Characteristics of Position and Pressure Control of Separating Metering Electro-Hydraulic Servo System with Varying Supply Pressure for Rolling Shear

Abstract

:Featured Application

Abstract

1. Introduction

2. Working Principle of a Rolling Shear and Schematic of an Electro-Hydraulic Servo System

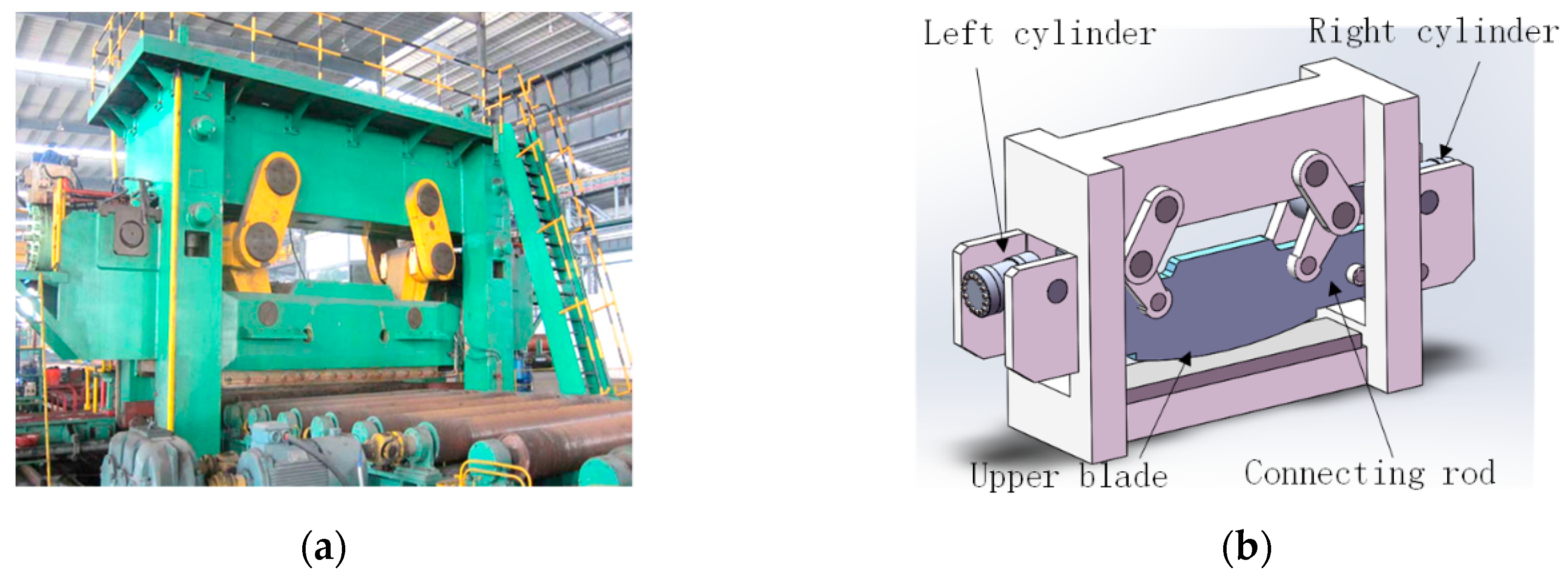

2.1. Working Principle of a Rolling Shear

2.2. Electro-Hydraulic Servo System

3. Electro-Hydraulic Servo System Modeling

3.1. Modeling of the Position Servo System

3.2. Modeling of the Pressure Servo System

4. Design of the Controller

4.1. Supply Pressure Regulator

4.2. Design of the Position Controller

4.3. Design of the Pressure Controller

4.4. Stability Analysis

5. Experiments

5.1. Test Rig

5.2. Position/Pressure Tracking Experiments

5.3. Analysis of the Energy-Saving Characteristics

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Abuowda, K.; Okhotnikov, I.; Noroozi, S.; Godfrey, P.; Dupac, M. A review of electrohydraulic independent metering technology. ISA Trans. 2019. [Google Scholar] [CrossRef] [PubMed]

- Lyu, L.; Chen, Z.; Yao, B. Energy Saving Motion Control of Independent Metering Valves and Pump Combined Hydraulic System. IEEE-ASME Trans. Mechatron. 2019, 24, 1909–1920. [Google Scholar] [CrossRef]

- Zhang, X.; Qiao, S.; Quan, L.; Ge, L. Velocity and Position Hybrid Control for Excavator Boom Based on Independent Metering System. IEEE Access 2019, 7, 71999–72011. [Google Scholar] [CrossRef]

- Zhao, W.; Zhou, X.; Wang, C.; Luan, Z. Energy analysis and optimization design of vehicle electro-hydraulic compound steering system. Appl. Energy 2019, 255, 113713. [Google Scholar] [CrossRef]

- Quan, Z.; Quan, L.; Zhang, J. Review of energy efficient direct pump controlled cylinder electro-hydraulic technology. Renew. Sustain. Energy Rev. 2014, 35, 336–346. [Google Scholar] [CrossRef]

- Li, J.; Fu, Y.l.; Wang, Z.l.; Zhang, G.Y. Research on fast response and high accuracy control of an airborne electro hydrostatic actuation system. In Proceedings of the International Conference on Intelligent Mechatronics & Automation, Chengdu, China, 26–31 August 2004. [Google Scholar]

- Huang, J.H.; Hu, Z.; Quan, L.; Zhang, X.G. Development of an asymmetric axial piston pump for displacement-controlled system. Proc. Inst. Mech. Eng. Part. C J. Eng. Mech. Eng. Sci. 2014, 228, 1418–1430. [Google Scholar] [CrossRef]

- Jiang, J.H. Direct drive variable speed electro-hydraulic servo system to position control of a ship rudder. In Proceedings of the 4th International Fluid Power Conference Dresden, Dresden, Germany, 24 March 2004; pp. 103–114. [Google Scholar]

- Minav, T.A.; Laurila, L.I.E.; Pyrhönen, J.J. Analysis of electro-hydraulic lifting system’s energy efficiency with direct electric drive pump control. Autom. Constr. 2013, 30, 144–150. [Google Scholar] [CrossRef]

- Wang, L.k.; Book, W.J.; Huggins, J.D. A hydraulic circuit for single rod cylinders. J. Dyn. Sys. Meas. Control. 2012, 134, 011019. [Google Scholar] [CrossRef] [Green Version]

- Bloomquist, J.V.; Niemiec, A.J. Electrohydraulic System and Apparatus with Bidirectional Electric-Motor/Hydraulic-Pump Unit. United States Patent Application No. 5778671, 14 July 1998. [Google Scholar]

- Wang, B.; Wang, W. An Energy-Saving Control Strategy with Load Sensing for Electro-Hydraulic Servo Systems. Strojniški Vestnik J. Mech. Eng. 2016, 62, 709–716. [Google Scholar] [CrossRef]

- Xu, B.; Cheng, M.; Yang, H.Y.; Zhang, J.H.; Sun, C.S. A Hybrid Displacement/Pressure Control Scheme for an Electrohydraulic Flow Matching System. IEEE ASME Trans. Mechatron. 2015, 20, 2771–2782. [Google Scholar] [CrossRef]

- Xu, B.; Zeng, D.R.; Ge, Y.Z.; Liu, Y.J. Research on characteristic of mode switch of separate meter in and meter out load sensing control system. J. Zhejiang Univ. 2011, 5, 14. [Google Scholar]

- Collier Hallman, S.J. Electro-Hydraulic Power Steering Control with Fluid Temperature and Motor Speed Compensation of Power Steering Load Signal. United States Patent Application No. US6092618A, 25 July 2000. [Google Scholar]

- Shi, J.; Quan, L.; Zhang, X.; Xiong, X. Electro-hydraulic velocity and position control based on independent metering valve control in mobile construction equipment. Autom. Constr. 2018, 94, 73–84. [Google Scholar] [CrossRef]

- Choi, K.; Seo, J.; Nam, Y.; Kim, K.U. Energy-saving in excavators with application of independent metering valve. J. Mech. Sci. Technol. 2015, 29, 387–395. [Google Scholar] [CrossRef]

- Ge, L.; Quan, L.; Zhang, X.G.; Zhao, B.; Yang, J. Efficiency improvement and evaluation of electric hydraulic excavator with speed and displacement variable pump. J. Mech. Sci. Technol. 2017, 150, 62–71. [Google Scholar] [CrossRef]

- Xu, B.; Ding, R.Q.; Zhang, J.H.; Cheng, M.; Tong, S. Pump/valves coordinate control of the independent metering system for mobile machinery. Autom. Constr. 2015, 57, 98–111. [Google Scholar] [CrossRef]

- Liu, B.; Quan, L.; Ge, L. Research on the performance of hydraulic excavator with pump and valve combined separate meter in and meter out circuits. Chin. J. Mech. Eng.-En 2016, 52, 173–180. [Google Scholar]

- Xu, B.; Ding, R.Q.; Zhang, J.H. Experiment research on individual metering systems of mobile machinery based on coordinate control of pump and valves. J. Zhejiang Univ. 2018, 49, 93–101. [Google Scholar]

- Liu, Y.J.; Xu, B.; Yang, H.Y.; Zeng, D.R. Modeling of Separate Meter In and Separate Meter Out Control System. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009. [Google Scholar]

- Liu, Y.; Xu, B.; Yang, H.; Zeng, D. Simulation of Separate Meter In and Separate Meter Out Valve Arrangement used for synchronized control of two cylinders. In Proceedings of the 2009 IEEE/ASME International Conference on Advanced Intelligent Mechatronics, Singapore, 14–17 July 2009; pp. 1665–1670. [Google Scholar]

- Shenouda, A.; Book, W. Energy Saving Analysis Using a Four-Valve Independent Metering Configuration Controlling a Hydraulic Cylinder. In Proceedings of the Sae Commercial Vehicle Engineering, Chicago, IL, USA, 1–3 November 2005. [Google Scholar]

- Yao, B.; Liu, S. Energy-saving control of hydraulic systems with novel programmable valves. In Proceedings of the World Congress on Intelligent Control & Automation, Shanghai, China, 10–14 June 2002. [Google Scholar]

- Zhang, Q.; Wei, J.H.; Fang, J.; Li, M.J. Nonlinear motion control of the hydraulic press based on an extended piecewise disturbance observer. Proc. Inst. Mech. Eng. Part. I J. Syst Control. Eng. 2016, 230, 830–850. [Google Scholar] [CrossRef]

- Merritt, H.E. Hydraulic Control. Systems; Wiley: New York, NY, USA, 1967. [Google Scholar]

- Wang, J.; YuSun, B.; Huang, Q.X.; Li, H.Z.; Han, H.Y. Research on the Position-Pressure Master-Slave Control for a Rolling Shear Hydraulic Servo System. Stroj. Vestn. J. Mech. Eng. 2015, 61, 265–272. [Google Scholar]

- Du, J.; Abraham, A.; Yu, S.; Zhao, J. Adaptive dynamic surface control with Nussbaum gain for course-keeping of ships. Eng. Appl. Artif. Intell. 2014, 27, 236–240. [Google Scholar] [CrossRef]

- Chen, M.; Tao, G.; Jiang, B. Dynamic Surface Control Using Neural Networks for a Class of Uncertain Nonlinear Systems With Input Saturation. IEEE Trans. Neural Netw. Learn. Syst. 2015, 26, 2086–2097. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.P.; Yu, H.Y. Composite Learning From Adaptive Dynamic Surface Control. IEEE Trans. Autom. Control 2016, 61, 2603–2609. [Google Scholar] [CrossRef]

- Swaroop, D.; Hedrick, J.K.; Yip, P.P.; Gerdes, J.C. Dynamic surface control for a class of nonlinear systems. IEEE Trans. Autom. Control 2000, 45, 1893–1899. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P. Design and phase plane analysis of an arctangent-based tracking differentiator. Chin. Control Appl. 2010, 4, 533–537. [Google Scholar]

- Zhong, J. PID Controller Tuning: A short Tutorial; Purdue University: West Lafayette, IN, USA, 2006. [Google Scholar]

- Han, J. From PID to active disturbance rejection control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

| Item | Value | Units |

|---|---|---|

| Pump displacement (1 and 10) | 40 | mL/r |

| Motor speed | 1500 | rpm |

| Servo valve rated flow (3.1) | 63 | L/min |

| Servo valve rated flow (3.2) | 38 | L/min |

| Piston diameter of cylinders (5 and 8) | 63 | mm |

| Rod diameter of cylinders (5 and 8) | 36 | mm |

| Weight of the moving part | 100 | Kg |

| Cylinder strokes (5 and 8) | 300 | mm |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, S.; An, G.; Huang, J.; Wang, J.; Guo, Y. Characteristics of Position and Pressure Control of Separating Metering Electro-Hydraulic Servo System with Varying Supply Pressure for Rolling Shear. Appl. Sci. 2020, 10, 435. https://doi.org/10.3390/app10020435

Lin S, An G, Huang J, Wang J, Guo Y. Characteristics of Position and Pressure Control of Separating Metering Electro-Hydraulic Servo System with Varying Supply Pressure for Rolling Shear. Applied Sciences. 2020; 10(2):435. https://doi.org/10.3390/app10020435

Chicago/Turabian StyleLin, Suhong, Gaocheng An, Jiahai Huang, Jun Wang, and Yuhang Guo. 2020. "Characteristics of Position and Pressure Control of Separating Metering Electro-Hydraulic Servo System with Varying Supply Pressure for Rolling Shear" Applied Sciences 10, no. 2: 435. https://doi.org/10.3390/app10020435