Nondestructive Evaluation of Solids Based on Deformation Wave Theory

Abstract

:1. Introduction

2. Field Theory of Deformation and Fracture

2.1. Field Theory Overview

2.2. Field Equations

2.2.1. Elasto-Plastic Dynamics

2.2.2. Fracture Dynamics

2.3. Conditions for Deformation Stages and Wave Equations

2.3.1. Linear Elastic Stage

2.3.2. Elasto-Plastic Stage

2.3.3. Fracturing Stage

2.4. Wave Equations

2.4.1. Linear Elastic Stage

2.4.2. Elasto-Plastic Stage

2.4.3. Fracturing Stage

3. Experimental and Numerical Methods

3.1. Experimental

3.2. Finite Element Model

4. Results and Discussions

4.1. Transition from Linear Elastic to Elasto-Plastic Regime

4.2. Propagation of Elasto-Plastic Wave

5. Summary and Concluding Remarks

- The fringe patterns obtained at approximately one-third of the yield strain exhibit the elastic deformation criterion.

- The fringe patterns obtained at 80–90% of the yield strain indicate , one of the conditions constituting the plastic deformation criterion. The u (the differential displacement component perpendicular to the tensile axis) fringe patterns obtained at approximately 95% of the yield strain show a circular pattern that represents the transverse-wave in the plastic stage. These observations indicate that plastic deformation starts 10–15% prior to the yield point.

- When the normal strain reaches 2.19% past the yield strain of 1.0%, the u and v fringe patterns start to show traveling wave like behaviors. The numerical solutions to the wave equations confirm that these fringe patterns represent the transverse wave characteristics in the u-component and the longitudinal wave characteristics in the v-component of the differential displacement vector. The transverse and longitudinal waves propagate along the length of the specimen at the same speed. From this post-yield stage onward until the stress reaches the peak on the stress-strain curve, the wave motions repeat.

- In the above-mentioned post-yield stage, the u and v fringe patterns are not uniformly distributed along the length of the specimen. This makes the u fringe consist of two half-circle patterns and the v fringe concentrated over approximately half the length of the specimen. The pair of half-circles in the u pattern is initially horizontally symmetric, and it propagates along the specimen length maintaining the half-circle shape. As the stress increases, the semi-circle patterns become asymmetric, and approximately linear slant fringe patterns (shear bands) appear between the asymmetrically located semi-circle patterns. The shear band propagates at the same speed as the semi-circle patterns.

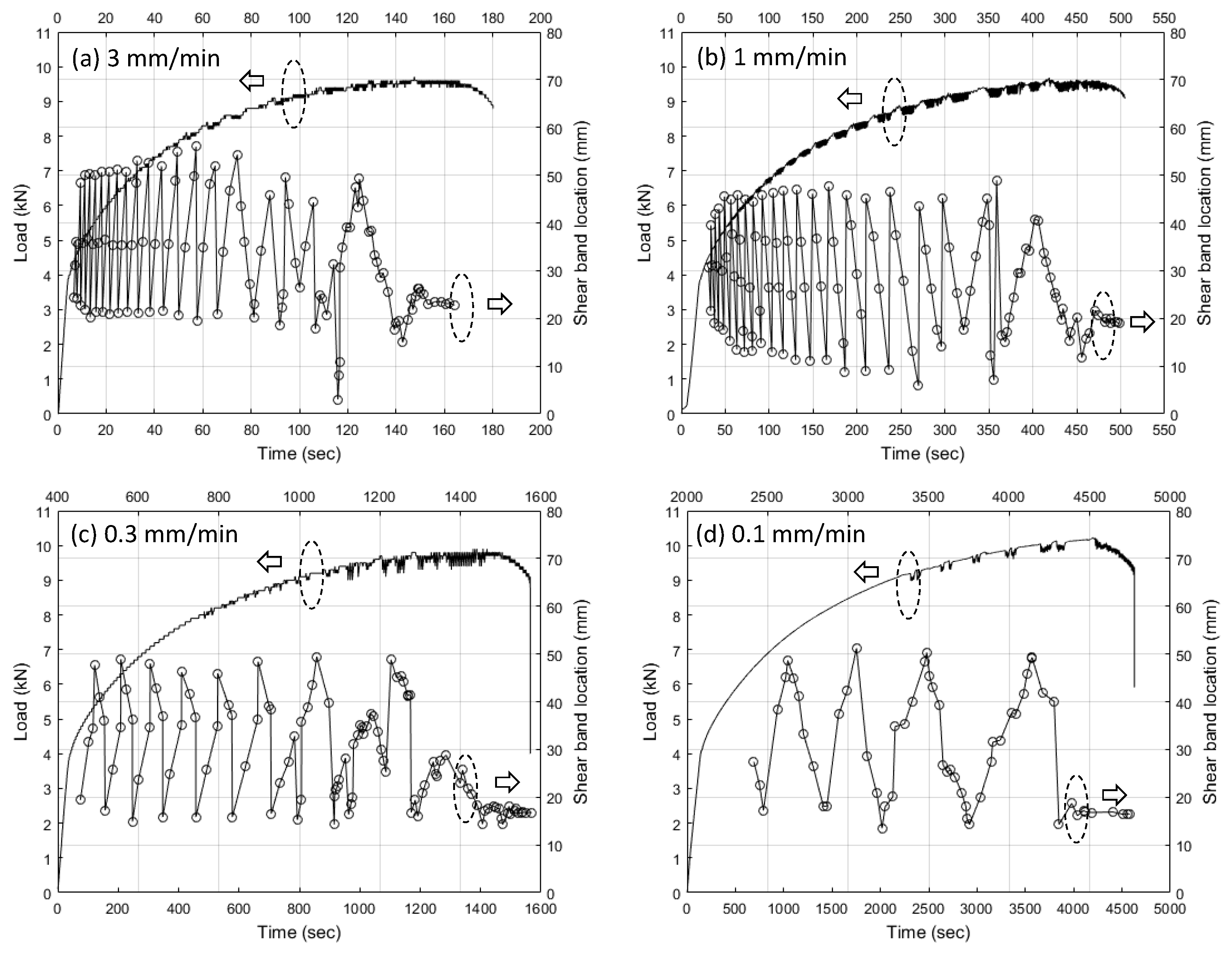

- The shear band propagation speed decreases towards the final fracture as a function of the elapsed time from the beginning of tensile loading. This behavior strongly indicates that the shear band formation and propagation are related to the mobile dislocation dynamics.

Author Contributions

Funding

Conflicts of Interest

Appendix A. Local Symmetry

Appendix B. Elastic Shear and Longitudinal Forces

Appendix C. Vector Potential and Displacement Vector

Appendix D. Strain Tensor and Coordinate System

Appendix E. Analogy to Electrodynamics

References

- Suzuki, T.; Takeuchi, S.; Yoshinaga, H. Dislocation Dynamics and Plasticity; Springer Series in Material Science 12; Springer: Berlin/Heidelberg, Germany, 1991. [Google Scholar]

- Egorushkin, V.E. Gauge dynamic theory of defects in nonuniformly deformed media with a structure, interface behavior. Sov. Phys. J. 1990, 33, 135–149. [Google Scholar] [CrossRef]

- Timoshenko, S.P.; Goodier, J.N. Theory of Elasticity; McGraw-Hil: New York, NY, USA, 1951. [Google Scholar]

- Marsden, J.E.; Hughes, T.J.R. Mathematical Foundations of Elasticity; Prentice-Hall: Englewood Cliffs, NJ, USA, 1983. [Google Scholar]

- Landau, L.D.; Lifshitz, E.M. Theory of Elasticity. Course of Theoretical Physics, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 1986; Volume 7. [Google Scholar]

- Gokhfeld, D.A.; Sadakov, O.S. A Unified Mathematical Model for Plasticity and Creep Under Variable-Repeated Loading. In Creep in Strucutures; Zyczkowski, M., Ed.; Springer: Berlin, Germany, 1991; pp. 23–28. [Google Scholar]

- Hill, R. The Mathematical Theory of Plasticity; Oxford University Press: Oxford, UK, 1998. [Google Scholar]

- Barsom, J.M.; Rolfe, S.T. Fracture and Fatigue Control in Structures, 3rd ed.; ASTM: Philadelphia, PA, USA, 1999. [Google Scholar]

- Yoshida, S. Deformation and Fracture of Solid-State Materials—Field Theoretical Approach and Engineering Applications; Springer: New York, NY, USA, 2015. [Google Scholar]

- Elliot, J.P.; Dawber, P.G. Symmetry in Physics; Macmillan: London, UK, 1984; Volume 1. [Google Scholar]

- Aitchson, I.J.R.; Hey, A.J.G. Gauge Theories in Particle Physics; IOP Publishing: Bristol, UK, 1989. [Google Scholar]

- Chaichian, M.; Nelipa, N.F. Introduction to Gauge Field Theories, 1st ed.; Springer: Berlin, Germany, 1984. [Google Scholar]

- Yoshida, S.; Pardede, M.H.; Sijabat, N.; Simangunsong, H.; Simbolon, T.; Kusnowo, A. Observation of plastic deformation wave in a tensile-loaded aluminum alloy. Phys. Lett. A 1999, 251, 54–60. [Google Scholar] [CrossRef] [Green Version]

- Yoshida, S.; Suprapedi, A.; Widiastuti, R.; Pardede, M.; Hutagalon, S.; Marpaung, J.; Faizal, A.; Kusnowo, A. Direct observation of developed plastic deformation and its application to nondestructive testing. Jpn. J. Appl. Phys. 1996, 35, L854–L857. [Google Scholar] [CrossRef]

- Toyooka, S.; Widiastuti, R.; Qingchuan, Z.; Kato, H. Dynamic observation of localized strain pulsation generated in the plastic deformation process by electronic speckle pattern interferometry. J. Appl. Phys. 2001, 40, 310–313. [Google Scholar] [CrossRef] [Green Version]

- Yoshida, S.; Ishii, H.; Ichinose, K.; Gomi, K.; Taniuchi, K. An Optical Interferometric Band as an Indicator of Plastic Deformation Front. J. Appl. Mech. 2005, 72, 792–794. [Google Scholar] [CrossRef] [Green Version]

- Yoshida, S.; Ishii, H.; Ichonose, K.; Gomi, K.; Taniuchi, K. Observation of Optical Interferometric Band Structure Representing Plastic Deformation Front under Cyclic Loading. Jpn. J. Appl. Phys. 2004, 43, 5451–5454. [Google Scholar] [CrossRef]

- Yoshida, S. Wave nature in deformation of solids and comprehensive description of deformation dynamics. Proc. Est. Acad. Sci. 2015, 64, 438–448. [Google Scholar] [CrossRef]

- Todorov, M.D. Nonlinear Waves: Theory, Computer Simulation, Experiment; Morgan and Claypool: San Rafael, CA, USA, 2018. [Google Scholar]

- Ziv, R.; Shmuel, G. Smooth waves and shocks of finite amplitude in soft materials. Mech. Mater. 2019, 135, 67–76. [Google Scholar] [CrossRef] [Green Version]

- Lints, M.; Salupere, A.; Dos Santos, S. Simulation of solitary wave propagation in carbon fibre reinforced polymer. Proc. Est. Acad. Sci. 2015, 64, 297–303. [Google Scholar] [CrossRef]

- Drescher-Krasicka, E.; Willis, J.R. Mapping stress with ultrasound. Nature 1996, 384, 52–55. [Google Scholar] [CrossRef]

- Broughton, W.R.; Lodeiro, M.J.; Sims, G.D. Validation of Procedures for Ultrasonic C-Scan Inspection of PMCs: Internation Round-Robin. NPL Report No. MATC(A)2. Available online: http://eprintspublications.npl.co.uk/id/eprint/1931 (accessed on 4 August 2020).

- Atalar, A.; Quate, C.F.; Wickramasinghe, H.K. Phase imaging in reflection with the acoustic microscope. Appl. Phys. Lett. 1977, 31, 791–793. [Google Scholar] [CrossRef] [Green Version]

- Zinin, P.V. Quantitative Acoustic Microscopy of Solids. Dynamic Methods for Measuring the Elastic Properties of Solids. In Handbook of Elastic Properties of Solids, Liquids, and Gases; Levy, M., Bass, H., Stern, R., Keppens, V., Eds.; Academic Press: New York, NY, USA, 2001; Volume I, pp. 187–226. [Google Scholar]

- Cullity, B.D.; Stock, S.R. Elements of X-ray Diffraction, 3rd ed.; Pearson: New York, NY, USA, 2001. [Google Scholar]

- Fitzpatrick, M.E.; Fry, A.T.; Holdway, P.; Kandil, F.A.; Shackleton, J.; Suominen, L. Determination of Residual Stresses by X-ray Diffraction—Issue 2; Measurement Good Practice Guide No. 52; National Physical Laboratory: Teddington, UK, 2005. [Google Scholar]

- Lints, M.; Dos Santos, S.; Salupere, A. Solitary waves for non-destructive testing applications: Delayed nonlinear time reversal signal processing optimization. Wave Motion 2017, 71, 101–112. [Google Scholar] [CrossRef]

- Semenova, I.; Samsonov, A.; Belashov, A. Holographic tracking of strain solitons as a tool for NDT of laminated composites. In Proceedings of the Latin America Optics and Photonics Conference, Cancun, Mexico, 16–21 November 2014. [Google Scholar]

- Zheng, B.; Rizzo, P.; Nasrollahi, A. Outlier analysis of nonlinear solitary waves for health monitoring applications. Struct. Health Monit. 2019. [Google Scholar] [CrossRef]

- Yoshida, S.; Rourks, R.L.; Mita, T.; Ichinose, K. Physical mesomechanical Criteria of plastic deformation and fracture. Phys. Mesomech 2009, 12, 249–253. [Google Scholar] [CrossRef] [Green Version]

- Yoshida, S.; Sasaki, T. Deformation wave theory and application to optical interferometry. Materials 2020, 13, 1363. [Google Scholar] [CrossRef] [Green Version]

- Leendertz, J.A. Interferometric displacement measurement on scattering surfaces utilizing speckle effect. J. Phys. E 1970, 3, 214–218. [Google Scholar] [CrossRef]

- Sirohi, R.S. Speckle Metrology; Marcel Dekker: New York, NY, USA, 1993. [Google Scholar]

- Sciammarella, C.A.; Sciammarella, F.M. Experimental Mechanics of Solids; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Panin, V.E. Physical fundamentals of mesomechanics of plastic deformation and fracture of solids. In Physical Mesomechanics of Heterogeneous Media and Computer-Aided Design of Materials; Panin, V.E., Ed.; Cambridge International Science Publishing: Cambridge, UK, 1998. [Google Scholar]

- Rose, J.L. Ultrasonic Waves in Solid Media; Cambridge University Press: Cambridge, UK, 1999; Chapter 4. [Google Scholar]

- Starosvetsky, Y.; Arif Hasan, M.; Vakakis, A.F. Nonlinear Pulse Equipartition in Weakly Coupled Ordered Granular Chains With No Precompression. J. Comput. Nonlinear Dynam 2013, 8, 034504. [Google Scholar] [CrossRef]

- Spencer, A.J.M. Continuum Mechanics; Longman: London, UK, 1980. [Google Scholar]

- Yoshida, S. Scale-independent approach to deformation and fracture of solid-state materials. J. Strain Anal 2011, 46, 380–386. [Google Scholar] [CrossRef]

- Yoshida, S. Comprehensive description of deformation of solids as wave dynamics. Math. Mech. Complex Syst. 2015, 3, 243–272. [Google Scholar] [CrossRef]

- Yoshida, S. Consideration on fracture of solid-state materials. Phys. Lett. A 2000, 270, 320–325. [Google Scholar] [CrossRef] [Green Version]

- Bazelyan, E.M.; Raizer, Y.P. Spark Discharge; CRC Press: Boca Raton, FL, USA, 1997. [Google Scholar]

- Meek, J.M. Electrical Breakdown of Gases; Wiley: New York, NY, USA, 1978. [Google Scholar]

- Griffiths, D.J. Introduction to Electrodynamics, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1999. [Google Scholar]

- Multiphysics Cyclopedia. Available online: https://www.comsol.com/multiphysics/introduction-to-physics-pdes-and-numerical-modeling (accessed on 15 June 2019).

- Totten, G.E.; MacKenzie, D.S. Handbook of Aluminum; Physical Metallurgy and Processes; Marcel Dekker, Inc.: New York, NY, USA, 2003. [Google Scholar]

- Alcoa Global Cold Finished Products, ALLOY 7075, Understanding Cold Finished Aluminum Alloys. Available online: https://www.spacematdb.com/spacemat/manudatasheets/alcoa_alloy_7075.pdf (accessed on 13 July 2020).

- Yoshida, S.; Sasaki, T. Field Theoretical Description of Shear Bands. In Proceedings of the SEM 2015 Annual Conference, Fracture, Fatigue, Failure and Damage Evolution, Costa Mesa, CA, USA, 8–11 June 2015; pp. 141–149. [Google Scholar]

- Alrasheedi, N.H.; Yousfi, M.A.; Hajlaoui, K.; Mahfoudh, B.J.; Tourki, Z.; Yavari, A.R. On the Modelling of the Transient Flow Behavior of Metallic Glasses: Analogy with Portevin-Le Chatelier Effect. Metals 2016, 6, 48. [Google Scholar] [CrossRef]

- Yamada, H.; Tsuyoshi Kami, T.; Mori, R.; Kudo, T.; Okada, M. Strain Rate Dependence of Material Strength in AA5xxx Series Aluminum Alloys and Evaluation of Their Constitutive Equation. Metals 2018, 8, 576. [Google Scholar] [CrossRef] [Green Version]

- Jiang, H.; Zhang, Q.; Chen, X.; Chen, Z.; Jiang, Z.; Wu, X.; Fan, J. Three types of Portevin-Le Chatelier effects: Experimental and modelling. Acta Mater. 2007, 55, 2219–2228. [Google Scholar] [CrossRef]

- Henry Ovria, H.; Steglicha, D.; Dieringab, H.; Lilleoddena, E.T. Grain-scale investigation of the anisotropy of Portevin-Le Chatelier effect in Mg AZ91 alloy. Mater. Sci. Eng. A 2019, 740–741, 226–234. [Google Scholar] [CrossRef]

- Zhao, S.; Meng, C.; Mao, F.; Hu, W.; Gottstein, G. Influence of severe plastic deformation on dynamic strain aging of ultrafine grained Al–Mg alloys. Acta Mater. 2014, 76, 54–67. [Google Scholar] [CrossRef]

- Halim, H.; Wilkinson, D.S.; Niewczas, M. The Portevin–Le Chatelier (PLC) effect and shear band formation in an AA5754 alloy. Acta Mater. 2007, 55, 4151–4160. [Google Scholar] [CrossRef]

- Hähner, P.; Ziegenbein, A.; Rizzi, E.; Neuhä, H. Spatiotemporal analysis of Portevin–Le Châtelier deformation bands: Theory, simulation, and experiment. Phys. Rev. B 2007, 65, 134109. [Google Scholar]

- Nakamura, T.; Sasaki, T.; Yoshida, S. Analysis of Portevin-Le Chatelier Effect of Al-Mg Alloy by Electronic Speckle Pattern Interferometry. In Advancement of Optical Methods in Experimental Mechanics; Conference Proceedings of the Society for Experimental Mechanics Series; Springer International Publishing AG: Cham, Switzerland, 2014; Volume 3. [Google Scholar]

- Panin, V.E.; Russian Academy of Sciences, Tomsk, Russia. Personal communication, 1989.

- Bishop, C.M. Natural Networks for Pattern Recognition; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Cherrington, B.E. Gaseous Electronics and Gas Lasers; Pergamon Press: Oxford, UK, 1979. [Google Scholar]

| G (N/m) | (N/m) | (kg/m) | Pulling Rate (m/s) | |||

|---|---|---|---|---|---|---|

| 1 | 0.3 | 1 | 35 |

| Pulling Rate (mm/min) | 3 | 1 | 0.5 | 0.3 | 0.1 |

|---|---|---|---|---|---|

| Onset time (s) | 6.6 | 31.1 | 150.1 | 456.2 | 2415 |

| Elongation (mm) | 0.55 | 0.51 | 1.25 | 2.28 | 4.02 |

| Normal strain (%) | 2.2 | 2.0 | 5.0 | 9.1 | 16.1 |

| Dislocation velocity (cm/s) | 1.92 | 7.16 | 1.77 | 6.03 | 1.16 |

| Dislocation density (cm) | 3.6 | 3.3 | 6.6 | 1.2 | 2.0 |

| Solitary wave amplitude (mm/min) | 11.5 | 4.29 | 1.06 | 0.36 | 0.07 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoshida, S.; McGibboney, C.; Sasaki, T. Nondestructive Evaluation of Solids Based on Deformation Wave Theory. Appl. Sci. 2020, 10, 5524. https://doi.org/10.3390/app10165524

Yoshida S, McGibboney C, Sasaki T. Nondestructive Evaluation of Solids Based on Deformation Wave Theory. Applied Sciences. 2020; 10(16):5524. https://doi.org/10.3390/app10165524

Chicago/Turabian StyleYoshida, Sanichiro, Conor McGibboney, and Tomohiro Sasaki. 2020. "Nondestructive Evaluation of Solids Based on Deformation Wave Theory" Applied Sciences 10, no. 16: 5524. https://doi.org/10.3390/app10165524

APA StyleYoshida, S., McGibboney, C., & Sasaki, T. (2020). Nondestructive Evaluation of Solids Based on Deformation Wave Theory. Applied Sciences, 10(16), 5524. https://doi.org/10.3390/app10165524