Power Flow and Efficiency Analysis of High-Speed Heavy Load Herringbone Planetary Transmission Using a Hypergraph-Based Method

Abstract

:1. Introduction

1.1. Motivation and Challenge

1.2. Literature Review

1.3. Scientific Contribution

1.4. Outline of the Paper

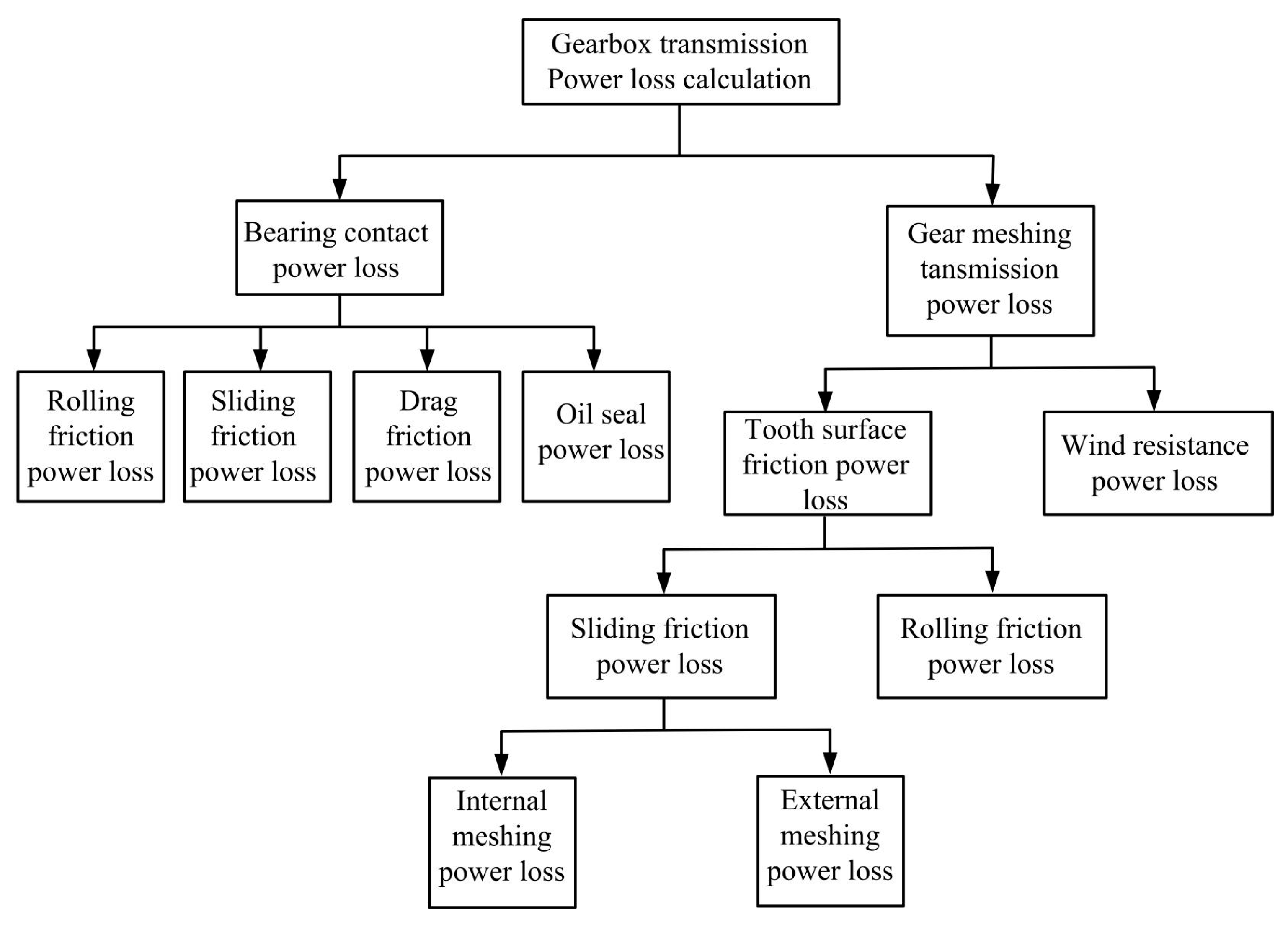

2. Loss Mechanism Hypergraph of Single-Stage Planetary Gear Transmission

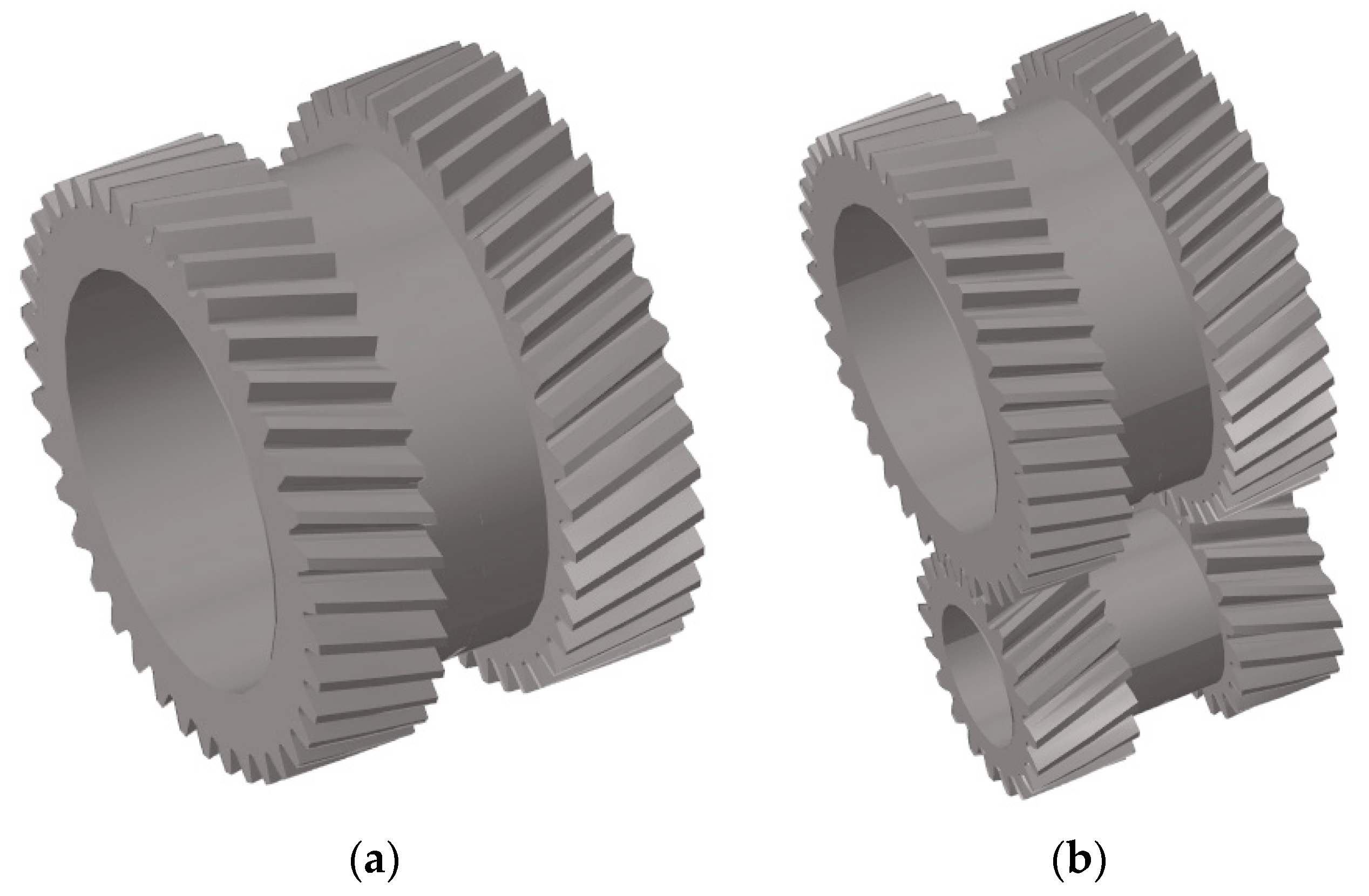

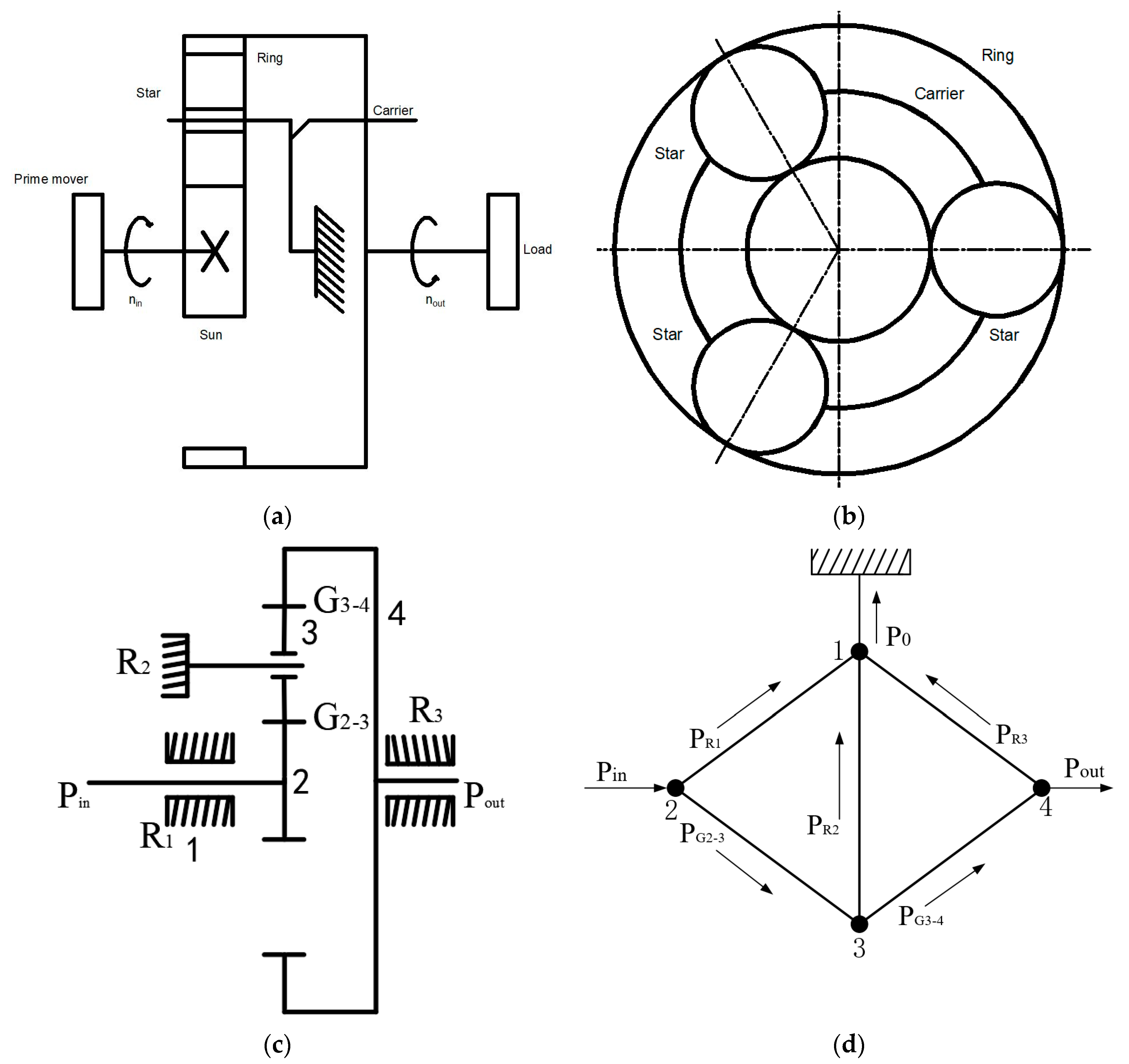

2.1. Basic Structure of Planetary Transmission System

2.2. Loss Mechanism of Single-Stage Planetary Gear Transmission

2.2.1. Hypergraph of Single-Stage Planetary Gear Transmission

2.2.2. Power Loss Mechanism of Single-Stage Planetary Gear Transmission System

2.2.3. Structural Kinematics of Single-Stage Planetary Gear Transmission

3. Efficiency Analysis of Herringbone Planetary Gear

3.1. Bearing Contact Power Loss

3.1.1. Rolling Friction Moment of Cylindrical Roller Bearing

3.1.2. Sliding Friction Moment of Cylindrical Roller Bearing

3.1.3. Drag Friction Moment of Cylindrical Roller Bearing

3.1.4. Reduction of Friction Coefficient Due to Heat and Backfill

3.1.5. Analysis of Total Power Loss of Cylindrical Roller Bearing

3.2. Power Loss Due to Gear Meshing

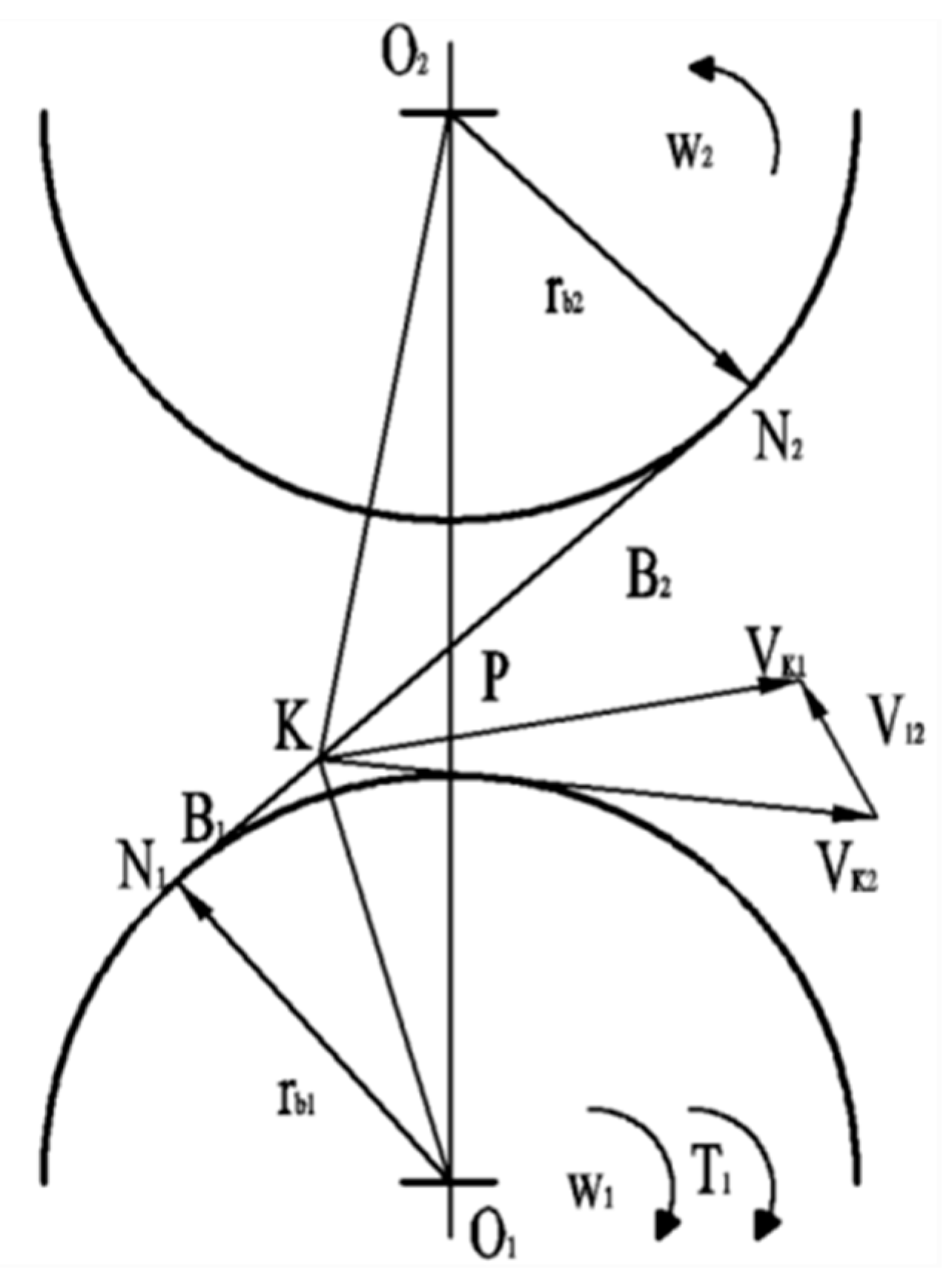

3.2.1. Calculation of Gear Frictional Power Loss

- Under the EHL (Elastohydrodynamic lubrication) state, friction surfaces of the meshed teeth are completely separated by a viscous fluid film. The film thickness is determined by relative sliding speed of the tooth surfaces. Pressure generated by the fluid film balances the external load.

- With boundary lubrication, gear teeth must be separated by boundary lubrication in order to separate the tooth flanks. However, absolutely smooth tooth flanks do not exist, and for this reason, almost all gears work in a hybrid lubrication state.

- In the hybrid lubrication state, the elastic oil film will either be in a mixed or boundary-lubricated state. Mixed lubrication refers to the combination of fluid lubrication and boundary lubrication, that is, the normal load is shared by the fluid lubrication film and the boundary film, and the friction force includes fluid damping and boundary friction components.

3.2.2. Rolling Friction Power Loss

3.2.3. Calculation of Power Loss Due to Gear Transmission Windage

4. Power Flow Diagram of Herringbone Gear Planetary Drive System

4.1. System Power Flow

4.2. System Equations

5. Case Study

5.1. Power Flow Analysis Ignoring Power Loss

5.2. Power Flow Analysis Considering Power Loss

5.3. Results and Discussion

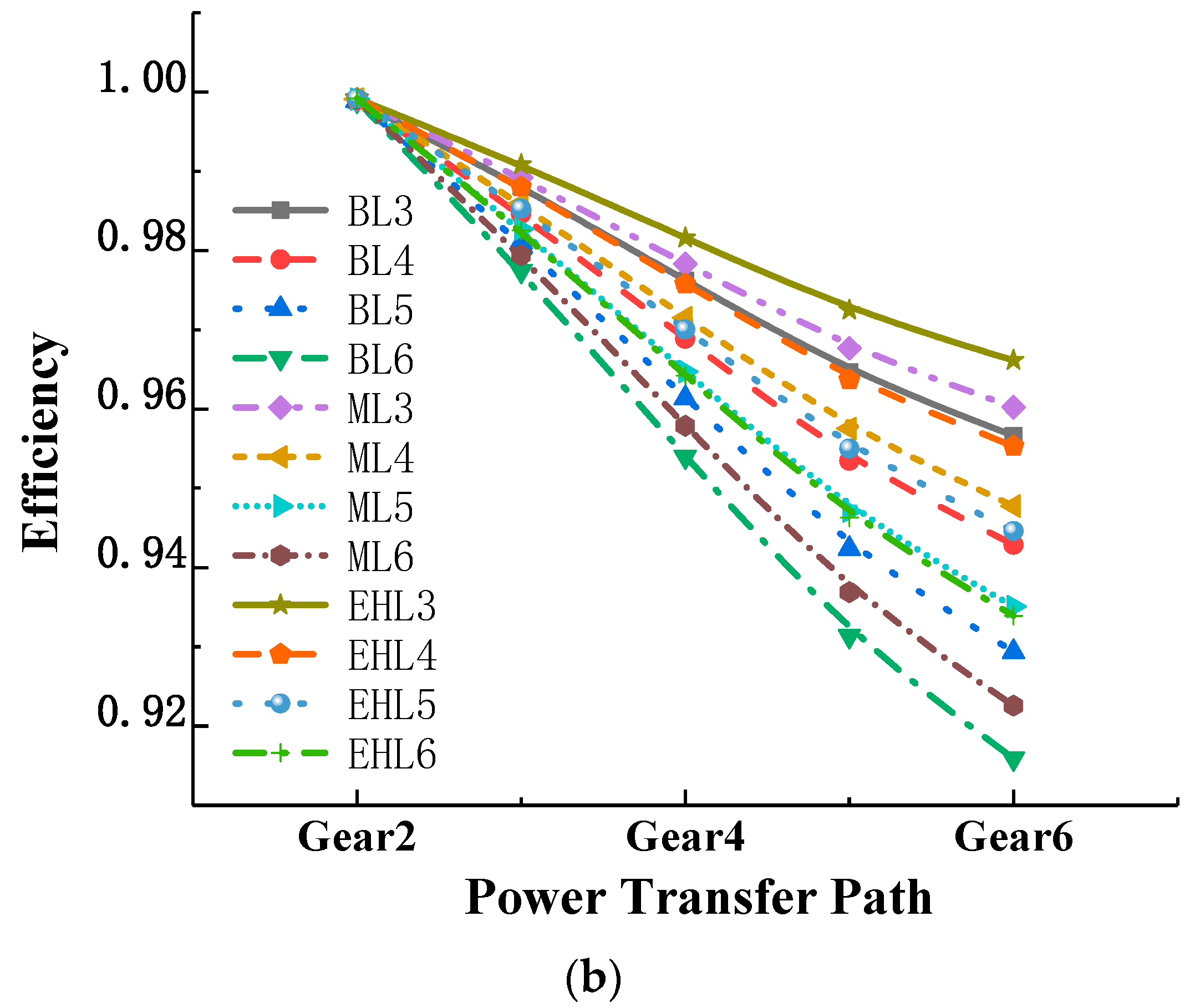

5.3.1. Analysis of Transmission Efficiency under Different Lubrication Conditions

5.3.2. Variation of Transmission Efficiency with Input Speed

5.3.3. Variation of Transmission Efficiency with Input Power

5.4. Algorithm Verification

5.5. Summary

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yuan, S.; Dong, H.; Li, X. Contact analysis of helical gears based on MEPE and EHL theories. J. Tribol. 2012, 32, 286–290. [Google Scholar] [CrossRef]

- Nutakor, C.; Kłodowski, A.; Sopanen, J.; Mikkola, A.; Pedrero, J.I. Planetary gear sets power loss modeling: Application to wind turbines. Tribol. Int. 2017, 105, 42–54. [Google Scholar] [CrossRef]

- Kahraman, A.; Hilty, D.R.; Singh, A. An experimental investigation of spin power losses of a planetary gear set. Mech. Mach. Theory 2015, 86, 48–61. [Google Scholar] [CrossRef]

- Tang, X.L.; Yang, W.; Hu, X.S.; Zhang, D.J. A novel simplified model for torsional vibration analysis of a series-parallel hybrid electric vehicle. Mech. Syst. Signal Process. 2017, 85, 329–338. [Google Scholar] [CrossRef]

- Yang, W.; Tang, X.L.; Liang, Q. Tooth Surface Contact Analysis of Involute Rotate Vector Reducer Based on a Finite Element Linear Programming Method. IEEE Access 2019, 7, 176719–176731. [Google Scholar] [CrossRef]

- Xu, L.X.; Chen, B.K.; Li, C.Y. Dynamic modelling and contact analysis of bearing-cycloid-pinwheel transmission mechanisms used in joint rotate vector reducers. Mech. Mach. Theory 2019, 137, 432–458. [Google Scholar] [CrossRef]

- Xu, L.X. A dynamic model to predict the number of pins to transmit load in a cycloidal reducer with assembling clearance. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4247–4269. [Google Scholar] [CrossRef]

- Yang, W.; Tang, X.L. Modelling and modal analysis of a hoist equipped with two-stage planetary gear transmission system. Proc. Inst. Mech. Eng. Part K J. Multibody Dyn. 2017, 231, 739–749. [Google Scholar] [CrossRef]

- Xu, L.X.; Han, Y.C.; Dong, Q.B.; Jia, H.L. An approach for modelling a clearance revolute joint with a constantly updating wear profile in a multibody system: Simulation and experiment. Multibody Syst. Dyn. 2019, 45, 457–478. [Google Scholar] [CrossRef]

- Mo, S.; Ma, S.; Guoguang, J.; Jiabei, G.; Ting, Z.; Shengping, Z. Design principle and modeling method of asymmetric involute internal helical gears. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 233, 244–255. [Google Scholar] [CrossRef]

- Tang, X.L.; Hu, X.S.; Yang, W.; Yu, H.S. Novel Torsional Vibration Modeling and Assessment of a Power-Split Hybrid Electric Vehicle Equipped with a Dual-Mass Flywheel. IEEE Trans. Veh. Technol. 2018, 67, 1990–2000. [Google Scholar] [CrossRef]

- Mo, S.; Zhang, Y.; Wu, Q.; Wang, F.; Matsumura, S.; Houjoh, H. Load Sharing Behavior of Star Gearing Reducer for Geared Turbofan Engine. Chin. J. Mech. Eng. 2017, 30, 796–803. [Google Scholar] [CrossRef]

- Marques, P.M.T.; Martins, R.C.; Seabra, J.H.O. Gear dynamics and power loss. Tribol. Int. 2016, 97, 400–411. [Google Scholar] [CrossRef]

- Diez-Ibarbia, A.; del Rincón, A.F.; de-Juan, A.; Iglesias, M.; Garcia, P.; Viadero, F. Frictional power losses on spur gears with tip reliefs. The load sharing role. Mech. Mach. Theory 2017, 112, 240–254. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, C.M.C.G.; Marques, P.M.T.; Martins, R.; Seabra, J. Gearbox power loss. Part II: Friction losses in gears. Tribol. Int. 2015, 88, 309–316. [Google Scholar] [CrossRef]

- Benedict, G.H.; Kelley, B.W. Instantaneous Coefficient of Gear Tooth Friction. ASLE Trans. 1961, 4, 59–70. [Google Scholar] [CrossRef]

- Shao, Y.; Li, X.; Li, H. Efficiency Analysis of Planetary Gear Train under Ring Gear Deformation. In Proceedings of the 18th International Conference on Control, Automation and Systems (ICCAS 2018), YongPyong Resort, PyeongChang, Korea, 17–20 October 2018. [Google Scholar]

- Wang, C.; Wang, S.-R.; Wang, G.-Q. A method for calculating gear meshing efficiency by measured data from gear test machine. J. Cent. South Univ. Nat. Sci. Ed. 2018, 119, 97–101. [Google Scholar] [CrossRef]

- Xue, H.-L.; Liu, G.; Yang, X.-H. A review of graph theory application research in gears. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 230, 1697–1714. [Google Scholar] [CrossRef]

- Liu, J.; Yu, L.; Zeng, Q.; Li, Q. Synthesis of multi-row and multi-speed planetary gear mechanism for automatic transmission. Mech. Mach. Theory 2018, 128, 616–627. [Google Scholar] [CrossRef]

- Ayats, J.G.; Diego-Ayala, U.; Minguella-Canela, J.; Fenollosa, F.; Vivancos, J. Hypergraphs for the analysis of complex mechanisms comprising planetary gear trains and other variable or fixed transmissions. Mech. Mach. Theory 2012, 51, 217–229. [Google Scholar] [CrossRef]

- Laus, L.; Simas, H.; Martins, D. Efficiency of gear trains determined using graph and screw theories. Mech. Mach. Theory 2012, 52, 296–325. [Google Scholar] [CrossRef]

- Chen, C.; Chen, J. Efficiency analysis of two degrees of freedom epicyclic gear transmission and experimental validation. Mech. Mach. Theory 2015, 87, 115–130. [Google Scholar] [CrossRef]

- Li, J.; Hu, Q. Power Analysis and Efficiency Calculation of the Complex and Closed Planetary Gears Transmission. In Proceedings of the 3rd International Conference on Power and Energy Systems Engineering, CPESE 2016, Kitakyushu, Japan, 8–12 September 2016. [Google Scholar]

- Yang, F.; Feng, J.; Zhang, H. Power flow and efficiency analysis of multi-flow planetary gear trains. Mech. Mach. Theory 2015, 92, 86–99. [Google Scholar] [CrossRef]

- Carlos, F. Power Loss in Rolling Bearings and Gears Lubricated with Wind Turbine Gear Oils. Ph.D. Thesis, Porto Engineering University, Porto, Portugal, 2015. [Google Scholar] [CrossRef]

- Tang, X.; Zou, L.; Yang, W.; Huang, Y.; Wang, H. Novel mathematical modelling methods of comprehensive mesh stiffness for spur and helical gears. Appl. Math. Model. 2018, 64, 524–540. [Google Scholar] [CrossRef]

- Xu, L.; Yang, Y. Dynamic modeling and contact analysis of a cycloid-pin gear mechanism with a turning arm cylindrical roller bearing. Mech. Mach. Theory 2016, 104, 327–349. [Google Scholar] [CrossRef]

- Radzevich, S.P. Theory of Gearing; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Crook, A.W. The lubrication of rollers IV. Measurements of friction and effective viscosity. Philos. Trans. R. Soc. 1963, 255, 281–312. [Google Scholar] [CrossRef]

- Dowson, D.; Higginson, G. Elasto-Hydrodynamic Lubrication; Pergamon: Oxford/London, UK, 1977. [Google Scholar]

- AGMA. Specification for High Speed Helical Gear Units: ANSI/AGMA 6011—I03, 1st ed.; Alexandria, S., Ed.; AGMA: Alexandria, VA, USA, 2004. [Google Scholar]

- Dawson, P.H. Windage Loss in Larger High-Speed Gears. Proc. Inst. Mech. Eng. 1984, 198, 51–59. [Google Scholar] [CrossRef]

- Diab, Y.; Ville, F.; Velex, P. Investigations on power losses in high-speed gears. Proc. Inst. Mech. Eng. Part J 2014, 220, 191–198. [Google Scholar] [CrossRef]

- Talbot, D.; Kahraman, A. A methodology to predict power losses of planetary gear sets. In Proceedings of the International Gear Conference 2014, Lyon, France, 26–28 August 2014; pp. 625–635. [Google Scholar]

| Parameter | R1 | S1 | S2 | KL0 | KZ0 | Krs | VM0 |

|---|---|---|---|---|---|---|---|

| Value | 1.48 × 10−6 | 0.16 | 1.5 × 10−3 | 0.65 | 5.1 | 6 × 10−8 | 1.2 × 10−4 |

| 0 | 4920 | −4640 | −1190.4 | 1344 | 429.6 |

| Gear Parameter | Pinion | Gear |

|---|---|---|

| Number of teeth | z2 = z4″ = 35 z3 = z5 = 31 | z4 = z6 = 97 |

| Normal modulus (mm) | 7 | |

| Normal pressure angle (°) | 20 | |

| Helix angle β (°) | 22 | |

| Tooth width (mm) | 80 | |

| Elastic modulus (Gpa) | 210 | |

| Poisson’s ratio | 0.3 | |

| Root mean square roughness (um) | 0.1 | |

| Face addendum coefficient | 1 | |

| Face radial coefficient | 0.25 | |

| Ambient temperature (K) | 323 | |

| Ambient viscosity (Pa.s) | 0.08 | |

| Bearing inner diameter (mm) | 110 | |

| Bearing outer diameter (mm) | 170 | |

| Bearing width (mm) | 38 | |

| Bearing clearance (mm) | 0.06 | |

| Input speed (rpm) | 4920 | |

| Input power (kW) | 424 | |

| Efficiency (%) | ηIN-2 | η2-3 | η3-4 | η4-5 | η5-6 | |

|---|---|---|---|---|---|---|

| Number of Planetary Gears | ||||||

| 3 | 99.98 | 98.83 | 99.09 | 98.89 | 99.23 | |

| 4 | 99.98 | 98.46 | 98.82 | 98.52 | 98.97 | |

| 5 | 99.98 | 98.08 | 98.55 | 98.16 | 98.71 | |

| 6 | 99.98 | 97.71 | 98.29 | 97.79 | 98.46 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yang, W.; Tang, X.; Lin, X.; He, Z. Power Flow and Efficiency Analysis of High-Speed Heavy Load Herringbone Planetary Transmission Using a Hypergraph-Based Method. Appl. Sci. 2020, 10, 5849. https://doi.org/10.3390/app10175849

Wang Y, Yang W, Tang X, Lin X, He Z. Power Flow and Efficiency Analysis of High-Speed Heavy Load Herringbone Planetary Transmission Using a Hypergraph-Based Method. Applied Sciences. 2020; 10(17):5849. https://doi.org/10.3390/app10175849

Chicago/Turabian StyleWang, Yun, Wei Yang, Xiaolin Tang, Xi Lin, and Zhonghua He. 2020. "Power Flow and Efficiency Analysis of High-Speed Heavy Load Herringbone Planetary Transmission Using a Hypergraph-Based Method" Applied Sciences 10, no. 17: 5849. https://doi.org/10.3390/app10175849