CO2 Emission Calculation Method during Construction Process for Developing BIM-Based Performance Evaluation System

Abstract

:1. Introduction

2. Literature Review

2.1. Related Research

2.2. LCA (Life-Cycle Assessment)

- (1)

- Materials production: this phase includes the process of the manufacturing and processing of raw materials; the building materials to be charged into the building consume resources, and the energy required for production, such as the production of products [5].

- (2)

- Construction: this phase includes all the activities necessary for tunnel construction, such as earthworks, concrete pouring, material transport etc.

- (3)

- Use and maintenance: this phase includes the operation for using, repairing and manage the tunnel project until it is demolished, such as, repairment of tunnel road pavement, maintenance of lighting and ventilation condition inside the tunnel, etc.

- (4)

- End of life: the last phase occurs when the tunnel reaches the end of its useful life. According to the tunnel management strategy, the tunnel may be recovered or demolished, and removed materials may be recycled or left in the field, increasing the burden on the environment [7].

3. Research Scope and Method

- (1)

- In the aspect of BIM model, the authors used CAD to draw the tunnel cross section, then imported it to the Revit, and used the Revit family to create the 3D model of each part, then gave material information to each part, and finally combined them together.

- (2)

- With respect to tunnel materials, the authors investigated the related CO2 emission factors, and did a survey about the main engineering equipment used in the construction process.

- (3)

- The authors inputted the CO2 emission factors to the Revit, and set the calculated value formula for the CO2 emission. Finally, through the function of Revit, the authors could derive the quantity of each part of the tunnel and calculate the related CO2 emission automatically.

- (4)

- With regard to the quantity derived from the Revit, and referring to the national standard estimating reference, published by the Korea Institute of Construction Technology (KICT), the authors calculated the fuel consumption for the main construction equipment, and then multiplied it by the CO2 emission factors. The authors obtained the CO2 emission for the main equipment in the process of tunnel construction.

- (5)

- The authors analyzed the CO2 emission during the tunnel construction process, including the CO2 emission from the material, and the CO2 emission produced by the main equipment used in the construction process. By using the EU emissions trading system, the authors calculated the CO2 emission cost, and economic analysis was also carried out.

4. CO2 Emission Calculation for a Tunnel Project

4.1. Creating the 3D Tunnel Section by BIM Tool

4.2. Survey for CO2 Emission Factor and Main Equipment

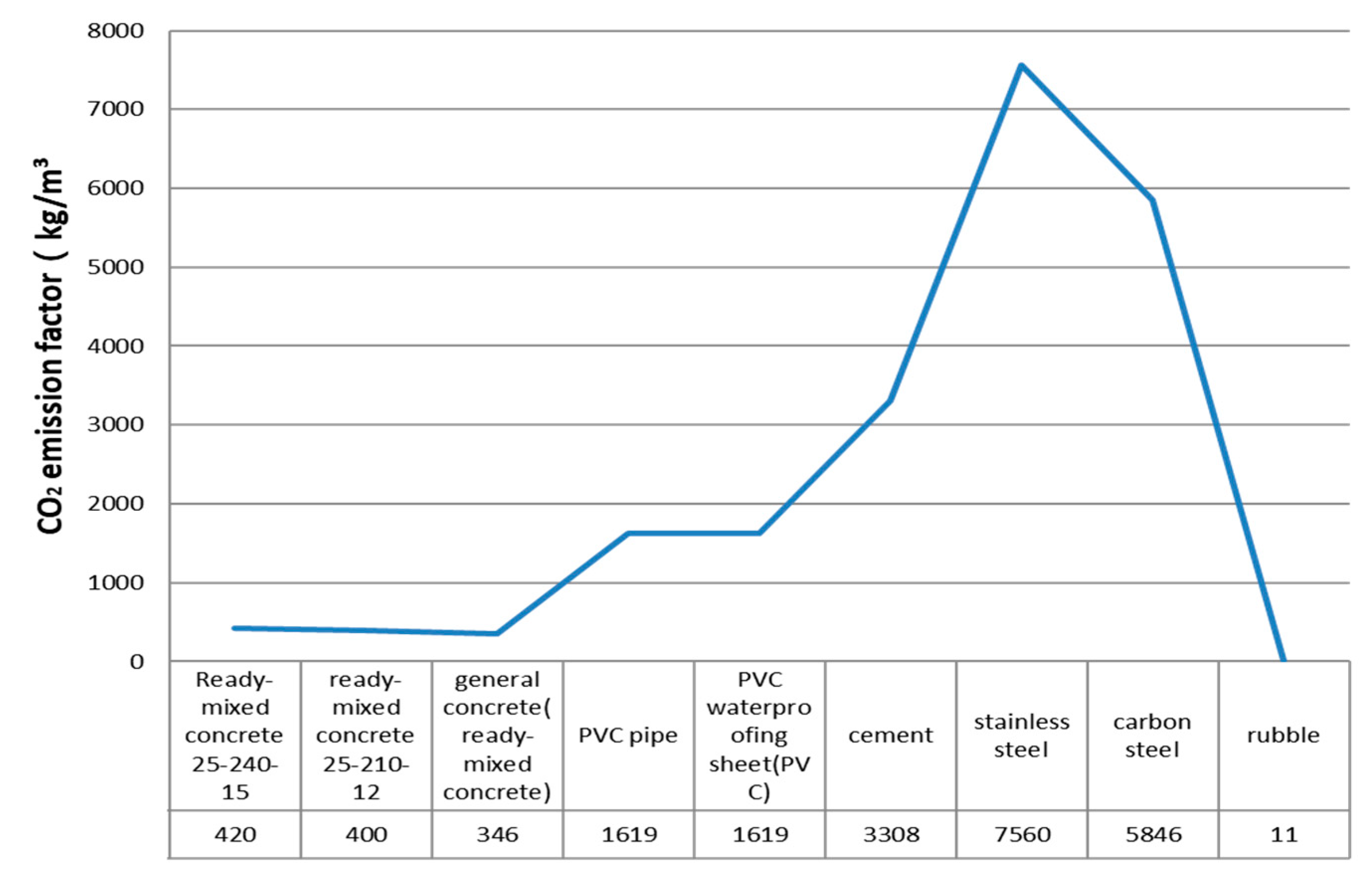

4.2.1. Survey for CO2 Emission Factor

4.2.2. Survey for Main Equipment

4.3. Extracting Materials Quantity and Calculating CO2 Emission

4.4. CO2 Emission Calculation of the Main Equipment

4.4.1. The Process of Calculating CO2 Emission for the Main Equipment is Illustrated for the Wheel Loader Used for Earthwork Below

4.4.2. Calculating the CO2 Emission for Other Equipment

(m3/h)

(l/v1 + l/v2)·60 + t3 + t4 + t5)] (m3/h)

5. The Result Analysis

5.1. CO2 Emission Factors of Materials and the Proportion of Quantity of Each Section in Tunnel

5.2. Economic Analysis of CO2 Emission during the Tunnel Construction Process

5.3. Results and Discussion

- (1)

- From the results in Table 9, we can see that the CO2 emission fee of tunnel material is 467,445,245 won, and the CO2 emission fee of main equipment is 21,832,991 won. The tunnel material takes over 95.32% of the total CO2 emission fee; in order to reduce the tunnel CO2 emission cost, the researchers should focus on the development of low carbon materials.

- (2)

- For the tunnel material, the CO2 emission fee of cement treated base, concrete lining, drainage way and concrete slab (30 cm) is very high. Four of them take over 84.9% of the tunnel material CO2 emission fee. Areas for further research would be to reduce the CO2 emission factor of cement and concrete, for example, by developing new types of cement and concrete, or using a replacement with lower CO2 emission factor.

- (3)

- Even though, compared with the tunnel material, the CO2 emission fee of the main equipment is not very high, it is a large expense for the whole tunnel project. According to the results, we can see that most of the CO2 emission fee comes from the dump truck. During the tunnel construction, the quantity of earthwork is very high, so there is more use of the dump truck. As a consequence, we should take the reduction of earthwork as an important consideration in the tunnel design. We can also design a reasonable construction route to reduce the transportation distance and improve the equipment, to reduce the fuel consumption of the dump truck.

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- United States Environmental Protection Agency (EPA). Greenhouse Gas (GHG) Emissions. Available online: https://www.epa.gov/ghgemissions (accessed on 22 May 2020).

- Ministry of Foreign Affairs Republic of Korea, Korea’s Efforts to Address Climate Change. Available online: http://www.mofa.go.kr/eng/wpge/m_5655/contents.do (accessed on 22 May 2020).

- Röck, M.; Saade, M.; Balouktsi, M.; Rasmussen, F.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG emissions of buildings: The hidden challenge for effective climate change mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- Kim, B.; Lee, H.; Park, H.; Kim, H. Greenhouse gas emissions from onsite equipment usage in road construction. J. Constr. Eng. Manage. 2012, 138, 982–990. [Google Scholar] [CrossRef]

- Cho, S.; Chae, C. A study on life cycle CO2 emissions of low-carbon building in South Korea. Sustainability 2016, 8, 579. [Google Scholar] [CrossRef] [Green Version]

- Cho, S.H.; Chae, C.U. The comparative study on the environmental impact assessment of construction material through the application of carbon reducing element-focused on global warming potential of concrete products. Korea Inst. Ecol. Archit. Environ. 2015, 33, 149–156. [Google Scholar]

- Araujo, J.; Oliveira, J.; Silva, H. The importance of the use phase on the LCA of environmentally friendly solutions for asphalt road pavements. Transp. Res. Part D 2014, 32, 97–110. [Google Scholar] [CrossRef] [Green Version]

- Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide To Building Information Modeling: For Owners, Managers, Designers, Engineers, and Contractors.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Duarte, P.; Cooke, M. Sustainability and the Tunnelling Industry, TunnelTECH. 2013. Available online: https://www.tunneltalk.com/TunnelTECH-Dec2013-Sustainability-and-the-tunnelling-industry.php (accessed on 22 May 2020).

- Kim, J. A Study of Reliability-Based Quantity Estimation Error Analysis Apply. Master’s Thesis, Hanyang University, Seoul, Korea, 2013. [Google Scholar]

- Yang, M. IFC-BIM based Calculation of CO2 Emission from Major Construction Materials of Steel Box Girder Railway Bridge. Master Thesis, Yonsei University, Seoul, Korea, 2012. [Google Scholar]

- Oh, M.; Na, S. Building Information Modelling (BIM) Based CO2 emissions assessment in the early design stage. Int. J. Civ. Eng. Technol. 2017, 8, 1411–1425. [Google Scholar]

- Jun, K.; Hong, J.; Yun, S. Comparison of construction cost of tile work including CO2 emission cost. Assoc. Korean Archit. Soc. J. Acad. Present. Conf. 2011, 233–236. [Google Scholar]

- Lee, Y.J.; Jun, H.J. Development of a BIM-based carbon dioxide emission estimation system -focus on an apartment in Korea. Archit. Res. 2016, 18, 145–149. [Google Scholar] [CrossRef]

- Krishna, I.V.; Manickam, V.; Davergave, A. Chapter five life cycle assessment, environmental management. Sci. Eng. Ind. 2017, 57–75. [Google Scholar]

- Korea LCI DB-Building Materials. Available online: http://epd.or.kr/lci/nationalDb.do?category=7 (accessed on 22 May 2020).

- 2017 Environmental Performance Indicators Certification Guide Volume 1. Available online: http://www.epd.or.kr/ information/bbs/filedown.do?bbsCode=6&file_idx=1480 (accessed on 22 May 2020).

- Korea LCI DB-Plastic. Available online: http://epd.or.kr/lci/nationalDb.do?category=15 (accessed on 22 May 2020).

- Korea LCI DB-Metal. Available online: http://epd.or.kr/lci/nationalDb.do?category=9 (accessed on 22 May 2020).

- Development of LCA Evaluation Tool at Design Stage Using BIM. Available online: http://www.prism.go.kr/homepage/researchCommon/downloadResearchAttachFile.do?work_key=001&file_type=CPR&seq_no=001&pdf_conv_yn=Y&research_id=1480000-201200241 (accessed on 22 May 2020).

- EU Emissions Trading System (EU ETS). Available online: https://ec.europa.eu/clima/policies/ets_en (accessed on 22 May 2020).

- CO2 European Emission Allowance in EUR-historical Prices. Available online: https://markets.businessinsider.com/commodities/historical-prices/co2-european-emission-allowances/ eur/1.1.2019_31.12.2019 (accessed on 22 May 2020).

- 2019 Average Exchange Rate of Euro to KRW. Available online: https://spot.wooribank.com/pot/Dream?withyou=FXXRT0016 (accessed on 22 May 2020).

| Name of the Material | CO2 Emission Factor | Unit | Resources |

|---|---|---|---|

| Ready mixed concrete25-240-15 | 420 | CO2 kg/m3 | MOTIE of Korea [16] |

| Ready-mixed concrete25-210-12 | 400 | CO2 kg/m3 | MOTIE of Korea [16] |

| General concrete (ready-mixed concrete) | 346 | CO2 kg/m3 | KEITI of Korea [17] |

| PVC | 1265 | CO2 kg/t | MOTIE of Korea [18] |

| Cement | 1050 | CO2 kg/t | ME of Korea [16] |

| Stainless steel | 2800 | CO2 kg/t | ME of Korea [19] |

| Carbon steel | 2165 | CO2 kg/t | ME of Korea [19] |

| Rubble | 11.33 | CO2 kg/m3 | Intergovernmental Panel on Climate Change (IPCC1996) [20] |

| Name of the Material | CO2 Emission Factor (Before) | Material Reference Density | CO2 Emission Factor (Changed) |

|---|---|---|---|

| PVC | 1265 kg/t | 1280 kg/m3 | 1619 kg/m3 |

| Cement | 1050 kg/t | 3150 kg/m3 | 3308 kg/m3 |

| Stainless steel | 2800 kg/t | 2700 kg/m3 | 7560 kg/m3 |

| Carbon steel | 2165 kg/t | 2700 kg/m3 | 5846 kg/m3 |

| Work Type | Main Equipment |

|---|---|

| Earthwork | Dump truck |

| Wheel loader | |

| Concrete work | Mixer-truck |

| Cement work | Mixer-truck |

| Equipment Variable | Data |

|---|---|

| q (bucket capacity) | 1.72 m3 |

| k (bucket coefficient) | 1.0 |

| f (soil conversion factor) | 77% |

| e (production efficiency) | 60% |

| m (reciprocal of the velocity) | 1.8(s/m) |

| l (average distance) | 8.0 m |

| t1 (load time) | 6 s |

| t2 (idle time) | 14 s |

| Work Type | Section | Volume(m3) |

|---|---|---|

| Earthwork | Excavation scope | 748.4 |

| Concrete work | Drainage way | 19.95 |

| Concrete lining | 62.61 | |

| Shotcrete | 11.45 | |

| Concrete slab (30 cm) | 22.5 | |

| Cement work | Cement treated base | 11.25 |

| Equipment Variable | Data |

|---|---|

| w (carrying capacity) | 6 m3 |

| e (production efficiency) | 95% |

| t1 (loading time) | 4.5 min |

| t3 (unloading time) | 3 min |

| t4 (waiting time) | 8 min |

| l (average distance) | 3 km |

| v1 (travel speed with loading) | 15 km/h |

| v2 (travel speed without loading) | 20 km/h |

| Equipment Variable | Data |

|---|---|

| T (carrying capacity) | 15 t |

| rt (density in natural stage) | 1.9 t/m3 |

| L (volume conversion rate) | 1.25 |

| f (soil conversion factor) | 77% |

| E (production efficiency of dump truck) | 90% |

| Cms (cycle time for loading by loader) | 34.4 s |

| q (bucket capacity) | 1.72 m3 |

| k (bucket coefficient) | 1.0 |

| Es (production efficiency of loader) | 60% |

| t3 (unloading time) | 0.8 min |

| t4 (waiting time for loading) | 0.42 min |

| t5 (automatic cover installation and dismantling time) | 0.5 min |

| l (average distance) | 6 km |

| v1 (travel speed with loading) | 15 km/h |

| v2 (travel speed without loading) | 20 km/h |

| Category | Division | 10 m Section CO2 Emission (kg) | Project A CO2 Emission (kg) (1477.6 m) | Average Price of CO2 Emission (eur/kg) | Annual Average Exchange Rate | Project A CO2 Emission Fee (won) |

|---|---|---|---|---|---|---|

| Tunnel material | Drainage way | 7978.07 | 1,178,840 | 0.02472 | 1305.86 | 38,053,956 |

| Cement treated base | 37,226.64 | 550,060.8 | 177,564,363 | |||

| Common ditch cover | 240 | 35,462.4 | 1,144,757 | |||

| Ditch cover | 5103 | 754,019.3 | 24,340,390 | |||

| Concrete lining | 26,298.03 | 3,885,797 | 125,436,863 | |||

| Drainage pipe filling | 85.15 | 12,581.76 | 406,150 | |||

| Drainpipe | 294.99 | 43,587.72 | 1,407,049 | |||

| Rock bolt | 3684.49 | 544,420.2 | 17,574,353 | |||

| Shotcrete | 3960.21 | 585,160.6 | 18,889,488 | |||

| Steel pipe | 266.29 | 39,347.01 | 1,270,155 | |||

| Waterproofing sheet | 501.46 | 74,095.73 | 2,391,874 | |||

| Concrete slab (30 cm) | 7784.96 | 1,150,306 | 37,132,856 | |||

| Main equipment | Dump truck | 3709.86 | 548,169 | 17,695,364 | ||

| Mixer-truck | 638.14 | 94,291.6 | 3,043,813 | |||

| Wheel loader | 229.32 | 33,884.3 | 1,093,815 |

| Category | Division | CO2 Emission Fee (Won) | Total Fee (Won) |

|---|---|---|---|

| Tunnel material | Drainage way | 38,053,956 | 445,612,254 (95.32%) |

| Cement treated base | 177,564,363 | ||

| Common ditch cover | 1,144,757 | ||

| Ditch cover | 24,340,390 | ||

| Concrete lining | 125,436,863 | ||

| Drainage pipe filling | 406,150 | ||

| Drainpipe | 1,407,049 | ||

| Rock bolt | 17,574,353 | ||

| Shotcrete | 18,889,488 | ||

| Steel pipe | 1,270,155 | ||

| Waterproofing sheet | 2,391,874 | ||

| Concrete slab (30 cm) | 37,132,856 | ||

| Main equipment | Dump truck | 17,695,364 | 21,832,991 (4.67%) |

| Mixer-truck | 3,043,813 | ||

| Wheel loader | 1,093,815 | ||

| Total | - | - | 467,445,245 (100%) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, H.; Park, Y. CO2 Emission Calculation Method during Construction Process for Developing BIM-Based Performance Evaluation System. Appl. Sci. 2020, 10, 5587. https://doi.org/10.3390/app10165587

Sun H, Park Y. CO2 Emission Calculation Method during Construction Process for Developing BIM-Based Performance Evaluation System. Applied Sciences. 2020; 10(16):5587. https://doi.org/10.3390/app10165587

Chicago/Turabian StyleSun, Hongwei, and Yeongmog Park. 2020. "CO2 Emission Calculation Method during Construction Process for Developing BIM-Based Performance Evaluation System" Applied Sciences 10, no. 16: 5587. https://doi.org/10.3390/app10165587

APA StyleSun, H., & Park, Y. (2020). CO2 Emission Calculation Method during Construction Process for Developing BIM-Based Performance Evaluation System. Applied Sciences, 10(16), 5587. https://doi.org/10.3390/app10165587