A Low-Cost Constant-Moisture Automatic Irrigation System Using Dynamic Irrigation Interval Adjustment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data and Equipment

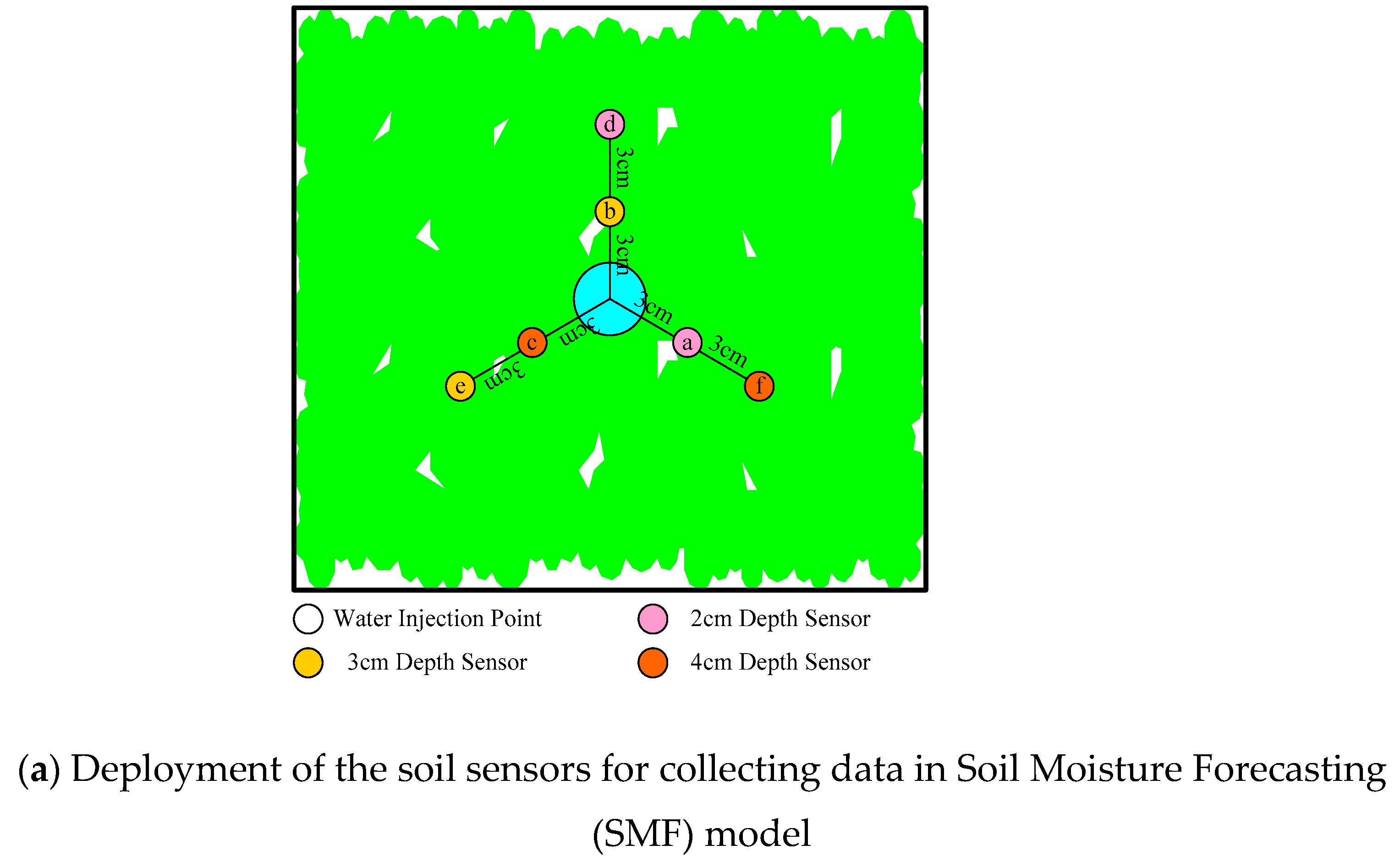

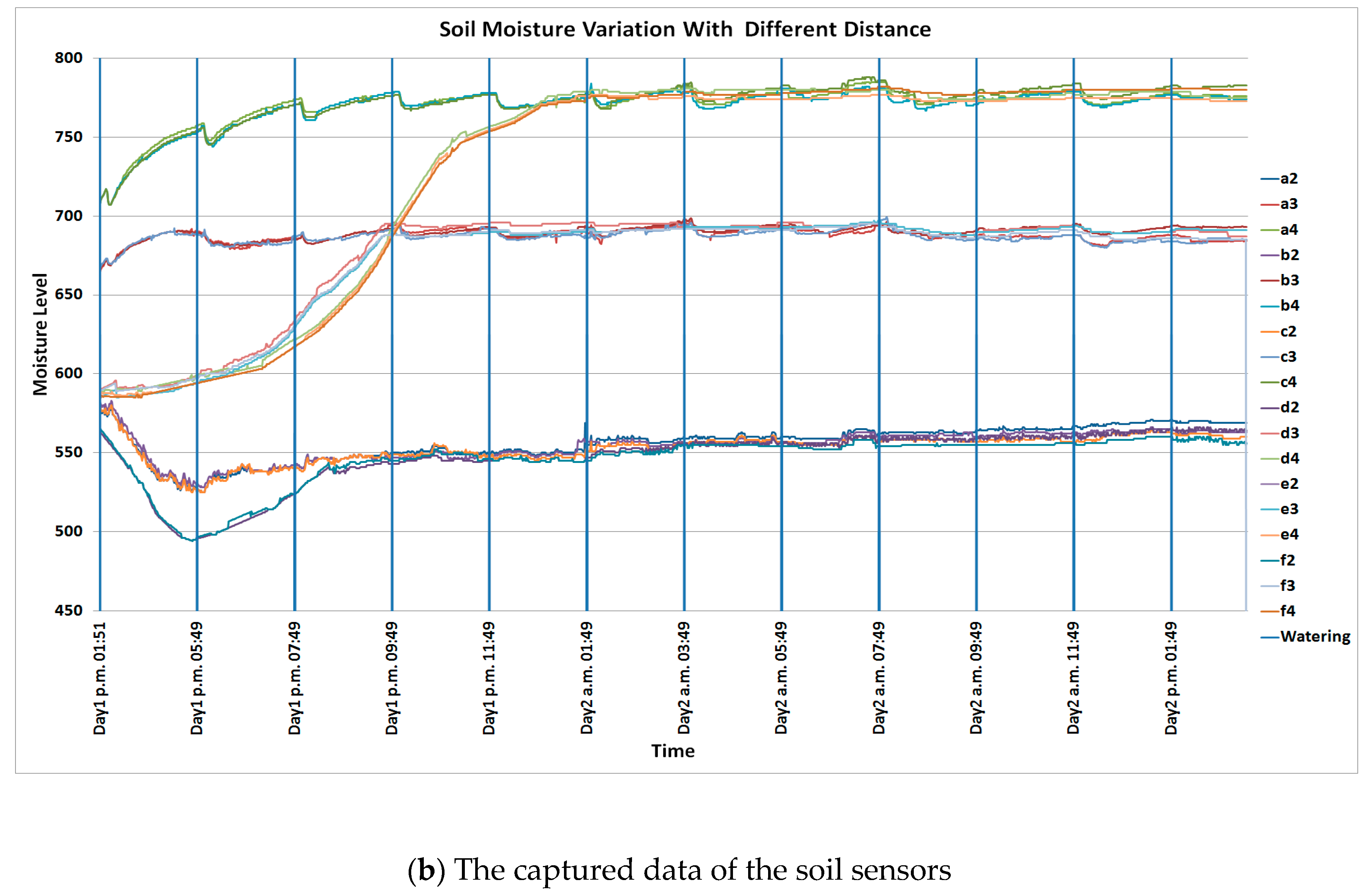

2.2. Soil Moisture Forecasting (SMF) Model Construction

2.2.1. Approaches for Modeling Soil Moisture

2.2.2. The Proposed SMF Model

2.3. Constant-Moisture Automatic Irrigation System

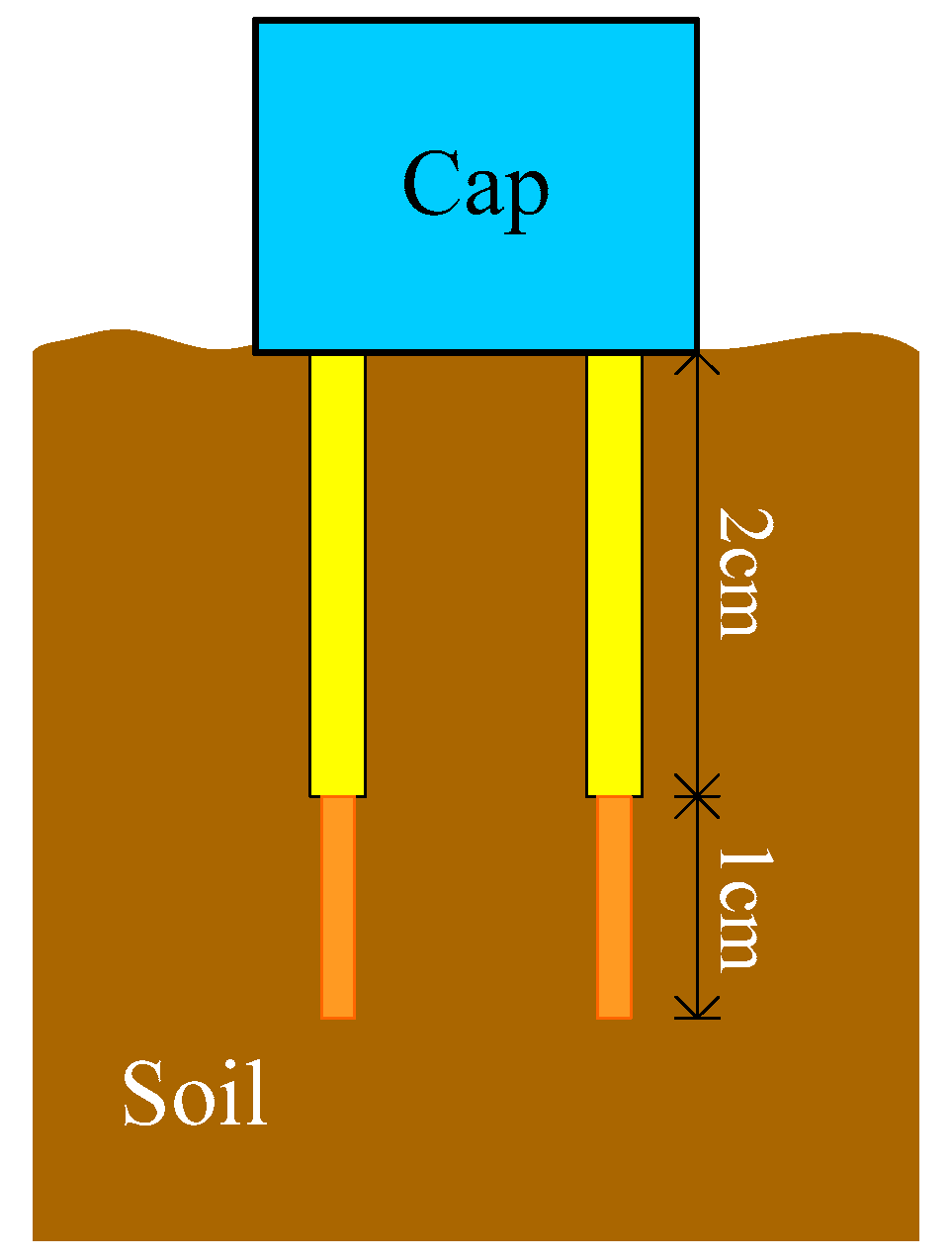

2.3.1. Platform Implementation

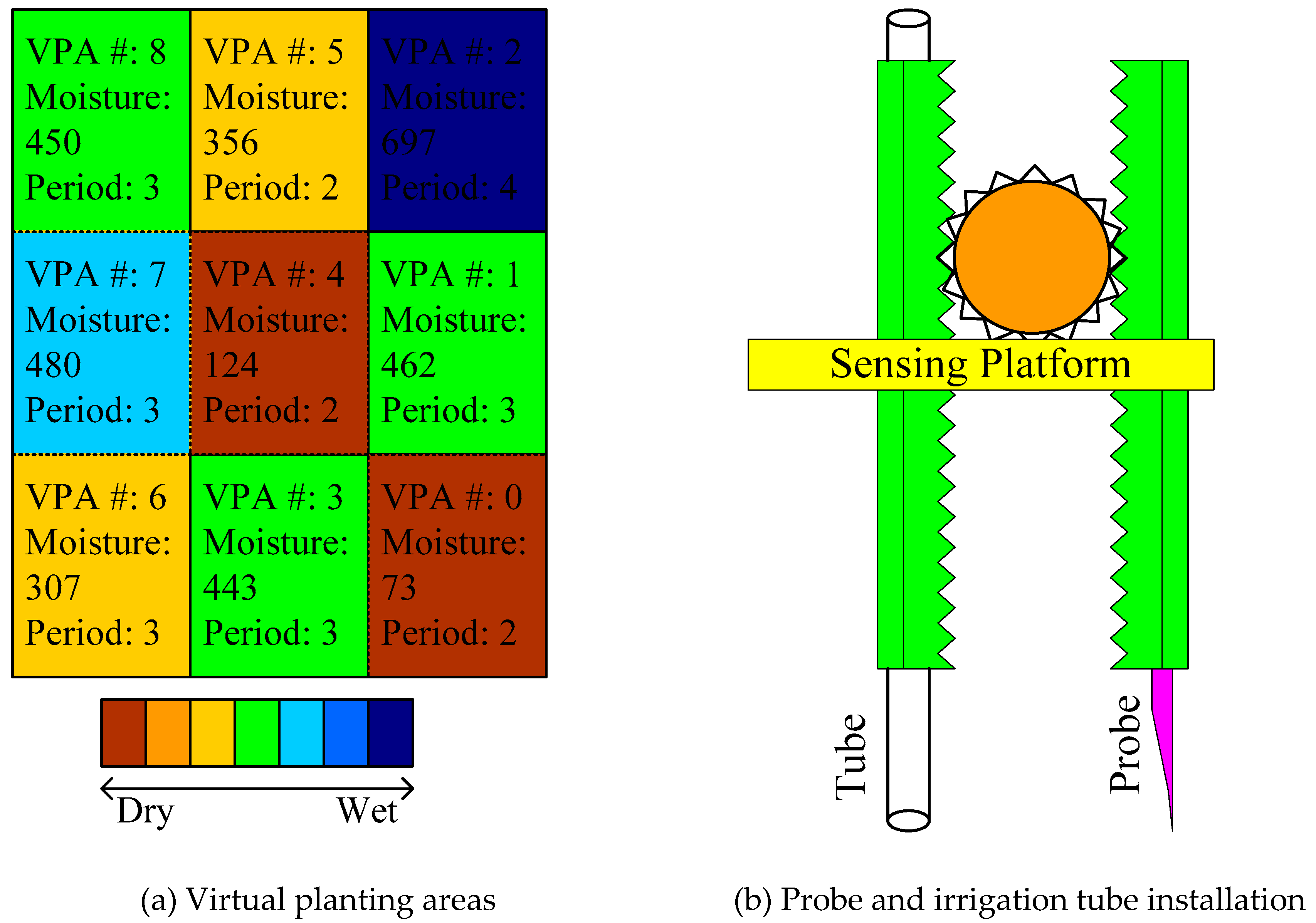

2.3.2. Constant Moisture Irrigation Mechanism

3. Results

3.1. Evaluation of Soil Sensors

3.2. Experiment 1: Evaluation of SMF Model

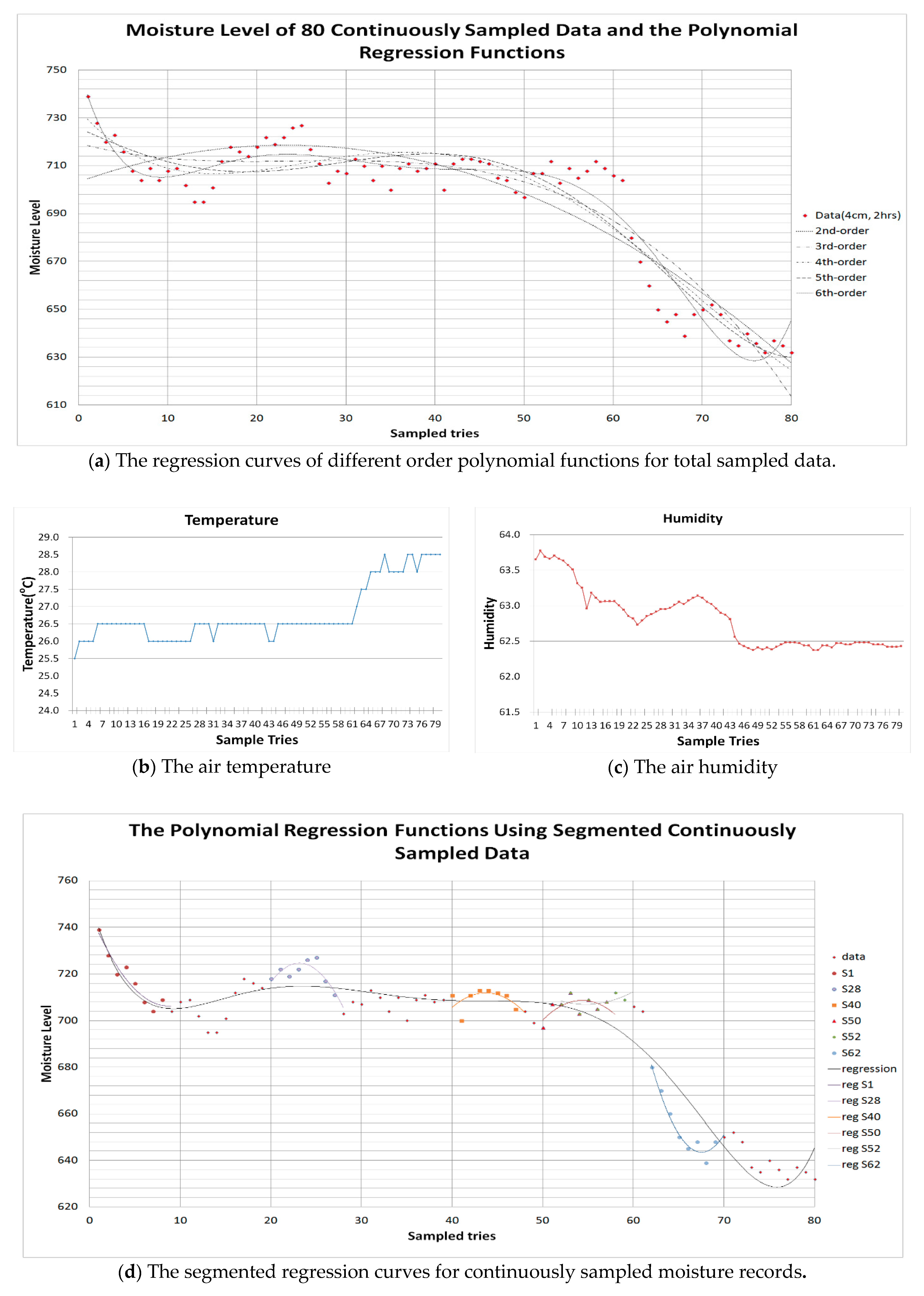

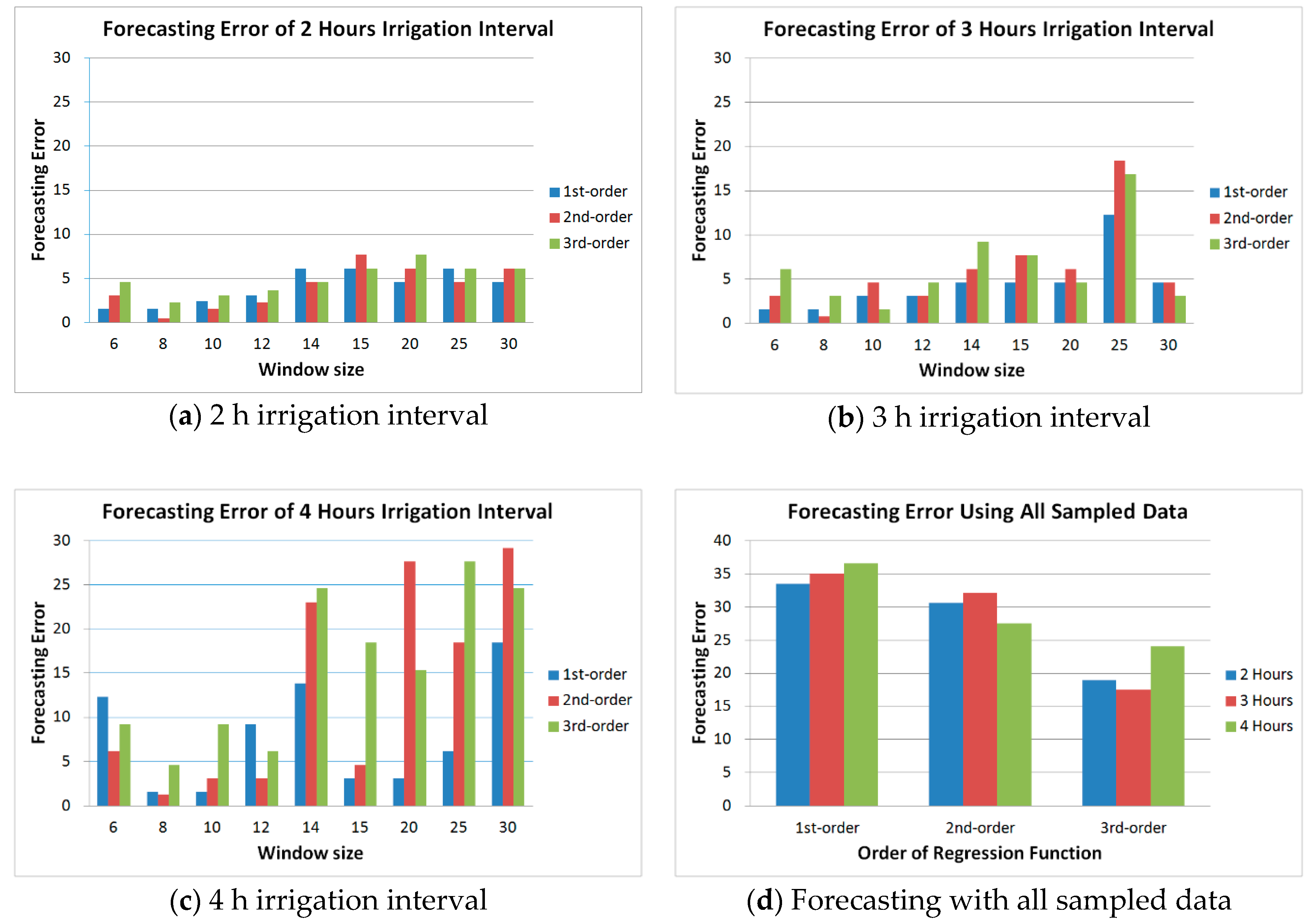

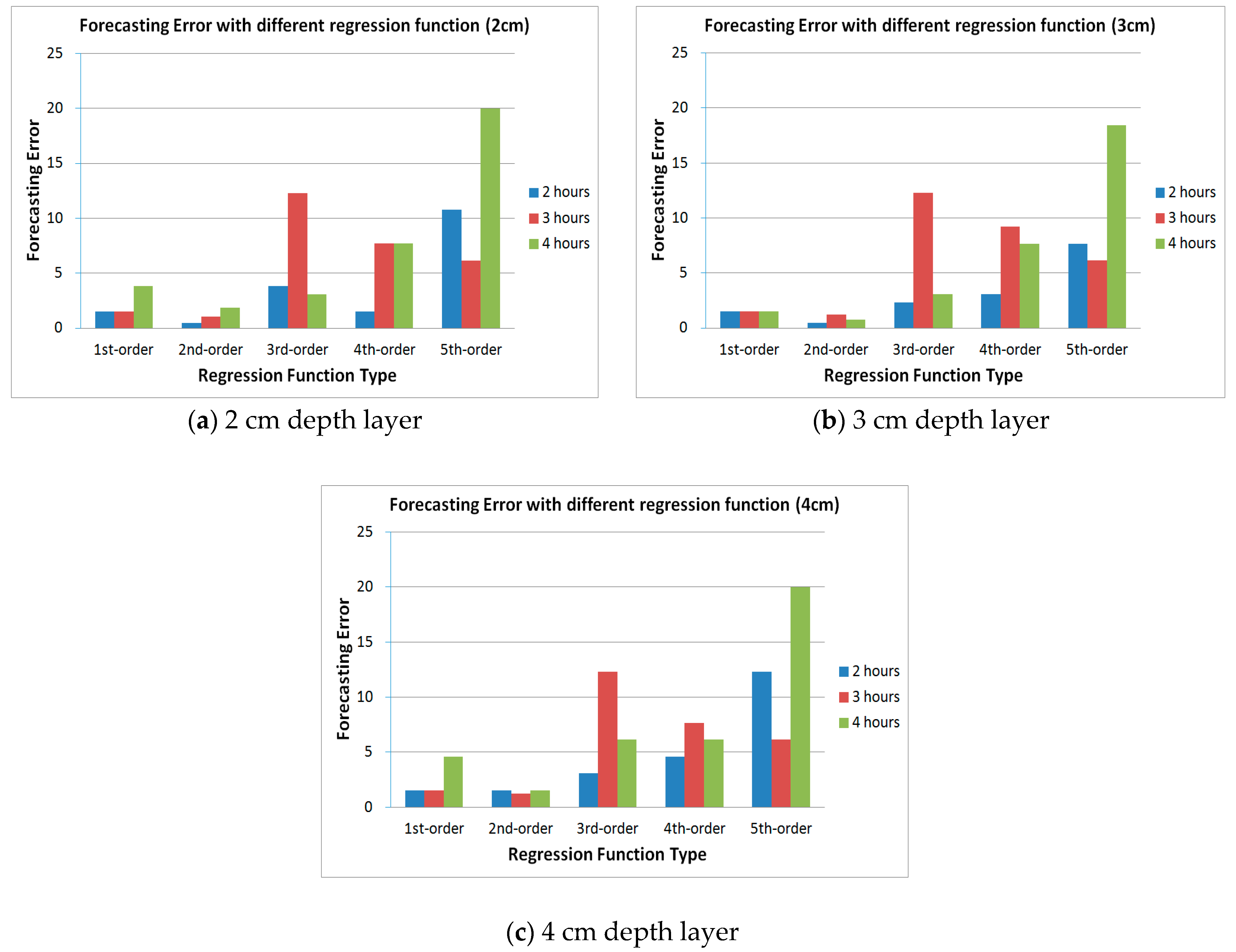

3.2.1. SMF Model Deduction

3.2.2. Experimental Results

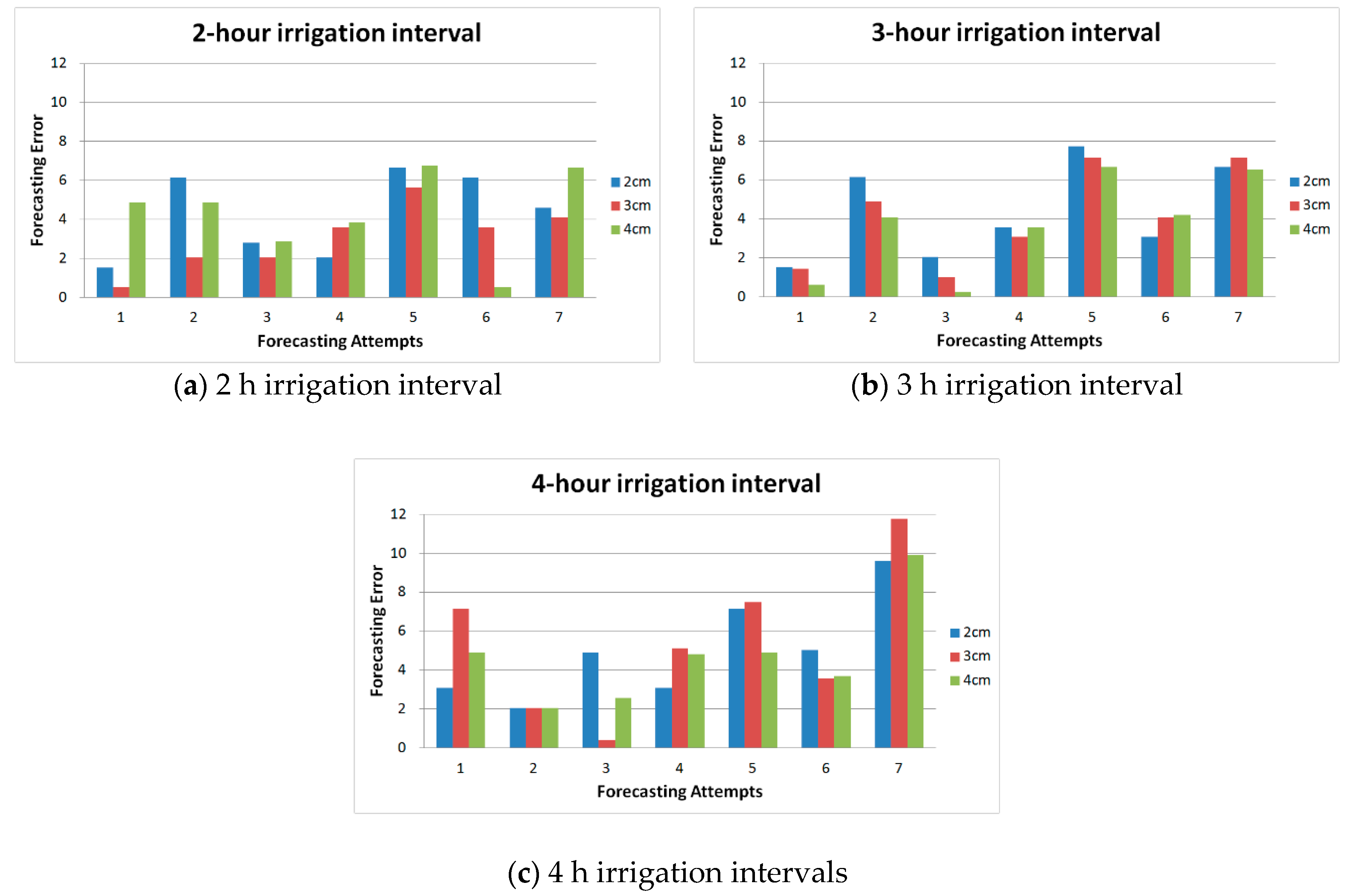

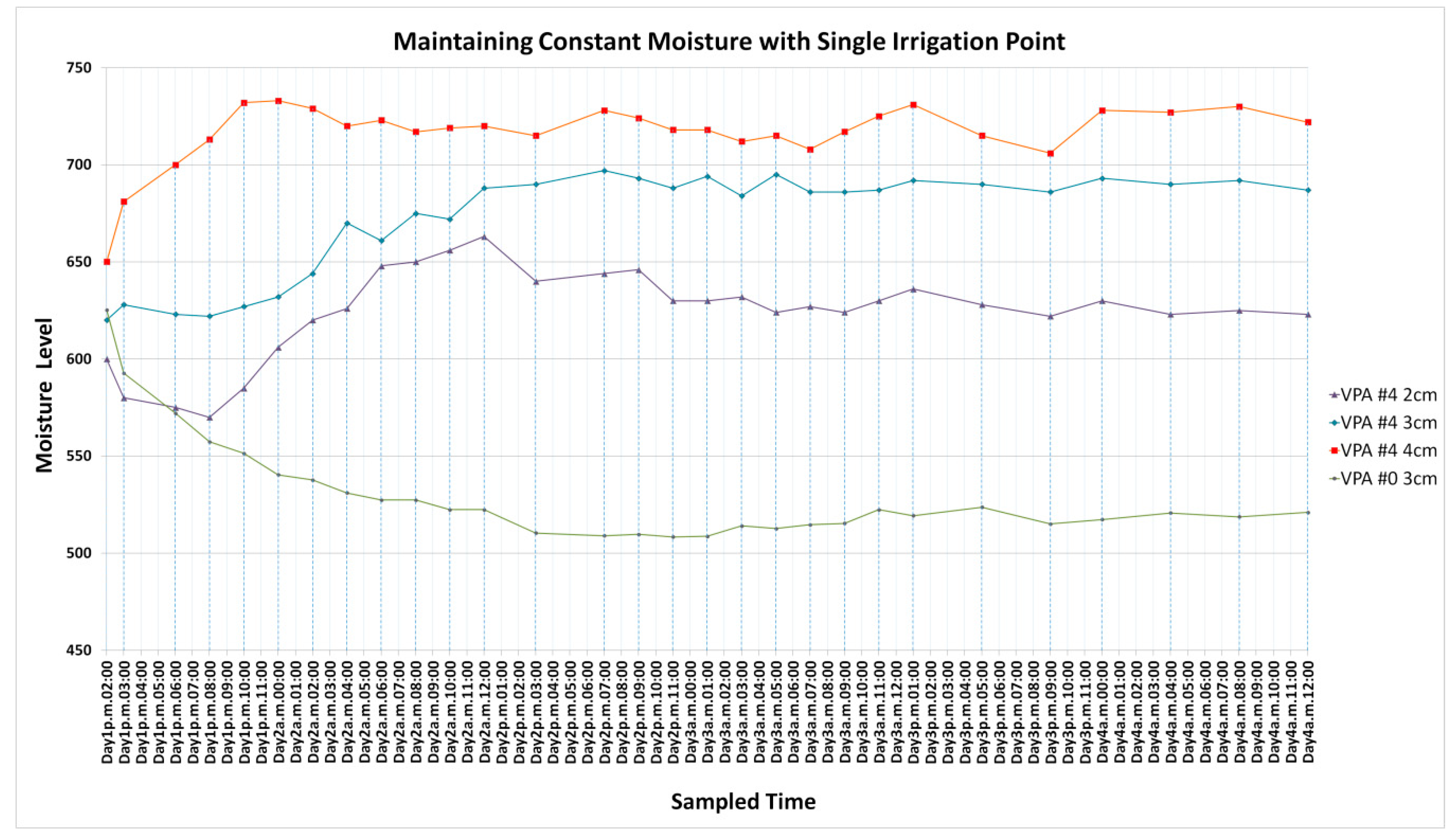

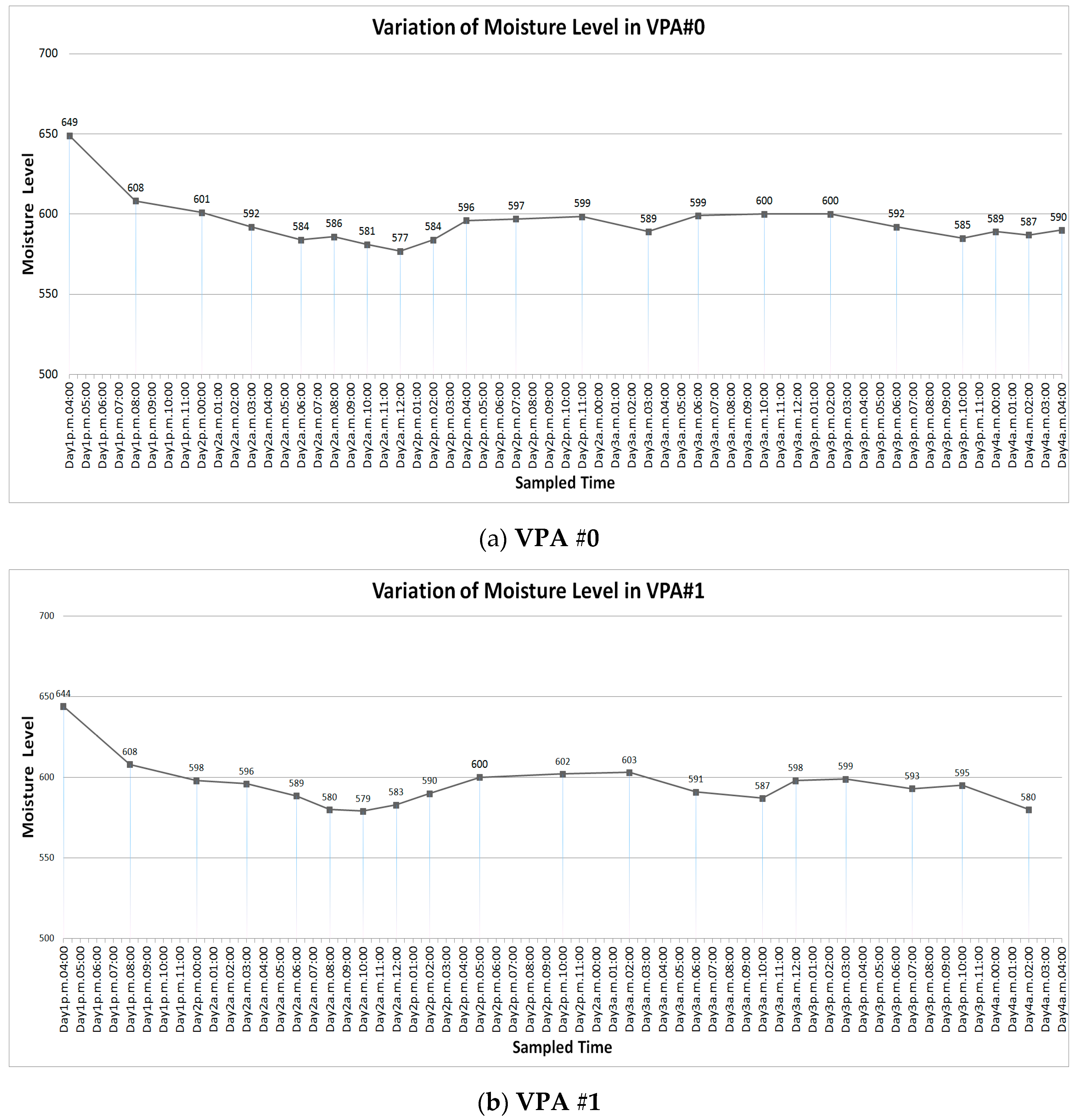

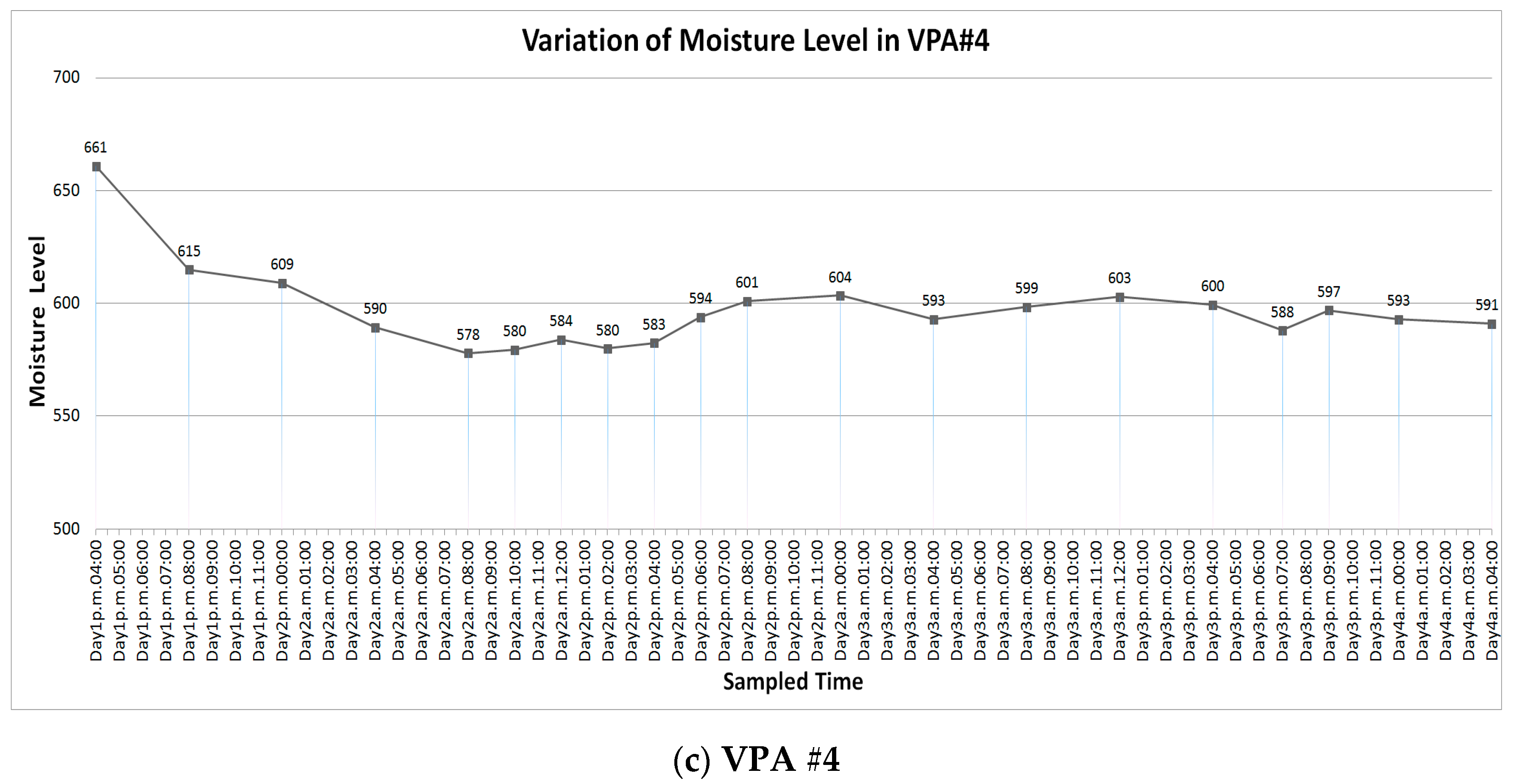

3.3. Experiment 2: Evaluation of the CAIS with Single Irrigation Point

3.4. Experiment 3: Evaluation of the CAIS with Multiple Irrigation Points

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gutiérrez, J.; Villa-Medina, J.F.; Nieto-Garibay, A.; Porta-Gándara, M.Á. Automated Irrigation System Using a Wireless Sensor Network and GPRS Module. IEEE Trans. Instrum. Meas. 2014, 63, 166–176. [Google Scholar] [CrossRef]

- Kim, Y.; Evans, R.G.; Iversen, W.M. Remote Sensing and Control of an Irrigation System Using a Distributed Wireless Sensor Network. IEEE Trans. Instrum. Meas. 2008, 57, 1379–1387. [Google Scholar]

- Rao, R.N.; Sridhar, B. IoT based smart crop-field monitoring and automation irrigation system. In Proceedings of the International Conference on Inventive Systems and Control (ICISC), Coimbatore, India, 19–20 January 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 478–483. [Google Scholar]

- Ramachandran, V.; Ramalakshmi, R.; Srinivasan, S. An Automated Irrigation System for Smart Agriculture Using the Internet of Things. In Proceedings of the International Conference on Control, Automation, Robotics and Vision (ICARCV), Singapore, 18–21 November 2018; pp. 210–215. [Google Scholar]

- Silva, M.; Junior, L.H.; Carneiro, E.J.P.; de Matos, K.M.; Anacilia, J.P.; de Vieira, M.C.; da Silva Barreto, A. Raimundo. Tellus—Greenhouse Irrigation Automation System. In Proceedings of the IEEE Symposium on Computers and Communications (ISCC), Natal, Brazil, 25–28 June 2018; pp. 01239–01242. [Google Scholar]

- Muthukumar, S.; Karthikeyan, K.; Ranjithkumar, G.; Kavin, R. A Cost Effective System for Auto Irrigation, Soilmonitoring and Control. In Proceedings of the International Conference on Soft-computing and Network Security (ICSNS), Coimbatore, India, 14–16 February 2018; pp. 1–7. [Google Scholar]

- Li, M.; Tian, L.; Chen, Z.; Wu, X.; Wang, Y. A kind of imitated environment system for plant growth based on LED light source. In Proceedings of the Chinese Control and Decision Conference (CCDC), Taiyuan, China, 23–25 May 2012; pp. 652–655. [Google Scholar]

- Li, R.; Liu, H.; Wang, X.; Bian, Y.; Li, K. Design of intelligent control system for plant growth. In Proceedings of the Chinese Control and Decision Conference (CCDC), Chongqing, China, 28–30 May 2017; pp. 5966–5970. [Google Scholar]

- Limprasitwong, P.; Thongchaisuratkrul, C. Plant Growth Using Automatic Control System under LED, Grow, and Natural Light. In Proceedings of the International Conference on Advanced Informatics: Concept Theory and Applications (ICAICTA), Krabi, Thailand, 14–17 August 2018; pp. 192–195. [Google Scholar]

- Cui, S.; Lv, H.; Wu, X.; Zhang, Y.; He, L. Optimization of plant light source based on simulated annealing particle swarm optimization algorithm. In Proceedings of the Chinese Control and Decision Conference (CCDC), Shenyang, China, 9–11 June 2018; pp. 700–703. [Google Scholar]

- Amitrano, C.; Chirico, G.B.; Pascale, S.D.; Rouphael, Y.; Micco, V.D. Application of a MEC model for the irrigation control in green and red-leaved lettuce in precision indoor cultivation. In Proceedings of the IEEE International Workshop on Metrology for Agriculture and Forestry (MetroAgriFor), Portici, Italy, 24–26 October 2019; pp. 196–201. [Google Scholar]

- Prabha, R.; Sinitambirivoutin, E.; Passelaigue, F.; Ramesh, M.V. Design and Development of an IoT Based Smart Irrigation and Fertilization System for Chilli Farming. In Proceedings of the International Conference on Wireless Communications, Signal Processing and Networking (WiSPNET), Chennai, India, 22–24 March 2018; pp. 1–7. [Google Scholar]

- Singhal, A.; Kohli, R.; Dhamija, C.; Singh, N. RAIS—Remotely Accessible Irrigation System. In Proceedings of the Second International Conference on Intelligent Computing and Control Systems (ICICCS), Madurai, India, 14–15 June 2018; pp. 640–644. [Google Scholar]

- Sun, Z.; Chen, J.; Han, Y.; Huang, R.; Zhang, Q.; Guo, S. An Optimized Water Distribution Model of Irrigation District Based on the Genetic Backtracking Search Algorithm. IEEE Access 2019, 7, 145692–145704. [Google Scholar] [CrossRef]

- Wicha, S.; Sureephong, P. The development of IoT-wetting front detector (IOT-WFD) for efficient Irrigation management and decision support system. In Proceedings of the Joint International Conference on Digital Arts, Media and Technology with ECTI Northern Section Conference on Electrical, Electronics, Computer and Telecommunications Engineering (ECTI DAMT-NCON), Nan, Thailand, 30 January–2 February 2019; pp. 383–386. [Google Scholar]

- Wikipedia. LoRa, Long Range. Available online: https://en.wikipedia.org/wiki/LoRa (accessed on 26 May 2020).

- Islam, A.; Akter, K.; Nipu, N.J.; Das, A.; Mahbubur Rahman, M.; Rahman, M. IoT Based Power Efficient Agro Field Monitoring and Irrigation Control System: An Empirical Implementation in Precision Agriculture. In Proceedings of the International Conference on Innovations in Science, Engineering and Technology (ICISET), Chittagong, Bangladesh, 27–28 October 2018; pp. 372–377. [Google Scholar]

- Popović, T.; Gajinov, S.; Mugoša, M.; Popović, V.; Savović, A.; Pavićević, K.; Mirović, V. Optimal Irrigation as a tool of Precision Agriculture. In Proceedings of the The 8th Mediterranean Conference on Embedded Computing (MECO), Budva, Montenegro, 10–14 June 2019; pp. 1–4. [Google Scholar]

- Yubin, Z.; Zhengying, W.; Lei, Z.; Weibing, J. The Control Strategy and Verification for Precise Water-Fertilizer Irrigation System; Chinese Automation Congress (CAC): Xi’an, China, 25 November 2018; pp. 4288–4292. [Google Scholar]

- Niu, H.; Zhao, T.; Wang, D.; Chen, Y. A UAV Resolution and Waveband Aware Path Planning for Onion Irrigation Treatments Inference. In Proceedings of the International Conference on Unmanned Aircraft Systems (ICUAS), Atlanta, GA, USA, 10–14 June 2019; pp. 808–812. [Google Scholar]

- Abel Gomez, I.J.; Capraro, I.F.; Soria, I.C.; Peña, I.M. Design of an Irrigation Controller Based on a Water Movement Model in the Soil. In Proceedings of the Argentine Conference on Automatic Control (AADECA), Buenos Aires, Argentina, 7–9 November 2018; pp. 1–6. [Google Scholar]

- Ali, S.; Saif, H.; Rashed, H.; AlSharqi, H.; Natsheh, A. Photovoltaic Energy Conversion Smart Irrigation System-Dubai Case Study (Goodbye Overwatering & Waste Energy, Hello Water & Energy Saving). In Proceedings of the IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC), Waikoloa Village, IL, USA, 10–15 June 2018; pp. 2395–2398. [Google Scholar]

- RandomNerdTutorials.com. Guide for Soil Moisture Sensor YL-69 or HL-69 with Arduino. Available online: https://randomnerdtutorials.com/guide-for-soil-moisture-sensor-yl-69-or-hl-69-with-the-arduino/ (accessed on 26 May 2020).

- Stuetzle, W. Estimating the cluster tree of a density by analyzing the minimal spanning tree of a sample. J. Classif. 2003, 20, 25–47. [Google Scholar] [CrossRef]

- Goldberger, J.; Roweis, S. Hierarchical Clustering of a Mixture Model. In Proceedings of the International Conference on Neural Information Processing Systems, Vancouver, BC, Canada, 13–18 December 2004; pp. 505–512. [Google Scholar]

- Menardi, G. A review on modal clustering. Int. Stat. Rev. 2016, 84, 413–433. [Google Scholar] [CrossRef]

- Kriegel, H.P.; Kröger, P.; Sander, J.; Zimek, A. Density-based clustering. Wires Data Min. Knowl. Discov. 2011, 1, 231–240. [Google Scholar] [CrossRef]

- Jokinen, J.; Räty, T.; Lintonen, T. Clustering structure analysis in time-series data with density-based clusterability measure. IEEE/CAA J. Autom. Sin. 2019, 6, 1332–1343. [Google Scholar] [CrossRef]

- Azencott, R.; Muravina, V.; Hekmati, R.; Zhang, W.; Paldino, M. Automatic clustering in large sets of time series. In Partial Differential Equations and Applications; Chetverushkin, B.N., Fitzgibbon, W., Kuznetsov, Y.A., Neittaanmaki, P., Periaux, J., Pironneau, O., Eds.; Springer: Cham, Switzerland; Berlin/Heidelberg, Germany, 2019; pp. 65–75. [Google Scholar]

- Dau, H.A.; Bagnall, A.; Kamgar, K.; Michael, C.C.Y.; Zhu, Y.; Gharghabi, S.; Ratanamahatana, C.A.; Keogh, E. The UCR time series archive. IEEE/CAA J. Autom. Sin. 2019, 6, 1293–1305. [Google Scholar] [CrossRef]

- 65PJADJ-TNT Brass Impact Sprinkler. Available online: https://store.rainbird.com/sprinklers/65pjadj-tnt-brass-impact-sprinkler.html (accessed on 26 May 2020).

- 3-Outlet Hose Watering Timer. Available online: https://www.orbitonline.com/product/3-outlet-hose-watering-timer/ (accessed on 26 May 2020).

- Farmbot. Available online: https://farm.bot/ (accessed on 26 May 2020).

| Window Size | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

| Error(levels) | 42.4 | 46.7 | 53 | 57.1 | 59.8 | 63.3 | 67.9 | 79.4 |

| Window Size | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 |

| Error(levels) | 78.3 | 15.1 | 13.8 | 11.7 | 9.5 | 7.8 | 7.4 | 175.7 |

| # | Probe | Material | Rusted (Days) | Rusted Picture |

|---|---|---|---|---|

| 1 |  | Nickel-plated Fiberglass | 3~4 |  |

| 2 |  | Nickel-plated Fiberglass | 3~4 |  |

| 3 |  | Nickel-plated Iron wire | 6~7 |  |

| 4 |  | Copper wire | 13~14 |  |

| Product | CAIS | Brass Impact Sprinkler [31] | Orbit Watering Timer [32] | FarmBot Genesis [33] |

|---|---|---|---|---|

| Operation Area Length | 1.08 (1.2 × 0.9) m2 (Scalable) | < 78 (52 × π) m2 | < 78 (52 × π) m2 | 4.5 (3 × 1.5) m2 |

| Auto Irrigation | Yes | No | Yes | Yes |

| Irrigation Type | Pouring | Sprinkling | Sprinkling/Pouring | Pouring |

| Learning Mechanism | Yes | No | No | No |

| Constant Moisture Control | Yes | No | No | No |

| Moisture Sensing | Yes | No | No | Yes |

| Power Supply | Yes | No (Water Pressure) | Yes (+WaterPressure) | Yes |

| Price (USD) | ~350(~1500 for 3 × 1.5 m2) | 12–27 | 55 | 2995 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.-C.; Lin, Y.-Z. A Low-Cost Constant-Moisture Automatic Irrigation System Using Dynamic Irrigation Interval Adjustment. Appl. Sci. 2020, 10, 6352. https://doi.org/10.3390/app10186352

Huang S-C, Lin Y-Z. A Low-Cost Constant-Moisture Automatic Irrigation System Using Dynamic Irrigation Interval Adjustment. Applied Sciences. 2020; 10(18):6352. https://doi.org/10.3390/app10186352

Chicago/Turabian StyleHuang, Shih-Chang, and Ye-Ze Lin. 2020. "A Low-Cost Constant-Moisture Automatic Irrigation System Using Dynamic Irrigation Interval Adjustment" Applied Sciences 10, no. 18: 6352. https://doi.org/10.3390/app10186352

APA StyleHuang, S.-C., & Lin, Y.-Z. (2020). A Low-Cost Constant-Moisture Automatic Irrigation System Using Dynamic Irrigation Interval Adjustment. Applied Sciences, 10(18), 6352. https://doi.org/10.3390/app10186352