A Quality Study of a Self-Piercing Riveted Joint between Vibration-Damping Aluminum Alloy and Dissimilar Materials

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

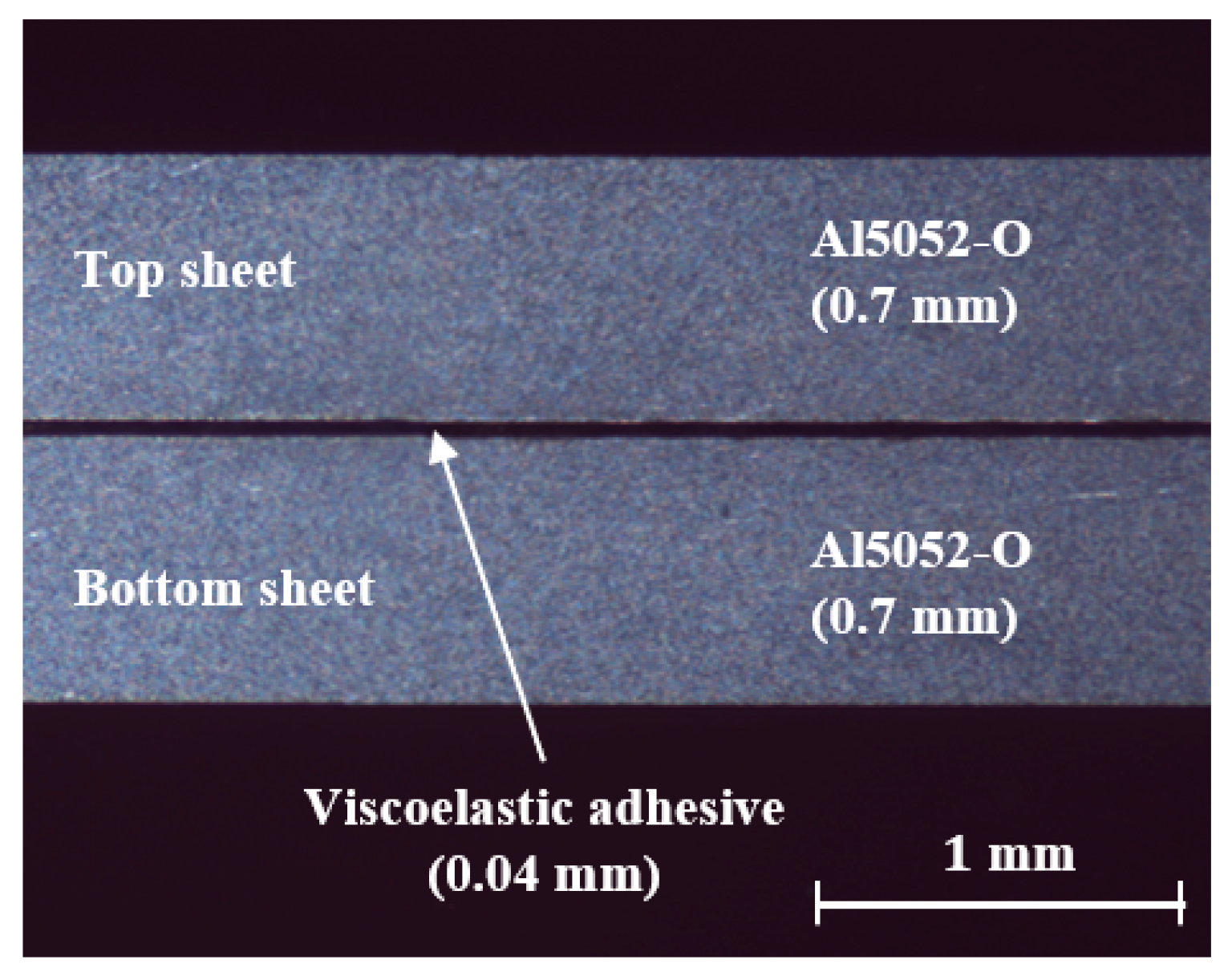

2.1. Materials

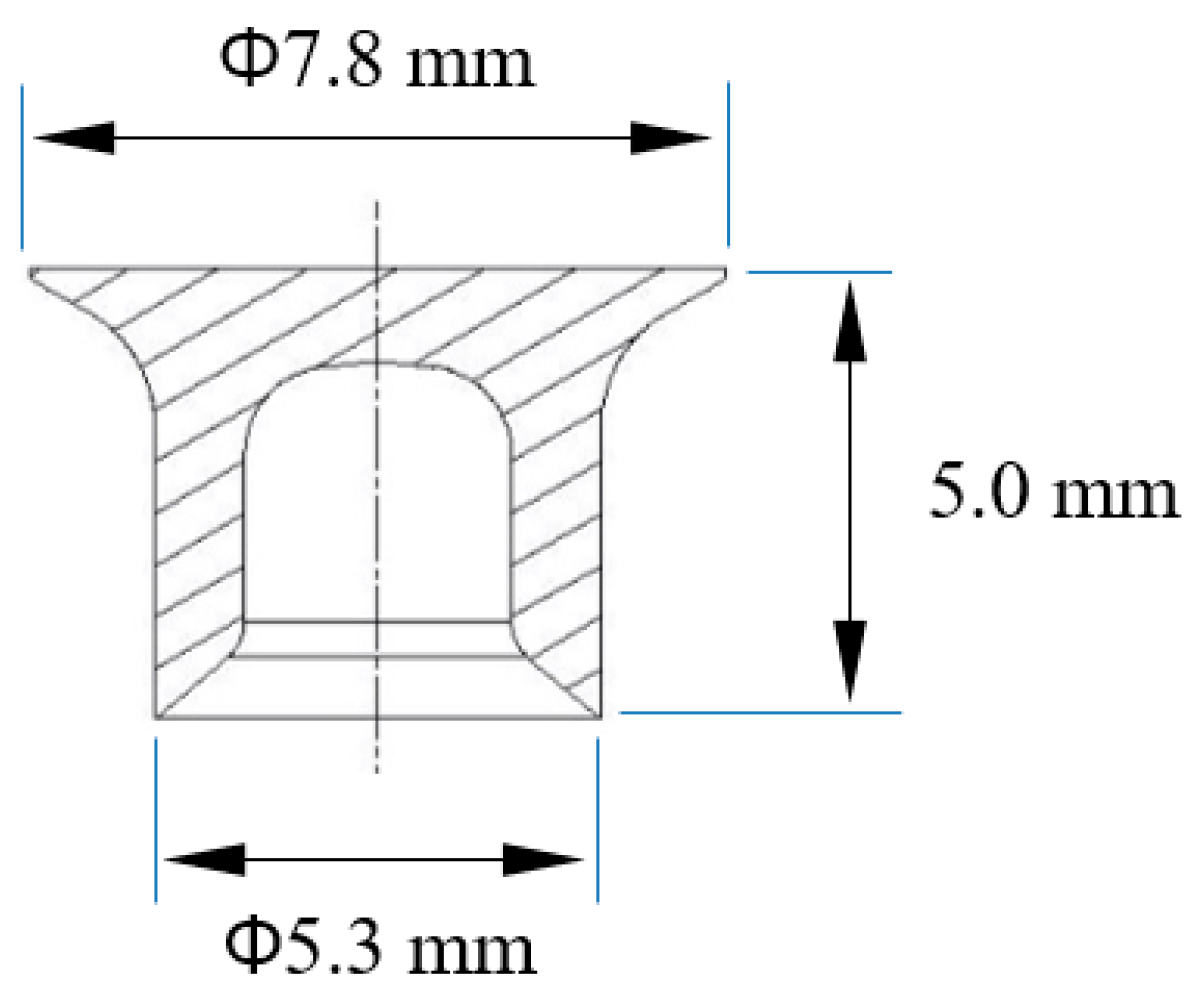

2.2. Rivet Fabrication and Die Types

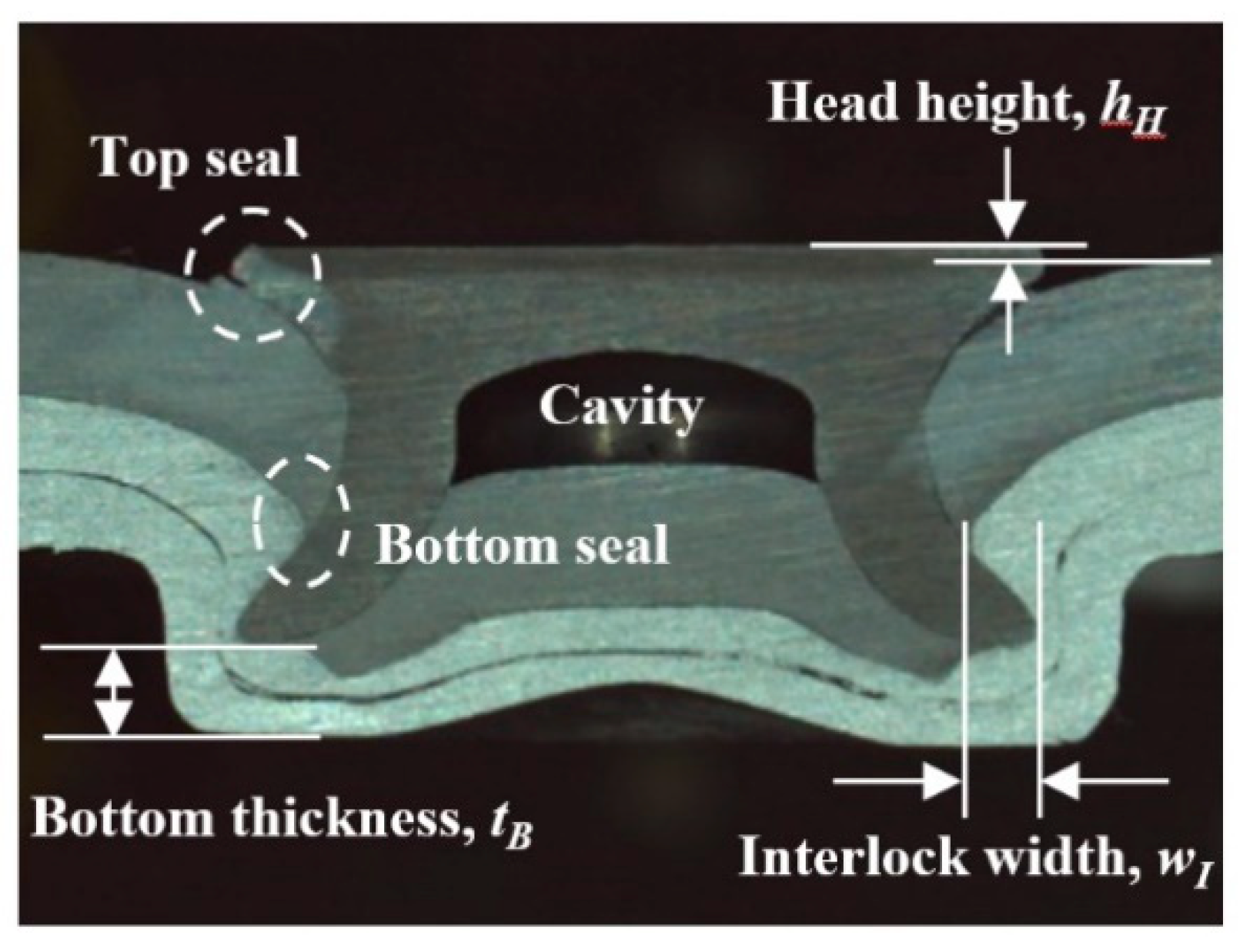

2.3. Cross-Section Analysis of Self-Piercing Riveted Joints

2.4. Joint Strength Test Apparatus

3. Results and Discussion

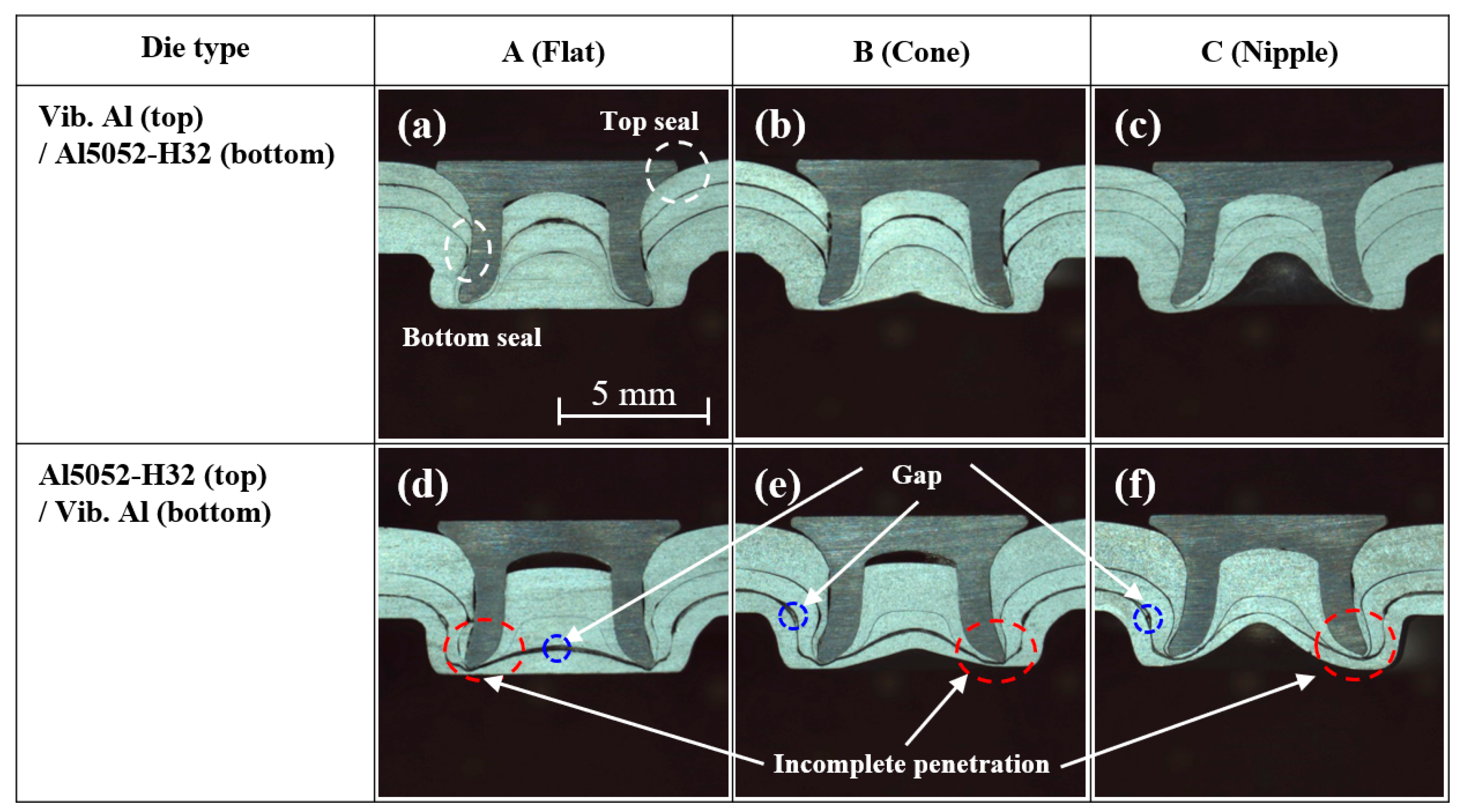

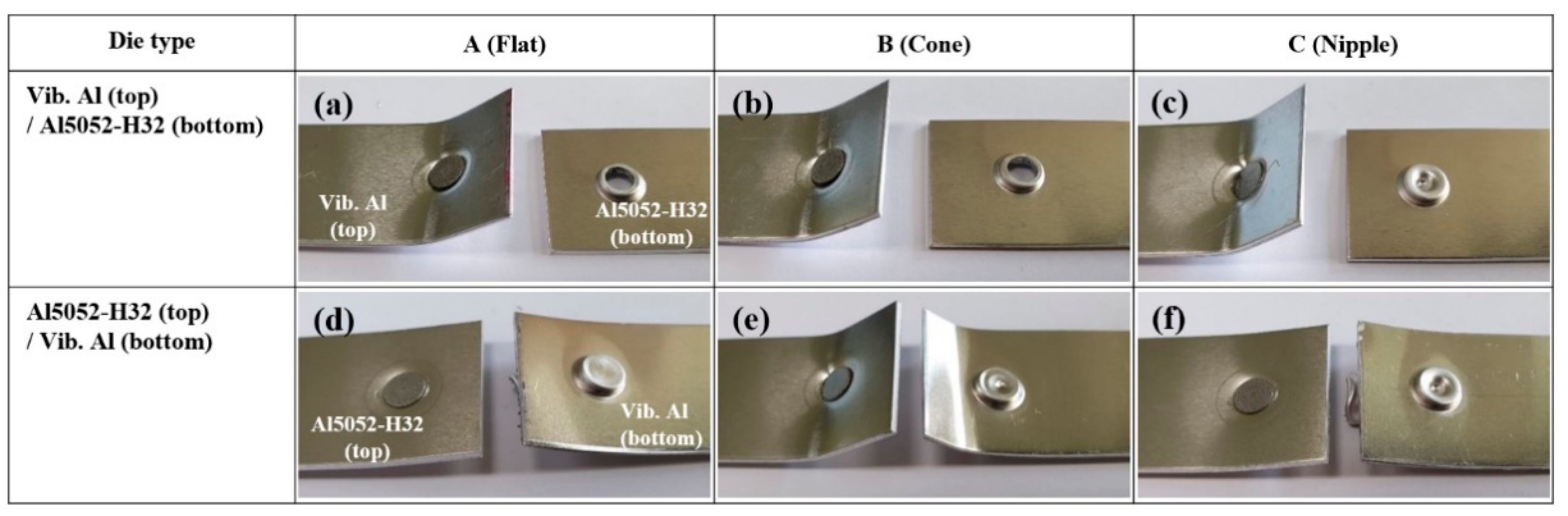

3.1. Self-Piercing Riveted Joint of Vibration-Damping Aluminum and Al5052-H32

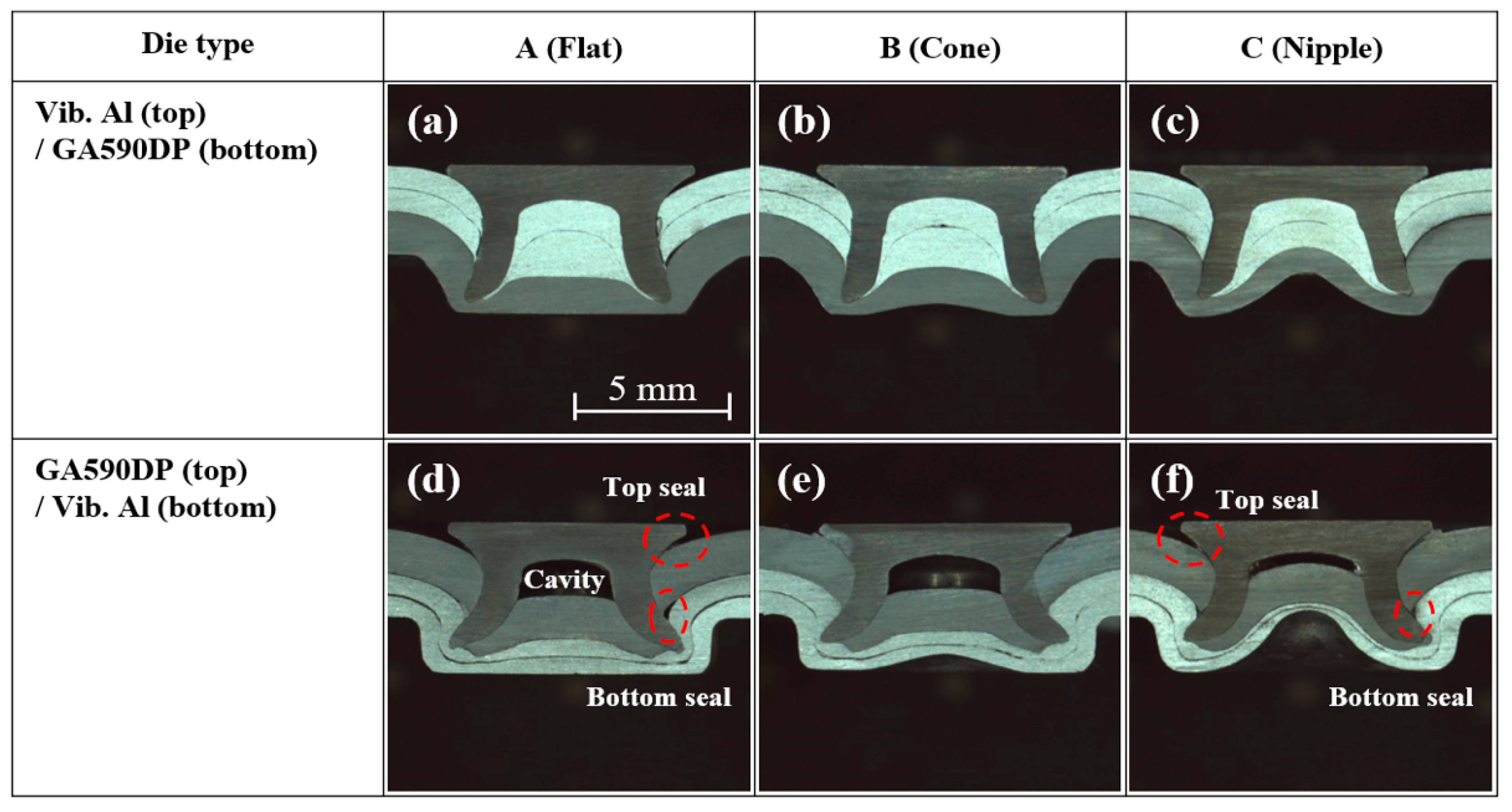

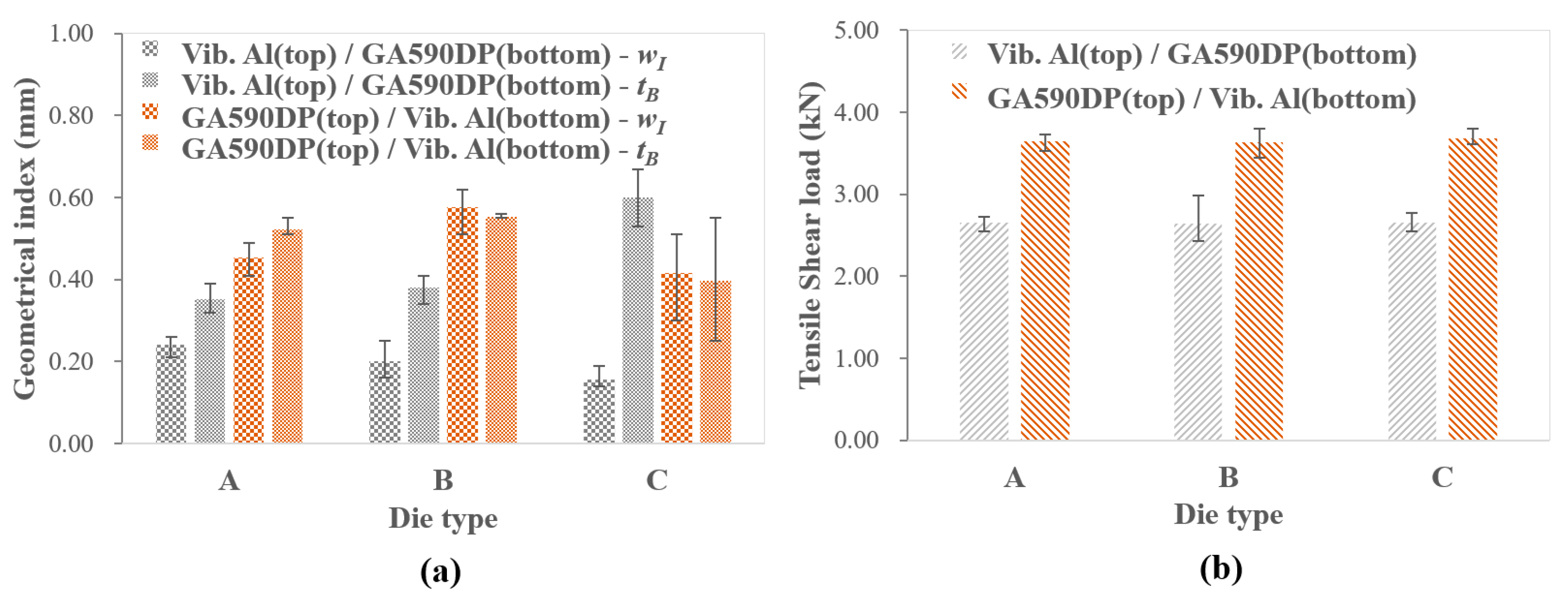

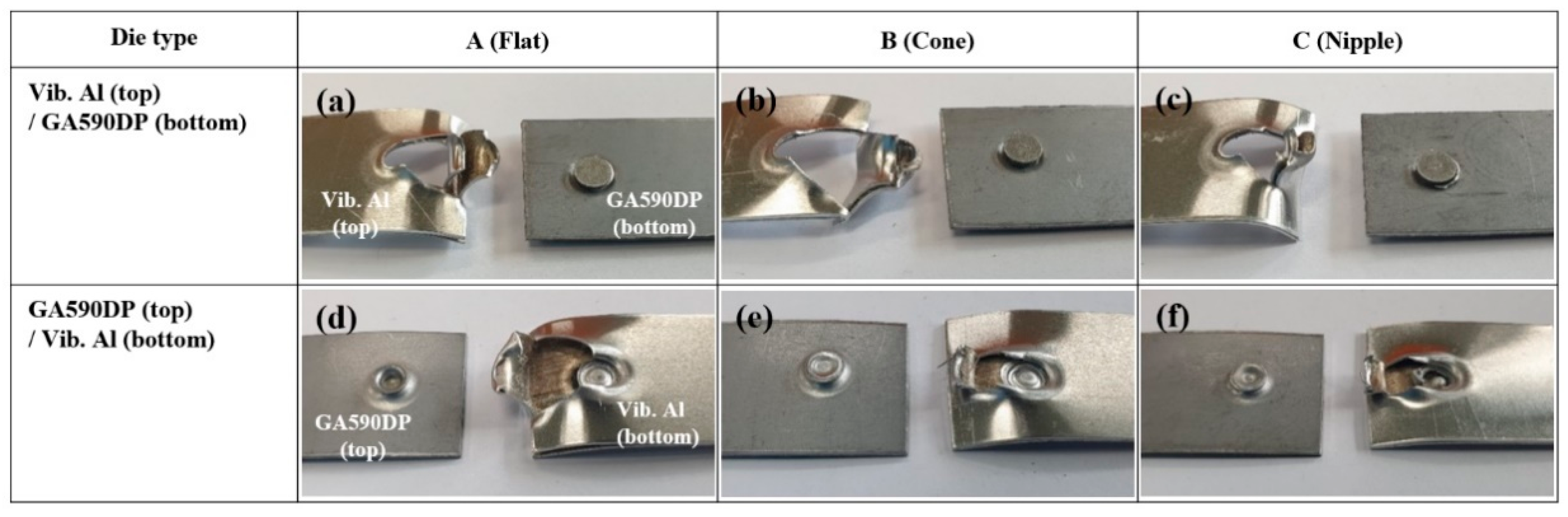

3.2. Self-Piercing Riveted Joint of Vibration-Damping Aluminum and GA590DP

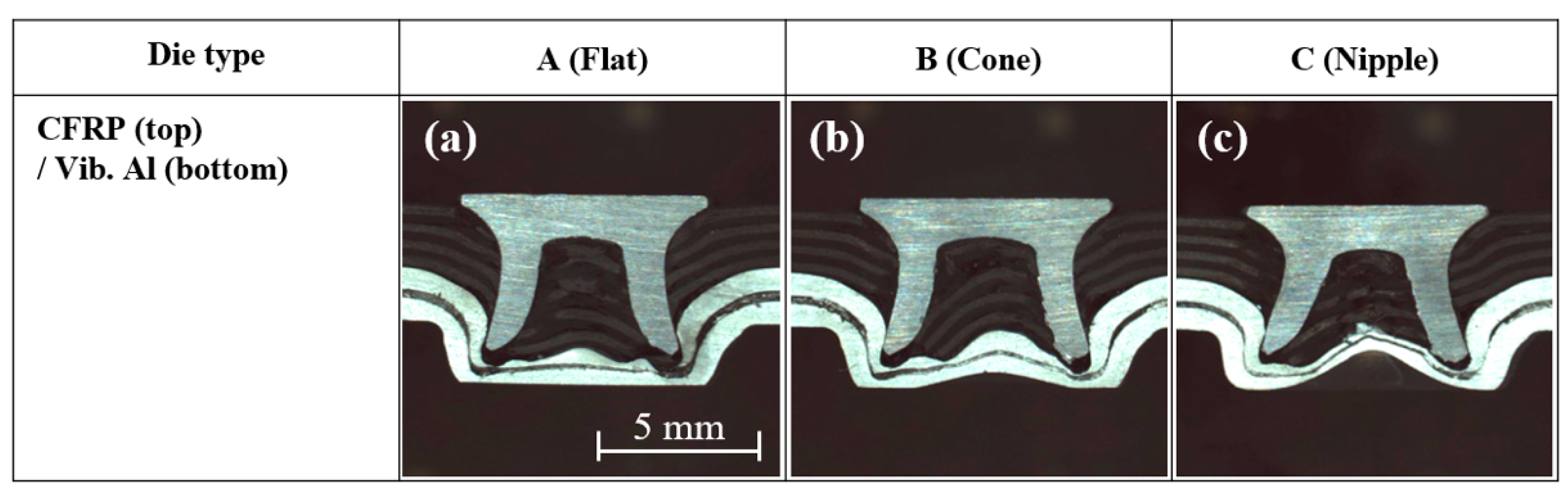

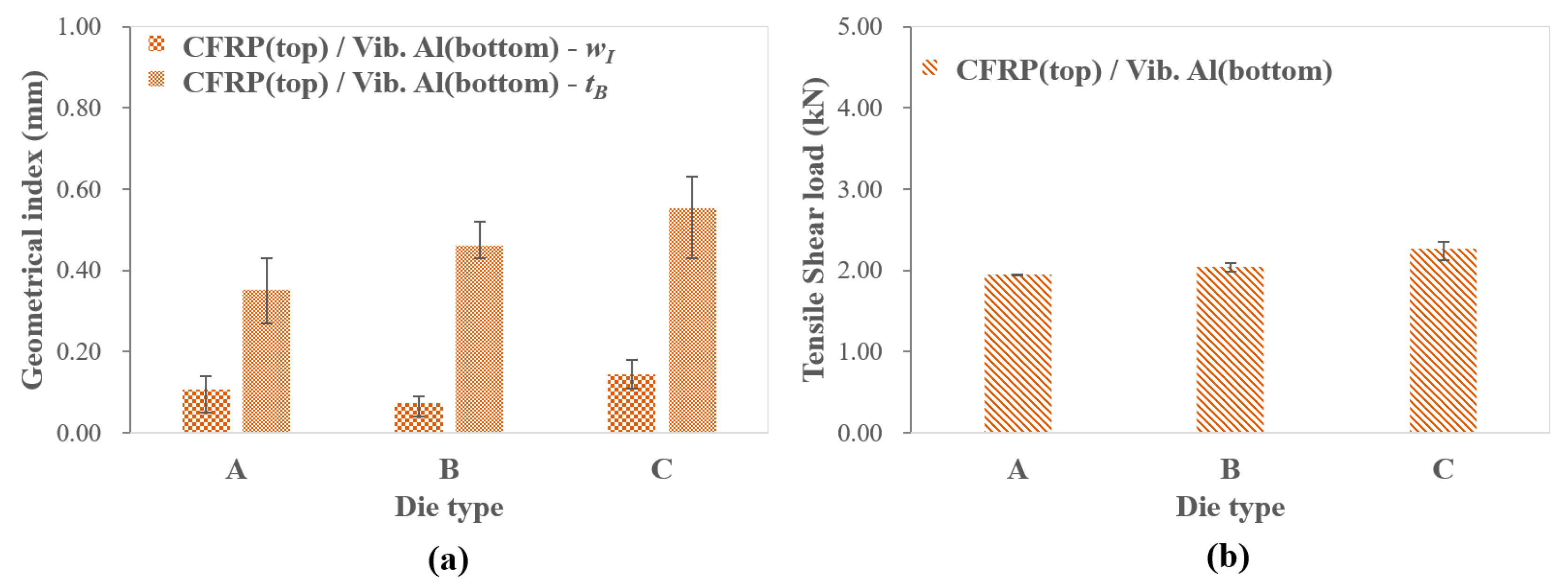

3.3. Self-Piercing Riveted Joint of Vibration-Damping Aluminum and CFRP

4. Conclusions

- When joining the vibration-damping Al panel with AL5052-H23 using the SPR process, the vibration-damping Al panel on top and die type C (nipple) showed the best cross-sectional characteristics and the maximum tensile shear strength.

- When joining the vibration-damping Al panel with GA590DP using the SPR process, the vibration-damping Al panel on the bottom showed the best cross-sectional characteristics regardless of the die type. It was found that, due to the high strength of the steel alloy, cavities are formed inside the rivet when the GA590DP panel is on top, but they do not affect the joining strength between the two materials.

- When joining the vibration-damping Al panel with CFRP using the SPR process, CFRP must be on top for the successful formation of the joint. The inhomogeneous and brittle characteristics of the CFRP result in an ununiform interface between the rivet and the top panel, and significant cracking can be observed within the rivet head.

Author Contributions

Funding

Conflicts of Interest

References

- Haque, R. Quality of self-piercing riveting (SPR) joints from cross-sectional perspective: A review. Arch. Civ. Mech. Eng. 2018, 18, 83–93. [Google Scholar] [CrossRef]

- Blacket, S. Self-pierce riveting technology. A joining solution for light metals. In Proceedings of the 1st International Light Metals Technology Conference, Brisbane, Australia, 18–20 September 2003; pp. 383–388. [Google Scholar]

- He, X.; Deng, C.; Zhang, X. Fretting behavior of SPR joining dissimilar sheets of titanium and copper alloys. Metals 2016, 6, 312. [Google Scholar] [CrossRef] [Green Version]

- Briskham, P.; Blundell, N.; Han, L.; Hewitt, R.; Young, K. Comparison of self-pierce riveting, resistance spot welding and spot friction joining for aluminium automotive sheet for static strength. SAE Int. 2006, 2006-01-0774. [Google Scholar] [CrossRef] [Green Version]

- Special Fasteners. 2017. Available online: http://www.boellhoff.de (accessed on 1 July 2020).

- Franco, G.D.; Fratini, L.; Pasta, A.; Ruisi, V.F. On the self-piercing riveting of aluminium blanks and carbon fibre composite panels. Int. J. Mater. Form. 2013, 6, 137–144. [Google Scholar] [CrossRef]

- Jeon, N.-K.; Jeong, T.-E.; Rhee, S.; Kam, D.-H. Evaluation of CFRP/Steel/Aluminum three layer joining with self-piercing rivet. J. Weld. Join. 2019, 37, 56. [Google Scholar] [CrossRef] [Green Version]

- Jeon, N.-K.; Rhee, S.; Kam, D.-H. Parametric Study of Self-Piercing Riveting for CFRP-Aluminum Dissimilar Joint. J. Weld. Join. 2018, 36, 8. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; He, X.; Xing, B.; Zhao, L.; Lu, Y.; Gu, F.; Ball, A. Influence of heat treatment on fatigue performances for self-piercing riveting similar and dissimilar titanium, aluminium and copper alloys. Mater. Des. 2017, 97, 108–117. [Google Scholar] [CrossRef] [Green Version]

- Zhao, L.; He, X.; Xing, B.; Lu, Y.; Gu, F.; Ball, A. Influence of sheet thickness on fatigue behavior and fretting of self-piercing riveted joints in aluminum alloy 5052. Mater. Des. 2015, 87, 1010–1017. [Google Scholar] [CrossRef]

- Jeong, T.-E.; Kim, M.-G.; Rhee, S.; Kam, D.-H. Joint quality study of self-piercing riveted aluminum and steel joints depending on the thickness and strength of base metal. J. Weld. Join. 2019, 37, 212. [Google Scholar] [CrossRef]

- Haque, R. Residual Stress and Deformation in SPR Joints of High Strength Materials. Ph.D. Thesis, Swinburne University of Technology, Melbourne, Australia, 2014. [Google Scholar]

- Isenstadt, A.; German, J.; Bubna, P.; Wiseman, M.; Venkatakrishnan, U.; Abbasov, L.; Guillen, P.; Moroz, N.; Richman, D.; Kolwich, G. Lightweighting Technology Development and Trends in U.S. Passenger Vehicles; Working Paper; ICCT: San Francisco, CA, USA, 2016; pp. 1–24. Available online: https://theicct.org/sites/default/files/publications/ICCT_PVtech_lightweighting_wp2016-25.pdf (accessed on 1 July 2020).

- Mascarin, A.; Hannibal, T.; Raghunathan, A.; Ivanic, Z.; Francfort, J. Vehicle lightweighting: 40% and 45% weight savings analysis: Technical cost modeling for vehicle lightweighting, INL/EXT-14-33863. 2015. Available online: https://inldigitallibrary.inl.gov/sites/sti/sti/6492855.pdf (accessed on 1 July 2020).

- Pramanik, A.; Basak, A.K.; Dong, Y.; Sarker, P.K.; Uddin, M.S.; Littlefair, G.; Dixit, A.R.; Chattopadhyaya, S. Joining of carbon fibre reinforced polymer (CFRP) composites and aluminium alloys—A review. Compos. Part A 2017, 101, 1–29. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.C.; Zhou, Z.J.; Huang, W. Mechanical behaviors of self-piercing riveting joining dissimilar sheets. Adv. Mater. Res. 2010, 97, 3932–3935. [Google Scholar] [CrossRef]

- Haque, R.; Durandet, Y. Investigation of self-pierce riveting (SPR) process data and specific joining events. J. Manuf. Process. 2017, 30, 148–160. [Google Scholar] [CrossRef]

- Eshtayeh, M.M.; Hrairi, M.; Mohiuddin, A.K.M. Clinching process for joining dissimilar materials: State of the art. Int. J. Adv. Manuf. Technol. 2016, 82, 179–195. [Google Scholar] [CrossRef]

- Mucha, J. The analysis of lock forming mechanism in the clinching joint. Mater. Des. 2011, 32, 4943–4954. [Google Scholar] [CrossRef]

- Hong, S.H.; Yan, F.; Sung, S.J.; Pan, J.; Su, X.; Friedman, P. Investigation of failure mode and fatigue behavior of flow drill screw joints in lap-shear specimens of aluminum 6082-T6 sheets. SAE Int. J. Mater. Manuf. 2016, 9, 746–750. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Pearson, I.; Young, K. Self-pierce riveting for sheet materials: State of the art. J. Mater. Process. Technol. 2008, 199, 27–36. [Google Scholar] [CrossRef]

- Ma, Y.W.; Lou, M.; Li, Y.B.; Lin, Z.Q. Effect of rivet and die on self-piercing rivetability of AA6061-T6 and mild steel CR4 of different gauges. J. Mater. Process. Technol. 2018, 251, 282–294. [Google Scholar] [CrossRef]

- Abe, Y.; Kato, T.; Mori, K. Joinability of aluminium alloy and mild steel sheets by self-piercing rivet. J. Mater. Process. Technol. 2006, 177, 417–421. [Google Scholar] [CrossRef]

- Han, L.; Chrysanthou, A.; Young, K.W. Mechanical behaviour of self-piercing riveted multi-layer joints under different specimen configurations. Mater. Des. 2007, 28, 2024–2033. [Google Scholar] [CrossRef]

- Wood, P.K.C.; Schley, C.A.; Williams, M.A.; Rusinek, A. A model to describe the high rate performance of self-piercing riveted joints in sheet aluminum. Mater. Des. 2011, 32, 2246–2259. [Google Scholar] [CrossRef]

- Kam, D.-H.; Jeong, T.-E.; Kim, M.-G.; Shin, J. Self-piercing riveted joint of vibration-damping steel and aluminum alloy. Appl. Sci. 2019, 9, 4575. [Google Scholar] [CrossRef] [Green Version]

- Saleem, M.; Zitoune, R.; Sawi, I.E.; Bougherara, H. Role of the surface quality on the mechanical behavior of CFRP bolted composite joints. Int. J. Fatigue 2015, 80, 246. [Google Scholar] [CrossRef]

- Haeger, A.; Grudenik, M.; Hoffmann, M.J.; Knoblauch, V. Effect of drilling-induced damage on the open hole flexural fatigue of carbon/epoxy composites. Compos. Struct. 2019, 215, 238. [Google Scholar] [CrossRef]

| Panel Material | Ultimate Tensile Strength (MPa) | Thickness (mm) |

|---|---|---|

| Vibration-damping Al | 188 | 1.44 |

| Al5052-H32 | 233 | 1.5 |

| GA590DP | 609 | 1.4 |

| CFRP | 1032 (0°)/234 (45°)/1014 (90°) | 1.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kam, D.H.; Jeong, T.E.; Kim, J. A Quality Study of a Self-Piercing Riveted Joint between Vibration-Damping Aluminum Alloy and Dissimilar Materials. Appl. Sci. 2020, 10, 5947. https://doi.org/10.3390/app10175947

Kam DH, Jeong TE, Kim J. A Quality Study of a Self-Piercing Riveted Joint between Vibration-Damping Aluminum Alloy and Dissimilar Materials. Applied Sciences. 2020; 10(17):5947. https://doi.org/10.3390/app10175947

Chicago/Turabian StyleKam, Dong Hyuck, Taek Eon Jeong, and Jedo Kim. 2020. "A Quality Study of a Self-Piercing Riveted Joint between Vibration-Damping Aluminum Alloy and Dissimilar Materials" Applied Sciences 10, no. 17: 5947. https://doi.org/10.3390/app10175947

APA StyleKam, D. H., Jeong, T. E., & Kim, J. (2020). A Quality Study of a Self-Piercing Riveted Joint between Vibration-Damping Aluminum Alloy and Dissimilar Materials. Applied Sciences, 10(17), 5947. https://doi.org/10.3390/app10175947