Feasibility Study and Prospects of Rock Fragmentation Using Ultrasonic Vibration Excitation

Abstract

:1. Introduction

2. Overview of Rock Breakage Methods

3. The Theoretical Feasibility of Ultrasonic Rock Breakage

3.1. Mechanisms of Ultrasonic Action on Rock Mass

3.2. Ultrasonic Vibration Excitation Mechanisms for Rock Breakage

4. Engineering Application and Progress of Ultrasonic Excitation of Coal and Rock Mass

4.1. Application of Power Ultrasound in Underground Mining Engineering

4.2. High-Power Ultrasound Equipment

4.3. Rock Breakage Test Using Ultrasonic Excitation

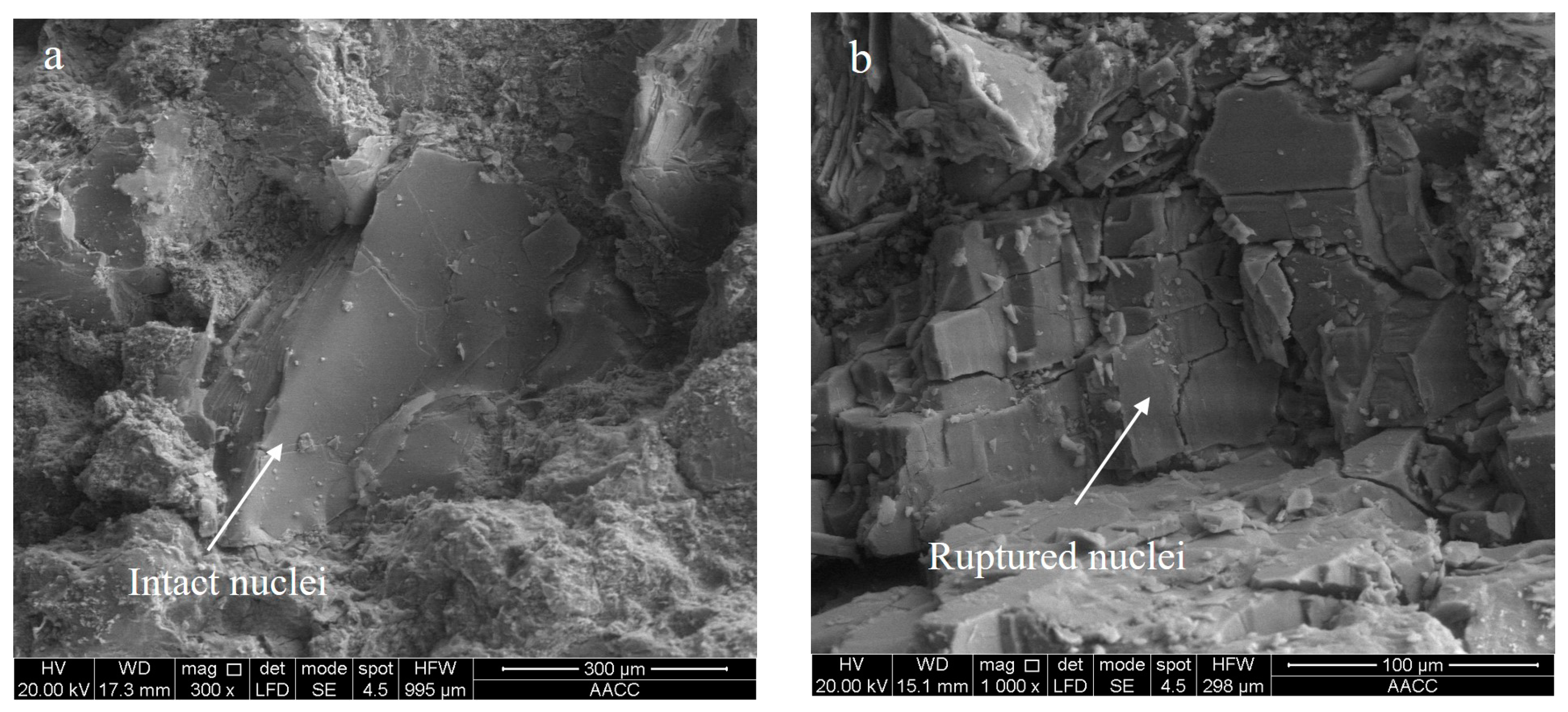

4.4. Evolution Characteristics of Microcracks in Specimens under Ultrasonic Excitation

4.5. Strength Characteristics of Specimen after Ultrasonic Vibration Excitation

5. Future Development and Prospects

6. Conclusions

- Ultrasonic excitation experiments were designed and performed on different rock types. Microcracks generate and cause the failure of the specimen in relatively short experimental time and under a relatively low axial stress, due to ultrasonic excitation. The fracture length and the fracture propagation speed under ultrasonic excitation are rock-type dependent. The granite specimen and the limestone specimen have the minimum “average maximum fracture length” and the maximum “average maximum fracture length”, respectively. The granite specimen has the shortest failure duration. All four rock types show the characteristics of “no macroscopic fracture-fracture generation-steady fracture propagation”.

- Energy continuously accumulates in the rock specimen as the time of ultrasonic excitation increases. This phenomenon not only leads to the generation of macroscopic fractures, but also causes the formation of microcracks that propagate along crystal boundaries and penetrate crystals. The development of these microcracks notably decreases the compressive strength of the rock specimens. The experimental results show that the compressive strength of red sandstone specimens decreases by 45.6 % after 140 s of ultrasonic excitation.

- Traditional rock breakage technology has the disadvantages of high energy consumption, high costs, and low efficiency. Ultrasonic excitation will become one of the important approaches to the effective breakage of hard rocks. It is highly significant to further investigate the mechanism of ultrasonic excitation and to develop relevant equipment in order to apply the mechanism to high-speed construction involving hard rock breakage.

Author Contributions

Funding

Conflicts of Interest

Data Availability

References

- He, Q.; Li, Y.; Xu, J.; Zhang, C. Prediction of Mechanical Properties of Igneous Rocks under Combined Compression and Shear Loading through Statistical Analysis. Rock Mech. Rock Eng. 2019, 53, 841–859. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, Y.; Zhao, Y.; Zhu, J. Uniaxial compression CT and acoustic emission test on the coal crack propagation destruction process. J. Coal Sci. Eng. (China) 2013, 19, 69–74. [Google Scholar] [CrossRef]

- Patadiya, D.M.; Jaisankar, S.; Sheshadri, T.S. Detonation initiated disintegration of coal particle due to the maximum strain energy theory. J. Coal Sci. Eng. (China) 2013, 19, 435–440. [Google Scholar] [CrossRef]

- Critello, C.D.; Fiorillo, A.S.; Matula, T.J. Size of Sclerosing Foams Prepared by Ultrasound, Mechanical Agitation, and the Handmade Tessari Method for Treatment of Varicose Veins. J. Ultrasound Med. 2017, 36, 649–658. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Critello, D.C.; Pullano, S.A.; Gallo, G.; Matula, T.J.; Fiorillo, A.S. Low frequency ultrasound as a potentially viable foaming option for pathological veins. Colloids Surfaces A Physicochem. Eng. Asp. 2020, 599, 124919. [Google Scholar] [CrossRef]

- Taheri-Shakib, J.; Shekarifard, A.; Naderi, H. The experimental investigation of effect of microwave and ultrasonic waves on the key characteristics of heavy crude oil. J. Anal. Appl. Pyrolysis 2017, 128, 92–101. [Google Scholar] [CrossRef]

- Li, X.; Harkness, P.; Worrall, K.; Timoney, R.; Lucas, M. A Parametric Study for the Design of an Optimized Ultrasonic Percussive Planetary Drill Tool. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2017, 64, 577–589. [Google Scholar] [CrossRef]

- Sun, L.; Bu, C.; Hu, P.; Xia, B. The transient impact of the resonant flexible drill string of a sonic drill on rock. Int. J. Mech. Sci. 2017, 122, 29–36. [Google Scholar] [CrossRef]

- Yin, S.; Zhao, D.; Zhai, G. Investigation into the characteristics of rock damage caused by ultrasonic vibration. Int. J. Rock Mech. Min. Sci. 2016, 84, 159–164. [Google Scholar] [CrossRef]

- Neeson, E.; Lucas, M. The effects of ultrasonics in fragmentation of saturated porous rock samples. Ultrasonics Symp. 2012, 1982–1985. [Google Scholar] [CrossRef]

- Fheed, A.; Kłodowski, K.; Krzyżak, A. Fracture orientation and fluid flow direction recognition in carbonates using diffusion-weighted nuclear magnetic resonance imaging: An example from Permian. J. Appl. Geophys. 2020, 174, 103964. [Google Scholar] [CrossRef]

- Fheed, A.; Krzyżak, A.; Świerczewska, A. Exploring a carbonate reef reservoir—Nuclear magnetic resonance and computed microtomography confronted with narrow channel and fracture porosity. J. Appl. Geophys. 2018, 151, 343–358. [Google Scholar] [CrossRef]

- Weglarz, W.P.; Krzyzak, A.; Machowski, G.; Stefaniuk, M. ZTE MRI in high magnetic field as a time effective 3D imaging technique for monitoring water ingress in porous rocks at sub-millimetre resolution. Magn. Reson. Imaging 2018, 47, 54–59. [Google Scholar] [CrossRef] [PubMed]

- Tang, Z.; Zhai, C.; Zou, Q.; Qin, L. Changes to coal pores and fracture development by ultrasonic wave excitation using nuclear magnetic resonance. Fuel 2016, 186, 571–578. [Google Scholar] [CrossRef]

- Thirumalai, K. Rock Mechanics and Development of Advanced Hard Rock Breaking Methods. Appl. Rock Mech. 1975, 1975, 449–467. [Google Scholar]

- Tong, J.L.; Yan, Y.Y.; Zhao, B. Ultrasonic-Vibration Hard Cutting Force Analysis with the Finite Element Method. Key Eng. Mater. 2010, 455, 360–364. [Google Scholar] [CrossRef]

- Sajjady, S.A.; Nouri Hossein Abadi, H.; Amini, S.; Nosouhi, R. Analytical and experimental study of topography of surface texture in ultrasonic vibration assisted turning. Mater. Des. 2016, 93, 311–323. [Google Scholar] [CrossRef]

- Harichandran, R.; Selvakumar, N. Effect of nano/micro B4C particles on the mechanical properties of aluminium metal matrix composites fabricated by ultrasonic cavitation-assisted solidification process. Arch. Civ. Mech. Eng. 2016, 16, 147–158. [Google Scholar] [CrossRef]

- Prikhod’ko, V.M.; Aleksandrov, V.A.; Fatyukhin, D.S.; Petrova, L.G. Effect of Ultrasonic Cavitation on Nitrided Steel Surface Layer Condition. Met. Sci. Heat Treat. 2015, 57, 300–303. [Google Scholar] [CrossRef]

- Aoyagi, R.; Fujiwara, R.; Niita, T. Possibility of Metal Processing Using Ultrasonic Cavitation Jet. Jpn. J. Appl. Phys. 2001, 40, 3784–3786. [Google Scholar] [CrossRef]

- Xiao, X.; Pan, Y.; Lu, X.; Yang, X. Mechanism of methane permeability enhance through ultrasonic irradiating on low permeable coal seam. Chin. J. Geophys. 2013, 56, 1726–1733. [Google Scholar]

- Hauwaert, A.V.; Thimus, J.F.; Delannay, F. Use of ultrasonics to follow crack growth. Ultrasonics 1998, 36, 209–217. [Google Scholar] [CrossRef]

- Xie, F.; Ji, B.; Yuan, Z.; Fu, Z.; Ge, H. Ultrasonic Detecting Method and Repair Technology Based on Fatigue Crack Features in Steel Box Girder. J. Perform. Constr. Facil. 2016, 30, 04015006. [Google Scholar] [CrossRef]

- Yang, K. Research on Drilling Corer Based on Ultrasonic/Acoustic Energy Coupling Mechanism. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2012. [Google Scholar]

- Yang, G. 160kW Ultrasonic Power Source. China Patent CN102882360A, 1 January 2013. [Google Scholar]

- Zhang, Y. The Optimization of Structural Parameters of the Oil Production Increasing Ultrasonic Transducer Based on Electromechanical Coupling. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2014. [Google Scholar]

- Pu, C.; Shi, D.; Zhao, S.; Xu, H.; Shen, H. Technology of removing near wellbore inorganic scale damage by high power ultrasonic treatment. Pet. Explor. Dev. 2011, 38, 243–248. [Google Scholar] [CrossRef]

| Category | Methods | Mechanism | Characteristic |

|---|---|---|---|

| Mechanical energy rock breakage | Blasting | The borehole is filled with explosives and the rock is broken by the energy generated by explosives | Large disturbance, inconsistency in rock fragmentation, relies on drilling, difficult to automate |

| Mechanical breakage | Use the energy generated from the mechanical cutting rig | Low efficiency, rigs are prone to wear out easily | |

| Water jet method | Use of a high-pressure water jet to increase the rock’s free surface and increase cutting depth | Affected by the pressure factors of a high-pressure water pump (domestic pumps generally do not exceed 35 MPa), difficult to carry out for large scale hard rock crushing | |

| Projectile impact | Gas is fired at the bottom of the shallow borehole, resulting in pulse pressure and the formation of tensile stress | Low material consumption, the broken rock section is easy to control | |

| Thermal rock breakage | Plasma method | Under the high-temperature and high-speed plasma arc, the thermal stress generated exceeds the strength limit of the rock, thereby crushing the rock | Suitable for hard rock breakage, but prone to deflection |

| Laser method | Use of laser heat to crush the rock | Low cost; easier to be affected by the development of laser technology, rock types and road sections | |

| Microwave method | The rock mass is heated by microwaves to change its petrophysical properties | Low level of vibration, flying rock ejection and noise; microwave equipment and the life of the oscillator are difficult to determine |

| Lithology | Size/mm | Static Pressure/N | Time/s | Group Count |

|---|---|---|---|---|

| Sandstone | Φ50 × 100 | 20 | 60 | 4 |

| Granite | Φ50 × 100 | 20 | 60 | 4 |

| Marble | Φ50 × 100 | 20 | 60 | 4 |

| Limestone | Φ50 × 100 | 20 | 60 | 4 |

| Rock Type | Before Ultrasonic Excitation | After Ultrasonic Excitation | Maximum Fracture Length (mm) | Average Failure Time(s) |

|---|---|---|---|---|

| Red sandstone |  |  | 30.16 | 63 |

| Granite |  |  | 28.32 | 94.6 |

| Marble |  |  | 36.15 | 10.5 |

| Limestone |  |  | 47.33 | 43.2 |

| E/GPa | μ | R/MPa | Rm/MPa | θ/° | C/MPa |

|---|---|---|---|---|---|

| 70 | 0.25 | 53.6 | 6.01 | 42.38 | 18.15 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Wang, X.; Wang, J.; Tian, Z. Feasibility Study and Prospects of Rock Fragmentation Using Ultrasonic Vibration Excitation. Appl. Sci. 2020, 10, 5868. https://doi.org/10.3390/app10175868

Wang X, Wang X, Wang J, Tian Z. Feasibility Study and Prospects of Rock Fragmentation Using Ultrasonic Vibration Excitation. Applied Sciences. 2020; 10(17):5868. https://doi.org/10.3390/app10175868

Chicago/Turabian StyleWang, Xufeng, Xuanlin Wang, Jiyao Wang, and Zhongxi Tian. 2020. "Feasibility Study and Prospects of Rock Fragmentation Using Ultrasonic Vibration Excitation" Applied Sciences 10, no. 17: 5868. https://doi.org/10.3390/app10175868