Structural Analysis of Factors Influencing the Costs of Facade System Implementation

Abstract

:1. Introduction

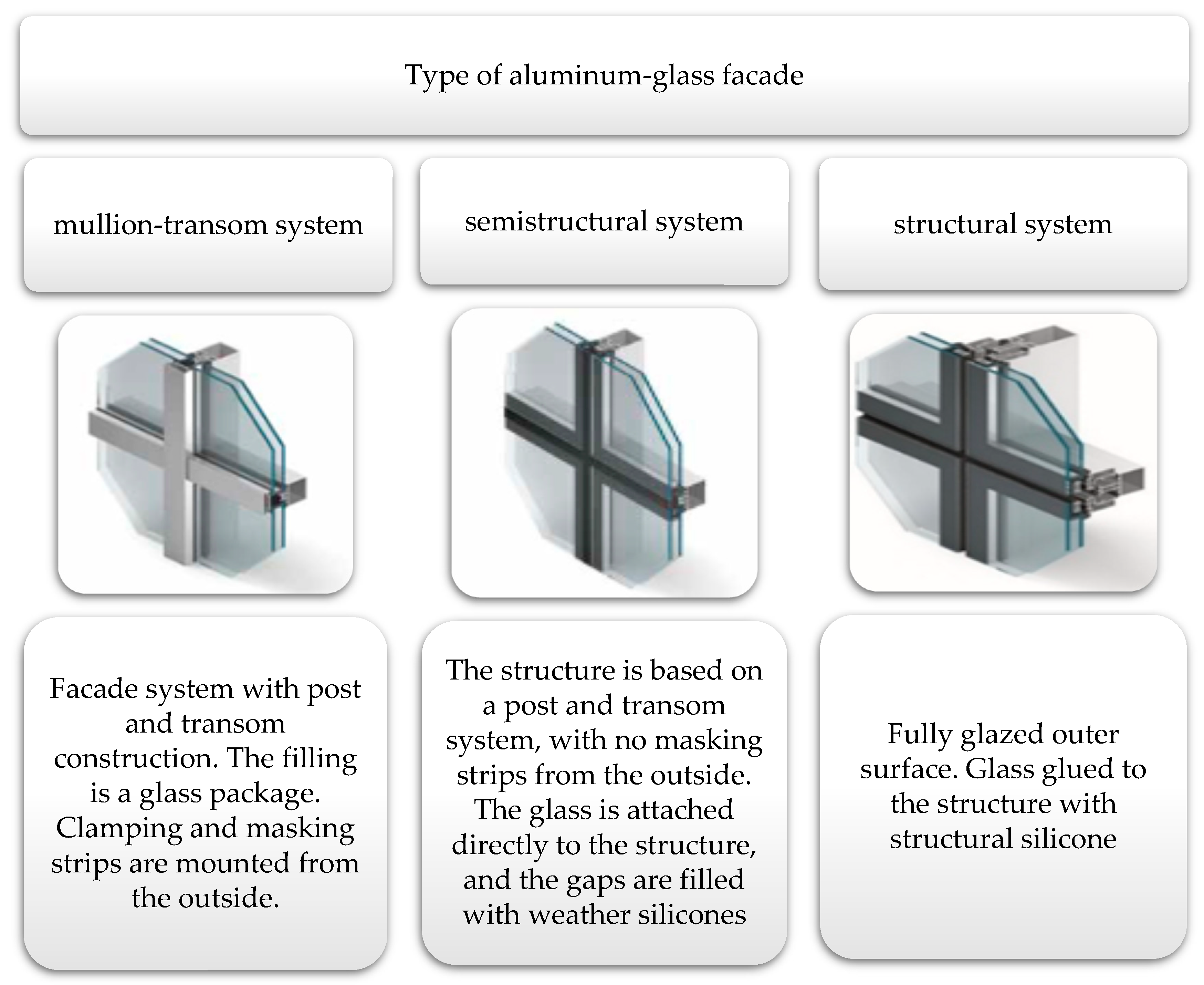

2. Short Characteristic of Selected Facade Systems

- external panels (for instance, cement, stone, wood-based, plastic, metal, or laminate) attached to the grate (suspended, glued, or screwed to the grate);

- grate (made of metal or wood) attached—suspended, glued, or screwed—to the external wall;

- fastening elements;

- insulating material.

3. The Structural Analysis: Methodology

3.1. The First Stage: Identfication of Factors

3.2. The Second Stage: Description of Factor Relationships

3.3. The Third Stage: Examination of Factors’ Impacts

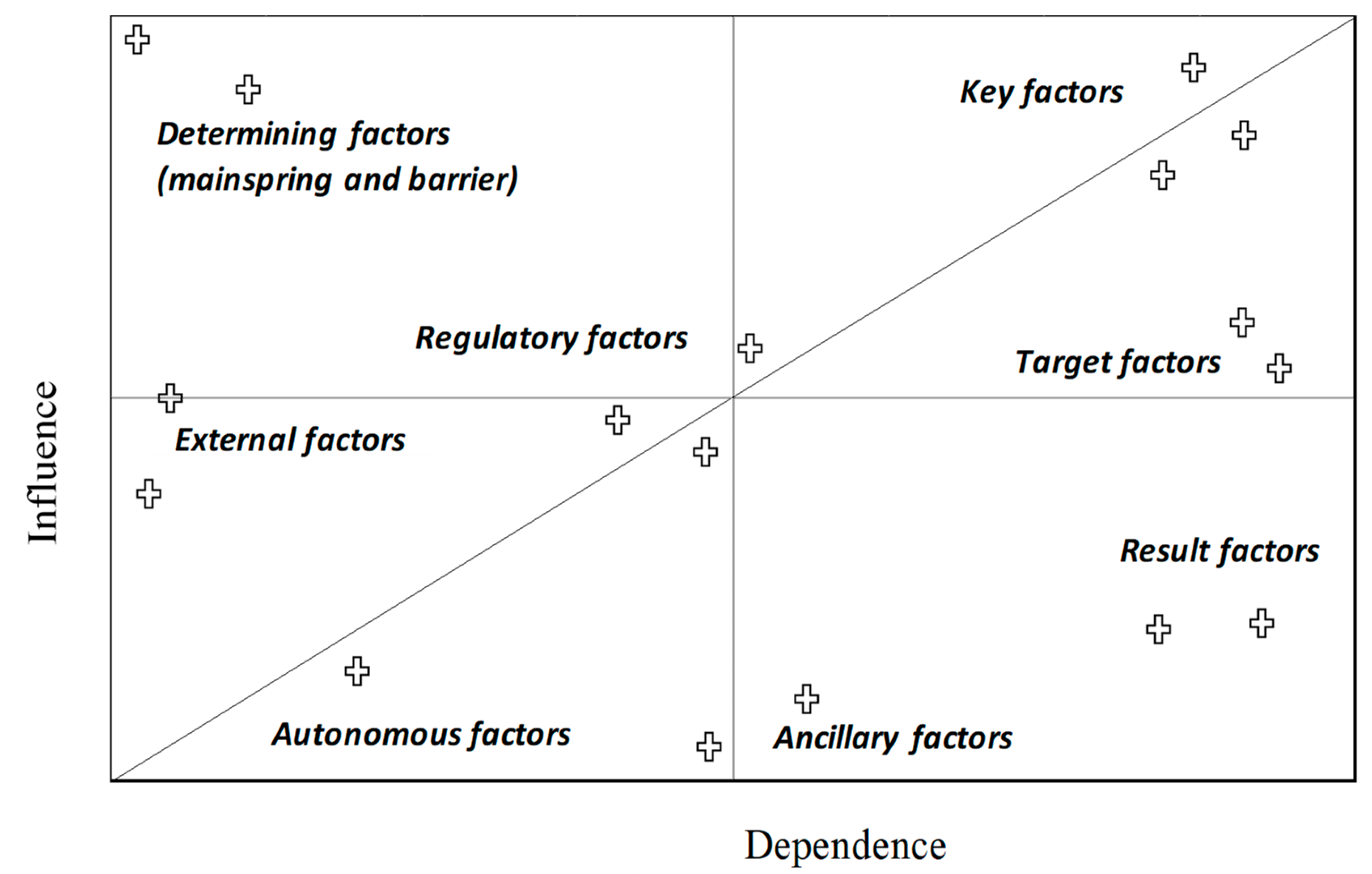

3.4. The Fourth Stage: Identification of Factor Groups

- Key factors, which are characterized by a very high impact on other factors;

- Target factors, which involve variables that change themselves to a large extent under the influence of factors other than those that affect them;

- Result factors, which have a low impact on the structure of the research area, but are very dependent on other factors;

- Determining factors (mainspring and barrier), which describe, characterize, and control the structure of the research topic. These have a real impact on the whole system, either driving it or being a barrier to the whole operation;

- Regulatory factors and ancillary factors, which do not affect the structure and do not have any strong dependencies on other factors, but help to define the strategic objective;

- Autonomous and external factors, which include secondary factors that have very little influence on the system and its forecasts.

4. Results and Discussion

4.1. Identified Cost Factors

4.2. Conduct and Results of Factor Analysis

- Factor A affects on average factors B, I, and K, which is why the matrix was assigned a grade 2 according to a five-degree scale;

- Factor A does not affect factors C, D, E, F, H, J, L, M, N, and O—therefore, a degree of 0 is assigned in the matrix;

- Factor A potentially affects factor G; therefore, a grade P is assigned in the matrix.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Saeedi, M. Study the Effects of Constructions New Techniques and Technologies on Time, Cost and Quality of Construction Projects from the Perspective of Construction Management. J. Civ. Eng. Mater. Appl. 2017, 1, 61–76. [Google Scholar] [CrossRef]

- Colinart, T.; Bendouma, M.; Glouannec, P. Building renovation with prefabricated ventilated façade element: A case study. Energy Build. 2019, 186, 221–229. [Google Scholar] [CrossRef]

- Leśniak, A.; Górka, M. Analysis of the cost structure of aluminum and glass facades. In Advances and Trends in Engineering Sciences and Technologies III, Proceedings of the 3rd International Conference on Engineering Sciences and Technologies (ESaT 2018), Tatranské Matliare, Slovak Republic, 12–14 September 2018; Al Ali, M., Platko, P., Eds.; CRC Press: Leiden, The Netherlands, 2019; p. 445. [Google Scholar]

- Górka, M. Use of aluminium and glass facades in urban architecture. Civ. Eng. Archit. 2019, 18, 29–40. [Google Scholar] [CrossRef] [Green Version]

- Balocco, C. A simple model to study ventilated facades energy performance. Energy Build. 2002, 34, 469–475. [Google Scholar] [CrossRef]

- Schabowicz, K.; Sulik, P.; Zawiślak, Ł. Identification of the Destruction Model of Ventilated Facade under the Influence of Fire. Materials 2020, 13, 2387. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Brzezicki, M.; Kutnar, A. State of the art in building façades. In Bio-Based Building Skin; Springer: Singapore, 2019; pp. 1–26. [Google Scholar]

- Schabowicz, K.; Gorzelańczyk, T.; Mateusz Szymków, M. Modern ventilated facade systems—Types and requirements. Izolacje 2017, 7, 8. [Google Scholar]

- Besir, A.B.; Cuce, E. Green roofs and facades: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 915–939. [Google Scholar] [CrossRef]

- Ihara, T.; Gustavsen, A.; Jelle, B.P. Effect of facade components on Energy efficiency in office buildings. Appl. Energy 2015, 158, 422–432. [Google Scholar] [CrossRef]

- Ikram, H.A.; Ahmad, M.; Qadeer, R.M.; Nawaz, M. Evaluation of key factors influencing process quality during construction projects in Pakistan. Grey Syst. Theory Appl. 2019, 9, 321–335. [Google Scholar] [CrossRef]

- Juszczyk, M. Early Cost Estimates of Bridge Structures Aided by Artificial Neural Networks. In VIII International Scientific Siberian Transport Forum; Springer: Cham, Switzerland, 2019; Volume 1116. [Google Scholar] [CrossRef]

- Wieczorek, D.; Plebankiewicz, E.; Zima, K. Model estimation of the whole life cost of a building with respect to risk factors. Technol. Econ. Dev. Econ. 2019, 25, 20–38. [Google Scholar] [CrossRef] [Green Version]

- Krzemiński, M. Optimization of work schedules executed using the flow shop model, assuming multitasking performed by work crews. Arch. Civ. Eng. 2017, 63, 3–19. [Google Scholar] [CrossRef]

- Nowogońska, B.; Korentz, J. Value of Technical Wear and Costs of Restoring Performance Characteristics to Residential Buildings. Buildings 2020, 10, 9. [Google Scholar] [CrossRef] [Green Version]

- Sztubecka, M.; Skiba, M.; Mrówczyńska, M.; Bazan-Krzywoszańska, A. An Innovative Decision Support System to Improve the Energy Efficiency of Buildings in Urban Areas. Remote Sens. 2020, 12, 259. [Google Scholar] [CrossRef] [Green Version]

- Juszczyk, M.; Zima, K.; Lelek, W. Forecasting of sports fields construction costs aided by ensembles of neural networks. J. Civ. Eng. Manag. 2019, 25, 715–729. [Google Scholar] [CrossRef] [Green Version]

- Leśniak, A.; Górka, M.; Wieczorek, D. Identification of factors shaping tender prices for lightweight curtain walls. Sci. Rev. Eng. Environ. Sci. 2019, 2, 171–182. [Google Scholar] [CrossRef] [Green Version]

- Leśniak, A.; Zima, K. Cost calculation of construction projects including sustainability factors using the Case Based Reasoning (CBR) method. Sustainability 2018, 10, 1608. [Google Scholar] [CrossRef] [Green Version]

- Kowacka, M.; Skorupka, D.; Duchaczek, A.; Zagrodnik, P. Identification of geodetic risk factors occurring at the construction project preparation stage. Open Eng. 2019, 9, 14–17. [Google Scholar] [CrossRef]

- Hoła, B.; Nowobilski, T. Analysis of the influence of socio-economic factors on occupational safety in the construction industry. Sustainability 2019, 11, 4469. [Google Scholar] [CrossRef] [Green Version]

- Mrówczyńska, M.; Skiba, M.; Bazan-Krzywoszańska, A.; Sztubecka, M. Household standards and socio-economic aspects as a factor determining energy consumption in the city. Appl. Energy 2020, 264, 114680. [Google Scholar] [CrossRef]

- Kapliński, O. Innovative solutions in construction industry. Review of 2016–2018 events and trends. Eng. Struct. Technol. 2018, 10, 27–33. [Google Scholar] [CrossRef] [Green Version]

- Leśniak, A.; Kubek, D.; Plebankiewicz, E.; Zima, K.; Belniak, S. Fuzzy AHP application for supporting contractors’ bidding decision. Symmetry 2018, 10, 642. [Google Scholar] [CrossRef] [Green Version]

- Methods of Prospective. La Prospective. Available online: https://en.laprospective.fr/ (accessed on 10 April 2020).

- Aluprof Aluminium Systems, Folders, Brochures, Cataloges. Available online: https://aluprof.eu/producenci/do-pobrania/foldery-broszury-katalogi (accessed on 15 April 2020).

- ETAG 034. Guideline for European Technical Approval of Kits of External Wall Claddings Part I: Ventilated Cladding and Associated Fixing; EOTA: Brussel, Belgium, 2010. [Google Scholar]

- Arcade, J.; Godet, M.; Meunier, F.; Roubelat, F. Structural Analysis with the MICMAC Method & Factors Strategy with MACTOR Method; Ac/UNU Millenium Project Futures Research Methodology: Paris, France, 1999. [Google Scholar]

- Nazarko, J.; Ejdys, J.; Halicka, K.; Nazarko, Ł.; Kononiuk, A.; Olszewska, A. Structural Analysis as an Instrument for Identification of critical drivers of technology Development. Procedia Eng. 2017, 182, 474–481. [Google Scholar] [CrossRef]

- Ranzi, G.; Gilbert, R. Structural Analysis, Principles, Methods and Modelling; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Livesley, R.K. Matrix Methods of Structural Analysis, 2nd ed.; Pergamon International Library of Science, Technology, Engineering and Social Studies; Pergamon Press: Oxford, UK, 2013. [Google Scholar]

- Benjumea-Arias, M.; Castaneda, L.; Valencia-Arias, A. Structural analysis of strategic variables through MICMAC use: Case Study. Mediterr. J. Soc. Sci. 2016, 7, 11. [Google Scholar] [CrossRef]

| Public Buildings | |

|---|---|

| Building function | Service and commercial |

| Office | |

| Location | City centre |

| Outside city centre | |

| Out-of-town | |

| Type of facade | Aluminium–glass facade |

| Ventilated facade | |

| Type of aluminium–glass facade | Mullion–transom |

| Semistructural | |

| Structural | |

| Type of glass | Fire glass |

| Single glass | |

| Insulated glass | |

| Type of ventilated facade cladding | Composite board |

| Aluminium sheet | |

| Board fiber cement | |

| No. | Group of Factors/Factor | Symbol | Total Strength of Influence | Total Strength of Dependencies |

|---|---|---|---|---|

| Material | ||||

| 1 | Type of aluminium–glass facade | A | 6 | 16 |

| 2 | Type of glass used | B | 7 | 16 |

| 3 | Type of external cladding used for ventilated facades | C | 5 | 13 |

| Facility characteristics | ||||

| 4 | Height of the facility | D | 13 | 0 |

| 5 | Facade surface | E | 6 | 3 |

| 6 | Complexity of the building body | F | 13 | 0 |

| 7 | Number of window and door frames. | G | 3 | 1 |

| Contractual conditions | ||||

| 8 | Location of construction | H | 4 | 0 |

| 9 | Implementation time–duration | I | 8 | 29 |

| 10 | Implementation deadline (season) | J | 6 | 1 |

| Aesthetics | ||||

| 11 | Quality of execution | K | 2 | 16 |

| Macroeconomic factors | ||||

| 12 | Company size | L | 10 | 0 |

| 13 | Specialisation of subcontractors | M | 13 | 3 |

| 14 | Inflation | N | 2 | 0 |

| 15 | Availability of subcontractors | O | 4 | 4 |

| Regulatory Factors | Ancillary Factors | Determining Factors | Goal Factors | External Factors | Autonomous Factors |

|---|---|---|---|---|---|

| (A) Type of aluminium–glass façade (B) Type of glass used (C) Type of external cladding | (K) Quality of execution | (D) Height of the facility (E) Facade surface (F) Complexity of the building body (M) Specialisation of subcontractors | (I) Implementation time | (L) Company size (J) Implementation deadline (season) | (G) Number of window and door frames (H) Location of construction (N) Inflation (O) Availability of subcontractors |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leśniak, A.; Górka, M. Structural Analysis of Factors Influencing the Costs of Facade System Implementation. Appl. Sci. 2020, 10, 6021. https://doi.org/10.3390/app10176021

Leśniak A, Górka M. Structural Analysis of Factors Influencing the Costs of Facade System Implementation. Applied Sciences. 2020; 10(17):6021. https://doi.org/10.3390/app10176021

Chicago/Turabian StyleLeśniak, Agnieszka, and Monika Górka. 2020. "Structural Analysis of Factors Influencing the Costs of Facade System Implementation" Applied Sciences 10, no. 17: 6021. https://doi.org/10.3390/app10176021

APA StyleLeśniak, A., & Górka, M. (2020). Structural Analysis of Factors Influencing the Costs of Facade System Implementation. Applied Sciences, 10(17), 6021. https://doi.org/10.3390/app10176021