Effect of Processing Conditions on the Properties of Reticulated Porous Diatomite–Kaolin Composites

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

- (1)

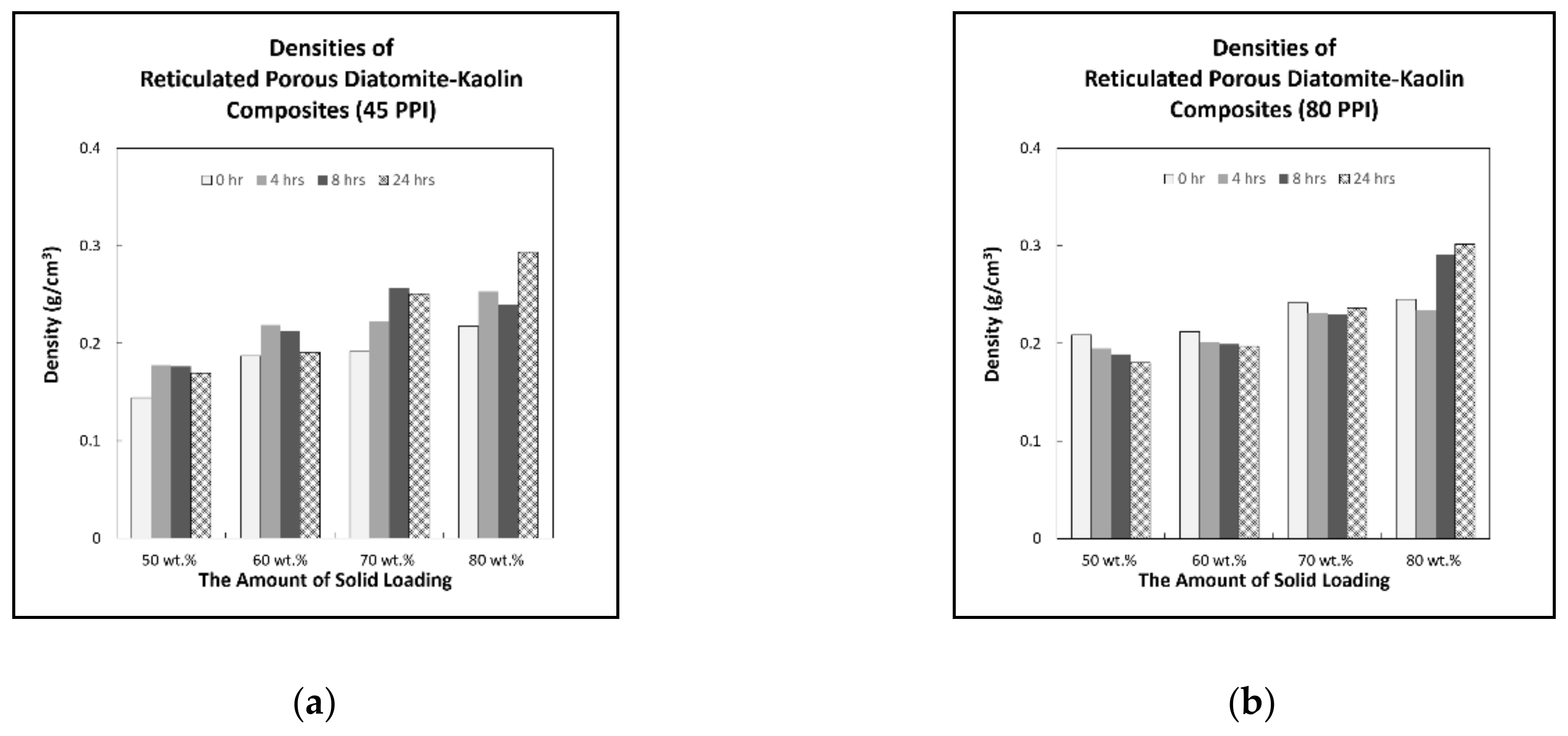

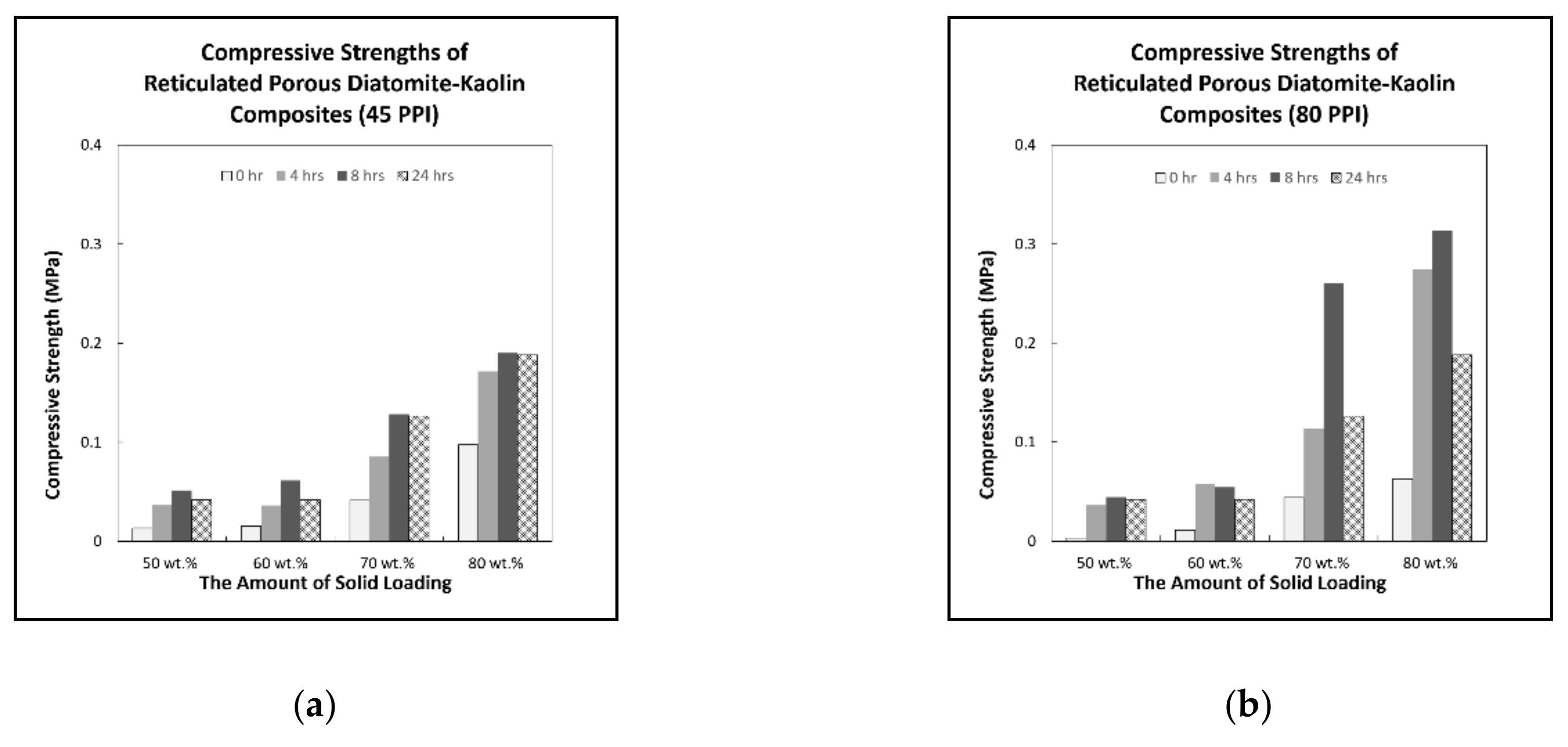

- At 45 PPI pore density, the increase in solid loading and the decrease in average particle size of the diatomite–kaolin composite slurry fully contributed to the increase in density of the reticulated porous diatomite–kaolin composite; accordingly, the compressive strength increased. We inferred that the pore density of the sacrificial polymer template (45 PPI) was low enough to ensure the coating of the strut walls and the removal of the residual diatomite–kaolin composite particles, and did not have a significant effect even under the conditions corresponding to the highest viscosity (50 wt.% solid loading and ball-milling for 24 h).

- (2)

- At 80 PPI pore density, the increase in solid loading and decrease in average particle size of the diatomite–kaolin composite slurry did not always affect the increase in density of the reticulated porous diatomite–kaolin composite, and the compressive strength peaked at a specific point (50 wt.% solid loading and ball milling for 8 h). This suggested that the pore density of the sacrificial polymer template (80 PPI) was too high to penetrate inside the sacrificial polymer template and to completely remove the residual diatomite–kaolin composite particles, and had a significant effect until the viscosity reached the value corresponding to 50 wt.% solid loading and ball milling for 8 h.

- (3)

- The pore density of practical and easily obtained reticulated porous ceramics can be extended to 80 PPI, by using a diatomite–kaolin composite and applying appropriate processing conditions.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Studart, A.R.; Gonzenbach, U.T.; Tervoort, E.; Gauckler, L.J. Processing Routes to Macroporous Ceramics: A Review. J. Am. Ceram. Soc. 2006, 89, 1771–1789. [Google Scholar] [CrossRef]

- Ha, J.H.; Bukhari, S.Z.A.; Lee, J.; Song, I.H. Preparation and characterisation of aluminabased composite support layers. Adv. Appl. Ceram. 2016, 115, 229–235. [Google Scholar] [CrossRef]

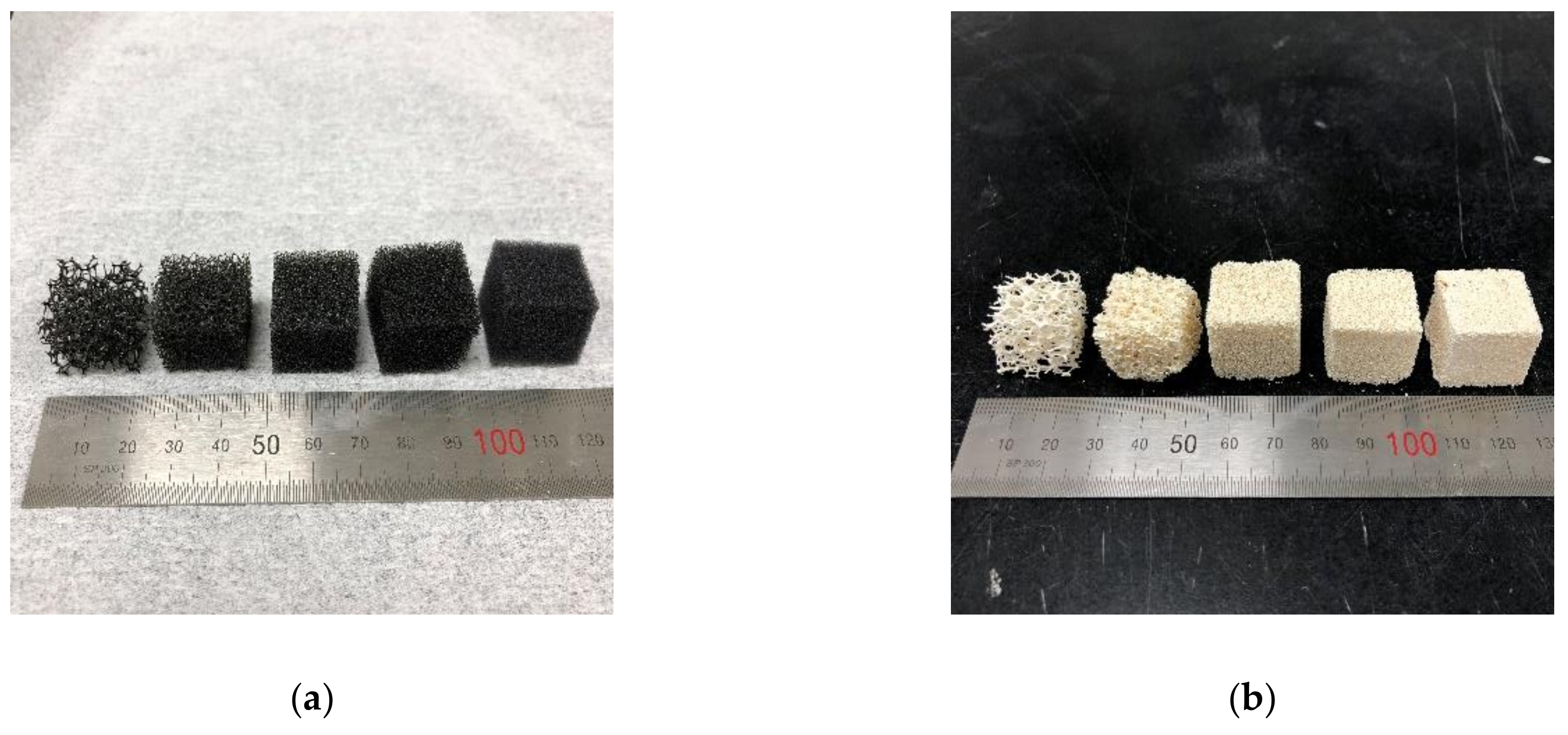

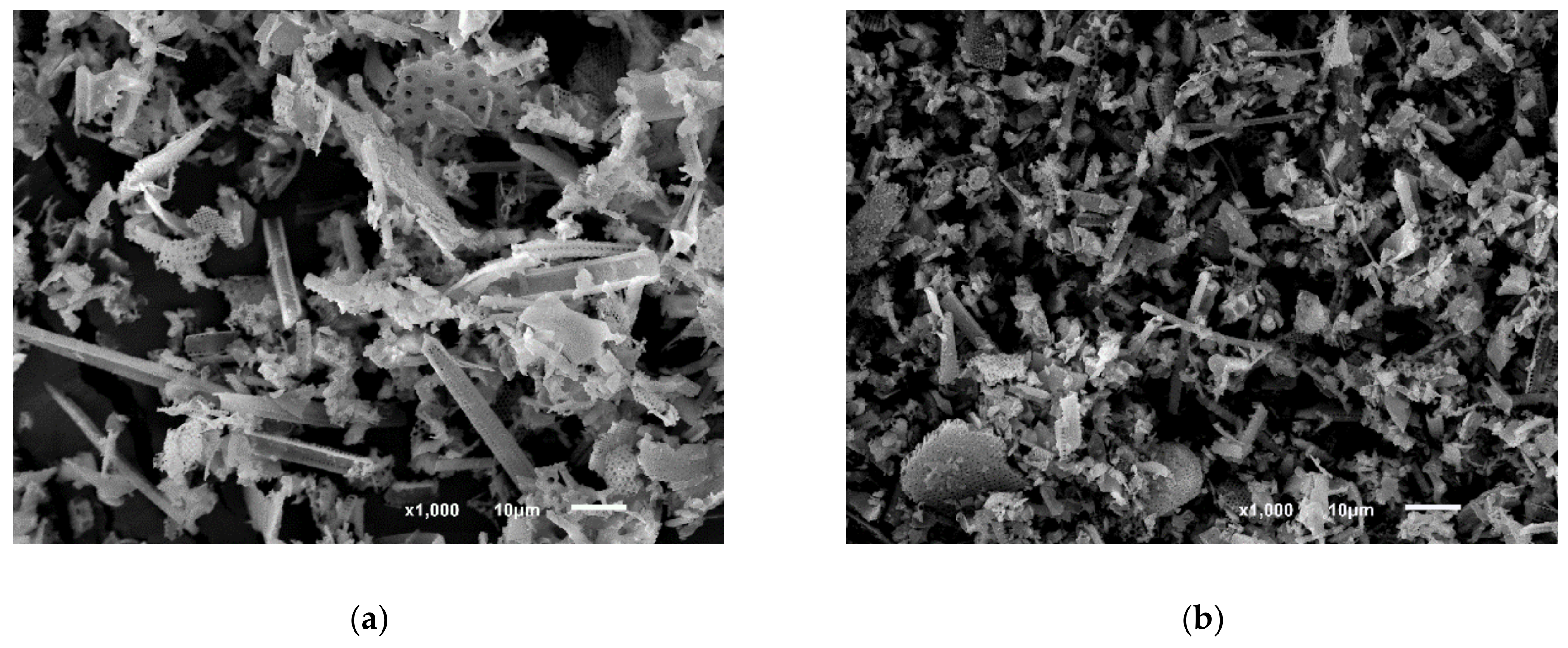

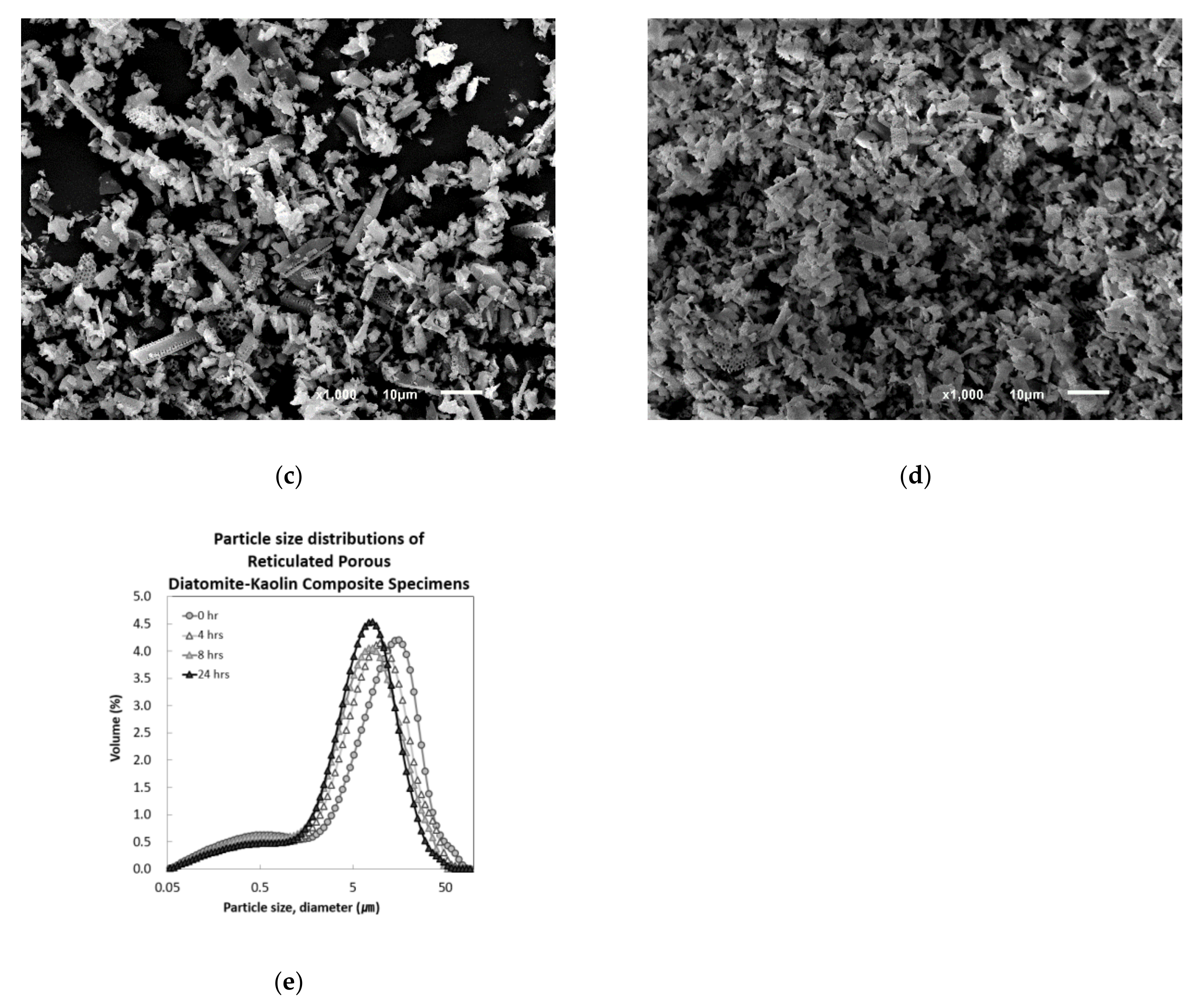

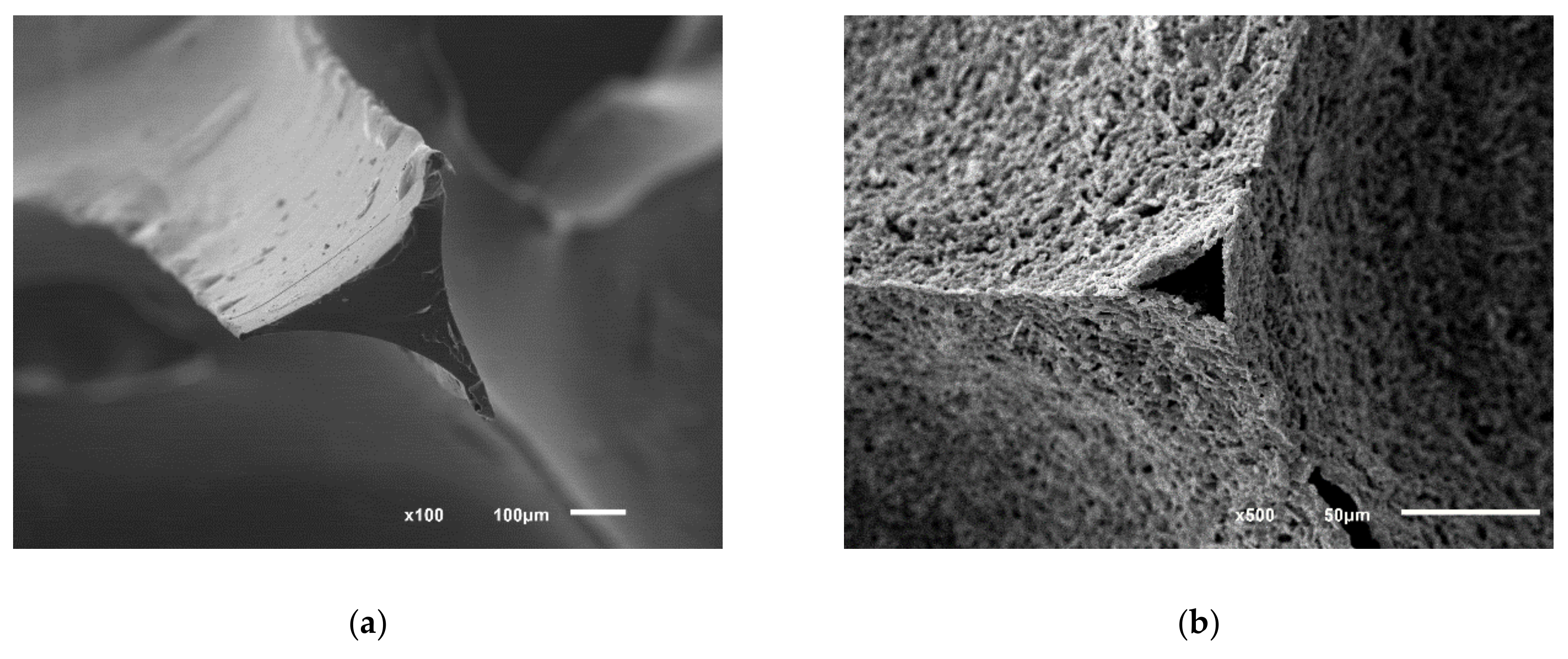

- Lee, S.; Ha, J.H.; Lee, J.; Song, I.H.; Kwon, S.H. Preparation and Characterization of a Low-Cost and Natural Material-Based Reticulated Porous Diatomite-Kaolin Composite. Appl. Sci. 2020, 10, 2125. [Google Scholar] [CrossRef] [Green Version]

- Rannabauer, S.; Söffker, G.M.; Scheunemann, M.; Betke, U.; Scheffler, M. Increased Mechanical Stability and Thermal Conductivity of Alumina Reticulated Porous Ceramics (RPC) by Nanoparticle Infiltration Processing. Adv. Eng. Mater. 2017, 19. [Google Scholar] [CrossRef]

- Yao, X.; Tan, S.; Huang, Z.; Jiang, D. Effect of recoating slurry viscosity on the properties of reticulated porous silicon carbide ceramics. Ceram. Int. 2006, 32, 137–142. [Google Scholar] [CrossRef]

- Liang, X.; Li, Y.; Sang, S.; Xu, Y.; Chen, Y.; Li, B.; Aneziris, C. Enhanced mechanical properties of SiC reticulated porous ceramics via adjustment of residual stress within the strut. Int. J. Appl. Ceram. Technol. 2018, 15, 28–35. [Google Scholar] [CrossRef] [Green Version]

- Jun, I.K.; Koh, Y.H.; Song, J.H.; Lee, S.H.; Kim, H.E. Improved compressive strength of reticulated porous zirconia using carbon coated polymeric sponge as novel template. Mater. Lett. 2006, 60, 2507–2510. [Google Scholar] [CrossRef]

- Akpinar, S.; Altun, I.A.; Onel, K. Effects of SiC addition on the structure and properties of reticulated porous mullite ceramics. J. Eur. Ceram. Soc. 2010, 30, 2727–2734. [Google Scholar] [CrossRef]

- Liang, X.; Li, Y.; Pan, L.; Sang, S.; Zhu, T.; Li, B.; Aneziris, C.G. Preparation and enhancement of mullite reticulated porous ceramics for porous media combustion. Ceram. Int. 2019, 45, 22226–22232. [Google Scholar] [CrossRef]

- Betke, U.; Lieb, A.; Scheffler, F.; Scheffler, M. Manufacturing of Reticulated Open-Cellular Aluminum Nitride Ceramic Foams from Aqueous AlN Suspensions. Adv. Eng. Mater. 2016, 19, 1600660. [Google Scholar] [CrossRef]

- Biswas, P.; Varaprasad, K.; Ramavath, P.; Suresh, M.B.; Khanra, A.K.; Johnson, R. Development of Cordierite Based Reticulated Foams with Improved Mechanical Properties for Porous Burner Applications. Trans. Indian Ceram. Soc. 2017, 76, 56–61. [Google Scholar] [CrossRef]

- Ha, J.H.; Lee, S.; Abbas Bukhari, S.Z.; Lee, J.; Song, I.H. The preparation and characterization of alumina-coated pyrophyllite-diatomite composite support layers. Ceram. Int. 2017, 43, 1536–1542. [Google Scholar] [CrossRef]

- Voigt, C.; Aneziris, C.G.; Hubálková, J. Rheological Characterization of Slurries for the Preparation of Alumina Foams via Replica Technique. J. Am. Ceram. Soc. 2015, 98, 1460–1463. [Google Scholar] [CrossRef]

- Touzin, M.; Béclin, F. Fabrication and characterization of composite sol–gel coatings on porous ceramic substrate. J. Eur. Ceram. Soc. 2011, 31, 1661–1667. [Google Scholar] [CrossRef]

- Liang, X.; Li, Y.; Liu, J.; Sang, S.; Chen, Y.; Li, B.; Aneziris, C.G. Improvement of the mechanical properties of SiC reticulated porous ceramics with optimized three-layered struts for porous media combustion. Ceram. Int. 2017, 43, 3741–3747. [Google Scholar] [CrossRef]

- Pu, X.; Liu, X.; Qiu, F.; Huang, L. Novel method to optimize the structure of reticulated porous ceramics. J. Am. Ceram. Soc. 2004, 87, 1392–1394. [Google Scholar] [CrossRef]

- Zhu, X.; Jiang, D.; Tan, S.; Zhang, Z. Improvement in the Strut Thickness of Reticulated Porous Ceramics. J. Am. Ceram. Soc. 2001, 84, 1654–1656. [Google Scholar] [CrossRef]

- Yue, H.; Wang, X.; Tian, J. Fabrication of Si3N4 reticulated porous ceramics reinforced by needle-like β-Si3N4. Ceram. Int. 2014, 40, 8525–8532. [Google Scholar] [CrossRef]

- Ha, J.H.; Lee, S.; Choi, J.R.; Lee, J.; Song, I.H.; Chung, T.J. A cobalt-coated reticulated porous alumina for radar-absorption applications. J. Aust. Ceram. Soc. 2019, 55, 883–891. [Google Scholar] [CrossRef]

- Ha, J.H.; Oh, E.; Ahmad, R.; Song, I.H. The effects of pore structures on the air permeation properties of sintered diatomite. Ceram. Int. 2013, 39, 3881–3884. [Google Scholar] [CrossRef]

- Ha, J.H.; Oh, E.; Song, I.H. The effect of sacrificial templates on the pore characteristics of sintered diatomite membranes. J. Ceram. Soc. Jpn. 2013, 121, 940–945. [Google Scholar] [CrossRef] [Green Version]

- Ha, J.H.; Oh, E.; Song, I.H. The use of a diatomite-kaolin composite coating to design the pore characteristics of a sintered diatomite membrane. Ceram. Int. 2014, 40, 2221–2227. [Google Scholar] [CrossRef]

- Ha, J.H.; Oh, E.; Song, I.H. The fabrication and characterization of sintered diatomite for potential microfiltration applications. Ceram. Int. 2013, 39, 7641–7648. [Google Scholar] [CrossRef]

- Ha, J.H.; Oh, E.; Bae, B.; Song, I.H. The effect of kaolin addition on the characteristics of a sintered diatomite composite support layer for potential microfiltration applications. Ceram. Int. 2013, 39, 8955–8962. [Google Scholar] [CrossRef]

- Ha, J.H.; Lee, J.; Song, I.H.; Lee, S.H. The effects of diatomite addition on the pore characteristics of a pyrophyllite support layer. Ceram. Int. 2015, 41, 9542–9548. [Google Scholar] [CrossRef]

- Ha, J.H.; Bae, B.; Song, I.H. Effect of pore characteristics on permeability of sintered diatomite filter for microfiltration. Adv. Appl. Ceram. 2015, 114, 156–163. [Google Scholar] [CrossRef]

- Ha, J.H.; Park, Y.H.; Song, I.H. The preparation and pore characteristics of an alumina coating on a diatomite-kaolin composite support layer. J. Ceram. Soc. Jpn. 2014, 122, 714–718. [Google Scholar] [CrossRef] [Green Version]

- Ha, J.H.; Jung, D.W.; Song, I.H. The effect of an alumina coating on the pore characteristics of a diatomite–kaolin composite support layer. Ceram. Int. 2014, 40, 12961–12967. [Google Scholar] [CrossRef]

- Ha, J.H.; Park, Y.H.; Song, I.H. Alumina coating to realize desired pore characteristics of sintered diatomite membrane. Arch. Met. Mater. 2015, 60, 1175–1178. [Google Scholar] [CrossRef] [Green Version]

- Ha, J.H.; Bukhari, S.Z.A.; Lee, J.; Song, I.H.; Lee, S.H. The preparation and characterizations of pyrophyllite-diatomite composite support layers. J. Ceram. Soc. Jpn. 2015, 123, 1043–1050. [Google Scholar] [CrossRef] [Green Version]

- Ha, J.H.; Oh, E.; Ahmad, R.; Song, I.H. A particle-stabilized diatomite foam with a bimodal pore structure. J. Ceram. Soc. Jpn. 2013, 121, 426–429. [Google Scholar] [CrossRef] [Green Version]

- Šaponjić, A.; Stanković, M.; Majstorović, J.; Matović, B.; Ilić, S.; Egelja, A.; Kokunešoski, M. Porous ceramic monoliths based on diatomite. Ceram. Int. 2015, 41, 9745–9752. [Google Scholar] [CrossRef]

- Shen, W.; Feng, L.; Lei, A.; Liu, Z.; Chen, Y. Effects of porosity and pore size on the properties of AgO-decorated porous diatomite ceramic composites. Ceram. Int. 2014, 40, 1495–1502. [Google Scholar] [CrossRef]

- Van Garderen, N.; Graule, T.; Aneziris, C.G.; Clemens, F.J. Comparison methods for microstructure analysis on highly porous extrudates based on diatomite filter aids. Microporous Mesoporous Mater. 2013, 171, 215–222. [Google Scholar] [CrossRef]

- Van Garderen, N.; Clemens, F.J.; Kaufmann, J.; Urbanek, M.; Binkowski, M.; Graule, T.; Aneziris, C.G. Pore analyses of highly porous diatomite and clay based materials for fluidized bed reactors. Microporous Mesoporous Mater. 2012, 151, 255–263. [Google Scholar] [CrossRef]

- Vasconcelos, P.V.; Labrincha, J.A.; Ferreira, J.M.F. Permeability of diatomite layers processed by different colloidal techniques. J. Eur. Ceram. Soc. 2000, 20, 201–207. [Google Scholar] [CrossRef]

- Chen, R.; Jia, W.; Wang, Y.; Lao, D.; Hei, D.; Li, S. Optimization of the microstructure and properties of Al2O3-ZrO2 reticulated porous ceramics via in-situ synthesis of mullite whiskers and flowing-liquid phase. Mater. Lett. 2019, 243, 66–68. [Google Scholar] [CrossRef]

- Banerjee, A.; Bala Chandran, R.; Davidson, J.H. Experimental investigation of a reticulated porous alumina heat exchanger for high temperature gas heat recovery. Appl. Therm. Eng. 2015, 75, 889–895. [Google Scholar] [CrossRef] [Green Version]

- Voigt, C.; Zienert, T.; Schubert, P.; Aneziris, C.G.; Hubálková, J. Reticulated porous foam ceramics with different surface chemistries. J. Am. Ceram. Soc. 2014, 97, 2046–2053. [Google Scholar] [CrossRef]

- Voigt, C.; Jäckel, E.; Aneziris, C.G.; Hubálková, J. Investigations of reticulated porous alumina foam ceramics based on different coating techniques with the aid of μCT and statistical characteristics. Ceram. Int. 2013, 39, 2415–2422. [Google Scholar] [CrossRef]

- Cai, J.; Fan, S.; Liu, F.; Jiang, W.; Wu, H.; Fan, Z. Preparation of porous Al2O3 ceramic microspheres by a novel micro-droplet jetting rapid forming method. Ceram. Int. 2019, 45, 20583–20588. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.; Liu, C.; Liu, Y.; Zhu, J.; Lao, C. Preparation of high solid loading and low viscosity ceramic slurries for photopolymerization-based 3D printing. Ceram. Int. 2019, 45, 11549–11557. [Google Scholar] [CrossRef]

- Shafeiey, A.; Enayati, M.H.; Al-Haji, A. The effect of slip casting parameters on the green density of MgAl2O4 spinel. Ceram. Int. 2017, 43, 6069–6074. [Google Scholar] [CrossRef]

- Xing, H.; Zou, B.; Liu, X.; Wang, X.; Chen, Q.; Fu, X.; Li, Y. Effect of particle size distribution on the preparation of ZTA ceramic paste applying for stereolithography 3D printing. Powder Technol. 2020, 359, 314–322. [Google Scholar] [CrossRef]

- Güngör, G.L.; Kara, A.; Gardini, D.; Blosi, M.; Dondi, M.; Zanelli, C. Ink-jet printability of aqueous ceramic inks for digital decoration of ceramic tiles. Dyes Pigm. 2016, 127, 148–154. [Google Scholar] [CrossRef]

- Balzarotti, R.; Cristiani, C.; Latorrata, S.; Migliavacca, A. Washcoating of low surface area cerium oxide on complex geometry substrates. Part. Sci. Technol. 2016, 34, 184–193. [Google Scholar] [CrossRef]

- Liu, W.; Jin, L.; Wang, S. Preparation of transparent Y2O3 ceramic via gel casting: Realization of high solid volume via surface modification. J. Am. Ceram. Soc. 2019, 102, 6414–6421. [Google Scholar] [CrossRef]

- Gao, X.; Wang, R.; Zhao, J.; Huang, J.; Gao, Y.; Liu, H. Influence of surface oxide layer of SiC powder on the rheological properties of its slurry. Int. J. Appl. Ceram. Technol. 2020, 17, 484–490. [Google Scholar] [CrossRef]

- Van Garderen, N.; Clemens, F.J.; Mezzomo, M.; Bergmann, C.P.; Graule, T. Investigation of clay content and sintering temperature on attrition resistance of highly porous diatomite based material. Appl. Clay Sci. 2011, 52, 115–121. [Google Scholar] [CrossRef]

- Akhtar, F.; Rehman, Y.; Bergström, L. A study of the sintering of diatomaceous earth to produce porous ceramic monoliths with bimodal porosity and high strength. Powder Technol. 2010, 201, 253–257. [Google Scholar] [CrossRef]

- Gregorová, E.; Uhlířová, T.; Pabst, W.; Diblíková, P.; Sedlářová, I. Microstructure characterization of mullite foam by image analysis, mercury porosimetry and X-ray computed microtomography. Ceram. Int. 2018, 44, 12315–12328. [Google Scholar] [CrossRef]

- Liang, X.; Li, Y.; Yang, J.; Wang, Q.; Sang, S.; He, Z. Influence of template strut morphology on the mechanical performance of SiC reticulated porous ceramics. Ceram. Int. 2020, 46, 16820–16826. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.; Lee, C.Y.; Ha, J.-H.; Lee, J.; Song, I.-H.; Kwon, S.-H. Effect of Processing Conditions on the Properties of Reticulated Porous Diatomite–Kaolin Composites. Appl. Sci. 2020, 10, 7297. https://doi.org/10.3390/app10207297

Lee S, Lee CY, Ha J-H, Lee J, Song I-H, Kwon S-H. Effect of Processing Conditions on the Properties of Reticulated Porous Diatomite–Kaolin Composites. Applied Sciences. 2020; 10(20):7297. https://doi.org/10.3390/app10207297

Chicago/Turabian StyleLee, Sujin, Chae Young Lee, Jang-Hoon Ha, Jongman Lee, In-Hyuck Song, and Se-Hun Kwon. 2020. "Effect of Processing Conditions on the Properties of Reticulated Porous Diatomite–Kaolin Composites" Applied Sciences 10, no. 20: 7297. https://doi.org/10.3390/app10207297

APA StyleLee, S., Lee, C. Y., Ha, J. -H., Lee, J., Song, I. -H., & Kwon, S. -H. (2020). Effect of Processing Conditions on the Properties of Reticulated Porous Diatomite–Kaolin Composites. Applied Sciences, 10(20), 7297. https://doi.org/10.3390/app10207297