Value of Information (VoI) for the Chloride Content in Reinforced Concrete Bridges

Abstract

:1. Introduction

2. Problem Statement

3. Chloride Ingress Model

4. Measuring Techniques

5. Repair Methods

- Conservation activities with the intention to enable a structure to meet its intended service life, as envisaged at the time of design; and

- Conservation activities with the intention to prolong the planned service life of a structure or to enable it to meet altered performance requirements (e.g., altered loading or functionality needs).

- Consequences of a potential failure;

- Feasibility of evaluating the condition of the structure;

- Predictability of the service life of the structure or its components;

- Recording and quantification of the actions that occur during the service life of the structure;

- Feasibility of preventative or remedial interventions (e.g., repairs, replacements etc.); and

- Cost of conservation activities.

- Proactive conservation activities;

- Reactive conservation activities; and

- Situations where conservation activities are not feasible.

6. Pre-Posterior Analysis

7. Discussion

8. Conclusions

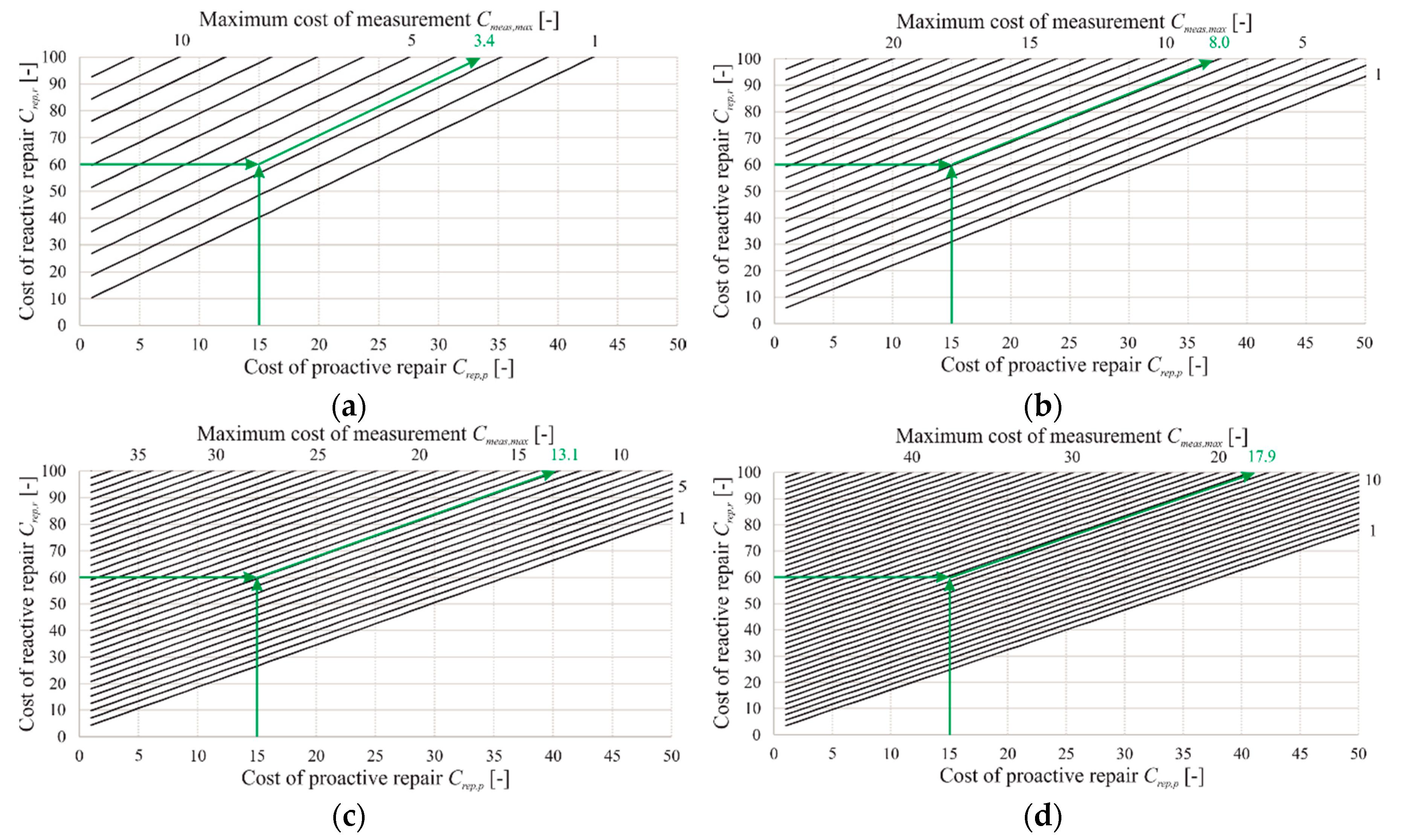

- With the increase of the initial probability of depassivation, Pdep, the maximum cost of measurement, Cmeas,max, which is still cost effective, increases;

- When observing the unit cost of measurement, Cmeas = 1, the minimum cost of reactive repair, Crep,r,min, which is still cost effective, slightly decreases with the increase in the probabilities of correct measurement, P (Dno-dep | Tno) and P (Ddep | Tyes); and

- The same conclusion can be made when observing the increase in the probability of damage once depassivation occurred, P (Dcrack | Ddep), with a rate of decrease being more pronounced.

- The paper focused on presenting the general procedure of obtaining the VoI for chloride content measurements and the outcome was presented as a ratio of the costs; however, to obtain the VoI of a certain structure or structural element, the real costs of repair and measurements have to be known and analyzed. Furthermore, several measurement and repair strategies and methods should be reviewed and compared in the analysis;

- The analysis should be broadened to include indirect costs related to the unavailability of the structure due to the repair activities, i.e., additional travel times and distances, together with associated environmental and social impacts;

- The analysis was performed taking into account only one deterioration phenomenon; however, the analysis should be broadened to take into account all possible deterioration phenomena that can occur, considering the combined effect of certain phenomena;

- The analysis in the paper did not focus on the exact bridge, bridge element, or exact location on the bridge; rather, the used parameters represent the holistic situation of a general case. However, to perform the analysis, a particular bridge element should be considered, in which the properties related to chloride ingress are homogeneous. In this way, an exact initial probability of depassivation, Pdep, could be determined;

- Since the accuracy of the measurement method plays an important role in calculating the measurement’s cost-effectiveness, exact properties of the chosen measurement method should be known and considered. Furthermore, spatial variability should be reviewed and taken into account. Based on the accuracy of the measurement method and the spatial variability, the number of taken samples should be adapted;

- The analysis was based on the decision tree presented in Figure 1. However, the presented decision tree is not definitive, and could be extended to include other events, which were not included here. This includes extending the decision tree to include events of the propagation phase, events of defective repair that can cause damage to the structure, events, such as unsuccessful reactive repair, etc.; and

- The decision tree was observed as a stationary process, meaning that the probabilities and costs of events were not associated with their duration. However, the time component of all the processes in the decision tree could be taken into account, in order to further investigate in which way the duration of certain events influences the cost efficiency of the measurement.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zambon, I.; Vidović, A.; Strauss, A.; Matos, J.C.; Friedl, N. Prediction of the remaining service life of existing concrete bridges in infrastructural networks based on carbonation and chloride ingress. Smart Struct. Syst. 2018, 21, 305–320. [Google Scholar] [CrossRef]

- Zambon, I.; Vidović, A.; Strauss, A.; Matos, J. Condition Prediction of Existing Concrete Bridges as a Combination of Visual Inspection and Analytical Models of Deterioration. Appl. Sci. 2019, 9, 148. [Google Scholar] [CrossRef] [Green Version]

- Condition Control and Assessment of Reinforced Concrete Structures Exposed to Corrosive Environment (Carbonation/Chlorides); fib Bulletin 59; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2011.

- Torres-Luque, M.; Bastidas-Arteaga, E.; Schoefs, F.; Sanchez-Silva, M.; Osma, J.F. Non-destructive methods for measuring chloride ingress into concrete: State of-the-art and future challenges. Constr. Build. Mater. 2014, 68, 68–81. [Google Scholar] [CrossRef] [Green Version]

- Nilsson, L.-O. Prediction models for chloride ingress and corrosion initiation in concrete structures. In Proceedings of the Nordic Mini Seminar & fib TG 5.5 Meeting, Goteborg, Sweden, 22–23 May 2001. [Google Scholar]

- Teply, B.; Chroma, M.; Vořechovská, D.; Rovnanik, P. FReET-D Deterioration Module Program Documentation; Cervenka Consulting: Prague, Czech Republic, 2008. [Google Scholar]

- Stipanović Oslaković, I.; Bjegović, D.; Mikulić, D. Evaluation of service life design models on concrete structures exposed to marine environment. Mater. Struct. 2010, 43, 1397–1412. [Google Scholar] [CrossRef]

- Pradelle, S.; Thiery, M.; Baroghel-Bouny, V. Comparison of existing chloride ingress models within concretes exposed to seawater. Mater. Struct. 2016, 49, 4497–4516. [Google Scholar] [CrossRef] [Green Version]

- Model Code for Concrete Structures 2010; fib Model Code 2010; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2012.

- Model Code for Service Life Design of Concrete Structures; fib Bulletin 34; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2006.

- Benchmarking of Deemed-to-Satisfy Provisions in Standards: Durability of Reinforced Concrete Structures Exposed to Chlorides; fib Bulletin 76; DCC Document Competence Centre Siegmar Kästl e. K.: Ostfildern, Germany, 2015.

- Sandberg, P. Report: “Durability of Concrete in Saline Environment—Systematic Collection of Field Data for Service Life Prediction of Concrete Structures”; Cementa AB: Lund, Sweden, 1996. [Google Scholar]

- Nilsson, L.-O.; Sandberg, P.; Sørensen, H.E. HETEK Report No. 33: Chloride Penetration into Concrete, State-of-the-ART: Transport Processes, Corrosion Initiation, Test Methods and Prediction Models; Danish Road Directorate: Copenhagen, Denmark, 1996; Report No. 53; ISBN 87-7491-736-6. ISSN 0909-4288. [Google Scholar] [CrossRef]

- DuraCRETE. Report: Modelling of Degradation: Probabilistic Performance Based Durability Design of Concrete Structures; EU Project (Brite EuRam III) No. BE95-1347, Report No 4-5; CUR: Gouda, The Netherlands, 1998. [Google Scholar]

- Lay, S.; Schießl, P.; Cairns, J. Lifecon Deliverable D 3.2: Instructions on Methodology and Application of Models for the Prediction of the Residual Service Life for Classified Environmental Loads and Types of Structures in Europe, Life Cycle Management of Concrete Infrastructures for Improved Sustainability; (G1RD-CT-2000-00378); European Community; CBM—Technische Universität München: München, Germany, 2003. [Google Scholar]

- DARTS—Durable and Reliable Tunnel Structures. Project with Financial Support of the European Commission under the Fifth Framework Program; GROWTH 2000 Project GRDI-25633; COWI A/S: Holstebro, Denmark, 2004. [Google Scholar]

- Luping, T. CHLOROTEST, Resistance of Concrete to Chloride Ingress—From Laboratory Tests to In-Field Performance: Guidelines for Practical Use of Methods for Testing the Resistance of Concrete to Chloride Ingress; SP Swedish National Testing and Research Institute: Boras, Sweden, 2005. [Google Scholar]

- Life-365. Service Life Prediction Model and Computer Program for Predicting the Service Life and Life-Cycle Cost of Reinforced Concrete Exposed to Chlorides. Life 365 Consortium II. 2012. Available online: http://www.life-365.org/resources.html (accessed on 25 October 2019).

- Jung, H.; Park, H.M.; Kim, J.H.; Kim, G.; Kong, J.S. Development of a probabilistic life-cycle cost model for marine structures exposed to chloride attack based on Bayesian approach using monitoring data. KSCE J. Civ. Eng. 2013, 17, 1073–1082. [Google Scholar] [CrossRef]

- Tran, T.-B.; Bastidas-Arteaga, E.; Schoefs, F.; Bonnet, S. Bayesian updating for optimization of inspection schedules of chloride ingress into concrete. In Proceedings of the 2nd International Symposium on Uncertainty Quantification and Stochastic Modelling, Rouen, France, 23–27 June 2014; Available online: https://hal.archives-ouvertes.fr/hal-01100565 (accessed on 17 October 2019).

- Tran, T.-B.; Bastidas-Arteaga, E.; Schoefs, F. Improved Bayesian Network Configurations for Probabilistic Model Parameters from Accelerated Tests: Application to Chloride Ingress into Concrete. Struct. Infrastruct. Eng. 2016, 12, 1162–1176. [Google Scholar] [CrossRef] [Green Version]

- Tran, T.-B.; Bastidas-Arteaga, E.; Schoefs, F. Improved Bayesian network configurations for random variable identification of concrete chlorination models. Mater. Struct. 2016, 49, 4705–4718. [Google Scholar] [CrossRef] [Green Version]

- Tran, T.-B.; Bastidas-Arteaga, E.; Schoefs, F. Bayesian Network Framework for Statistical Characterisation of Model Parameters from Accelerated Tests: Application to Chloride Ingress into Concrete. Struct. Infrastruct. Eng. 2017, 14, 580–593. [Google Scholar] [CrossRef]

- Memarzadeh, M.; Pozzi, M. Integrated Inspection Scheduling and Maintenance Planning for Infrastructure Systems. Comput. Aided Civ. Infrastruct. Eng. 2016, 31, 403–415. [Google Scholar] [CrossRef]

- Straub, D. Value of information analysis with structural reliability methods. Struct. Saf. 2014, 49, 75–85. [Google Scholar] [CrossRef]

- Thöns, S. On the Value of Monitoring Information for the Structural Integrity and Risk Management. Comput. Aided Civ. Infrastruct. Eng. 2018, 33, 79–94. [Google Scholar] [CrossRef]

- Quantifying the Value of Structural Health Monitoring—COST Action TU 1402. The Action. Available online: http://www.cost-tu1402.eu/ (accessed on 18 December 2019).

- Raiffa, H.; Schlaifer, R. Applied Statistical Decision Theory; Harvard University Press: Boston, MA, USA, 1961; ISBN 0-87584-017-5. [Google Scholar]

- Thöns, S.; Stewart, M.G. On Decision Optimality of Terrorism Risk Mitigation Measures for Iconic Bridges. Reliab. Eng. Syst. Saf. 2019, 188, 574–583. [Google Scholar] [CrossRef]

- Sýkora, M.; Diamantidis, D.; Markova, J.; Masciotta, M.G. Optimising In-Situ Testing for Historic Masonry Structures: A Case Study. In Proceedings of the RILEM Spring Convention and Sustainable Materials, Systems and Structures Conference, Rovinj, Croatia, 18–22 March 2019. [Google Scholar]

- Howiacki, T.; Sieńko, R.; Sýkora, M. Reliability Analysis of Serviceability of Long Span Roof Using Measurements and FEM Model. In Proceedings of the International Conference on Numerical Analysis and Applied Mathematics, Rhodes, Greece, 13–18 September 2018; AIP Publishing: Melville, NY, USA, 2019. [Google Scholar]

- Giordano, P.F.; Miraglia, S.; Limongelli, M.P. The benefit of permanent monitoring for seismic emergency management. In Proceedings of the SHMII-9th International Conference on Structural Health Monitoring of Intelligent Infrastructures, St. Louis, MO, USA, 4–7 August 2019. [Google Scholar]

- Mendoza, J.; Köhler, J. Risk-based Design of an Offshore Wind Turbine using VoI Analysis. In Proceedings of the ICASP13—13th International Conference on Applications of Statistics and Probability in Civil Engineering, Seoul, Korea, 26–30 May 2019. [Google Scholar]

- Hunkeler, F. Corrosion in Reinforced Concrete Structures. In Corrosion in Reinforced Concrete: Processes and Mechanisms; Bohni, H., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2005. [Google Scholar]

- Collepardi, M.; Marcialis, A.; Turriziani, R. Penetration of Chloride Ions into Cement Pastes. J. Am. Ceram. Soc. 1972, 55, 534–535. [Google Scholar] [CrossRef]

- Crank, J. The Mathematics of Diffusion; Calderon Press: Bristol, UK, 1956. [Google Scholar]

- Meijers, S.; Bijen, J.; de Borst, R.; Fraaij, A. Computational results of a model for chloride ingress in concrete including convection, drying-wetting cycles and carbonation. Mater. Struct. 2005, 38, 145–154. [Google Scholar] [CrossRef]

- Bastidas-Arteaga, E.; Stewart, M. Damage risks and economic assessment of climate adaptation strategies for design of new concrete structures subject to chloride-induced corrosion. Struct. Saf. 2015, 52, 40–53. [Google Scholar] [CrossRef] [Green Version]

- Gehlen, C. Probability-Based Service Life Design of Reinforced Concrete Structures—Reliability Studies for Prevention of Reinforced Corrosion; DAfStb Heft 510: Berlin, Germany, 2000. [Google Scholar]

- Zambon, I.; Vidovic, A.; Strauss, A.; Matos, J. Use of the chloride ingress model for condition assessment in bridge management. Civ. Eng. 2019, 71, 359–373. [Google Scholar] [CrossRef] [Green Version]

- Šomodíková, M.; Strauss, A.; Zambon, I.; Teplý, B. Quantification of parameters for modelling of chloride ion ingress into concrete. Struct. Concr. 2018, 20, 519–536. [Google Scholar] [CrossRef]

- Ferreira, R.M. Implications on RC structure performance of model parameter sensitivity: Effect on chlorides. J. Civ. Eng. Manag. 2010, 16, 561–566. [Google Scholar] [CrossRef] [Green Version]

- EN 206-1. Concrete—Part 1: Specification, Performance, Production and Conformity; CEN/TC 104 “Concrete and related products”; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- NT BUILD 443. Nordtest Method: Concrete, Hardened: Accelerated Chloride Penetration; The Nordic Council of Ministers: Copenhagen, Denmark, 1995. [Google Scholar]

- NT BUILD 492. Nordtest Method: Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments; The Nordic Council of Ministers: Copenhagen, Denmark, 1999. [Google Scholar]

- CEN/TS 12390-11. Testing Hardened Concrete—Part 11: Determination of the Chloride Resistance of Concrete, Unidirectional Diffusion; European Committee for Standardization: Brussels, Belgium, 2010. [Google Scholar]

- ISO 1920-11. Testing of Concrete—Part 11: Determination of the Chloride Resistance of Concrete, Unidirectional Diffusion; International Organization for Standardization: Geneva Switzerland, 2013. [Google Scholar]

- Atkins, C.; Carter, M.; Scantlebury, J. Sources of error in using silver/silver chloride electrodes to monitor chloride activity in concrete. Cem. Concr. Res. 2001, 31, 1207–1211. [Google Scholar] [CrossRef]

- Duffo, G.; Farina, S. Development of an embeddable sensor to monitor the corrosion process of new and existing reinforced concrete structures. Constr. Build. Mater. 2009, 23, 2746–2751. [Google Scholar] [CrossRef]

- Basheer, P.; Gilleece, P.; Long, A.; Carter, W. Monitoring electrical resistance of concretes containing alternative cementitious materials to assess their resistance to chloride penetration. Cem. Concr. Compos. 2002, 24, 437–449. [Google Scholar] [CrossRef]

- McPolin, D.; Basheer, P.; Long, A.; Grattan, K.; Sun, T. Obtaining progressive chloride profiles in cementitious materials. Constr. Build. Mater. 2005, 19, 666–673. [Google Scholar] [CrossRef]

- Li, H.; Li, D.S.; Song, G.B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Lam, C.; Mandamparambil, R.; Sun, T.; Grattan, K.; Nanukuttan, S.; Taylor, S.; Basheer, P. Optical fiber refractive index sensor for chloride ion monitoring. Sens. J. 2009, 9, 525–532. [Google Scholar] [CrossRef]

- Bonnet, S.; Schoefs, F.; Ricardo, J.; Salta, M. Effect of error measurements of chloride profiles on reliability assessment. In Proceedings of the 10th International Conference on Structural Safety and Reliability, Osaka, Japan, 13–17 September 2009. [Google Scholar]

- Bastidas-Arteaga, E.; Schoefs, F. Stochastic improvement of inspection and maintenance of corroding reinforced concrete structures placed in unsaturated environments. Eng. Struct. 2012, 41, 50–62. [Google Scholar] [CrossRef] [Green Version]

- RILEM TC 178-TMC. Analysis of total chloride content in concrete. Mater. Struct. 2002, 35, 583–585. [Google Scholar]

- Bonnet, S.; Schoefs, F.; Salta, M. Sources of uncertainties for total chloride profile measurements in concrete: Quantization and impact on probability assessment of corrosion initiation. Eur. J. Environ. Civ. Eng. 2017, 24, 232–247. [Google Scholar] [CrossRef] [Green Version]

- Matthews, S.; Bigaj-van Vliet, A.; Ueda, T. Conservation of concrete structures according to fib Model Code 2010. Struct. Concr. 2013, 14, 362–377. [Google Scholar] [CrossRef]

- EN1504-9:2005. Products and Systems for the Protection and Repair of Concrete Structures—Definitions, Requirements, Quality Control, and Evaluation of Conformity—Part 9: General Principles for the Use of Products and Systems; National Standards Authority of Ireland: Dublin, Ireland, 2008. [Google Scholar]

- Raupach, M.; Büttner, T. Concrete Repair to EN 1504: Diagnosis, Design, Principles and Practice; CRC Press—Taylor & Francis Group: Boca Raton, FL, USA, 2014. [Google Scholar]

- Matthews, S. CONREPNET: Performance-based approach to the remediation of reinforced concrete structures: Achieving durable repaired concrete structures. J. Build. Apprais. 2007, 3, 6–20. [Google Scholar] [CrossRef] [Green Version]

| Variable: | Description: |

|---|---|

| Pdep | Initial probability of depassivation; |

| P (Dcrack | Ddep) | Probability of damage (cracking) given that depassivation occurred; |

| P (Ddep | Tno) | Probability of depassivation given that the measurements indicated no depassivation (inaccuracy of the test); |

| P (Dno-dep | Tno) | Probability of no depassivation given that the measurements indicated no depassivation (accuracy of the test); |

| P (Ddep | Tyes) | Probability of depassivation given that the measurements indicated depassivation (accuracy of the test); |

| P (Dno-dep | Tyes) | Probability of no depassivation given that the measurements indicated depassivation (inaccuracy of the test); |

| Prep | Probability of successful repair; |

| Cmeas | Cost of measurement (test); |

| Crep,p | Cost of proactive repair; |

| Crep,r | Cost of reactive repair; |

| Ui | Total cost. |

| Outcome: | Formulation: |

|---|---|

| Outcome 1 | E1 = (1 − Pdep) ∗ U1 |

| Outcome 2 | E2 = Pdep ∗ (1 − P (Dcrack | Ddep)) ∗ U2 |

| Outcome 3 | E3 = Pdep ∗ P (Dcrack| Ddep) ∗ U3 |

| Outcome 4 | E4 = (1 − Pdep) ∗ P (Dno-dep | Tno) ∗ U4 |

| Outcome 5 | E5= Pdep ∗ P (Ddep|Tno) ∗ (1 − P (Dcrack | Ddep)) ∗ U5 |

| Outcome 6 | E6= Pdep ∗ P (Ddep|Tno) ∗ P (Dcrack | Ddep) ∗ U6 |

| Outcome 7 | E7= (1 − Pdep) ∗ P (Dno-dep | Tyes) ∗ 1 ∗ U7 |

| Outcome 8 | E8= Pdep ∗ P (Ddep | Tyes) ∗ Prep ∗ U8 |

| Outcome 9 | E9= Pdep ∗ P (Ddep | Tyes) ∗ (1 − Prep) ∗ U9 |

| Variable: | Value [–] |

|---|---|

| Pdep | 0.2, 0.4, 0.6, 0.8 |

| P (Dcrack | Ddep) | 0.80 |

| P (Ddep | Tno) | 0.10 |

| P (Dno-dep | Tno) | 0.90 |

| P (Ddep | Tyes) | 0.90 |

| P (Dno-dep | Tyes) | 0.10 |

| Prep | 0.875 |

| Pdep | a0 | a1 |

|---|---|---|

| 0.20 | 2.14 | 8.23 |

| 0.40 | 1.78 | 4.10 |

| 0.60 | 1.59 | 2.74 |

| 0.80 | 1.52 | 2.10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zambon, I.; Santamaria Ariza, M.P.; Campos e Matos, J.; Strauss, A. Value of Information (VoI) for the Chloride Content in Reinforced Concrete Bridges. Appl. Sci. 2020, 10, 567. https://doi.org/10.3390/app10020567

Zambon I, Santamaria Ariza MP, Campos e Matos J, Strauss A. Value of Information (VoI) for the Chloride Content in Reinforced Concrete Bridges. Applied Sciences. 2020; 10(2):567. https://doi.org/10.3390/app10020567

Chicago/Turabian StyleZambon, Ivan, Monica Patricia Santamaria Ariza, José Campos e Matos, and Alfred Strauss. 2020. "Value of Information (VoI) for the Chloride Content in Reinforced Concrete Bridges" Applied Sciences 10, no. 2: 567. https://doi.org/10.3390/app10020567