High-Pressure Sensors Based on Laser-Manufactured Sintered Silicon Carbide

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sintered SiC Laser Processing

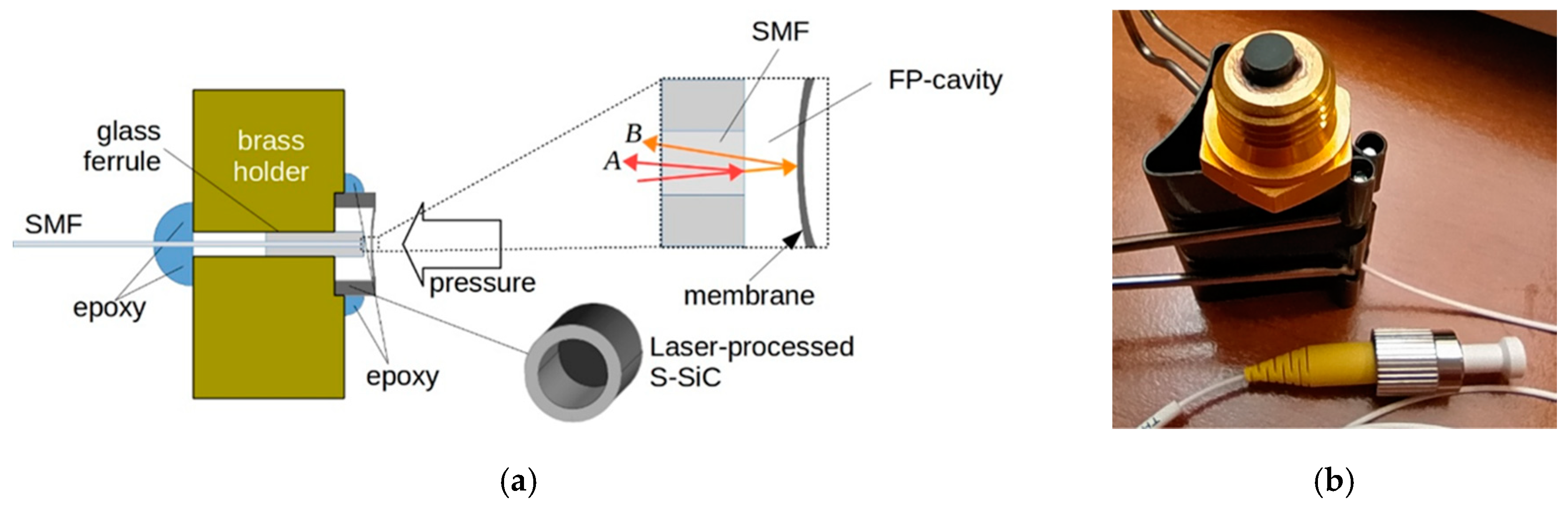

2.2. Low-Finesse Fabry-Perot Pressure-Sensor Structure and Measurement Set-Up

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Steen, W.M.; Mazumder, J. Laser Material Processing, 4th ed.; Springer: London, UK, 2010. [Google Scholar]

- Tuersley, I.P.; Jawaid, A.; Pashby, I.R. Review: Various methods of machining advanced ceramic materials. J. Mater. Process. Technol. 1994, 42, 77–390. [Google Scholar] [CrossRef]

- Chryssolouris, G. Laser Machining: Theory and Practice; Springer: New York, NY, USA, 1991. [Google Scholar]

- Leone, C.; Genna, S.; Tagliaferri, F.; Palumbo, B.; Dix, M. Experimental investigation on laser milling of aluminium oxide using a 30W Q-switched Yb:YAG fiber laser. Opt. Laser Technol. 2016, 76, 127–137. [Google Scholar] [CrossRef]

- Ponticelli, G.S.; Guarino, S.; Giannini, O. An Optimal Genetic Algorithm for Fatigue Life Control of Medium Carbon Steel in Laser Hardening Process. Appl. Sci. 2020, 10, 1401. [Google Scholar] [CrossRef] [Green Version]

- Ponticelli, G.S.; Lambiase, F.; Leone, C.; Genna, S. Combined Fuzzy and Genetic Algorithm for the Optimisation of Hybrid Composite-Polymer Joints Obtained by Two-Step Laser Joining Process. Materials 2020, 13, 283. [Google Scholar] [CrossRef] [Green Version]

- Leone, C.; Papa, I.; Tagliaferri, F.; Lopresto, V. Investigation of CFRP laser milling using a 30W Q-switched Yb:YAG fiber laser: Effect of process parameters on removal mechanisms and HAZ formation. Compos. Part A Appl. Sci. Manuf. 2013, 55, 129–142. [Google Scholar] [CrossRef]

- Komlenok, M.S.; Kononenko, V.V.; Ralchenko, V.G.; Pimenov, S.M.; Konov, V.I. Laser Induced Nanoablation of Diamond Materials. Phys. Procedia 2011, 12, 37–45. [Google Scholar] [CrossRef] [Green Version]

- Kononenko, T.V.; Ralchenko, V.G.; Ashkinazi, E.E.; Polikarpov, M.; Ershov, P.; Kuznetsov, S.; Yunkin, V.; Snigireva, I.; Konov, V.I. Fabrication of polycrystalline diamond refractive X-ray lens by femtosecond laser processing. Appl. Phys. A 2016, 122, 152. [Google Scholar] [CrossRef]

- Komlenok, M.; Bolshakov, A.; Ralchenko, V.; Konov, V.; Conte, G.; Girolami, M.; Oliva, P.; Salvatori, S. Diamond detectors with laser induced surface graphite electrodes. Nucl. Instrum. Methods Phys. Res. Sect. A 2016, 837, 136–142. [Google Scholar] [CrossRef]

- Salvatori, S.; Rossi, M.C.; Conte, G.; Kononenko, T.; Komlenok, M.; Khomich, A.; Ralchenko, V.; Konov, V.; Jaksic, M.; Provatas, G. Diamond detector with laser-formed buried graphitic electrodes: Micron-scale mapping of stress and charge collection efficiency. IEEE Sens. J. 2019, 19, 11908–11917. [Google Scholar] [CrossRef] [Green Version]

- Girolami, M.; Conte, G.; Trucchi, D.M.; Bellucci, A.; Oliva, P.; Kononenko, T.; Khomich, A.; Bolshakov, A.; Ralchenko, V.; Konov, V.; et al. Investigation with β-particles and protons of buried graphite pillars in single-crystal CVD diamond. Diam. Relat. Mater. 2018, 84, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, H. Silicon carbide powder and sintered materials. J. Ceram. Soc. Jpn. 2011, 119, 218–233. [Google Scholar] [CrossRef] [Green Version]

- Smith, T.P.; Davis, R.F. Silicon Carbide. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R., Flemings, M., Ilschner, B., Kramer, E., Mahajan, S., Veyssiere, P., Eds.; Elsevier Science Ltd., Pergamon Press: Oxford, UK, 2001; pp. 8497–8502. [Google Scholar]

- Yamada, K.; Mohri, M. Properties and Applications of Silicon Carbide Ceramics. In Silicon Carbide Ceramics—1; Sömiya, S., Inomata, Y., Eds.; Springer: Dordrecht, The Netherlands, 1991. [Google Scholar] [CrossRef]

- Ji, R.; Liu, Y.; Zhang, Y.; Dong, X.; Chen, Z.; Cai, B. Experimental research on machining characteristics of SiC ceramic with end electric discharge milling. J. Mech. Sci. Technol. 2011, 25, 1535–1542. [Google Scholar] [CrossRef]

- König, W.; Dauw, D.F.; Levy, G.; Panten, U. EDM-future steps towards the machining of ceramics. CIRP Ann. Manuf. Technol. 1988, 37, 623–631. [Google Scholar] [CrossRef]

- Román-Manso, B.; Domingues, E.; Figueiredo, F.M.; Belmonte, M.; Miranzo, P. Enhanced electrical conductivity of silicon carbide ceramics by addition of graphene nanoplatelets. J. Eur. Cer. Soc. 2015, 35, 2723–2731. [Google Scholar] [CrossRef]

- Pachaury, Y.; Tandon, P. An overview of electric discharge machining of ceramics and ceramic based composites. J. Manuf. Process. 2017, 25, 369–390. [Google Scholar] [CrossRef]

- Guarino, S.; Ponticelli, G.S.; Giannini, O.; Genna, S.; Trovalusci, F. Laser milling of yttria-stabilized zirconia by using a Q-switched Yb:YAG fiber laser: Experimental analysis. Int. J. Adv. Manuf. Technol. 2018, 94, 1373–1385. [Google Scholar] [CrossRef]

- Shi, Y.; Sun, Y.; Liu, J.; Tang, J.; Li, J.; Ma, Z.; Cao, H.; Zhao, R.; Kou, Z.; Huang, K.; et al. UV nanosecond laser machining and characterization for SiC MEMS sensor application. Sens. Actuators A Phys. 2018, 276, 196–204. [Google Scholar] [CrossRef]

- Maboudian, R.; Carraro, C.; Senesky, D.G.; Roper, C.S. Advances in silicon carbide science and technology at the micro-and nanoscales. J. Vac. Sci. Technol. A Vac. Surf. Film. 2013, 31, 050805. [Google Scholar] [CrossRef]

- Pecholt, B.; Gupta, S.; Molian, P. Review of laser microscale processing of silicon carbide. J. Laser Appl. 2011, 23, 012008. [Google Scholar] [CrossRef]

- Kim, S.; Bang, B.S.; Ren, F.; d’Entremont, J.; Blumenfeld, W.; Cordock, T.; Pearton, S.J. High-Rate Laser Ablation for Through-Wafer via Holes in SiC Substrates and GaN/AlN/SiC Templates. J. Semicond. Technol. Sci. 2004, 4, 217–221. [Google Scholar]

- Duc, D.H.; Naoki, I.; Kazuyoshi, F. A study of near-infrared nanosecond laser ablation of silicon carbide. Int. J. Heat. Mass. Transf. 2013, 65, 713–718. [Google Scholar] [CrossRef]

- Okojie, R.S.; Ned, A.A.; Kurtz, A.D. Operation of α (6H)-SiC pressure sensor at 500 °C. Sens. Actuators A Phys. 1998, 66, 200–204. [Google Scholar] [CrossRef]

- Okojie, R.S.; Nguyen, P.; Nguyen, V.; Savrun, E.; Lukco, D.; Buehler, J.; McCue, T. Failure mechanisms in MEMS based silicon carbide high temperature pressure sensors. In Proceedings of the 2007 IEEE International Reliability Physics Symposium Proceedings. 45th Annual, Phoenix, AZ, USA, 15–19 April 2007; pp. 429–432. [Google Scholar] [CrossRef]

- Atwell, A.R.; Okojie, R.S.; Kornegay, K.T.; Roberson, S.L.; Beliveau, A. Simulation, fabrication and testing of bulk micromachined 6H-SiC high-g piezoresistive accelerometers. Sens. Actuators A Phys. 2003, 104, 11–18. [Google Scholar] [CrossRef]

- Yasseen, A.A.; Zorman, C.A.; Mehregany, M. Fabrications and testing of surface micromachined polycrystalline SiC micromotors. EEE Electron. Device Lett. 2000, 21, 164–166. [Google Scholar] [CrossRef]

- Reynolds, J.K.; Catling, D.; Blue, R.C.; Maluf, N.I.; Kenny, T. Packaging a piezoresistive pressure sensor to measure low absolute pressures over a wide sub-zero temperature range. Sens. Actuators A Phys. 2000, 83, 142–149. [Google Scholar] [CrossRef]

- Huang, R.; Zhang, Y.; Chen, X.; Nie, B. A Wireless Flexible Pressure Sensor for Human Motion Detection. In Proceedings of the 12th International Congress on Image and Signal Processing, BioMedical Engineering and Informatics (CISP-BMEI), Suzhou, China, 19–21 October 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Di, H.; Shen, T. Mutual information of cylinder pressure and combustion phase estimation in spark ignition engines. Control Theory Technol. 2019, 18, 34–42. [Google Scholar] [CrossRef]

- Young, D.; Du, J.; Zorman, C.; Ko, W. High-Temperature Single-Crystal 3C-SiC Capacitive Pressure Sensor. IEEE Sens. J. 2004, 4, 464–470. [Google Scholar] [CrossRef]

- Trevino, J.; Fu, X.; Zorman, C.; Mehregany, M. Low-stress Heavily-Doped Polycrystalline Silicon Carbide for MEMS Applications. In Proceedings of the 18th IEEE International Conference on Micro Electro Mechanical Systems, 2005. MEMS 2005, Orlando, FL, USA, 30 January–3 February 2005; pp. 451–454. [Google Scholar] [CrossRef]

- Li, C.; Mehregany, M. A silicon carbide capacitive pressure sensor for high temperature and harsh environment applications. In Proceedings of the TRANSDUCERS 2007–2007 International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, A. Miniature fiber-optic pressure sensor. IEEE Photonics Technol. Lett. 2005, 17, 447–449. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, J.; Yang, D.; Zhang, K.; Li, D.; Zhao, J. Miniaturized Fiber Fabry-Perot Interferometer for Strain Sensing. Microw. Opt. Technol. Lett. 2016, 58, 1510–1514. [Google Scholar] [CrossRef]

- Liu, J.; Jia, P.; Zhang, H.; Tian, X.; Liang, H.; Hong, Y.; Liang, T.; Liu, W.; Xiong, J. Fiber-optic Fabry–Perot pressure sensor based on low-temperature co-fired ceramic technology for high-temperature applications. Appl. Opt. 2018, 57, 4211–4215. [Google Scholar] [CrossRef]

- Salvatori, S.; Pettinato, S.; Piccardi, A.; Sedov, V.; Voronin, A.; Ralchenko, V. Thin Diamond Film on Silicon Substrates for Pressure Sensor Fabrication. Materials 2020, 13, 3697. [Google Scholar] [CrossRef] [PubMed]

- Parry, J.P.; Shephard, J.D.; Hand, D.P.; Moorhouse, C.; Jones, N.; Weston, N. Laser micromachining of zirconia (Y-TZP) ceramics in the picosecond regime and the impact on material strength. Int. J. Appl. Ceram. Technol. 2011, 8, 163–171. [Google Scholar] [CrossRef]

- Born, M.; Wolf, E. Multiple-beam Interference. In Principles of Optics, 6th ed.; Cambridge University Press: Cambridge, UK, 1980; Chapter 7.6. [Google Scholar]

- Timoshenko, S.P.; Woinowsky-Krieger, S. Symmetrical Bending of Circular Plates. In Theory of Plates and Shells, 2nd ed.; McGraw-Hill Higher Education: New York, NY, USA, 1964; Chapter 3. [Google Scholar]

| Characteristics | Value | Unit | |

|---|---|---|---|

| Composition | SiC | 99.6 | % wt |

| B4C | 0.6 | % wt | |

| Diameter | 5 ± 0.2 | mm | |

| Height | 2 ± 0.2 | mm | |

| Density | 3.4 | g cm−3 | |

| Hardness | 26.0 ± 0.3 | GPa | |

| Flexural strength | 530 | MPa | |

| Elastic modulus | 400 | GPa | |

| Compressive strength | 2200 | MPa | |

| Fracture toughness | 4 | MPa m1/2 | |

| Thermal conductivity | 110 | W K−1 m−1 | |

| Max use temperature | 1300 | °C | |

| Characteristics | Value | Unit | |

|---|---|---|---|

| Wavelength | 1064 | nm | |

| Pulse width | 50 | ns | |

| Repetition rate | 30–80 | kHz | |

| Pulse energy (30 kHz) | 1 | mJ | |

| Beam quality | TEM | 00 | |

| M2 | 1.2–1.5 | ||

| Focused beam diameter | 80 | µm | |

| Scan area | 100 × 100 | mm2 | |

| Max scan speed | 5000 | mm s−1 | |

| Parameter | Value | Unit |

|---|---|---|

| Laser scan speed | 500 | mm s−1 |

| Repetition rate | 30 | kHz |

| Scanning mode | CROSS | - |

| Number of repetition 1 | 50–75 | - |

| Laser fluence 2 | 20 | J cm−2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salvatori, S.; Ponticelli, G.S.; Pettinato, S.; Genna, S.; Guarino, S. High-Pressure Sensors Based on Laser-Manufactured Sintered Silicon Carbide. Appl. Sci. 2020, 10, 7095. https://doi.org/10.3390/app10207095

Salvatori S, Ponticelli GS, Pettinato S, Genna S, Guarino S. High-Pressure Sensors Based on Laser-Manufactured Sintered Silicon Carbide. Applied Sciences. 2020; 10(20):7095. https://doi.org/10.3390/app10207095

Chicago/Turabian StyleSalvatori, Stefano, Gennaro Salvatore Ponticelli, Sara Pettinato, Silvio Genna, and Stefano Guarino. 2020. "High-Pressure Sensors Based on Laser-Manufactured Sintered Silicon Carbide" Applied Sciences 10, no. 20: 7095. https://doi.org/10.3390/app10207095