1. Introduction

Mango is a popular fruit of Asia. There has been a growing demand for high-quality mangoes in markets. Therefore, grading the quality of fruit has become vitally important for farmers. Besides, the quality of mangoes is not only affected by the growth and maturation before harvesting but also depends on the post-harvest. Manual grading and classifying of mangoes is laborious, resulting in the cost of fruits increasing and quality being uneven. Increasingly, vendors are placing requirements not only on external factors like size, color, and firmness but on internal quality factors such as sugar content and acidity. Although consumers buy fruit based on their external appearances, the taste of the fruit is used to determine whether the consumer buys again. Therefore, in this study, we use Machine Learning (ML) to grade the mango’s quality based on external features taken from the computer vision system combined with weight. The internal quality of the fruit is determined by various measurement techniques based on non-destructive testing (NDT) [

1]. This technique has many advantages but it still has certain limitations such as poor reliability and the need for constant recalibration. The problem of mango evaluation has been of concern in many studies. Most of them used both numerical approach and analytical approach based on external features of mangoes such as color, dimensions, shape, weight, or defects that extracted from image data. Many authors used different algorithms of ML for evaluating the quality of mango like as a new trend in agriculture. Nandi et al. [

2] proposed an ML technique for sorting mangoes in terms of maturity. The captured images from the camera are converted to the binary images and then the sizes of mangoes is estimated. These features were used to grade mango into four groups based on the Support Vector Machine (SVM) method. Pise, Dnyaneshwari, and G.D. Upadhye [

3] graded mango by determining the mango’s maturity as well as quality in the form of size, shape, and surface defects. Experiments of Pandey et al. [

4] considered 600 mango samples from several orchards. The quality of mango was decided by its grading standard. The classification related to distinguishing healthy or diseased mangoes, ripe or mature. Therefore, the color was used to classify fruits into different categories. Several other studies also mentioned the estimated volume of mango based on the cylinder approximation analysis method [

5]. There were also some researches using both SVM and Discriminant Analysis (DA) to analyze and estimate the shape of mango. Thereby, weights of mango were determined in order to classify them [

6]. The volume data were analyzed through a variety of methods. The mangoes were also classified based on their sweetness [

7] which was measured with Near-Infrared Diffuse Reflectance. The quality of mangoes was also graded by maturity. Nandi et al. [

8] graded the quality of mangoes based on RFE-SVM and the Multi-Attribute Decision Making (MADM) approaches. Besides, image processing was used to extract the color, size, sphericity, and weight, which was possible to know the maturity time of the mangoes in each stage as well as grading mango [

9]. Procedures [

2,

3,

4,

5,

6] performed well in mango classification based on weights and sizes of them. Color and defect were concerned [

8,

9].

In general, the combination of all the features to classify mangoes is necessary. This brings more accuracy for evaluation of mango quality. This paper proposes a novel mango grading system based on external features taken from the computer vision system combined with weight. In computer vision, a camera is used to capture the external features of mango and the weight is taken from the load-cell sensor. Furthermore, the algorithm can be applied for the other fruits. The main idea of the proposed method is to use supervised ML to grade the mango based on the combination of appearance features and density. The efficiency of the proposed method is evaluated through a small labeled dataset acquired randomly from several orchards. Supervised ML is the process based on previously labeled data to give predictions to unlabeled objects. The proposed algorithm is relevant to Multiclass Classification (MC). Many previous studies presented some effective models in fruit categorization such as Support Vector Machine (SVM) [

3,

5,

8], Linear Discriminant Analysis (LDA) [

5,

6,

9], Random Forest (RF) [

10], and K-Nearest Neighbors (KNN) [

11]. This study, by including four ML models of SVM, DA, KNN, and RF, is different from previous ones. In reality, density is directly considered as the factor of quality for a variety of fruits. The contribution of this paper is a mango classification method which uses fruit density as one of the main factors to classify quality with size and defect. Besides, density-based methods with external features can be applied to other fruits to evaluate the quality of the internal quality without complex

NDT equipment. The main method based on RF algorithm is a calculation procedure using the weight and external features extracted from the vision machine. In addition, three ML models like KNN, LDA, and SVM are applied to grade and classify. On the other hand, a NCV method is employed to confirm the accuracy of mango classification. Experimental results show that the system has a high accuracy of 98.1%.

2. Structure of Quality Grading System

This study has been applied and put into practice to experiment in many orchards in Vietnam. The hardware of the grading system is shown in

Figure 1. To acquire the data from captured images and evaluate geometric parameters of mangoes, several models are employed. The signal of weight is taken from the load-cell and processed to give weight shown in

Figure 2. The signal from the load-cell is eliminated noise by Kalman filter.

A system in

Figure 1 is designed and developed for this study. The sorting system consists of two main parts. The first part is the image processing system that implements conventional image processing using a series of algorithms that convert unstructured data into structured data to extract three external features such as length, width, and defect. The external features of mangoes can be extracted by various methods such as image processing, ML, and deep learning. In this study, the image processing is more efficient, because of its fast processing time without a large training dataset. This method changes processing parameters, which are determined more difficult in both ML and deep learning. The extracted features of the captured image are combined with weight to generate a full data set in order to leverage machine learning models. The second part is the weighting and grading system to classify mango into

G1,

G2, and

G3.

In the sorting system, the mangoes enter the vision chamber by a roller conveyor system. During movement, the mango is rotated around the roller axis and captured at different positions by a camera to accurately predict its external features. The mangoes then move into the tray conveyor to weigh and sort them based on the central processing signal. After that, in the central processing unit, the mangoes’ weight and external features are combined to generate a data set which prepared for the training in ML models. The unstructured data is converted to structured data, then it is put into models of ML to predict the grades. Last but not least, the data transmission is carried out on the server to ensure all processed data in the best.

The density depends on weight and volume which is a function of size. The change in weight and size of mangoes gradually increases with the mango’s quality. The quality parameters such as size, shape, color, total soluble solids (

TSS), acidity, pH, physiological weight, juice, pulp, and moisture content are important for evaluating the external and internal qualities. They are determined by various parameters, which involve

NDT techniques. However, the most important parameter is sweetness from evaluating the internal quality. The sweetness of mango depends on its density. Mango of high density has the better quality in the range of more than 1.0. The most sort after mangoes have characteristics such as bright yellow skin and sweetness. In contrast, a mango with a lower density than 1.0 is of poor quality; it could be sour because of lack of nutrients in the maturity stage.

Figure 3 shows relationship between sweetness and density. Therefore, weight a factor to classify quality along with size and defect.

The operating procedure of the system is summarized in

Figure 4. Input data is processed and then ML is applied to classify mango simultaneously by the central processor. The input data undergoes several image processing algorithms to achieve structured data including length, width, defects, and weight, then saves all this data to the server. At the same time, the central processor takes data from the server to train the model and then gives predictions whether the mango is

G1,

G2, or

G3.

In many references, supervised ML models were chosen to apply because these are simple and common models in the classification that have been evaluated to be effective in a number of other studies about grading fruits with artificial intelligence. These models are simple and require few operating resources thus bring an advantage in processing time for the system. ML is used to train machines to handle the data more efficiently based on algorithms and statistical models. In this study, applying ML is implemented to grade and sort the mango by learning from data. A supervised ML algorithm is used with external assistance. The input data set is divided into testing, validation, and training data. Supervised ML is the algorithm that creates a function that maps input data to the desired outputs, which are appropriate for the classification problems. The supervised machine learning algorithm learns from training datasets for classifying the mangoes into different groups based on desired standards. All algorithms learn some kind of sample from the training dataset and apply them to the testing data for classification. The four common models are discussed include

RF,

LDA,

SVM, and

KNN. The image process of sorting mango using ML is described in the schematic of

Figure 3. The software of all the experiments was carried out on Python 3.6 (Python Software Foundation, Fredericksburg, VA, USA).

4. Image Processing

In this part, the vision machine is applied to the analysis of visible imaging. This process consists of 3 steps shown in

Figure 5. In the first step, the images are acquired through the roller conveyor system inside the image processing chamber which is sealed and lighted. In the second step, captured images are processed by multiple algorithms such as increase fps (frames per second), image noise filter, edge detection, and boundary tracking. In the final step, length, width, and defect are extracted to generate a dataset. A reference [

5] described a threshold method. The digital images are converted into binary images, then it is processed via a sequence of morphological image processing. Each frame is handled through different algorithms including filtered noise, edge detection, and boundary trace to detect objects in the images [

12]. The structure of the hardware and the vision chamber are designed based on the required productivity of the system, therefore the flow of moving mango is treated continuously during its movement.

During the movement of mango inside the vision chamber, the image of the mango is sent to a central processor consecutively. The sorting system should handle continuously for a certain time so mango’s images are acquired in real-time. The frame rate is a factor that affects the accuracy of processing. The accuracy is proportional to the increase in frame rate. Therefore, using algorithms to increase frame rate is a suitable choice. Besides, the defect is detected from captured images, therefore depth-aware video frame interpolation [

13] is used to ensure the small error estimation. The new

ith frame (f

i) is created from two adjacent frames (f

i−1) and (f

i+1), the value of frame rate increases to more double. The new frame is synthesized from 2 successive frames (f

i−1) and (f

i+1) by arbitrary-time flow interpolation [

14]. The intermediate frame (f

i) is relied on visual flow from image

and image

in Equations (7) and (8).

A Gaussian filter [

15] is used to solve noised image, then the boundaries of the objects are detected. The Kernel matrix slides across each row and multiply by area of the image. Let

μ,

σ be mean, variance of Gaussian distribution, respectively.

x and

y are two variables of Equation (9) and

.

After filtering the frames, the next step is to reduce the number of dimensions of the image to detect mango position. The RGB images are converted to appropriate binary image depending on the color values. Conversion from original RGB to greyscale uses NTSC method [

16]. Next, conversion from grayscale to binary image based on Otsu’s method [

17]. The threshold

C separates pixels into two classes. The weighted sum of variances of the two classes

is defined by Equation (10). The probabilities are q

1 (Equation (11)) and q

2 (Equation (12)) which are from the

I bins. Variances of the two classes are

and

mean. The means μ

1 and μ

2 of probabilities q

1 and q

2 are calculated using the Equations (13) and (14), respectively.

From Equations (11)–(14), the variance is calculated as Equations (15) and (16).

I(x,y) is the light intensity at a single pixel and INP(x,y) is the intensity of the pixel on the binary, 0 < x < Length and 0 < y < Width. The thresholding method is used to detect the color threshold. Values exceeding the threshold value are set to 1 and vice versa values inside threshold value are set to 0. The input of the method is the gray image and the threshold value.

From the binary image, the edges of the object are highlighted, then the remaining thing is to connect those points to form the boundary of the object. There are two methods of edge detection such as algebraic and geometric methods, but algebraic methods give unstable results, so it is appropriate to use geometric methods based on partial geometric differential equations. For a better understanding of the algorithms in [

18], a brief description is given. A model satisfies the maximum principle and permits a rigorous mathematical analysis was used effectively. The algorithm to find the contour of objects is done by two methods of mathematics and geometry. The boundary of the object

Eint are detected and interpolated into curves according to the Equation (17).

where

v(

t) = (

x(s),

y(s)),

s ∈ (0, 1),

α > 0 and

β > 0 are the factors that affect the elasticity and rigidity coefficients of curve.

The edges

Eext are detected based on Equation (18) with maximum curve possible ∇

I(

v(

t)). Combining both of the above formulas, edge detection, and boundary tracking

E(

v,

α,

β,

λ) are shown through Equation (19).

In the above section, the image processing methods are described to extract mango size easily and quickly through a series of effective algorithms.

5. Extracting Mango External Features from Captured Images

The images were segmented with a level of 0 for the pixel area of the mango and 1 for the remaining pixel area in each frame. The next task is to calculate the area of the pixels according to the actual size. This is the step that greatly affects the accuracy of the process. With binary images, the pixel area is used to estimate actual size by Equation (20).

Length

L is the length to be estimated,

Aboundary is the number of pixels and

K is a ratio constant between size in pixel and the actual size. Moving objects make the distance from the camera to the objects change, therefore the proportional constants are also changed. In other words, the rate of constant changes with the distance from the camera to the object. Therefore, the

K ratio factor should be appropriately estimated. With the same length at each focal distance, the number of pixels representing that length varies. Therefore, the closer to the camera is more pixels that represent for that length. That means the area of each pixel will decrease as the distance decreases. To determine the size of the mango from a binary image whose coefficient of

K changes due to the motion of the mango, the scale factor from real data is estimated

K ≈ F(

Length). This is a linear function because as the number of pixels increases, the length also increases. So linear planning is an appropriate option. The length is

L, the number of pixels in the image is

A, and the values are considered on

n images. The average length

is given by Equation (21).

From Equation (19), the

ratio factor can be found in Equation (22).

The length

is estimated by

in Equation (20). The coefficient of determination is defined in Equation (23).

The error of

K is given in Equation (24).

The defect of the mango is the damage on the surface caused by insects or collisions during its growth that can be scars, dark, spots, etc. The defect areas are detected by the boundaries of the rectangle (

Figure 6). All defects are accumulated on the whole surface and then give the final defect level of each mango. Therefore, the areas of its disability should first be detected and zoned to be detected effectively based on the specific areas of the binary image. The disabled areas are quite small, so they should be covered by the rectangle, so the area of the disability is the area of those rectangles. The mango defects are identified by the total pixel’s area of the zero value inside the mango boundary in the binary image. Because the pixel size ratio is

K, the area of each pixel is

K2. Where

Adefect is the number of defect pixels, (

) is estimated defect; (∆

de) is error of defect depending on the error (ε) of

K. We can calculate the actual defect by Equation (25).

In this section, the actual dimensions of mango are estimated through the implemented algorithms. Based on a series of calculation, the size in pixel is determined to the actual size with an acceptable error. The estimation is calibrated depending on the hardware of the machine. Besides, the size of defects on the mango’s surface is calculated based on summing defective areas.

6. Estimating Volume and Density

The estimation of volume and density depends on the shape of the mango, which varies by region and country. Therefore, the shape is extracted before estimating its volume and density. The harvested mangoes from orchards are shown in

Figure 7. These mango samples are measured by the vision machine and then weighted to generate the data. The prepared data for training models are structured data converted from image and weight signal. The estimation of volume and density consists of 3 steps. In the first step, length, width, and defect are extracted from the captured image by a camera. In the second step, the length, width, and defect are combined with the weight to create the completed dataset. Finally, the volume and density are predicted approximately based on length and width and then its errors are evaluated. The schematic of the preprocessing procedure for predicting the volume and density is shown in

Figure 8.

The internal quality of mango is high if its density is higher than the average level. Farmers can use their experience to evaluate the internal quality by feeling the mango in their hands. The mango volume (

V) has many deterministic methods such as modeling, statistical analysis based on size or weight. In this study, the volume of mangoes is calculated based on two-dimensional images because this method not only requires little resources but also has fast processing time. Since the mango has a complex shape that helps it rotate on the roller, the image processing gives images of a mango in a random orientation. In several references, there are three variables to determine the volume of mango. However, other studies [

19,

20] have shown that width (

wi) and length (

le) are related, therefore, the volume can be determined by

wi and

le instead of three variables. The processed images allow us to extract the values of the mango length and width. In the extraction of features, the orientations of mangoes are random with

n positions presented in

Figure 9a. The mango is detected by a rectangle covering them based on image processing algorithms. During the sampling process,

le and

wi are extracted

n times at

n positions. The process of detecting mangoes and extracting

le and

wi are given in

Figure 9b. In

Figure 9b, two features are determined into

n value pairs (

wi,

le) from

ith mango at

n positions. Experimental results show that the method is effective in mango in Vietnam.

The collected data from images shows the volume depending on two variables as length (

le), width (

wi). An actual process to measure reality mango is carried out with variables like

le,

wi, and

V in

m samples of mango. The task is to predict the volume with the length and width. So, for the regression method,

le and

wi are independent variables and

is a dependent variable that is calculated by Equation (26).

When predicting volume, there is always an error ε. The coefficients of the variables are

. The actual volume

V is calculated in Equation (27).

To evaluate the accuracy of this regression expression, we need to make the sum of squared residuals as small as possible with the sum of squared residuals

ΔV determined by the Equation (28).

The density which varies between mangoes is determined from volume and weight. The internal quality of mango is very important to grade the quality of the mango but has not been considered in previous studies of mango classification [

2,

3,

4,

5,

6,

7,

8,

9]. The density

D of a mango which is given in Equation (29) is estimated by the weight (

we) that get from the load-cell and the volume is predicted by

le and

wi.

The density function is calculated based on

we and

V that have an error in the estimation. Therefore, the error of the density function error is a cumulative error of

we and

V. Therefore, the error of the density function is determined within a range of tolerances. If the cumulative error is too large, it is a bad estimate in this case. From that point of view, the weight error is ∆

we, and the volumetric error is ∆

V. The cumulative error ∆

D is determined in Equation (30).

The cumulative error ∆D is compensated for errors of calculating and estimating the density to ensure the least error in the estimates. This section ends, the volume and density that significantly affect the quality of mangoes have been estimated by a linear regression method.

7. Using Machine Learning for Grading Mangoes

The internal quality of mango is a nonlinear function of features such as length, width, defect, and weight. The quality of mango is graded based on the local standard (VietGAP) or international standards (Global GAP), which are implemented easily to classify according to each feature, but it is difficult to grade the fruits with combination of different features. The relationship of features is found in several methods such as regression, statistical, and machine learning. In this paper, ML is proposed to grade the internal quality of mango, because of its strong ability in calculating and analyzing repeated problems. The papers [

2,

3,

4,

5,

6,

7,

8,

9,

10,

11,

12] looked particularly closely at the application of supervised ML techniques to mango classification. Hence, in this study, four supervised learning algorithms such as

SVM,

LDA,

KNN, and

RF are proposed for grading and sorting mango. The trained models are based on the sampling mango surveys in many orchards in Vietnam. In detail, the samples of mango are randomly selected, and then their types are determined (

Figure 10) by evaluating standards accurately.

Dataset is generated by manually grading mango based on density (

D), volume (

V), and defect (

de). This manual grading is carried out by agricultural experts from Vietnam. The labeled types including

G1,

G2, and

G3 of mangoes are measured by

D,

V, and

de from four extracted features

de,

we,

wi, and

le. Instead of estimating density and volume to classify mango type, in automatic classification, four models namely

RF,

LDA,

KNN, and

SVM are trained and evaluated by the labeled dataset obtained from the manual grading. The hardware and software of the sorting system were presented in

Section 2 and the grading standard is shown in

Table 1.

The dataset is divided into three parts as training, validating, and testing data. The ten-fold Nested CV (

NCV) [

21] was used to separate data. In the outer layer, 10% of the original data was separated for testing data to determine the performance of models. The rest of the data was used to develop a model. The rest of the 90% of the original data was used in the inner layer for the tuning of parameters. Such data are separated into training data for the model to provide a prediction or quality assessment, the validation data are to evaluate the model’s accuracy and select the best parameters of the model based on the given output objectively. This process not only provides the best performance for algorithms but also controls overfitting. The classification of mango is implemented by four steps including normalizing data, eliminating outliers, fitting models, model evaluation. During the data collection process, there are some data points outside the distribution of a statistical dataset called outliers, these points cause a significant error in the classification model. Thus, the dataset needs to be eliminated outliers to create a better new dataset. The outliers can be detected and removed based on the normalization method such as feature scaling, min-max, and z-score, etc. Depending on the purpose, one of the above methods can be used most flexible. The best method for mango data is the z-score [

22] because the normalizations are based on the mean and variance of each variable. The data points are optimized in the distribution of the variables. Because of the features are on significantly different ranges, the feature with a larger scale dominates the predicted results of machine learning. By the z-score normalization, the effect of different features scales is avoided on prediction. Using z-score normalization, four features are reshaped to be between −3 and 3. Data points outside this range are eliminated from data. The effectiveness of data normalization and elimination of outliers to the performance of the four models is illustrated in the experiment section.

The supervised ML models and implementation platforms suitable for the prediction of types of mango are determined by comparing prediction accuracies. Additionally, the optimized parameters of each model to fit the data of mango are discussed. Following analysis of the data to determine the relationship of variables, models are fitted into their parameters to achieve the most effective performance. In the previous studies, several classification models demonstrate the efficiency in grading mango as

SVM [

3,

5,

8],

LDA [

5,

6,

9],

RF [

10], and

KNN [

11]. Hence, in this paper,

SVM,

LDA,

RF, and

KNN models are applied and compared to find the most accurate model in mango classification. The framework of the training process is shown in

Figure 11, which includes six parts: Input, output, Random Forest (

RF), K-Nearest Neighbors (

KNN), Linear Discriminant Analysis (

LDA), and Support Vector Machine (

SVM).

Model

RF: in

RF model, training data consists of k subset randomly selected with replacement. Hence, the set of k subset is denoted

B = {

bi: 0 <

i ≤

k}, where

bi is the

ith subset. The predicted label is determined by majority vote method from k decision tree in

RF. In training process,

RF model separates four features into nodes to lead the final decision node. Low correlation and reasonable strength of the trees are two criteria to improve the performance of

RF [

23]. Consulting many parameters of

RF, two criteria can be achieved by the parameters such as the number of observations that are drawn for each tree (sample_size), splitting criteria in the nodes (splitting_rule), the number of trees in the forest (n_estimators), and the maximum depth of each tree (max_depth). In sample_size, decreased sampling size produces more separate trees and hence a lower correlation between the trees, which positively affects the accuracy of aggregated prediction from trees. However, the precision of individual trees decreases, as the training requires fewer observations. Therefore, Bootstrapping, which uses random samples with replacement to control the sample size of the trees. In splitting_rule, this is one of the main characterizing the RF. There are two rules, such as

Gini impurity or Entropy, but Gini impurity is the better option for this analysis, as

Gini can minimize misclassification and find the largest class while

Entropy finds class groups that account for about 50% of data. Hence, the computing time of

Gini impurity is faster than

Entropy. Each tree in the forest is created by

Gini impurity [

24]. In the maximum depth of each tree and the number of trees in the forest, increasing max_deep and n_estimators lead to deeper trees and more trees, respectively thereby longer computation time. Nevertheless, the prediction efficiency grows up with their increase. Hence, the choice of max_deep and n_estimators can be seen as a trade-off between strength and the accuracy of the trees.

Model

KNN: Let

K be the number of nearest neighbors; the predicted label is aggregated from

K by Large Margin Nearest Neighbor algorithm (

LMNN) [

25]. In

KNN, the number of neighbors is the core deciding factor. The outcome is significantly influenced by the noise of a limited number of neighbors. However, a large number of neighbors have expensive computations. Therefore, the number of neighbors depends on kinds of data sets.

At the same time,

KNN and

RF classify three mango types, while

SVM and

LDA use the ‘

One_vs_all’ method [

26] only to grade a single classifier per class.

Model

SVM: The output is classified based on three hyperplanes

hp1,

hp2, and

hp3. Because three types of mango are classified using hyperplanes generated by various kernels, the kernel function [

27] is the main parameter of SVM. The kernel functions (

rbf) are proposed in this study. The parameter

C and

γ influence the level penalty for misclassification and the complex boundary of separation, respectively. For different data sets, these parameters are different. In this study,

γ and C ranged from 0.3 to 1 and 70 to 100, respectively.

Model LDA: three linear lines are found to separate three types including G1, G2, G3, …. The main factor of the LDA model is the number of returned features which reduce the features of the initial data.

In this section, four supervised learning approaches on the theory and how to apply them to the data in this paper were discussed. The advantages and disadvantages of each model are distinct. The next experiment section will provide insight into the relevance of these models to the existing data set. To evaluate the performance of models, we proposed the well-known and persuasive evaluation metrics for classification (precision, sensitivity, F-measure (F1 score), and accuracy) [

28].

8. Experiments and Discussions

These experiments used 4983 mango samples harvested from November to June to meet the requirements of standards. They were measured accurately by the sorting system of the vision machine and weight. Acquired data from grading work was important and necessary to predict exact grades. The data was collected from the vision machine to get length, width, and area of the defect. This data combined the weight of each mango measured based on load-cell. The parameters of ML were determined to grade the mango quality employing input and output sets. The features of the original data set were collected by image processing and weight. Besides, their labels were classified by the manual classification system. Training and validation data from 90% of the original data were separated by using the NCV method. Besides, testing data accounted for the remaining 10% of the original data. The ML models were implemented to grade the mango quality based on its external features and weight. The models gave the results for 3 types of mangoes as good grade (G1), medium grade (G2), or bad grade (G3). Besides, these models also showed the relations between the input and output with different features. The models predicted the quality based on the qualification standards automatically instead of the manual evaluation. The credibility of models was confirmed by the empirical method using the confusion matrix to evaluate the performance of models. The accuracy of the image processing part was evidenced by the experimental results in which actual and estimated values are compared. The data was measured actually in with length, width, and area of defect by Mitutoyo’s tools with an accuracy of 0.05 mm. The testing data checked the final solution in order to confirm the actual predictive work. Besides, the weight was the subset of testing set measured by electronic scales with an error of 0.01 g. Thereby, the volume (V) of the mango was determined by the overflow method with 1000 mL glass jar with accuracy 0.4 mL. Each feature of mango such as weight, width, and length was measured 10 times to calculate the expected value. From the above sections, the models are recommended to predict types of mangoes. There are four models to apply and implement such as RF, LDA, SVM, and KNN fitted by data.

The mango samples were collected to generate data set applying to the machine learning models considered in previous sections. Then, the accidental error was determined from the comparison between the actual value and the estimated one. The measurement error was smaller, so we can say that this data is reliable and considered as the prepared dataset for machine learning algorithms. Then actual sizes were determined and compared with predicted values which are extracted by the vision machine to give the bias. Besides, the grading and sorting the fruit were carried out according to the standard applied largely. The characteristics of length, width, volume, defect, and density are described in

Table 1. The column of density is not the appearance in any standard for grading the mango or other tropical fruits because their grades depend on the external features without density.

The density of mango cannot be determined indirectly, therefore the density should be predicted by the volume and weight estimated by captured images and load-cell, respectively. In this study, the mangoes are graded and classified into three groups:

G1,

G2, and

G3 with the highest quality being first grade (

G1). The steps of the image processing were experimented as shown in

Figure 12. The vision machine system took the data from the captured digital images of camera and used the platform to determine the parameters of mango using specific functions. The mangoes entered the vision chamber by a roller conveyor system and were captured by a camera. In each RGB image, the mango’s defect, length, and width were extracted through the image conversion stages: Calibration image, HSV image, and binary image. In

Figure 13, The distributions of length, width, and volume in the dataset have a shape similar to the Gaussian function. Besides, we observed that length and width have a linear relationship to volume (

V). Hence, the volume of mango is predicted from its length and width based on the prediction model of linear regression shown in Equation (31).

The estimated sizes as length and width from pixels of the binary image of mango were compared with the actual ones. Additionally, the estimated values of volume by external features were different from actual volumes, which determined by the overflow method. Thus, we utilized three measures to compare the performance of the estimation features. These measures (

Table 2) are the mean absolute error (

MAE), the root mean square error (

RMSE) [

29], and the mean absolute percentage error (

MAPE) [

30]. According to

Table 2, the results show good performance. The

MAPE with the maximum value of 0.01283 and the minimum value of 0.00486 are acceptable. The

MAE of length, width, defect, volume, and density are 0.65371, 0.50863, 0.02954, 5.79612, and 0.01376, respectively. Five features show that there are small error distributions due to insignificant differences between

RMSE and

MAE.

The importance of data normalization and elimination of outliers (

DNEO) in model accuracy was mentioned in

Section 7. The impact of the

DNEO process on model performance is therefore presented in this section. As can be seen from

Table 3, four features are in very different ranges which are determined by min and max values of variables. The ranges of

we,

he,

wi account for (112,784), (15,300), (16,300), respectively while that of defect only from (0–29) and it is the lowest scale. Although

de is important as a predictor, it intrinsically influences the result less due to its smaller value. After using the

DNEO process, in

Table 4, there is a significant decrease of 218 outliers in the original data. In

Figure 14a, the data points beyond the smallest, and the largest observation is considered outliers. Hence, there are a lot of outliers to remove in this data.

Figure 14b indicates that the range of features is normalized to about (−1712, 1737). The effect of data normalization and elimination of outliers (

DNEO) on the accuracy of the models is shown in

Figure 15.

The performances of models are evaluated by using the confusion matrix because it observes the relations between the classifier outputs and the true ones. The elements in the diagonal (

nij,

i =

j) (

i is row identifier and

j is the column identifier) are the elements correctly classified, while the elements out of the diagonal are misclassified. Four models are built with two choices: Without

DNEO and with

DNEO.

Figure 15 shows the effect of the data normalization and elimination of outliers on four models relying on the confusion matrix. A significant increase in performance is shown in all four models, if the

DNEO is used. In the original dataset, the accuracy of

RF,

LDA,

KNN, and

SVM models account for 41.31%, 44.00%, 41.31%, and 44.28%, respectively. After using

DNEO, the corresponding performances of these models considerably grow up to 91.50%, 86.56%, 86.20%, and 81.90%. According to

Figure 15, the accuracy of the

RF model is the highest, the

SVM model is the lowest.

Additionally, the prediction for class

G2 in all models is lower in the two other classes. After the implementation of the

DNEO, result has unqualified performance because of uncontrolled overfitting. Additionally, models’ parameters have still not been identified optimally. Varma and Simon [

21] showed that overly optimistic performance estimates can be produced by using the same data to validate and train models. They also suggested the unbiased performance estimates given in nested cross-validation (

NCV).

NCV method used to tune parameters with an internal

NCV loop while an external

NCV was used to calculate an estimate of the error. Considering the accuracy of the models by the size of the training data to select the number of folds in the

NCV method (

Figure 16). The horizontal axis denotes the percentage of the initial data used for training models. The vertical axis denotes the accuracy of the models that match the horizontal axis values. In

Figure 16, when training about 80% of the original dataset, the accuracy of models is the highest. Therefore, in both the inner and outer loops of the

NCV method, 10 folds were used to ensure that 80% of the data was used in training models.

The performance of the models was determined by testing data divided 10 times in the outer layer. The estimation of accuracy (

Figure 17) was implemented 10 times corresponding to 10 folds in the outer layer. The performances of four models with adjusting their parameters were evaluated by validation and testing data. The horizontal axis denotes the evaluating iteration of model performance and the vertical axis denotes the percentage of model performance. The black line in the figure presents the training score and the red line denotes the validation score of models with the best parameters. The training and validation scores were determined by validation and testing data, respectively. Finally, the gray area around the red line shows the standard deviation in the outer layer performance of each fold.

The model’s performances show that parameter selection in the NCV method is important for controlling overfitting. The separation of the initial data into training and testing data gives a smaller effect. The accuracy of RF, LDA, KNN, and SVM increase significantly to 98.1%, 87.2%, 94.8%, and 92.7%, respectively. The RF model obtains the highest accuracy at 98.1% if (n_estimators) is range from 80 to 100 and the nodes are expanded until all leaves are pure. The accuracy of the SVM model using Kernel function (rbf) is up 92.7% with γ and C ranged from 0.3 to 1 and 70 to 100, respectively. Moreover, the KNN model has a high accuracy of 94.8% in the number of neighbors ranging from 30 to 60. Finally, when reducing the number of features returned to 1, the LDA model allocates 89.6% accuracy.

The relationship of the features is the linear or nonlinear relationships shown in

Figure 18. Therefore, we should not apply the linear model to grade of mango. The data is divided into 3 parts including training data, validation data, testing data. The samples divided into three parts with 3194 training data visualized in

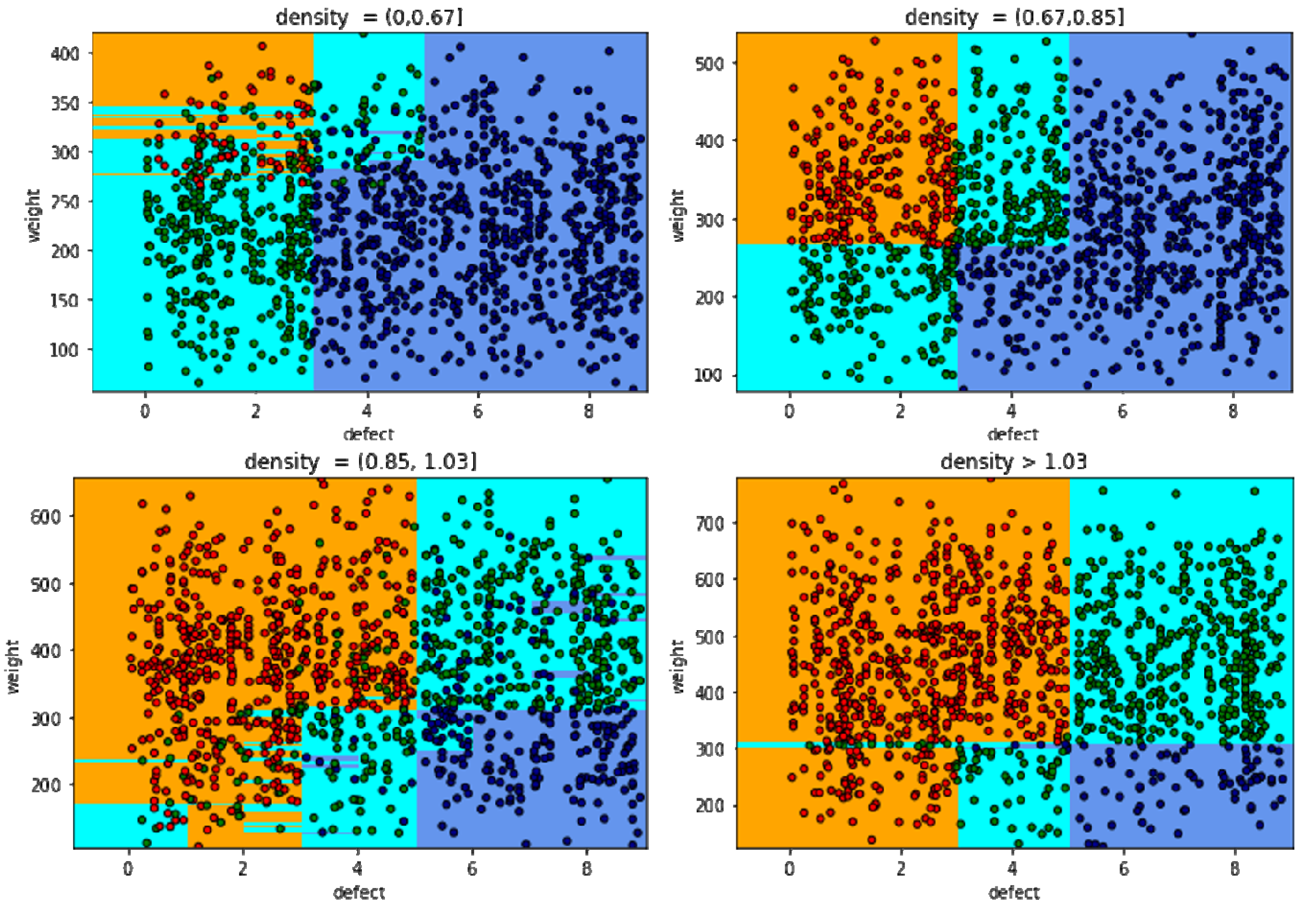

Figure 19, remaining data includes 771 validation, and 1035 testing. The distributing data on the boundary clusters obviously. The clusters in the middle of the data field are complex to classify. Besides, the area of density (0,0.67) and (1.03,1.2) are obvious, it is difficult to determine the boundary of the remaining area of density (0.67,1.03). Because the area of density is small or large, it is easy to identify the type of mango. Meanwhile, the mango classification of the region (0.75,1.03) is difficult to decide the types of mango, because these types depend on other grading factors as weight and volume.

In the experiments, we used four models for grading and classifying. The first model LDA was applied to grade the mangoes and it gave a relative accuracy of 87.9% shown in

Figure 20. The mangoes were clustered well with the density’s areas (0,0.67), and (1.03,1.2), where the mangoes are graded exactly. However, the error increased in the region of density (0.67,1.03), because the types of mangoes

G1,

G2, and

G3 have complex distribution in this density area. Thus, a significant difficulty of classification was seen in the created boundary by linear lines of the LDA method. Besides, many mangoes were classified inexactly in the area of density (0.67,1.03), which is the intersection between quality types of mangoes.

The second model

SVM is similar to

LDA: The clusters of mangoes have boundaries of the hyperplanes. The results of grade based on

SVM have an accuracy of 92.7%. The accuracy of the model

SVM depends on the Kernel function. The types of kernel functions considered for this study include

linear,

polynomial,

rbf, and

sigmoid. The experiments indicate that

rbf is the most efficient Kernel function. The results show that the classification of

SVM is better than the

LDA model (

Figure 21).

Similarly, grading results evaluation in field of density (0,0.67), and (1.03,1.2) is exact. The classification results in the density (0.67,1.03) also give more accurate results than the model of

LDA, because this area is clustered by the hyperplanes, and it makes the classification more flexible. The classification based on the

SVM model is reliable. However, there are inexact grades for classifying, because intersections of types blend together. Another model can support to solve inexact classification being

KNN. It is an algorithm that works and is considered based on predicted points, which affect the classification results and accuracy. The accuracy of the prediction is the proportion inversely neighbors of predicted points. If the number of neighbors are 30, the

KNN model gives grading results shown in

Figure 22.

The classification in density area (0.67,1.03) had more improvement than the SVM model, but in the remaining area, the KNN model is less reliable than the SVM model, because the boundaries of areas are distinct. Therefore, KNN is suitable for problems having many intersections. Three methods LDA, SVM, and KNN have their own advantages as well as a disadvantage in classifying mangoes or fruits.

The final model of

RF overcome the disadvantages of previous models. This model has differing accuracy depending on the number of trees in the forest. If the number of trees increases in number from 80 to 100 trees, the accuracy of the

RF model is between 97 to 98.1%. Therefore, the selected parameters for

RF model is to ensure the stability and training speed of the number of trees (

Figure 23). The disadvantages of the previous models are solved in the area of (0,12) explicitly and accurately according to the rules. The accuracy depends on the complex boundaries between types of mango. From experimental performances of four models LDA, SVM, KNN, and RF, the

RF model is selected to grade mangoes’ quality.

Figure 24 shows the comparison and evaluation of grading results based on four models to give the best model. Besides,

Table 5 shows sensitivity, precision, F1 score, and accuracy as well as the differences between models for grading [

28]. All models give accuracies of more than 87.9%. The best model is

RF with an accuracy of 98.1%.

RF model performed best with average values of sensitivity, precision, F1 score, and accuracy of 98.1%, 98.0%, 98.0%, and 98.1%, respectively. The sensitivity and precision values show that 98.1% of three types (

G1,

G2, and

G3) were correctly classified as corresponding three types and 98.0% correctly predicted types to the total predicted corresponding types. Besides, the lowest performance is

LDA model with average values of sensitivity, precision, F1 score, and accuracy of, respectively, 87.8%, 87.9%, 87.8%, and 87.9%. In comparison, the

KNN model results yielded average values of sensitivity, precision, F1 score, and accuracy of, respectively, 94.1%, 95.6%, 94.5%, and 94.8%, and corresponding average values for

SVM model are 92.6%, 92.0%, 92.3%, and 92.7%. F1 score (98.0%) and accuracy (98.1%) for the RF model are greater than corresponding values for the

KNN,

SVM, and

LDA models. Overall, the results from

Table 5 show that the

RF model outclassed the

KNN,

SVM, and

LDA models in predicting the types of mango in this study.