Influence of Blade Leading-Edge Shape on Rotating-Stalled Flow Characteristics in a Centrifugal Pump Impeller

Abstract

Featured Application

Abstract

1. Introduction

2. Pump Impeller Object

3. Numerical Modeling and Setup

3.1. Turbulence and Acoustic Modeling

3.2. Computational Fluid Dynamics Setup

- (a)

- Velocity inlet was given on the inlet boundary. The velocity value depends on the flow rate Q = 0.25 Qd. On this boundary, pressure followed the Neumann condition;

- (b)

- Pressure outlet was given on the outlet boundary. The average static pressure was 0 Pa, based on the environment pressure of 1 Atm. On this boundary, velocity followed the Neumann condition;

- (c)

- No-slip walls were set on the solid walls, including the blade, hub, and shroud.

4. Computational–Experimental Result Verification

5. Leading-Edge Reshaping

6. Comparative Results and Analysis

6.1. Alternating Stall Patterns

6.2. Impeller Performances

6.3. Contours of Flow-Field under Alternating Stall

6.3.1. Pressure Coefficient Cp

6.3.2. Turbulence Kinetic Energy (k2D)

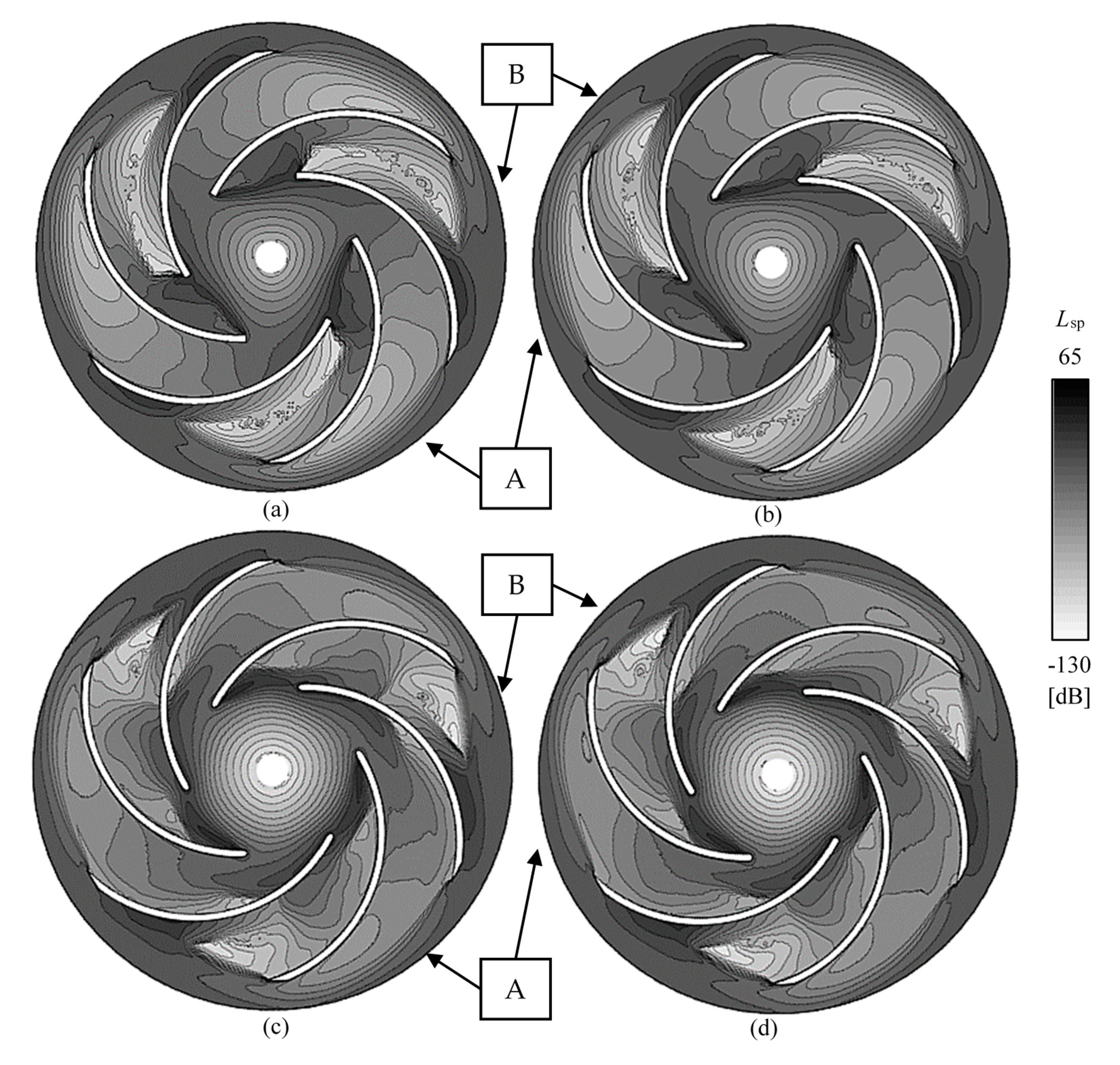

6.3.3. Sound Power Level (Lsp)

6.4. Pressure Pulsations

7. Conclusions

- (1)

- At partial-load (0.25 Qd in this study), incoming flow struck on the blade leading-edge on the pressure surface. Flow separation happened on the blade suction surface and induced the passage blockage. In this case, an alternating stall pattern was found in the impellers. In the six blade passages, three passages were well-behaved, and three passages were stalled (flow-blockage caused by backflow structures). The well-behaved and stalled passages distributed alternately and cite-fixed during rotation.

- (2)

- Leading-edge shape strongly influenced the alternating stall pattern and showed differences. In the blunt and sharp leading-edge impellers, the leading-edge geometry had sudden turned corners. Flow direction suddenly changed at the corner with large-scale separation. The stalled passages were completely blocked. Fluid went into the well-behaved passages. The flow pattern in the well-behaved passages was very smooth, without undesired flow structures, meaning that only three passages were accessible. In the ellipse and round leading-edge impellers, the geometry continually changed on the arc or elliptical-arc without sudden turning. The backflow scale in the stalled passages was smaller with slight accessibility because the leading-edge separation was not so strong. The flow rate in the well-behaved passages became smaller, and some backflow “vortex” structures occurred on the blade suction side.

- (3)

- Because of the difference of the leading-edge shape, the internal flow field became different. In the blunt and sharp leading-edge impellers, an extremely low-pressure region occurred at the inlet of the stalled passage. The pressure at the inlet of the wall-behaved passage was on a higher level. A high turbulence kinetic energy region occurred mainly in the stalled passage due to strong leading-edge separation. In the ellipse and round leading-edge impellers, a small-scale low-pressure region occurred on each blade’s leading-edge. The pressure distribution near the blade inlet was somehow averaged. A high turbulence kinetic energy region occurred in both the well-behaved passages and the stalled passages. It revealed the flow instability in all the blade passages of the ellipse and round leading-edge impellers.

- (4)

- The flow pattern in the blunt leading-edge impeller was similar to that in the sharp leading-edge impeller. Moreover, the flow pattern in the ellipse leading-edge impeller was similar to that in the round leading-edge impeller. However, the pressure pulsation characteristics in the four types of impellers were completely different. In the blunt leading-edge impeller, frequency of 9.67 Hz dominated. The amplitude of pressure pulsation on the monitoring points was up to about 6 × 10−6 Pa. In the sharp leading-edge impeller, a frequency of 0.81 Hz dominated. The amplitude of pressure pulsation on the monitoring points was up to about 1.2 × 10−3 Pa. In the ellipse leading-edge impeller, frequency of 2.41 Hz dominated. The amplitude of pressure pulsation on the monitoring points was up to about 1.2 × 10−2 Pa. In the round leading-edge impeller, a frequency of 1.00 Hz dominated. The amplitude of pressure pulsation on the monitoring points was up to about 1.8 × 10−2 Pa.

Author Contributions

Funding

Conflicts of Interest

References

- Guelich, J.F. Part load flow phenomena and excitation forces in centrifugal pumps. Vib. Wear High Speed Rotating Mach. 1990, 174, 113–134. [Google Scholar]

- Stepanoff, A.J. Centrifugal and axial flow pumps Theory, design, and application. J. Wiley N. Y. 1948. [Google Scholar]

- Derakhshan, S.; Pourmahdavi, M.; Abdolahnejad, E.; Reihani, A.; Ojaghi, A. Numerical shape optimization of a centrifugal pump impeller using artificial bee colony algorithm. Comput. Fluids 2013, 81, 145–151. [Google Scholar] [CrossRef]

- Yang, W.; Xiao, R. Multiobjective Optimization design of a pump–turbine impeller based on an inverse design using a combination optimization strategy. J. Fluids Eng. 2014, 136, 249–256. [Google Scholar] [CrossRef]

- Park, H.S.; Miao, F.; Nguyen, T.T. Impeller design for an axial-flow pump based on multi-objective optimization. Indian J. Eng. Mater. Sci. 2018, 25, 183–190. [Google Scholar]

- Wu, D.; Ren, Y.; Mou, J.; Gu, Y. Investigation of the correlation between noise & vibration characteristics and unsteady flow in a circulator pump. J. Mech. Sci. Technol. 2017, 31, 2155–2166. [Google Scholar]

- Wang, Y.; Liu, H.; Yuan, S.; Tan, M.; Wang, K. Experimental testing on cavitation vibration and noise of centrifugal pumps under off-design conditions. Trans. Chin. Soc. Agric. Eng. 2012, 28, 35–38. [Google Scholar]

- Wuibaut, G.; Bois, G.; Dupont, P.; Caignaert, G.; Stanislas, M. PIV measurements in the impeller and the vaneless diffuser of a radial flow pump in design and off-design operating conditions. J. Fluids Eng. 2002, 124, 791–797. [Google Scholar] [CrossRef]

- Miyabe, M.; Maeda, H.; Umeki, I.; Jittani, Y. Unstable head-flow characteristic generation mechanism of a low specific speed mixed flow pump. J. Therm. Sci. 2006, 15, 115–120. [Google Scholar] [CrossRef]

- Tan, L.; Cao, S.-L.; Wang, Y.-M.; Zhu, B.-S. Numerical simulation of cavitation in a centrifugal pump at low flow rate. Chin. Phys. Lett. 2012, 29, 014702. [Google Scholar] [CrossRef]

- Lucius, A.; Brenner, G. Numerical simulation and evaluation of velocity fluctuations during rotating stall of a centrifugal pump. J. Fluids Eng. 2011, 133, 081102. [Google Scholar] [CrossRef]

- Emmons, H.W.; Pearson, C.E.; Grant, U.H.P. Compressor surge and stall propagation. Trans. ASME 1955, 77, 455–469. [Google Scholar]

- Kshatriya, S.S.; Patwardhan, A.W.; Eaglesham, A. Experimental and CFD characterization of gas dispersing asymmetric parabolic blade impellers. Int. J. Chem. React. Eng. 2007, 5, 88. [Google Scholar] [CrossRef]

- Gravdahl, J.T.; Egeland, O. Centrifugal compressor surge and speed control. IEEE Trans. Control Syst. Technol. 1999, 7, 567–579. [Google Scholar] [CrossRef]

- Zheng, X.; Sun, Z.; Kawakubo, T.; Tamaki, H. Experimental investigation of surge and stall in a turbocharger centrifugal compressor with a vaned diffuser. Exp. Therm. Fluid Sci. 2017, 82, 493–506. [Google Scholar] [CrossRef]

- Tan, C.S.; Day, I.; Morris, S.; Wadia, A. Spike-type compressor stall inception, detection, and control. Annu. Rev. Fluid Mech. 2010, 42, 275–300. [Google Scholar] [CrossRef]

- Sinha, M. The flow structure during onset and developed states of rotating stall within a vaned diffuser of a centrifugal pump. J. Fluids Eng. 2001, 123, 490–499. [Google Scholar] [CrossRef]

- Cumpsty, N.A. Compressor Aerodynamics; Longman Scientific & Technical: Essex, UK, 1989. [Google Scholar]

- Cossar, B.F.J.; Moffatt, W.C.; Peacock, R.E. Compressor rotating stall in uniform and nonuniform flow. J. Eng. Gas Turbines Power 1980, 102, 762. [Google Scholar] [CrossRef]

- Dussourd, J.L.; Pfannebecker, G.W.; Singhania, S.K. An Experimental Investigation of the Control of Surge in Radial Compressors Using Close Coupled Resistances. J. Fluids Eng. 1977, 99, 64–76. [Google Scholar] [CrossRef]

- Gysling, D.L.; Dugundji, J.; Greitzer, E.M.; Epstein, A.H. Dynamic control of centrifugal compressor surge using tailored structures. J. Turbomach. 1989, 113, 710–722. [Google Scholar] [CrossRef][Green Version]

- Weigl, H.J. Active stabilization of rotating stall and surge in a transonic single stage axial compressor. Ph.D. Thesis, Massachusetts Institute of Technology, Boston, MA, USA, 1997. [Google Scholar]

- Day, I.J. Axial compressor performance during surge. J. Propuls. Power 1971, 10, 329–336. [Google Scholar] [CrossRef]

- Behnken, R.L.; Leung, M.; Murray, R.M. Characterizing the effects of air injection on compressor performance for use in active control of rotating stall. In Proceedings of the ASME International Gas Turbine & Aeroengine Congress & Exhibition, Orlando, FL, USA, 2–5 June 1997. [Google Scholar]

- Suder, K.L.; Hathaway, M.D.; Thorp, S.A.; Strazisar, A.J.; Bright, M.B. Compressor stability enhancement using discrete tip injection. J. Turbomach. 2001, 123, 14–23. [Google Scholar] [CrossRef]

- Mongeau, L.; Thompson, D.E.; Mclaughlin, D.K. Sound generation by rotating stall in centrifugal turbomachines. J. Sound Vib. 1993, 163, 1–30. [Google Scholar] [CrossRef]

- Righi, M.; Pachidis, V.; Könözsy, L.; Pawsey, L. Three-dimensional through-flow modelling of axial flow compressor rotating stall and surge. Aerosp. Sci. Technol. 2018, 78, 271–279. [Google Scholar] [CrossRef]

- Sundström, E.; Semlitsch, B.; Mihăescu, M. Generation mechanisms of rotating stall and surge in centrifugal compressors. Flow Turbul. Combust. 2018, 100, 705–719. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Engeda, A. Numerical simulation of rotating stall in a two-stage axial fan. Therm. Sci. 2018, 22, S655–S663. [Google Scholar] [CrossRef]

- Krause, N.; Zähringer, K.; Pap, E. Time-resolved particle imaging velocimetry for the investigation of rotating stall in a radial pump. Exp. Fluids 2005, 39, 192–201. [Google Scholar] [CrossRef]

- Takamine, T.; Furukawa, D.; Watanabe, S.; Watanabe, H.; Miyagawa, K. Experimental analysis of diffuser rotating stall in a three-stage centrifugal pump. Int. J. Fluid Mach. Syst. 2018, 11, 77–84. [Google Scholar] [CrossRef]

- Pedersen, N.; Jacobsen, C.B.; Larsen, P.S. Flow in a centrifugal pump impeller at design and off-design conditions-part I: Particle image velocimetry (PIV) and laser Doppler velocimetry (LDV) measurements. J. Fluids Eng. 2003, 125, 61–72. [Google Scholar] [CrossRef]

- Tao, R.; Xiao, R.; Wang, Z. Influence of blade leading-edge shape on cavitation in a centrifugal pump impeller. Energies 2018, 11, 2588. [Google Scholar] [CrossRef]

- Balasubramanian, R.; Sabini, E.; Bradshaw, S. Influence of impeller leading edge profiles on cavitation and suction performance. In Proceedings of the 27th International Pump Users Symposium, Houston, TX, USA, 12–15 September 2011. [Google Scholar]

- Huang, X.; Liu, Z.; Yang, W. Comparative study of SGS models for simulating the flow in a centrifugal-pump impeller using single passage. Eng. Comput. 2015, 32, 2120–2135. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, F.; Zhou, P. Evaluation of subgrid-scale models in large-eddy simulations of turbulent flow in a centrifugal pump impeller. Chin. J. Mech. Eng. 2012, 25, 911–918. [Google Scholar] [CrossRef]

- Menter, F.R. Ten years of experience with the SST turbulence model. Turbul. Heat Mass Transf. 2003, 4, 625–632. [Google Scholar]

- Spalart, P.R.; Shur, M. On the sensitization of turbulence models to rotation and curvature. Aerosp. Sci. Technol. 1997, 1, 297–302. [Google Scholar] [CrossRef]

- Proudman, I. The Generation of Noise by Isotropic Turbulence. Proc. R. Soc. A 1952, 214, 119–132. [Google Scholar]

| No. | Mesh Node Number of Initial Impeller | Residual of Hydraulic Efficiency |

|---|---|---|

| 1 | 159,836 | - |

| 2 | 323,332 | 2.53% |

| 3 | 602,024 | 1.32% |

| 4 | 1,500,322 | 0.951% |

| 5 | 3,112,086 | 0.217% |

| Leading-Edge Shape | Main Frequency fm (Hz) | fm/frt (Rotating Frequency) |

|---|---|---|

| Blunt | 9.67 | 0.8 |

| Sharp | 0.81 | 0.067 |

| Ellipse | 2.41 | 0.2 |

| Round | 1.00 | 0.083 |

| Leading-Edge Shape | Obvious Frequencies/Frequency Bands |

|---|---|

| Blunt | fmb, 3 fmb, 5 fmb, 14.5~20.7 fmb and 36.2~39.3 fmb |

| Sharp | fms, 2 fms, 3 fms and 4~6 fms |

| Ellipse | fme, 2 fme, 3 fme |

| Round | 0.33~1.35 fmr (including 1.0 fmr) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, H.; Tao, R.; Yang, J.; Wang, Z. Influence of Blade Leading-Edge Shape on Rotating-Stalled Flow Characteristics in a Centrifugal Pump Impeller. Appl. Sci. 2020, 10, 5635. https://doi.org/10.3390/app10165635

Luo H, Tao R, Yang J, Wang Z. Influence of Blade Leading-Edge Shape on Rotating-Stalled Flow Characteristics in a Centrifugal Pump Impeller. Applied Sciences. 2020; 10(16):5635. https://doi.org/10.3390/app10165635

Chicago/Turabian StyleLuo, Hongying, Ran Tao, Jiandong Yang, and Zhengwei Wang. 2020. "Influence of Blade Leading-Edge Shape on Rotating-Stalled Flow Characteristics in a Centrifugal Pump Impeller" Applied Sciences 10, no. 16: 5635. https://doi.org/10.3390/app10165635

APA StyleLuo, H., Tao, R., Yang, J., & Wang, Z. (2020). Influence of Blade Leading-Edge Shape on Rotating-Stalled Flow Characteristics in a Centrifugal Pump Impeller. Applied Sciences, 10(16), 5635. https://doi.org/10.3390/app10165635