1. Introduction

Bridges are among the most complex and important structures of civil infrastructure. They must operate in demanding environments, and withstand extreme loads and deterioration which occur during their operational lifespan [

1]. Therefore, maintenance and monitoring of their state is crucial, mainly for safety and economic reasons [

2]. Visual inspection represents a standard process in many countries [

3]. As mentioned in [

4], the identification of damages from visual inspections are usually influenced by the subjectivity of the expert. There are other issues with visual inspections—some locations are not accessible; at other times it is difficult to determine the severity of damage. Due to these reasons and possible road closures, bridge owners and managers are interested in automation of the process by using sensors. Many researchers across the United States [

1], Europe [

2,

5,

6,

7,

8], and Asia [

9,

10,

11,

12] have taken advantage of the rapid evolution of sensing technologies in the last few decades and implemented methods of structural health monitoring (SHM) to track the structural integrity of bridges. An important part of SHM is testing. Two main approaches to testing are known: destructive and non-destructive. Destructive methods use demolition of material to determine material characteristics. On the other hand, the advantage of non-destructive testing is that the observed structure will remain undamaged after a test. Therefore, non-destructive testing is a well-developed research and practical field, and vibration-based methods are one part of that field. According to [

13], vibration-based SHM techniques can be divided into global non-destructive techniques, local non-destructive techniques, and long-term application of SHM techniques. Local techniques deal with one structural element, such as cables [

12]. On the other hand, global techniques use data from a whole structure.

Furthermore, the testing methods can be divided according to how the response is excited: statically or dynamically. The design of static tests is less difficult, as only a stationary load is used. The possibility of easier evaluation is also advantageous, and the results can be simpler compared to the results from numerical models. On the other hand, they have less practical value, and they do not show the real behavior of structures during dynamic loads. Dynamic test methods that examine the behavior of structures under dynamic loads are mainly applied to bridges. These structures are loaded by moving vehicles, pedestrians, or ambient dynamic loads. The fast evolution of sensing technology has enabled the incorporation of SHM methods into the life cycle of bridges [

14]. It must be noted that a visual inspection cannot be completely substituted by SHM methods. Several types of measuring devices and compatible sensors are now available. The most common types of sensors are strain gauges, accelerometers, speedometer gauges, temperature sensors, and optical sensors, among others. The above-mentioned authors mainly used one type of sensor in their studies. Strains were measured in [

1], accelerometers were used in [

5] and [

8], and radar was applied in [

9]. The combination of multiple sensor types was presented in [

11]. A similar approach was selected in this work; a measuring device with the ability to measure accelerations, temperatures and strains was used in combination with the use of radar interferometry and a video camera.

This paper presents the development of a SHM strategy as an application of a fusion of well-known methods during various stages of testing (e.g., numerical modal analysis to obtain initial dynamic parameters, operational modal analysis [

15], verification and validation of a FEM model [

16], and vehicle–bridge interactions [

17]) in order to obtain the global static and dynamic response of a reinforced concrete bridge, along with local measurements of strains in external cables. To obtain a verified and validated FEM model, various tests were performed (e.g., a static test (measurements of displacements and strains), a dynamic test (measurements of displacements and accelerations), and operational modal analysis). The verified FEM model can serve as a tool for evaluating various damage scenarios and predicting changes in bridge responses in these scenarios on the basis of future measurements.

This paper consists of multiple sections.

Section 2 describes the bridge;

Section 3 deals with the FEM model of the bridge and moving vehicles;

Section 4 presents the measurement setup used for the tests;

Section 5 is devoted to the verification and validation of the FEM model, with the results from the static test and operational modal analysis also presented here;

Section 6 contains the comparison of the time history analysis performed by a numerical calculation and the measured displacement in the middle of the main span;

Section 7 shows the results of a local non-destructive test of external pre-stressed cables and finally, the main conclusions are presented in

Section 8.

2. Bridge Description

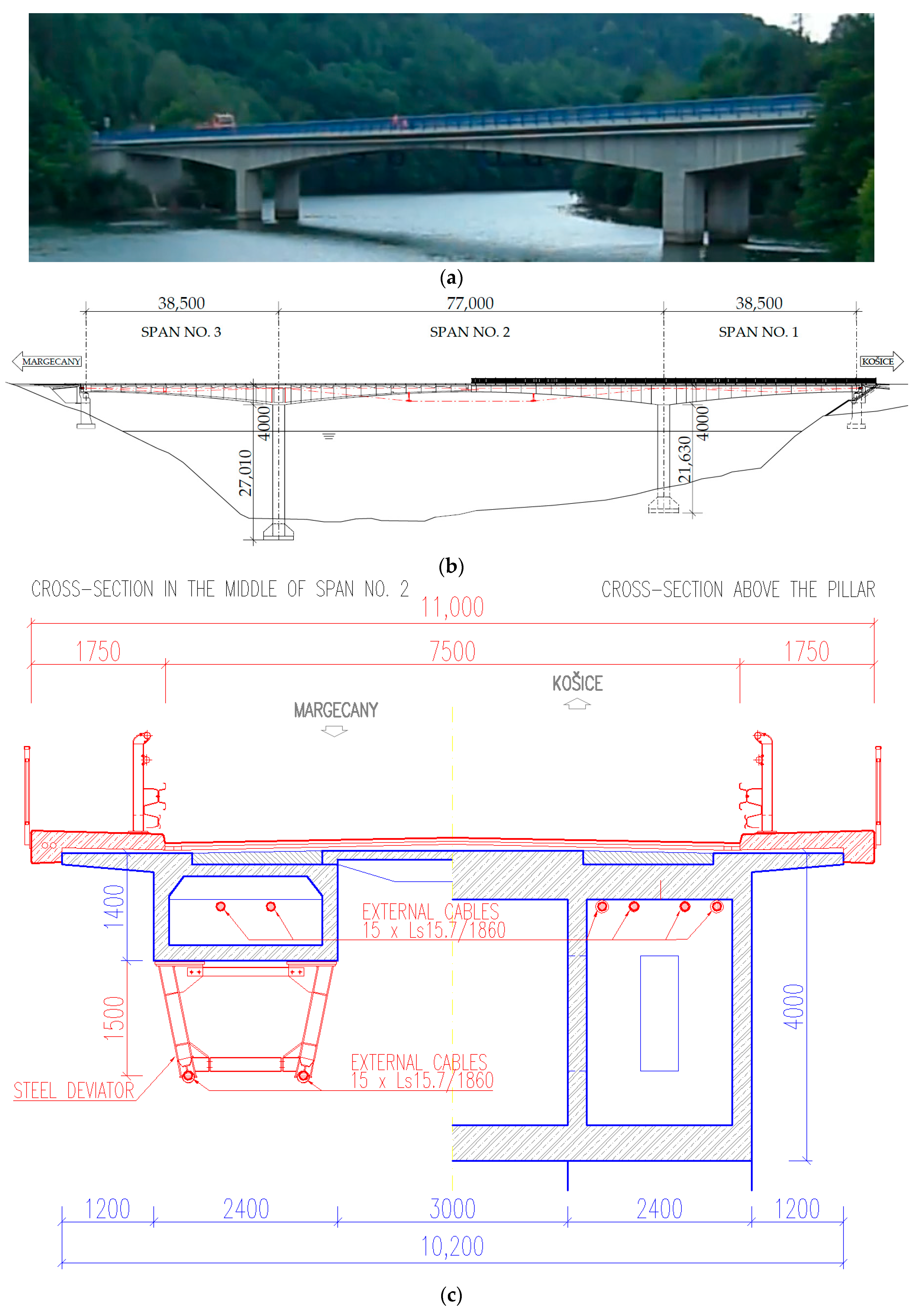

The bridge over the Ružín Dam has been in operation since 1967 and was renovated in 2017 (

Figure 1) as a result of its full closure in 2016 due to its critical state. The reason for the closure and for the necessity to renovate was the permanent (visible) displacement in the middle of the main span. The bridge structure consists of two parallel tapered box-girders with various heights between 1.4 m and 4.0 m. Pre-cast slabs are embedded between the two box-girders. The width of the bridge comprises the road surface (7.5 m) and the walkways on both sides (1.75 m); overall, the bridge is 11.0 m wide. The total length of the bridge is 154.0 m.

The bridge was repaired by changing the original structural system. The reconstruction was carried out by reinforcement of the original joint in the middle of span no. 2 and by the addition of external pre-stressed cables (

Figure 2). Pre-stressed cables consist of two groups. The first group of cables passes over the outer side of the box-girders and is fixed by additionally mounted steel deviators (two cables per box-girder). The second group of cables is placed inside the box-girders (two cables per box-girder). Therefore, the overall strengthening consists of eight cables (15 × LS15.7/1860; for geometric and material characteristics, see

Table 1 and

Table 2).

The pillars with heights of 29 m and 24 m are monolithically connected to the load-bearing structure. A new sloping abutment with an approach slab was built in 2017. Renovation of the wing walls was realized by coupling reinforced concrete walls. Concrete C30/37 and steel B500 (B) were used.

The bridge is of great importance in the regional road network. According to Slovak Road Administration data [

19], in 2015, more than 3300 vehicles passed over the bridge daily. Therefore, bridge closure could cause significant complications since alternative routes are more than 30 km longer.

3. Numerical Modelling of Vehicle–Bridge Interactions

The 2D FEM model of the bridge and a passing truck were prepared (

Figure 3) and numerical analyses were performed before executing the in situ tests in order to achieve the expected displacement of the bridge. The slab of box-girders was modelled with SHELL elements with a constant thickness of 0.2 m (width); flanges were modelled with BEAM elements: the upper flange had a constant height of cross section of 0.254 m, the bottom flanges had an increasing height of cross section, starting from 0.253 m in the middle of the span to 0.47 m in vicinity of the pier. The characteristics of cables are listed in

Table 2. All concrete elements were modelled with Young’s modulus of elasticity E = 36 GPa. Pillars were modelled with beam elements with cross sections of 2.4 × 2.4 m. Fixed supports were assumed for both pillars, with joint supports at the beginning of the first span and the end of the last span.

The added cables (characteristics in accordance with

Table 1 and

Table 2) were considered TRUSS elements. MASS elements represent the extra weight of accessories. The contribution of the water mass on immersed piers was also added according to [

20] with a value of 6800 kg/m.

3.1. Testing Vehicles

Mercedes Benz 1836 AK trucks were utilized for static and dynamic tests of the bridge. Their characteristics were assumed according to technical documentation (weighing ticket issued by a certified laboratory before the tests) and are listed in

Table 3. The characteristics of the axles for Truck 1 are listed in

Table 4. Truck 1 was only used for the dynamic test, whereas both trucks were used for static tests.

3.2. Non-Linear Dynamic Analysis of the Vehicle–Bridge Interaction

The FEM model including both the structure and the vehicle was used for the evaluation of the dynamic tests. The code was prepared in such a way that it is possible to define the arbitrary function of an uneven surface (

Figure 3a), which characterizes the displacement differences between truck contact DOFs (Degree of Freedom) and structure DOFs at particular time instances. These differences cause vertical inertial forces arising between the truck and the structure, and therefore result in additional dynamic load of the bridge. It is also possible to control the loss of contact. For the tested bridge, a new roadway was recently constructed, so only an arbitrary obstacle was assumed as an uneven surface. The tests included truck passage over the bridge at different velocities while crossing the uneven surface created by an artificial obstacle in the middle of span no. 2. The measurements were carried out during light traffic, so a particular case when only the testing truck was present on the bridge was analyzed. However, the dynamic response can also be analyzed assuming a complete traffic flow by recording all passing vehicles. The advantage of this method is that there is no need for significant traffic restrictions, which is the most convenient way of performing tests for bridge authorities.

To calculate the dynamic response of the structure, a non-linear numerical analysis assuming a vehicle–bridge interaction was performed. Contact effects depend on the velocity of the vehicle and on the uneven surface function between the bridge deck and the axle. Thus, the overall response of the vehicle–bridge system is calculated according to the system of equations in every time step:

where

M is a mass matrix,

C(t) is a damping matrix,

K(t) is a stiffness matrix,

f(t) is a vector of external loads and

y(t) is a vector of displacement.

Special attention is paid to vector elements with “contact” indices where the values do not depend only on TH (Time History) analysis, but also on the uneven surface. Loss of contact, which can occur in cases of higher speed, is also incorporated into the analysis. The procedure by which contact force and contact loss were analyzed is described in

Figure 3c, where displacements of the wheel v

w have been compared with the sum of displacements of the structure v

s and the uneven surface coordinate v

R defined in a particular time step. If the difference between the wheel and the structure ∆

structure − wheel = v

w − v

s − v

R is greater than zero, then loss of contact is expected and the zero-contact force F

contact acting between the vehicle and structure is assumed. Otherwise, contact still exists and the value of the contact force is calculated as the wheel reaction, depicted as F

w, acting on the axle and additional force, F

add, satisfying the correct condition of continuity of displacements; i.e., wheel is located on the structure (also assuming uneven surface). The value of F

add is a product of tire stiffness K

tire and ∆

structure − wheel.

6. Evaluation of Dynamic Displacements of the Bridge

The dynamic tests with the truck passage at different velocities were performed to obtain the dynamic response of the structure. Only traffic load was assumed in the numerical calculations. The wind effects during the tests were negligible and therefore not incorporated into the calculations. Effects of the structural dead weight were not included in the presented displacements.

A two-axle truck was used (see

Table 3, Truck 1) in the tests. An uneven surface was created by an obstacle placed in the middle of span no. 2 with a length of 0.5 m and a height of 0.06 m (

Figure 14). As the axles of the truck hit the uneven surface, significant dynamic effects occurred (

Figure 15).

Vertical displacements in the middle of span no. 2 were recorded by the IBIS-S radar. Both recorded and numerical results are presented in

Figure 15. The comparison of the obtained results in

Figure 15 shows that the overall responses, assuming different vehicle velocities (57, 36 and 21 km/h), of both test and analysis are similar. The most significant dynamic response is caused by the vehicle passing over the obstacle in the middle of span no. 2. The vehicle used during these tests (two-axle truck—Truck 1 from

Table 3) had a substantial effect on the overall response. If there are other cars in the traffic flow, they can be also assumed, and the partial effects can be added.

The calculated time histories have slightly smaller dynamic amplitudes than the displacement measurement records. The reason for this could be caused by an inappropriate assumption of the stiffness of the tires (see

Table 4). In this case, a rough estimation of tire stiffness was carried out by measuring changes in tire dimensions in the vertical and horizontal directions caused by gravitational forces. Tire pressure identification using sensors could be an option to obtain this data more accurately, as in [

28]. This effect should be studied further in the future.

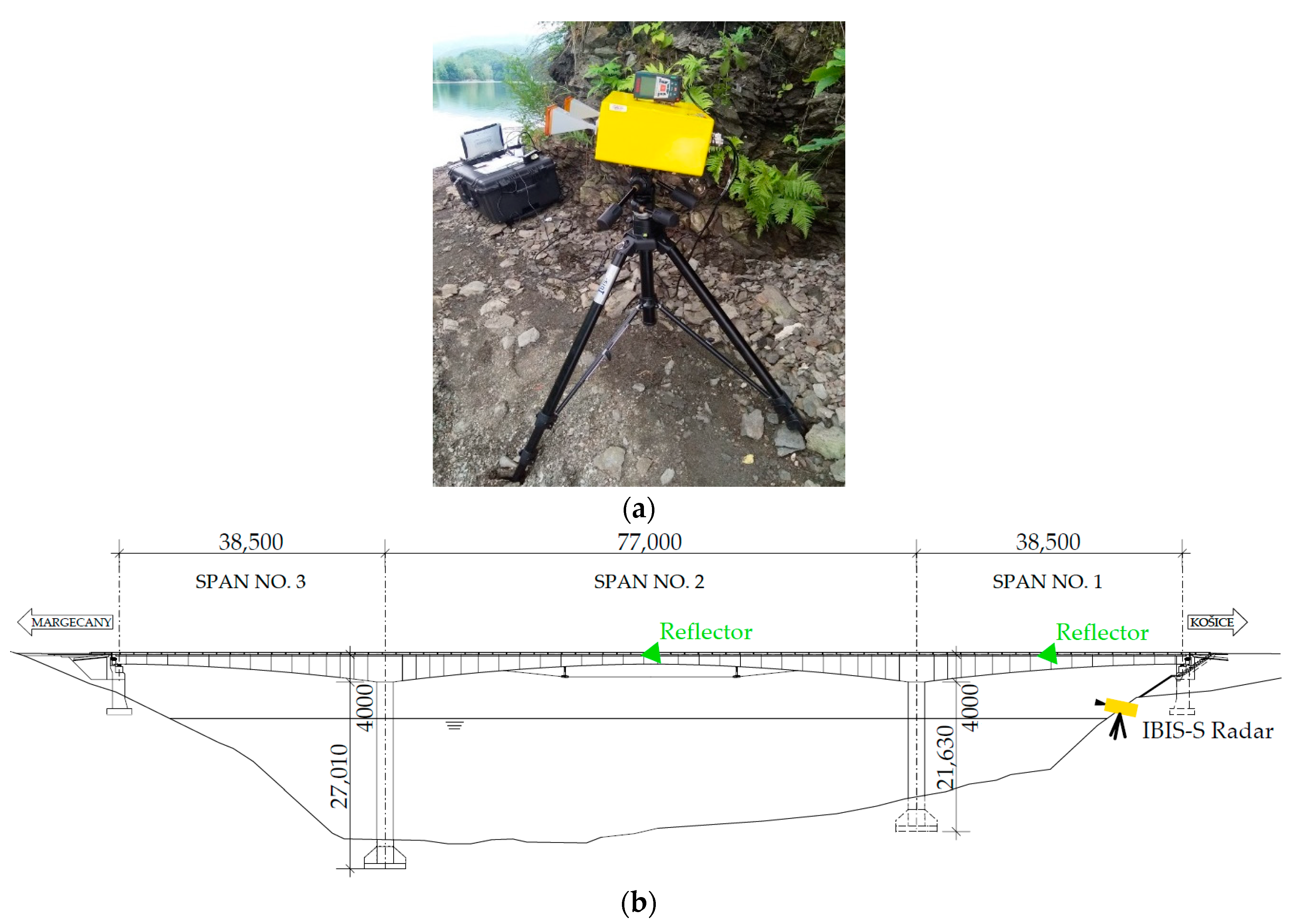

In general, IBIS-S radar allows for the measurement of hundreds of points along the bridge with a sampling rate of up to 200 samples/s. In the case study, results from only two points are presented. Two reflectors were installed (

Figure 5b) to achieve better radar signal. The two selected points are those where the displacement measurements needed to be carried out.

7. Evaluation of Axial Forces in Cables

The next comparison between the verified and validated FEM model and measurements concerns the axial forces in the external pre-stressed cables. The values of axial forces

Ntest in the cables can be determined from the measured frequencies and geometric and material characteristics of the cables (

Table 1) using Equation (4) from [

29]:

where

f1 is the first natural frequency,

L is the length of the cable and

μ is weight per meter.

To determine the axial forces

Ntest, accelerometers were mounted on two pre-stressed cables (on the northern and southern edge of the bridge, see

Figure 4). The first natural frequencies of these cables

f1 were found from the dynamic response achieved by using fast Fourier transform (

Figure 16). Two situations were considered: an unloaded and a bridge loaded by two heavy trucks (according to

Table 3). Both cables have the same geometric and material characteristics (see

Table 1 and

Table 2), which is proven in

Figure 16, where the first and second natural frequencies of both cables are the same.

The length of the cables was considered to be the free length between the deviators (see

Table 1). The axial forces were calculated from this data using Equation (3) as follows:

Ntest = 2.67 MN for the unloaded bridge and

Ntest = 2.69 MN in case of the structure being loaded with two heavy trucks. The difference between them (0.02 MN) matches well with the numerical value calculated as the predicted effect of the applied gravity forces of the load. There is therefore a good reason to believe that the total forces represent their real values on the bridge.

The values of axial forces

Ntest and natural frequencies

f of the cables can be considered a performance indicator (as in [

30]), which can be calculated from the measured data by permanently placed accelerometers to continuously measure the natural frequency. The value presented here for the unloaded bridge will be accounted for as the reference value of the performance indicator. The main benefits of this method are the possibility of measuring during regular traffic without restrictions and evaluating the actual value of the axial force even after years of service.

8. Conclusions

The development of a SHM strategy is presented in this paper using static and dynamic load tests, as well as numerical simulations. Therefore, the results of the tests and simulations of the static and dynamic response of the bridge subjected to traffic loads using a combination of devices, including interferometric radar and a complex measuring system, have been presented in the article. A static load test was performed to verify and validate the FEM model using measured strains and displacements. The combination of devices used is not common, and due to that, acceptable results were obtained from the presented comparisons. To obtain various types of data and to compare the dynamic characteristics, the combination of acceleration and displacement measurements can be used. Accelerometers are more suitable for detecting mode shapes, whereas interferometric radar can help validate numerical models comparing displacements, which are preferred in practice.

A satisfactory numerical model has been prepared. Natural frequencies and MAC values match each other, with the error not exceeding 10%. Structure–vehicle dynamic interactions incorporating uneven surface effects and loss of contact have been derived and used. Numerically predicted dynamic displacements and test results match sufficiently in cases of higher velocity of passing trucks (60 km/h), while the difference of amplitudes is doubled in case of smaller velocities (about 20 km/h). However, the results regarding periods match to each other well. Tire stiffness has to be studied and considered more accurately to improve future results. Deterministically defined loads correspond with real conditions and can be useful not only for the comparison of vibration amplitudes, e.g., accelerations and spectral values, but even for the analysis of dynamic strains and displacements caused by traffic. As shown in this paper, precisely modelled traffic can be used as a comparison tool for future applications of structural health monitoring techniques.

The goal to determine the actual forces in cables has been fulfilled. The presented SHM technique is relatively sensitive, e.g., the weight of only two vehicles could be identified. Moreover, this method provides the specification of the total value of axial force in the cable. Additionally, the natural frequencies of cables measured by accelerometers can be considered a performance indicator. The static and dynamic response of the bridge is similar to the response obtained by the numerical calculations of the FEM model prepared according to the project documentation of the real execution.