 ± 0.02 | 0.55 ± 0.01 |

| Cenospheres | ||||||||

| Bulk | 47.23 ± 0.56 | 22.92 ± 0.14 | 9.71 ± 0.48 | 10.89 ± 0.27 | 3.98 ± 0.12 | 4.54 ± 0.15 | 0.80 ± 0.02 | 0.06 ± 0.00 |

| <45 µm | 41.31 ± 0.16 | 19.61 ± 0.21 | 12.62 ± 0.15 | 15.50 ± 0.13 | 6.47 ± 0.10 | 3.76 ± 0.02 | 0.63 ± 0.00 | 0.11 ± 0.005 |

| 45–105 µm | 53.39 ± 0.17 | 25.02 ± 0.06 | 7.84 ± 0.06 | 6.36 ± 0.11 | 1.88 ± 0.11 | 4.72 ± 0.07 | 0.78 ± 0.02 | 0.06 ± 0.001 |

| 106–250 µm | 51.92 ± 0.23 | 23.72 ± 0.13 | 9.70 ± 0.11 | 8.28 ± 0.21 | 1.99 ± 0.04 | 3.57 ± 0.04 | 0.77 ± 0.005 | 0.06 ± 0.003 |

| >250 µm | 49.71 ± 0.93 | 20.80 ± 0.59 | 11.62 ± 0.99 | 11.56 ± 0.29 | 2.28 ± 0.31 | 3.23 ± 0.15 | 0.72 ± 0.02 | 0.08 ± 0.001 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoriya, S.; Tepsri, P. Separation Process and Microstructure-Chemical Composition Relationship of Cenospheres from Lignite Fly Ash Produced from Coal-Fired Power Plant in Thailand. Appl. Sci. 2020, 10, 5512. https://doi.org/10.3390/app10165512

Yoriya S, Tepsri P. Separation Process and Microstructure-Chemical Composition Relationship of Cenospheres from Lignite Fly Ash Produced from Coal-Fired Power Plant in Thailand. Applied Sciences. 2020; 10(16):5512. https://doi.org/10.3390/app10165512

Chicago/Turabian StyleYoriya, Sorachon, and Phattarathicha Tepsri. 2020. "Separation Process and Microstructure-Chemical Composition Relationship of Cenospheres from Lignite Fly Ash Produced from Coal-Fired Power Plant in Thailand" Applied Sciences 10, no. 16: 5512. https://doi.org/10.3390/app10165512

APA StyleYoriya, S., & Tepsri, P. (2020). Separation Process and Microstructure-Chemical Composition Relationship of Cenospheres from Lignite Fly Ash Produced from Coal-Fired Power Plant in Thailand. Applied Sciences, 10(16), 5512. https://doi.org/10.3390/app10165512