Synthesis and Properties of Novel Calcia-Stabilized Zirconia (Ca-SZ) with Nano Calcium Oxide Derived from Cockle Shells and Commercial Source for Dental Application

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Extraction of Calcium Oxide Cockle Shells

2.3. Fabrication of CaO Stabilized Zirconia Pellet

2.4. Physical and Mechanical Tests of Ca-SZ(CS) and Ca-SZ(CC) Sintered at Different Temperatures

3. Results

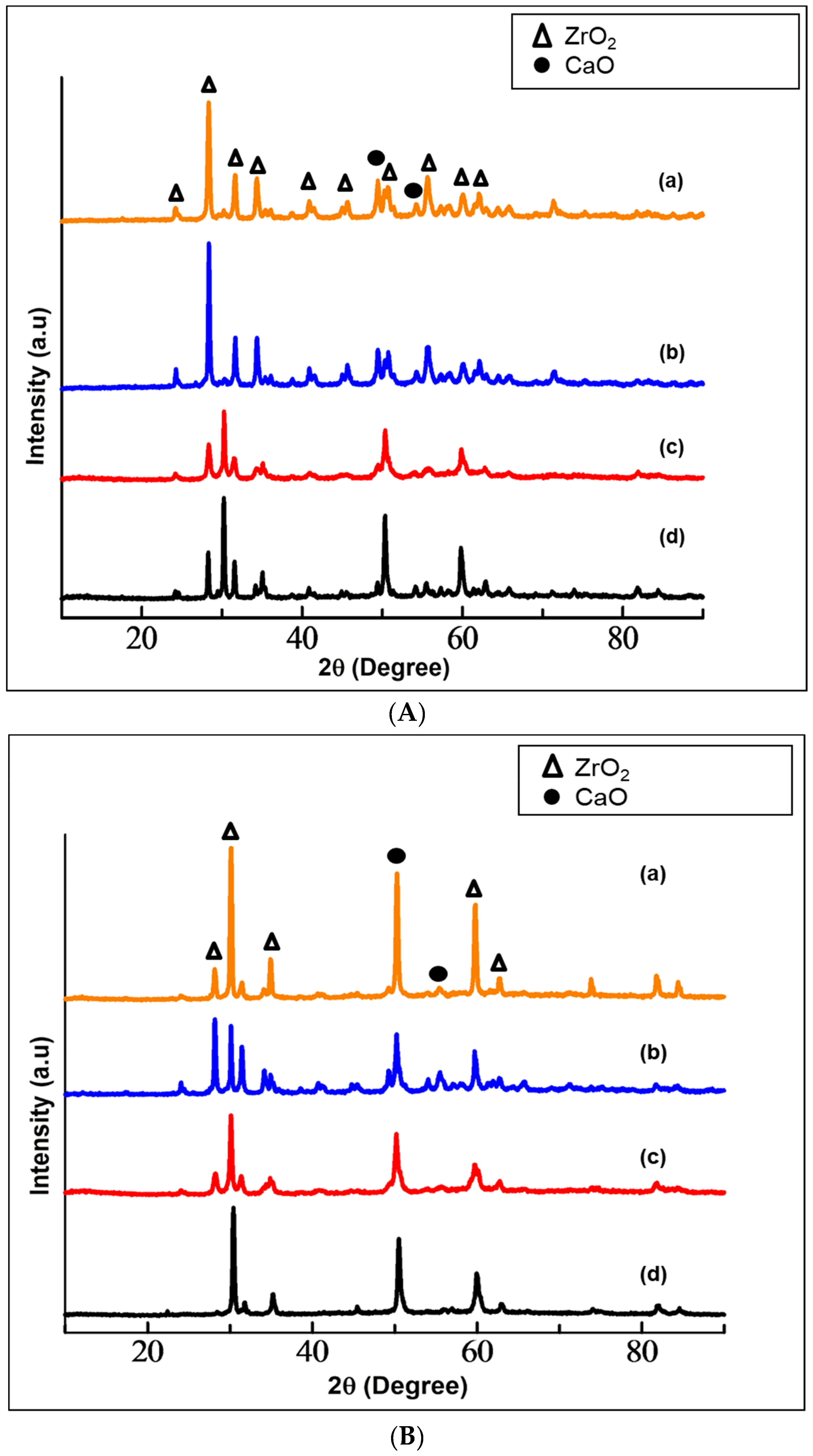

3.1. XRD Analyses

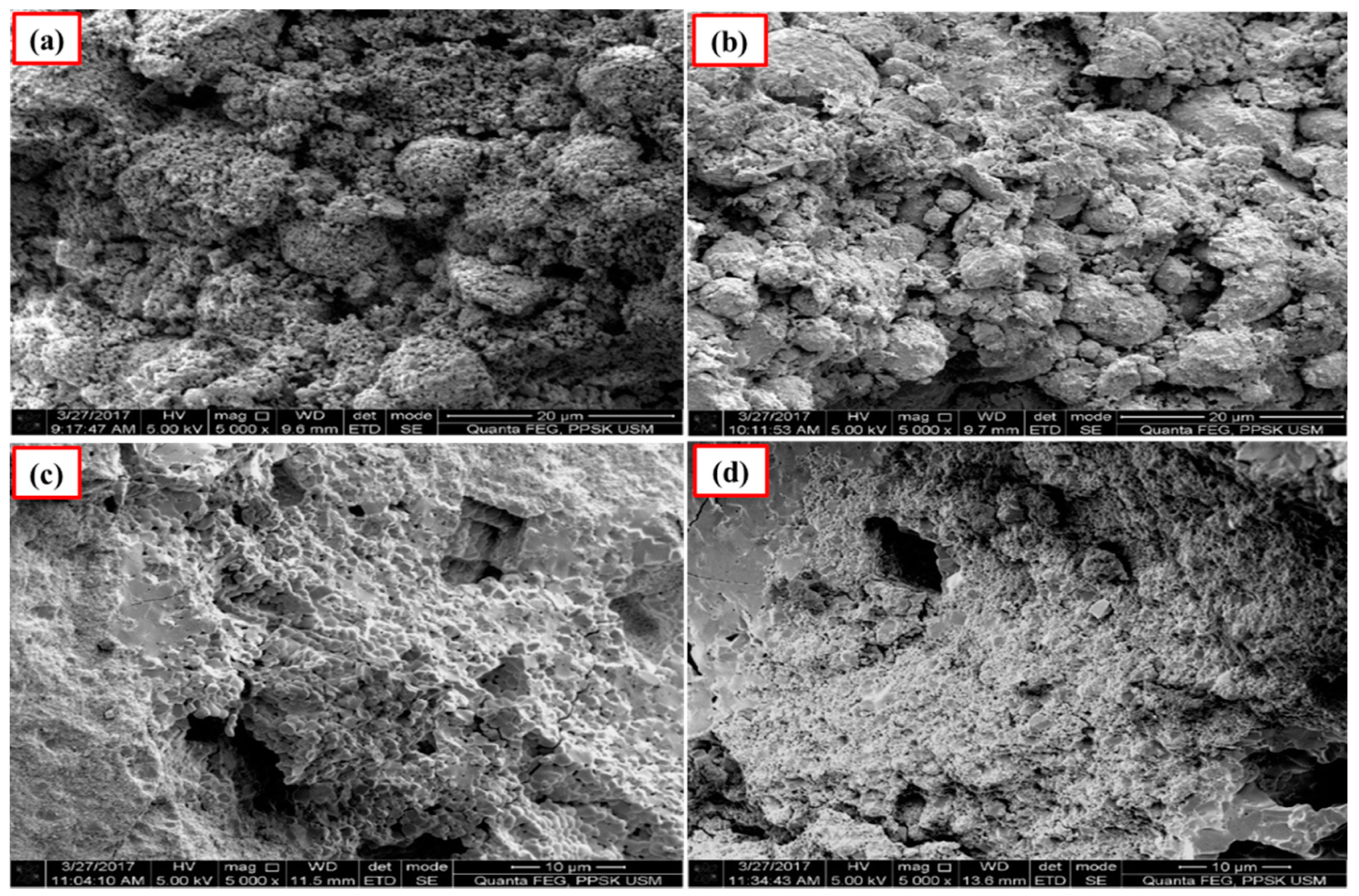

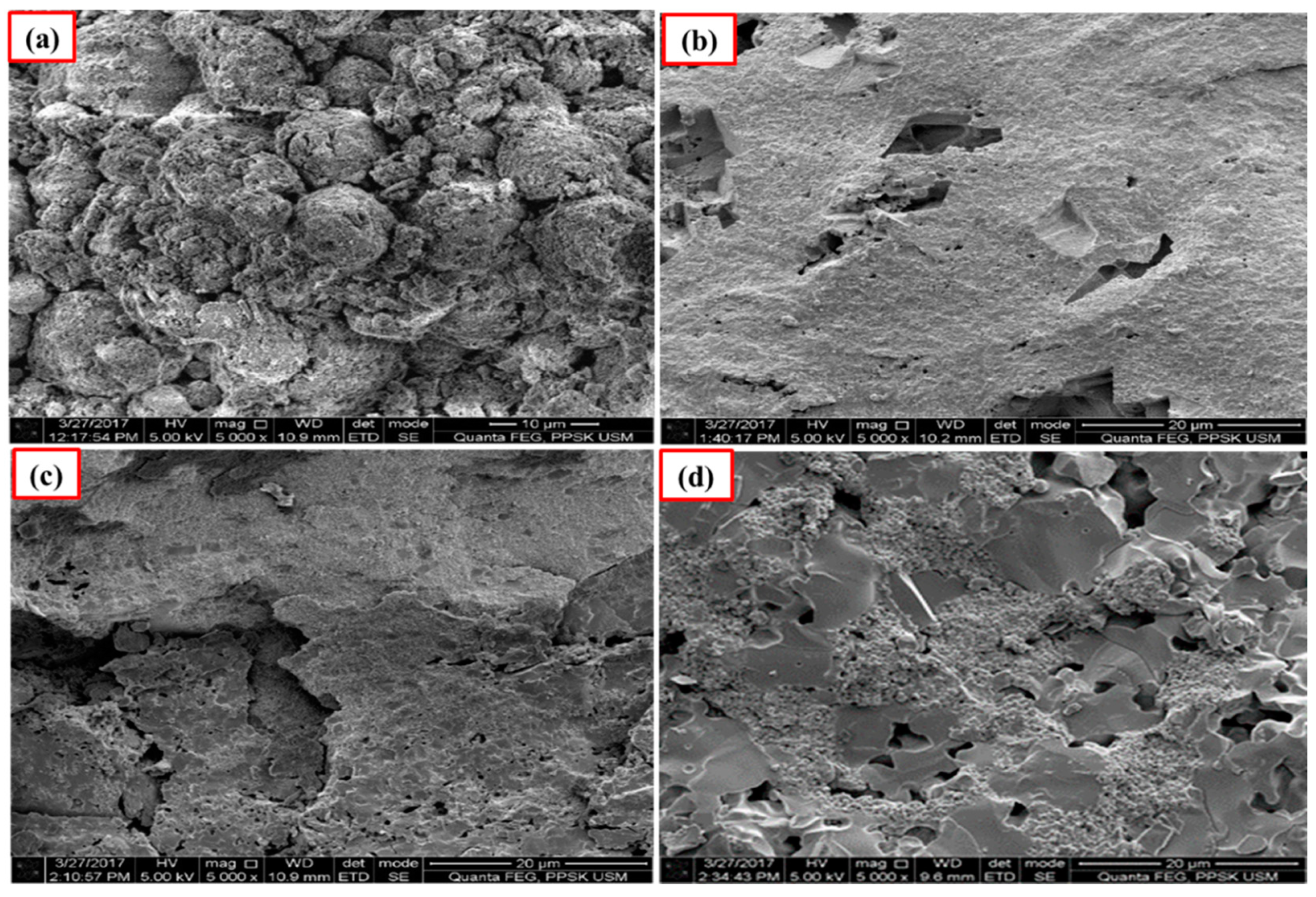

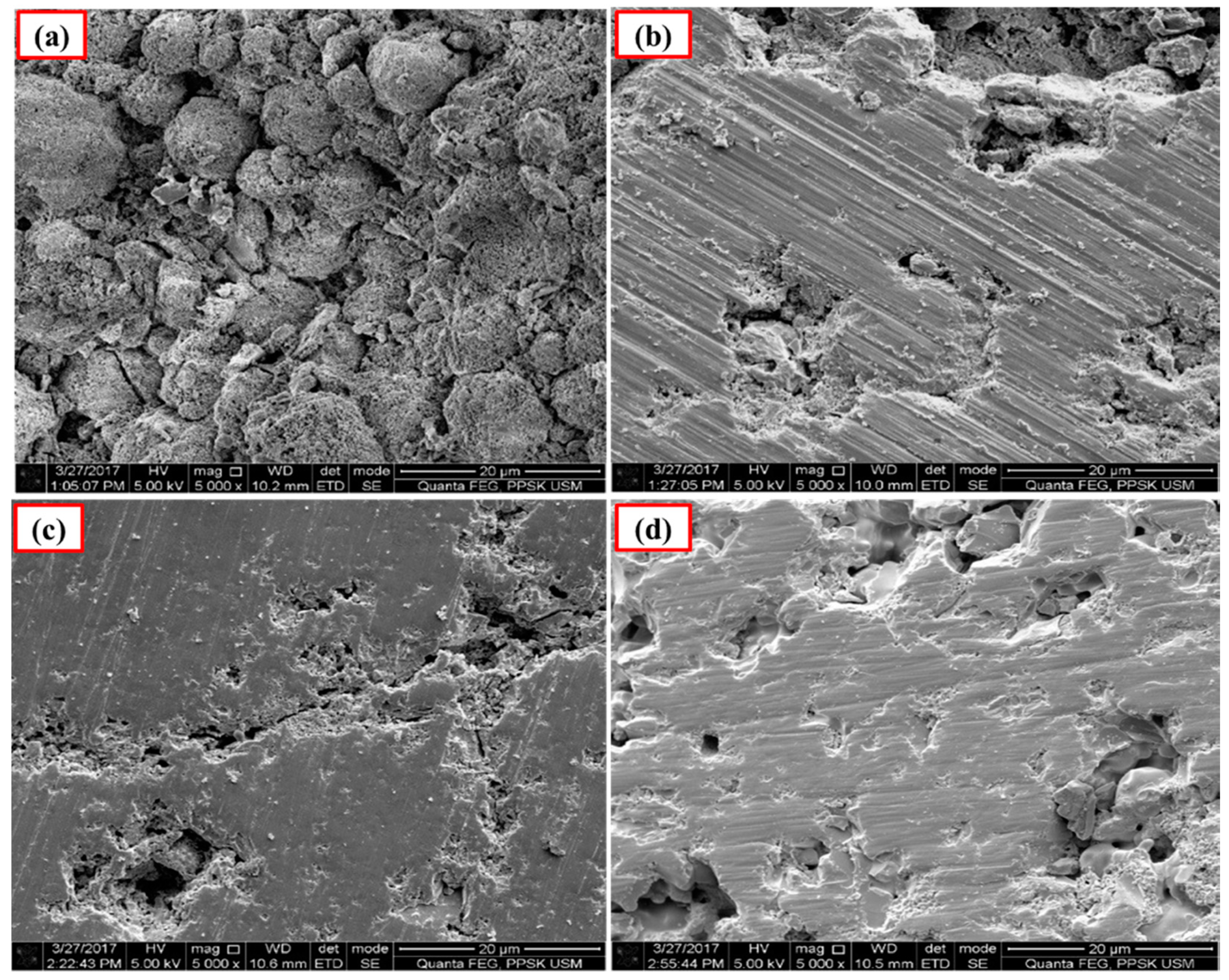

3.2. SEM Analyses

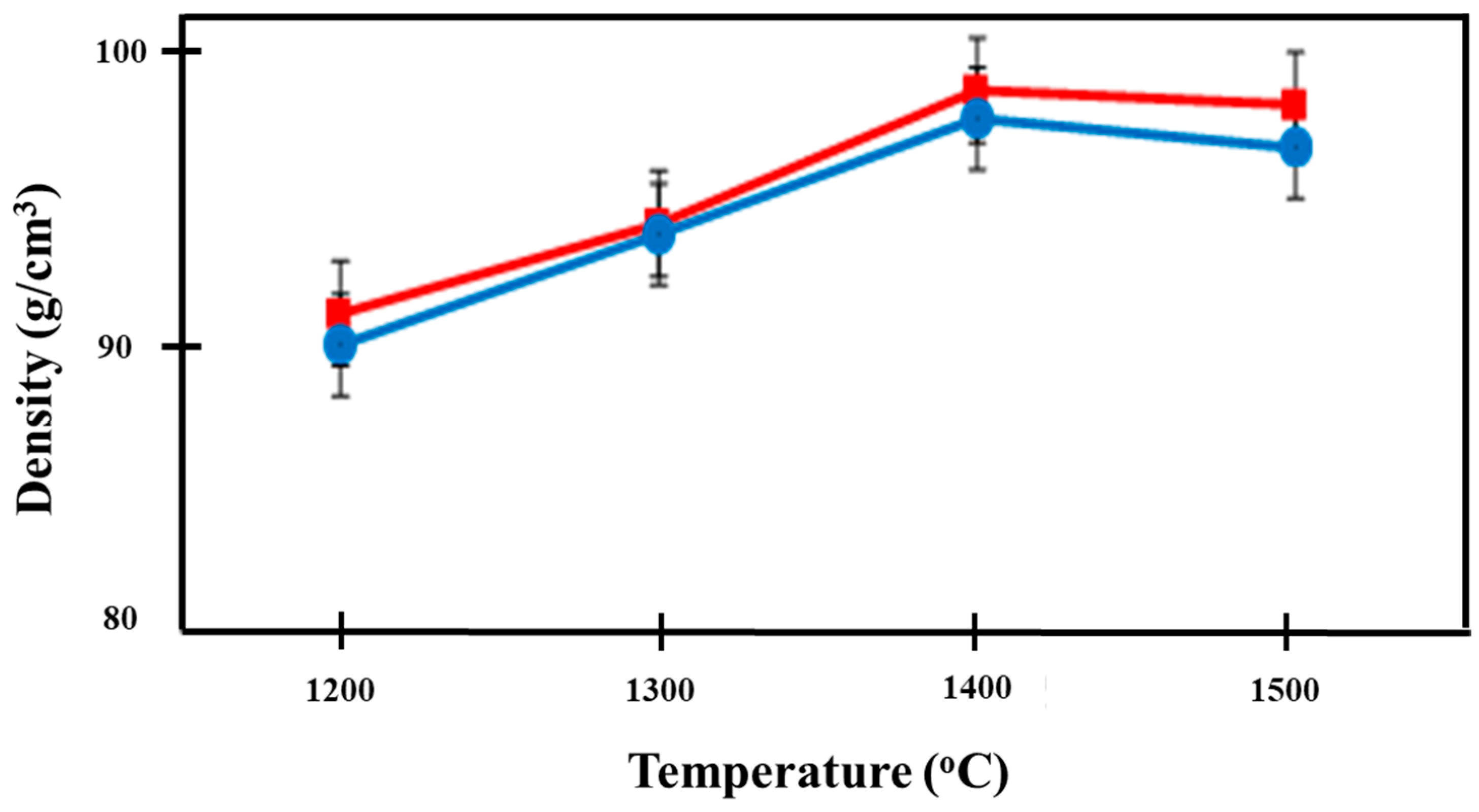

3.3. Density

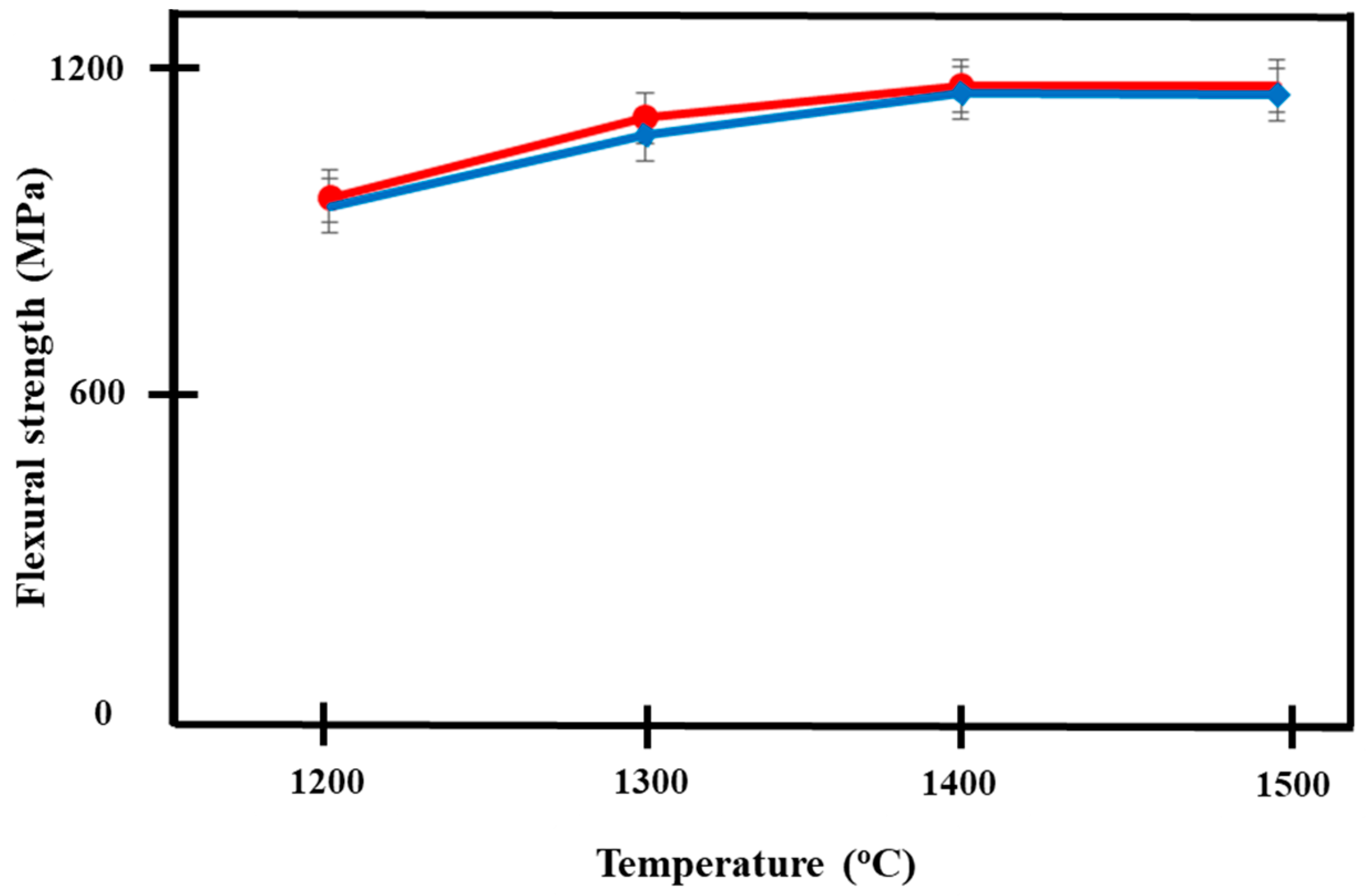

3.4. Flexural Strength

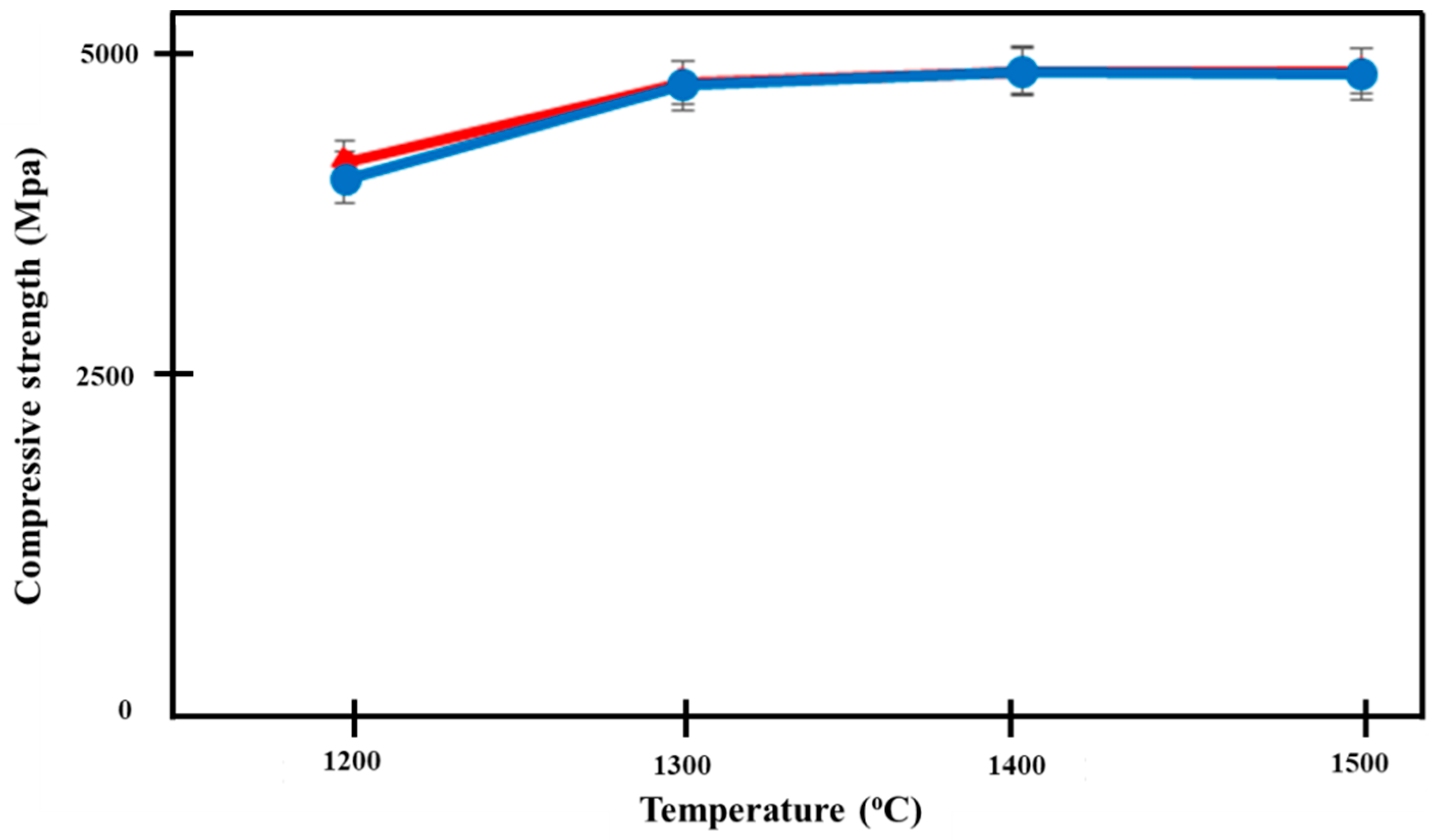

3.5. Compressive Strength

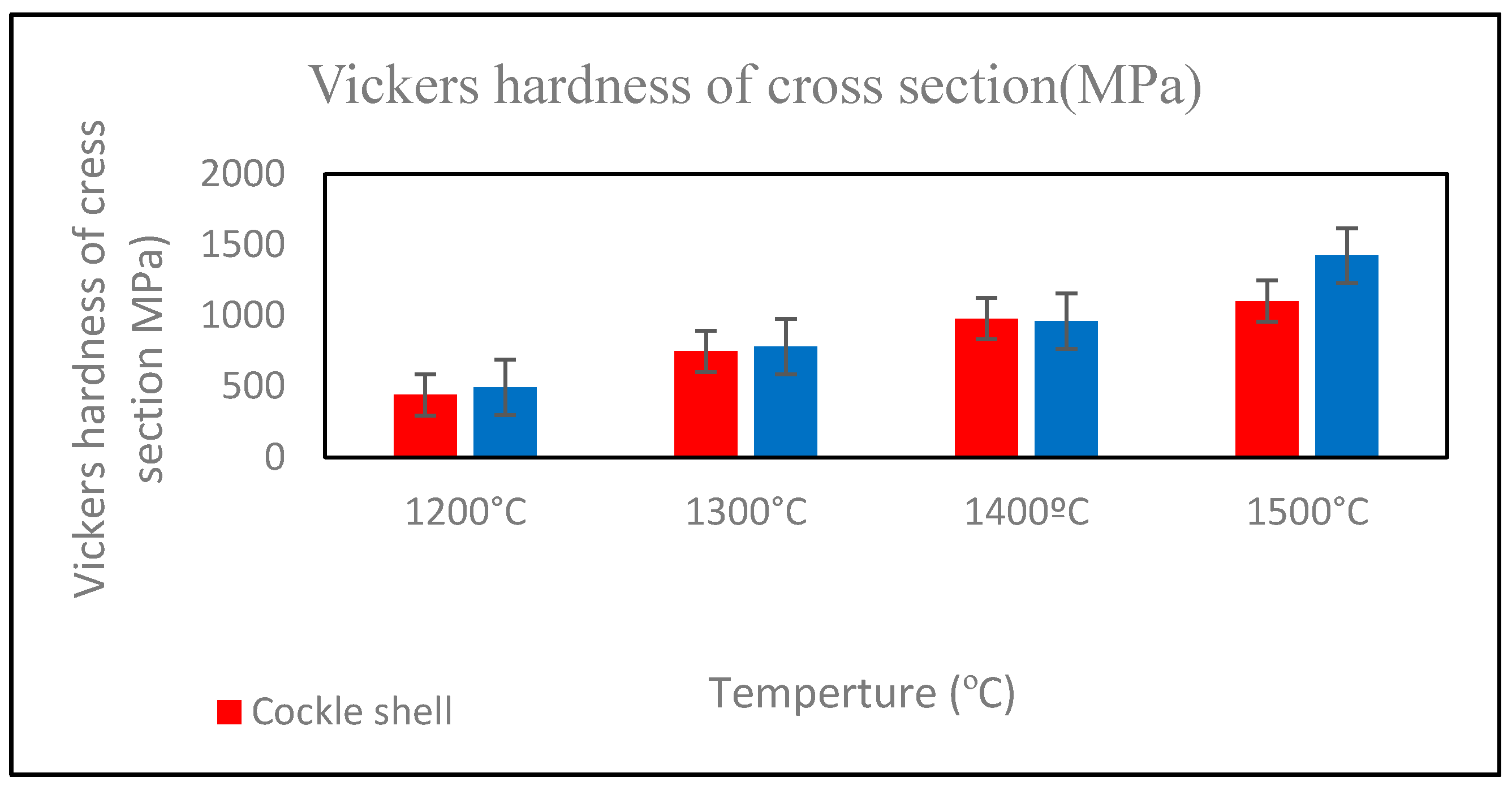

3.6. Vickers Hardness

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Afrashtehfar, K.I.; Del Fabbro, M. Clinical performance of zirconia implants: A meta-review. J. Prosthet. Dent. 2020, 123, 419–426. [Google Scholar] [CrossRef] [PubMed]

- Raigrodski, A.J. Contemporary materials and technologies for all-ceramic fixed partial dentures: A review of the literature. J. Prosthet. Dent. 2004, 92, 557–562. [Google Scholar] [CrossRef] [PubMed]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef] [PubMed]

- Lazar, D.R.; Bottino, M.C.; Özcan, M.; Valandro, L.F.; Amaral, R.; Ussui, V.; Bressiani, A.H. Y-TZP ceramic processing from coprecipitated powders: A comparative study with three commercial dental ceramics. Dent. Mater. 2008, 24, 1676–1685. [Google Scholar] [CrossRef]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef]

- Dion, I.; Rouais, F.; Baquey, C.; Lahaye, M.; Salmon, R.; Trut, L.; Cazorla, J.; Huong, P.; Monties, J.; Havlik, P. Physico-chemistry and cytotoxicity of ceramics: Part I–Characterization of ceramic powders. J. Mater. Sci. Mater. Med. 1997, 8, 325–332. [Google Scholar] [CrossRef]

- Nawa, M.; Nakamoto, S.; Sekino, T.; Niihara, K. Tough and strong Ce-TZP/alumina nanocomposites doped with titania. Ceram. Int. 1998, 24, 497–506. [Google Scholar] [CrossRef]

- Tanaka, K.; Tamura, J.; Kawanabe, K.; Nawa, M.; Oka, M.; Uchida, M.; Kokubo, T.; Nakamura, T. Ce-TZP/Al2O3 nanocomposite as a bearing material in total joint replacement. J. Biomed. Mater. Res. 2002, 63, 262–270. [Google Scholar] [CrossRef]

- Christel, P.; Meunier, A.; Heller, M.; Torre, J.; Peille, C. Mechanical properties and short-term in vivo evaluation of yttrium-oxide-partially-stabilized zirconia. J. Biomed. Mater. Res. 1989, 23, 45–61. [Google Scholar] [CrossRef]

- Guazzato, M.; Albakry, M.; Ringer, S.P.; Swain, M.V. Strength, fracture toughness and microstructure of a selection of all-ceramic materials. Part II. Zirconia-based dental ceramics. Dent. Mater. 2004, 20, 449–456. [Google Scholar] [CrossRef]

- Strub, J.R.; Rekow, E.D.; Witkowski, S. Computer-aided design and fabrication of dental restorations: Current systems and future possibilities. J. Am. Dent. Assoc. 2006, 137, 1289–1296. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, T.; Nakamura, T.; Matsumura, H.; Ban, S.; Kobayashi, T. Current status of zirconia restoration. J. Prosthodont. Res. 2013, 57, 236–261. [Google Scholar] [CrossRef] [PubMed]

- Hannink, R.H.; Kelly, P.M.; Muddle, B.C. Transformation toughening in zirconia-containing ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Kohorst, P.; Borchers, L.; Strempel, J.; Stiesch, M.; Hassel, T.; Bach, F.-W.; Hübsch, C. Low-temperature degradation of different zirconia ceramics for dental applications. Acta Biomater. 2012, 8, 1213–1220. [Google Scholar] [CrossRef] [PubMed]

- Nath, S.; Sinha, N.; Basu, B. Microstructure, mechanical and tribological properties of microwave sintered calcia-doped zirconia for biomedical applications. Ceram. Int. 2008, 34, 1509–1520. [Google Scholar] [CrossRef]

- Drazin, J.W.; Castro, R.H. Phase stability in calcia-doped zirconia nanocrystals. J. Am. Ceram. Soc. 2016, 99, 1778–1785. [Google Scholar] [CrossRef]

- Hussein, A.I. Synthesis of Nano Calcium Oxide from Cockle Shells as Stabilizer for Fabrication of Zirconia. Ph.D. Thesis, Pusat Pengajian Sains Pergigian, Universiti Sains Malaysia, Penang, Malaysia, 2018. [Google Scholar]

- Wahi, A.; Muhamad, N.; Sulong, A.B.; Ahmad, R.N. Effect of sintering temperature on density, hardness and strength of MIM Co30Cr6Mo biomedical alloy. J. Jpn. Soc. Powder Powder Metall. 2016, 63, 434–437. [Google Scholar] [CrossRef]

- Radfarnia, H.R.; Iliuta, M.C. Development of zirconium-stabilized calcium oxide absorbent for cyclic high-temperature CO2 capture. Ind. Eng. Chem. Res. 2012, 51, 10390–10398. [Google Scholar] [CrossRef]

- Gempita, G.; Hasratiningsih, Z.; Subrata, G.; Purwasasmita, B.S. Synthesis of mesh-shaped calcia partially stabilized zirconia using eggshell membrane template as filler composite. Padjadjaran J. Dent. 2017, 29. [Google Scholar] [CrossRef]

- Kurapova, O.Y.; Glumov, O.; Pivovarov, M.; Golubev, S.; Konakov, V. Structure and conductivity of calcia stabilized zirconia ceramics, manufactured from freeze-dried nanopowder. Rev. Adv. Mater. Sci. 2017, 52, 134–141. [Google Scholar]

- Tovar-Vargas, D.; Turon-Vinas, M.; Anglada, M.; Jimenez-Pique, E. Enhancement of mechanical properties of ceria-calcia stabilized zirconia by alumina reinforcement. J. Eur. Ceram. Soc. 2020. [Google Scholar] [CrossRef]

- Jung, J.-H.; Yon, S.-J.; Seok, J.-W. Cubic zirconia single crystal growth using shell by skull melting method. J. Korean Cryst. Growth Cryst. Technol. 2013, 23, 124–128. [Google Scholar] [CrossRef]

- Buasri, A.; Chaiyut, N.; Loryuenyong, V.; Worawanitchaphong, P.; Trongyong, S. Calcium oxide derived from waste shells of mussel, cockle, and scallop as the heterogeneous catalyst for biodiesel production. Sci. World J. 2013, 2013. [Google Scholar] [CrossRef] [PubMed]

- Laonapakul, T.; Sutthi, R.; Chaikool, P.; Mutoh, Y.; Chindaprasirt, P. Optimum conditions for preparation of bio-calcium from blood cockle and golden apple snail shells and characterization. Sci. Asia 2019, 45, 10–20. [Google Scholar] [CrossRef]

- Ghazali, S.S.; Kem, K.L.; Jusoh, R.; Abdullah, S.; Shariffuddin, J.H. Evaluation of La-Doped CaO Derived from Cockle Shells for Photodegradation of POME. Bull. Chem. React. Eng. Catal. 2019, 14, 205. [Google Scholar] [CrossRef]

- Mohamad, S.F.S.; Mohamad, S.; Jemaat, Z. Study of calcination condition on decomposition of calcium carbonate in waste cockle shell to calcium oxide using thermal gravimetric analysis. ARPN J. Eng. Appl. Sci. 2016, 11, 9917–9921. [Google Scholar]

- Papanagiotou, H.P.; Morgano, S.M.; Giordano, R.A.; Pober, R. In vitro evaluation of low-temperature aging effects and finishing procedures on the flexural strength and structural stability of Y-TZP dental ceramics. J. Prosthet. Dent. 2006, 96, 154–164. [Google Scholar] [CrossRef]

- Turon-Vinas, M.; Zhang, F.; Vleugels, J.; Anglada, M. Effect of calcia co-doping on ceria-stabilized zirconia. J. Eur. Ceram. Soc. 2018, 38, 2621–2631. [Google Scholar] [CrossRef]

- Jaiswal, N.; Kumar, D.; Upadhyay, S.; Parkash, O. Ceria co-doped with calcium (Ca) and strontium (Sr): A potential candidate as a solid electrolyte for intermediate temperature solid oxide fuel cells. Ionics 2014, 20, 45–54. [Google Scholar] [CrossRef]

- Jaiswal, N.; Kumar, D.; Upadhyay, S.; Parkash, O. Effect of Mg and Sr co-doping on the electrical properties of ceria-based electrolyte materials for intermediate temperature solid oxide fuel cells. J. Alloys Compd. 2013, 577, 456–462. [Google Scholar] [CrossRef]

- Meng, F.; Liu, C.; Zhang, F.; Tian, Z.; Huang, W. Densification and mechanical properties of fine-grained Al2O3–ZrO2 composites consolidated by spark plasma sintering. J. Alloys Compd. 2012, 512, 63–67. [Google Scholar] [CrossRef]

- Wang, C.-J.; Huang, C.-Y.; Wu, Y.-C. Two-step sintering of fine alumina–zirconia ceramics. Ceram. Int. 2009, 35, 1467–1472. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Wang, C.-A. Effect of sintering temperature on compressive strength of porous yttria-stabilized zirconia ceramics. Ceram. Int. 2010, 36, 1697–1701. [Google Scholar] [CrossRef]

- Benzaid, R.; Chevalier, J.; Saâdaoui, M.; Fantozzi, G.; Nawa, M.; Diaz, L.A.; Torrecillas, R. Fracture toughness, strength and slow crack growth in a ceria stabilized zirconia–alumina nanocomposite for medical applications. Biomaterials 2008, 29, 3636–3641. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussein, A.I.; Che Mat, A.N.; Abd Wahab, N.A.A.; Rahman, I.A.; Husein, A.; Ab-Ghani, Z. Synthesis and Properties of Novel Calcia-Stabilized Zirconia (Ca-SZ) with Nano Calcium Oxide Derived from Cockle Shells and Commercial Source for Dental Application. Appl. Sci. 2020, 10, 5751. https://doi.org/10.3390/app10175751

Hussein AI, Che Mat AN, Abd Wahab NAA, Rahman IA, Husein A, Ab-Ghani Z. Synthesis and Properties of Novel Calcia-Stabilized Zirconia (Ca-SZ) with Nano Calcium Oxide Derived from Cockle Shells and Commercial Source for Dental Application. Applied Sciences. 2020; 10(17):5751. https://doi.org/10.3390/app10175751

Chicago/Turabian StyleHussein, Abbas Ibrahim, Ahmad Nazeer Che Mat, Nur Ain Adila Abd Wahab, Ismail Ab. Rahman, Adam Husein, and Zuryati Ab-Ghani. 2020. "Synthesis and Properties of Novel Calcia-Stabilized Zirconia (Ca-SZ) with Nano Calcium Oxide Derived from Cockle Shells and Commercial Source for Dental Application" Applied Sciences 10, no. 17: 5751. https://doi.org/10.3390/app10175751

APA StyleHussein, A. I., Che Mat, A. N., Abd Wahab, N. A. A., Rahman, I. A., Husein, A., & Ab-Ghani, Z. (2020). Synthesis and Properties of Novel Calcia-Stabilized Zirconia (Ca-SZ) with Nano Calcium Oxide Derived from Cockle Shells and Commercial Source for Dental Application. Applied Sciences, 10(17), 5751. https://doi.org/10.3390/app10175751