Optical Element Surface Defect Size Recognition Based on Decision Regression Tree

Abstract

Featured Application

Abstract

1. Introduction

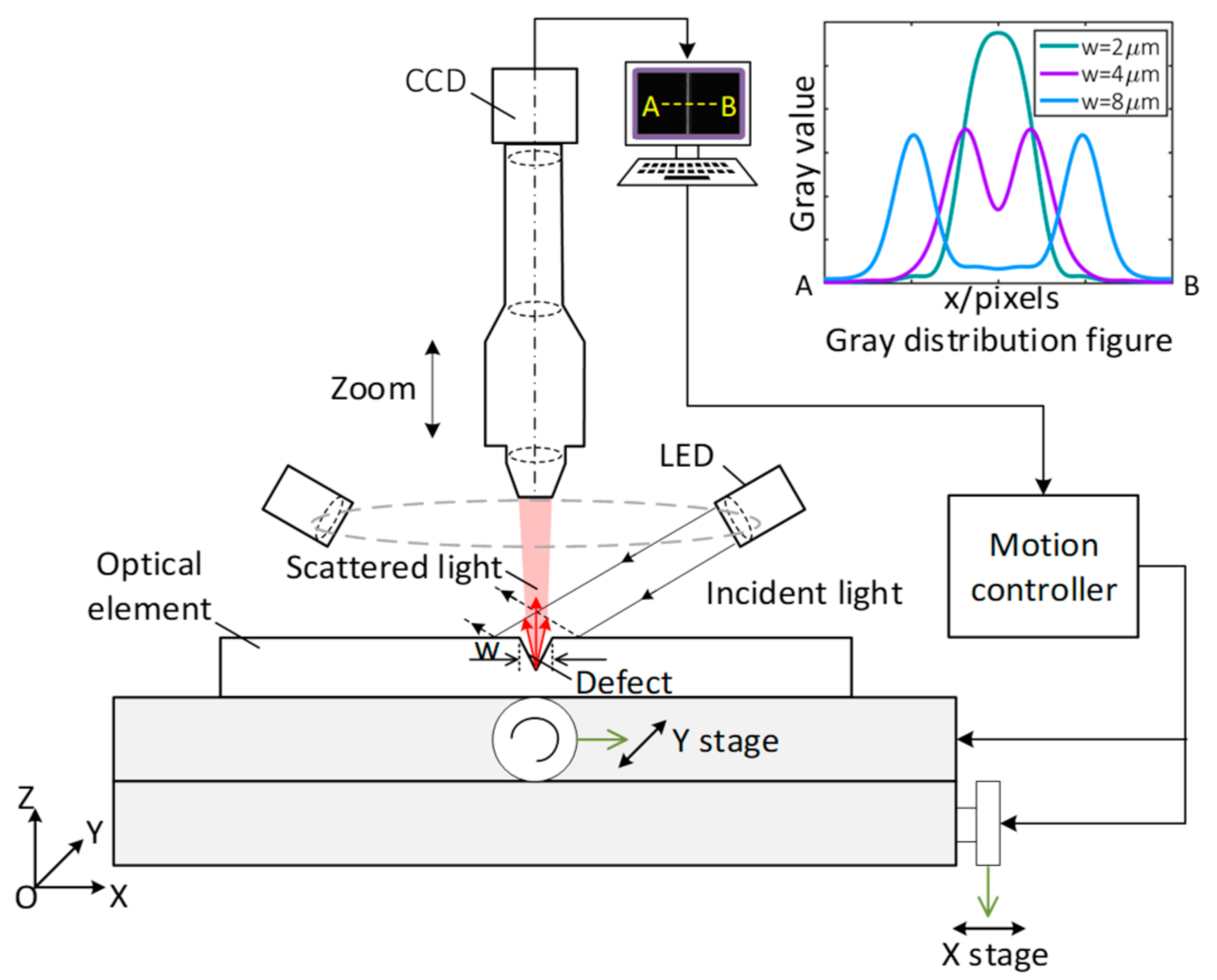

2. The Layout of the MSDI System

3. The Principle of Defect Size Recognition

3.1. The Far Field Light Intensity Distribution of the Defect

3.2. Defect Size Recognition Based on DRT

3.2.1. Generation of DRT

- Step 1.

- Arrange the training data set in ascending order according to the feature parameter , where and ;

- Step 2.

- Go through each in ascending order, and split into two subsets according to , which are and . Then, calculate the mean width of each subset, and use as the width estimation value of all in each subset. For instance, in the subset , the width estimation value of all and its error can be, respectively, expressed aswhere is a function for solving the mean value in the subset and ;

- Step 3.

- Find the optimum , where the value of is minimum, and mark this as . Take the two subsets and , which are split by as the two new sets . Go back to step 2 until the number of the feature parameter is less than 6 (i.e., ) or the variance of is less than 0.01 (i.e., ) in new set ;

- Step 4.

- Take the mean width as the prediction width of all in subset and denote this regression relationship as DRT . In case the overfitting of DRT occurs, DRT needs to be further optimized, and this optimization is called the DRT pruning [20], which is illustrated in Section 3.2.2.

3.2.2. The Pruning of DRT

4. Results and Discussion

4.1. Simulation of MSDI System

4.2. Revision of Simulation Light Intensity Distribution

4.3. Simulation of Scratch Width Recognition

4.3.1. Training Result of DRT

4.3.2. Recognition Error Analysis for the Scratch Cross-Section Shape Deviation

4.4. Experiment of Scratch Width Recognition

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kim, J.-H.; Aghaeimeibodi, S.; Carolan, J.; Englund, D.; Waks, E. Hybrid integration methods for on-chip quantum photonics. Optica 2020, 7, 308. [Google Scholar] [CrossRef]

- Tao, H.; Veetil, S.P.; Pan, X.; Liu, C.; Zhu, J. Visualization of the influence of the air conditioning system to the high-power laser beam quality with the modulation coherent imaging method. Appl. Opt. 2015, 54, 6639. [Google Scholar] [CrossRef] [PubMed]

- Yang, M.; Xu, F.; Ren, J.-G.; Yin, J.; Li, Y.; Cao, Y.; Shen, Q.; Yong, H.-L.; Zhang, L.; Liao, S.-K.; et al. Spaceborne, low-noise, single-photon detection for satellite-based quantum communications. Opt. Express 2019, 27, 36128. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.Y.; Chai, H.T.; Li, C.; Zhang, Y.H.; Wu, F.; Bai, J.; Shen, Y.B. Surface defects evaluation system based on electromagnetic model simulation and inverse-recognition calibration method. Opt. Commun. 2017, 390, 88–98. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Liu, C.G.; Wang, Y.H. 3D dark-field confocal microscopy for subsurface defects detection. Opt. Lett. 2020, 45, 660–663. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Cao, P.; Du, Y.; Hu, H.; Yang, Y. Calibration and Image Reconstruction in a Spot Scanning Detection System for Surface Defects. Appl. Sci. 2020, 10, 2503. [Google Scholar] [CrossRef]

- Forte, P.M.F.; Felgueiras, P.E.R.; Ferreira, F.P.; Sousa, M.A.; Nunes-Pereira, E.J.; Bret, B.P.J.; Belsley, M.S. Exploring combined dark and bright field illumination to improve the detection of defects on specular surfaces. Opt. Lasers Eng. 2017, 88, 120–128. [Google Scholar] [CrossRef]

- Kobayashi, H.; Lei, C.; Wu, Y.; Mao, A.L.; Jiang, Y.Y.; Guo, B.S.; Ozeki, Y.; Goda, K. Label-free detection of cellular drug responses by high-throughput bright-field imaging and machine learning. Sci. Rep. 2017, 7, 1–9. [Google Scholar] [CrossRef]

- Kurita, T.; Otsu, N.; Abdelmalek, N. Maxium-likelihood thresholding based on population mixture-models. Pattern Recognit. 1992, 25, 1231–1240. [Google Scholar] [CrossRef]

- Xu, X.Y.; Xu, S.Z.; Jin, L.H.; Song, E.M. Characteristic analysis of Otsu threshold and its applications. Pattern Recognit. Lett. 2011, 32, 956–961. [Google Scholar] [CrossRef]

- Jin, Y.; Zhang, D.D.; Li, M.Z.; Wang, Z.B.; Chen, Y.X. A Fuzzy Support Vector Machine-Enhanced Convolutional Neural Network for Recognition of Glass Defects. Int. J. Fuzzy Syst. 2019, 21, 1870–1881. [Google Scholar] [CrossRef]

- Li, C.; Tian, Y.; Li, W.J.; Tian, J.D.; Zhou, F. Low-Contrast Defects Recognition Using Low-Order Residual Network. IEEE Access 2019, 7, 91193–91201. [Google Scholar] [CrossRef]

- Mei, S.; Yang, H.; Yin, Z.P. Unsupervised-Learning-Based Feature-Level Fusion Method for Mura Defect Recognition. IEEE Trans. Semicond. Manuf. 2017, 30, 105–113. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- De’ath, G.; Fabricius, K.E. Classification and regression trees: A powerful yet simple technique for ecological data analysis. Ecology 2000, 81, 3178–3192. [Google Scholar]

- Geurts, P.; Ernst, D.; Wehenkel, L. Extremely randomized trees. Mach. Learn. 2006, 63, 3–42. [Google Scholar] [CrossRef]

- Oskooi, A.F.; Roundy, D.; Ibanescu, M.; Bermel, P.; Joannopoulos, J.D.; Johnson, S.G. MEEP: A flexible free-software package for electromagnetic simulations by the FDTD method. Comput. Phys. Commun. 2010, 181, 687–702. [Google Scholar] [CrossRef]

- Wolf, E. Electromagnetic diffraction in optical systems I. An integral representation of the image field. Proc. R. Soc. Lond. Ser. A-Math. Phys. Sci. 1959, 253, 349–357. [Google Scholar]

- Marchand, E.W. Deriviation of point spread function from line spread function. J. Opt. Soc. Am. 1964, 54, 915. [Google Scholar] [CrossRef]

- Melnikov, G.A.; Melnikov, T.A.; Gubarev, V.V. Regression tree pruning algorithms: An overview and empirical comparison. Inf. Technol. 2016, 22, 669–675. [Google Scholar]

- Li, C.; Yang, Y.; Chai, H.; Zhang, Y.; Wu, F.; Zhou, L.; Yan, K.; Bai, J.; Shen, Y.; Xu, Q.; et al. Dark-field detection method of shallow scratches on the super-smooth optical surface based on the technology of adaptive smoothing and morphological differencing. Chin. Opt. Lett. 2017, 15, 1–5. [Google Scholar]

- Li, C.; Zhang, F.; Ding, Y.; Liu, L. Surface deformation and friction characteristic of nano scratch at ductile-removal regime for optical glass BK7. Appl. Opt. 2016, 55, 6547–6553. [Google Scholar] [CrossRef] [PubMed]

- Fan, C.; Li, G.; Tao, C. Slant edge method for point spread function estimation. Appl. Opt. 2015, 54, 4097–4103. [Google Scholar] [CrossRef]

| Parameter | (μm) | (μm) | (μm) | |||

| Setting value | 0.4~0.75 | 0.5~5 | <1 | 1 | 9.7× |

| RMSE of Unpruned DRT (μm) | RMSE of Pruned DRT (μm) | |

|---|---|---|

| Training data set | 0.008 | 0.041 |

| Test data set | 0.153 | 0.045 |

| SEM Result (μm) | Otsu Method | Exponential Regression | Decision Regression Tree | |||

|---|---|---|---|---|---|---|

| Result (μm) | Relative Error | Result (μm) | Relative Error | Result (μm) | Relative Error | |

| 0.61 | 3.77 | >100% | 0.85 | 39.3% | 0.67 | 10.0% |

| 1.17 | 2.10 | 79.5% | 1.56 | 33.3% | 1.23 | 5.1% |

| 2.23 | 2.93 | 31.4% | 2.41 | 8.1% | 2.34 | 4.9% |

| 3.24 | 3.61 | 11.4% | 3.35 | 3.4% | 3.19 | 1.5% |

| 4.22 | 4.31 | 2.1% | 4.35 | 3.1% | 4.27 | 1.2% |

| 5.19 | 5.34 | 2.9% | 5.33 | 2.7% | 5.30 | 2.1% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lou, W.; Cao, P.; Zhang, D.; Yang, Y. Optical Element Surface Defect Size Recognition Based on Decision Regression Tree. Appl. Sci. 2020, 10, 6536. https://doi.org/10.3390/app10186536

Lou W, Cao P, Zhang D, Yang Y. Optical Element Surface Defect Size Recognition Based on Decision Regression Tree. Applied Sciences. 2020; 10(18):6536. https://doi.org/10.3390/app10186536

Chicago/Turabian StyleLou, Weimin, Pin Cao, Danhui Zhang, and Yongying Yang. 2020. "Optical Element Surface Defect Size Recognition Based on Decision Regression Tree" Applied Sciences 10, no. 18: 6536. https://doi.org/10.3390/app10186536

APA StyleLou, W., Cao, P., Zhang, D., & Yang, Y. (2020). Optical Element Surface Defect Size Recognition Based on Decision Regression Tree. Applied Sciences, 10(18), 6536. https://doi.org/10.3390/app10186536