The Effect of a Composite Nanostructure on the Mechanical Properties of a Novel Al-Cu-Mn Alloy through Multipass Cold Rolling and Aging

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results

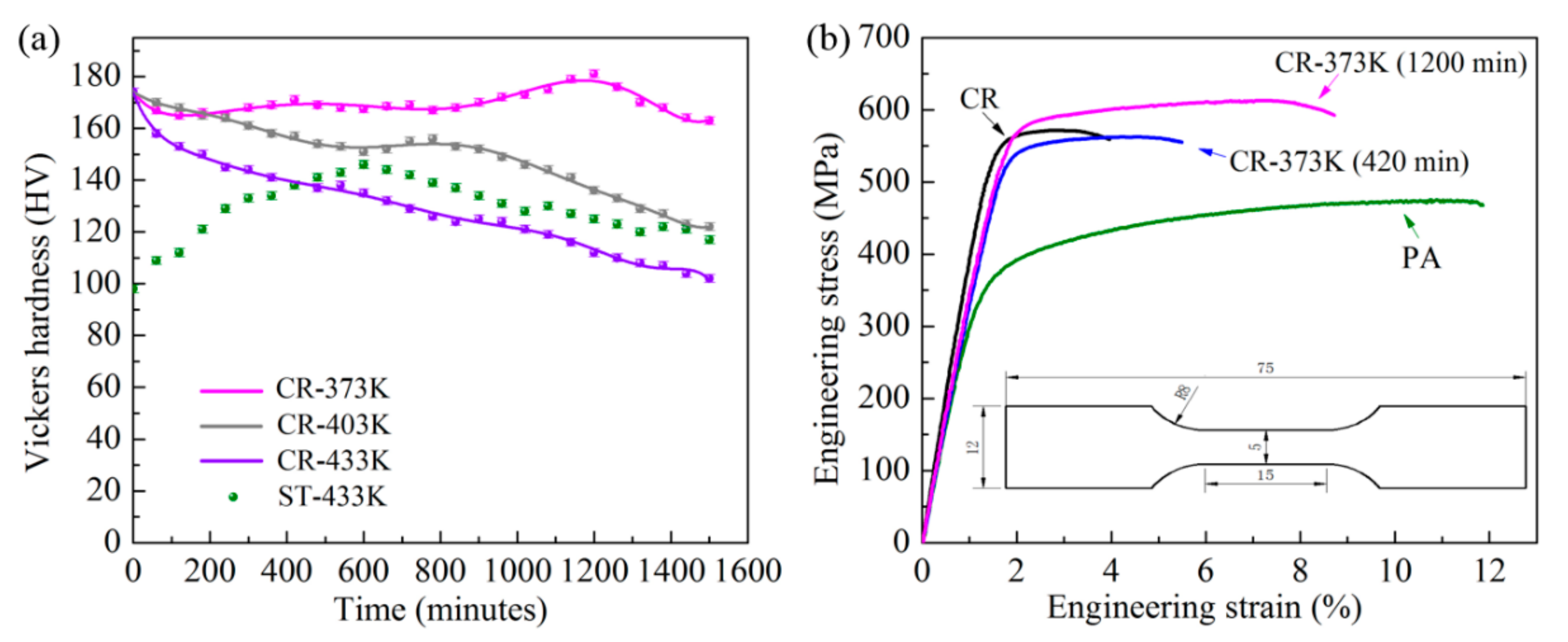

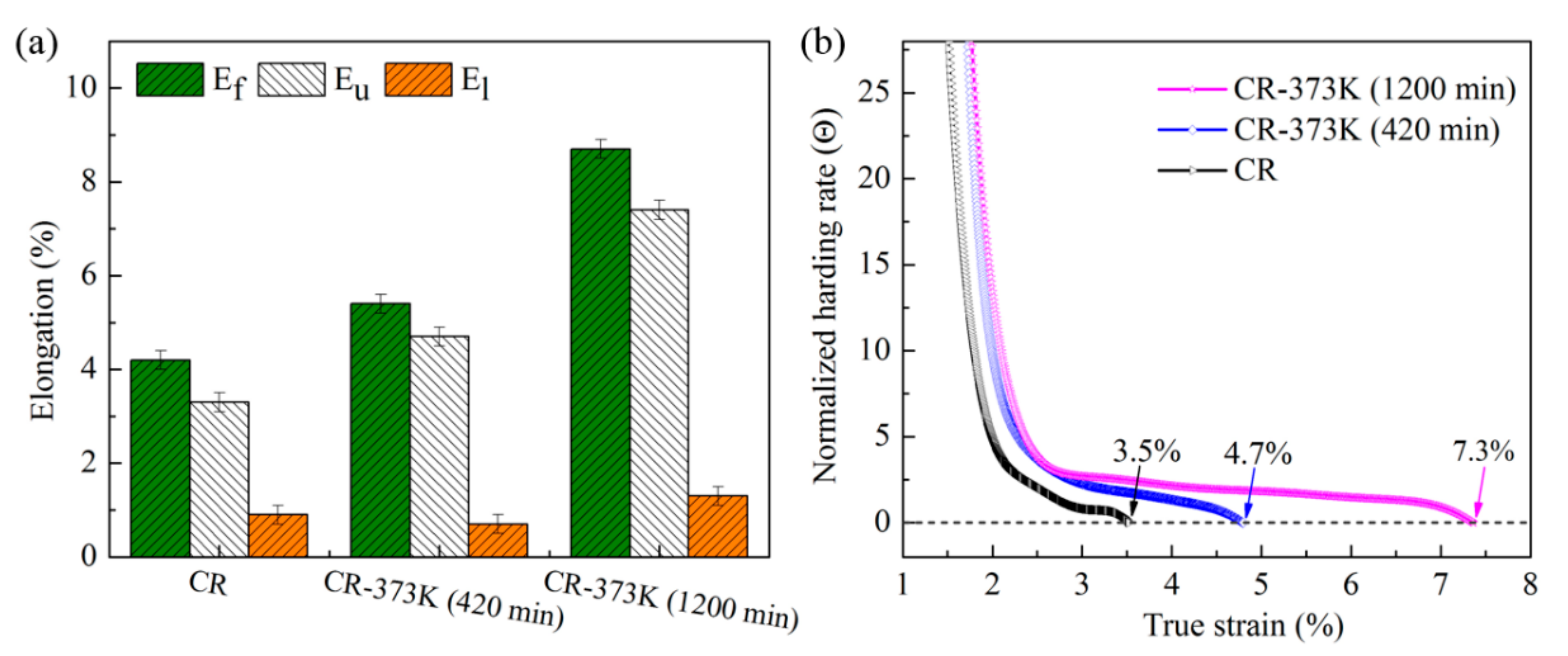

3.1. Mechanical Properties

3.2. Microstructures

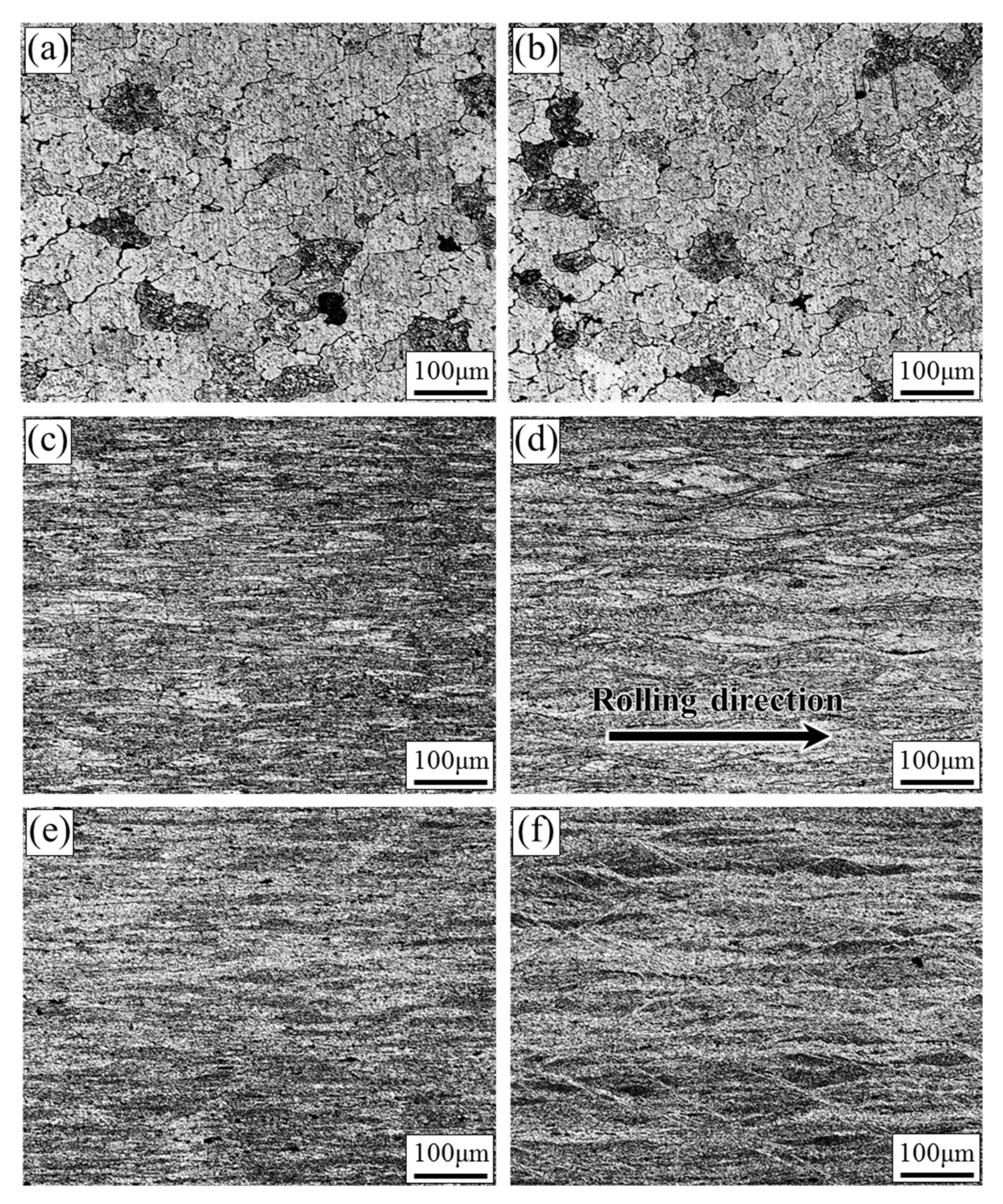

3.2.1. Optical Microstructures

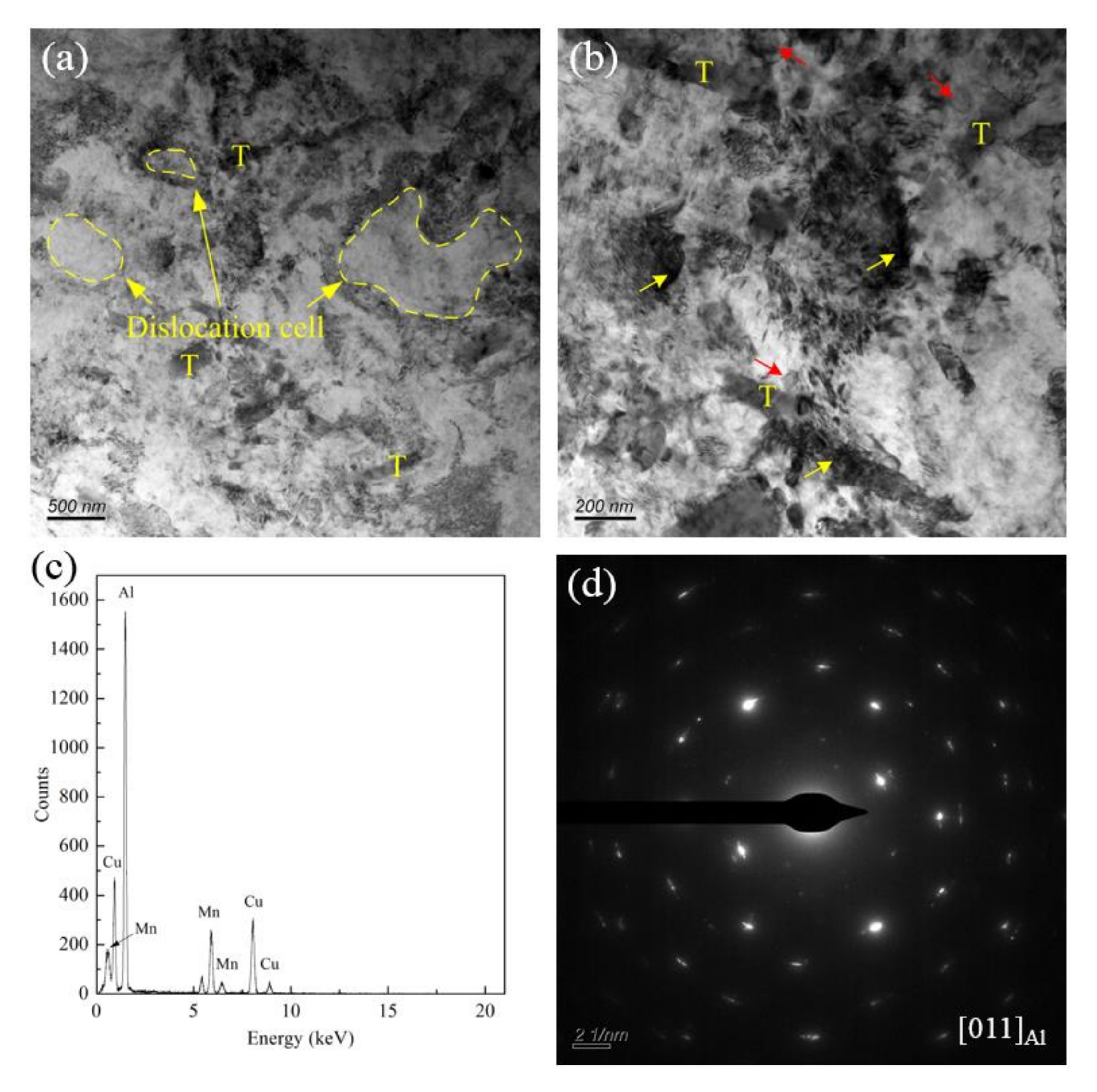

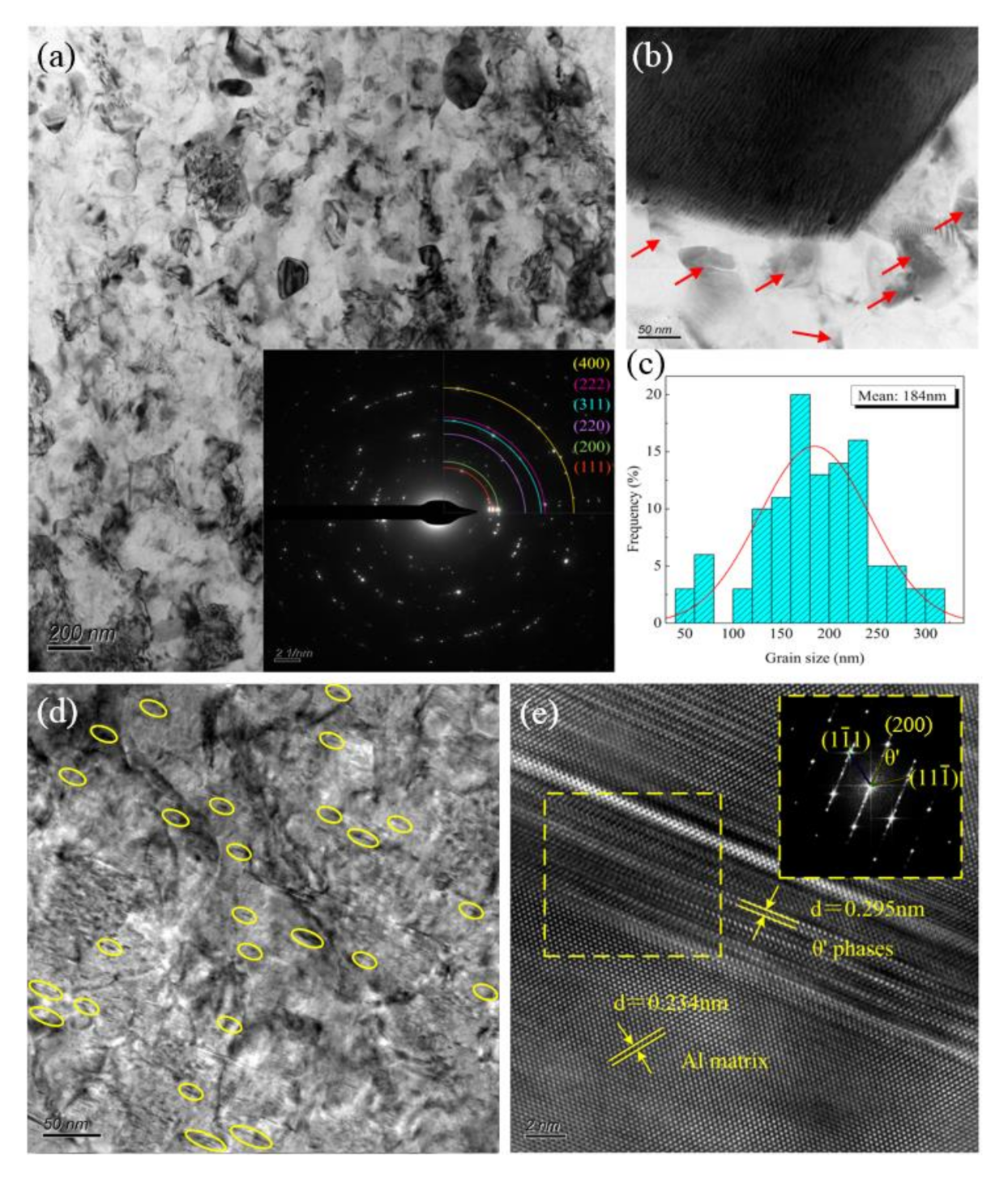

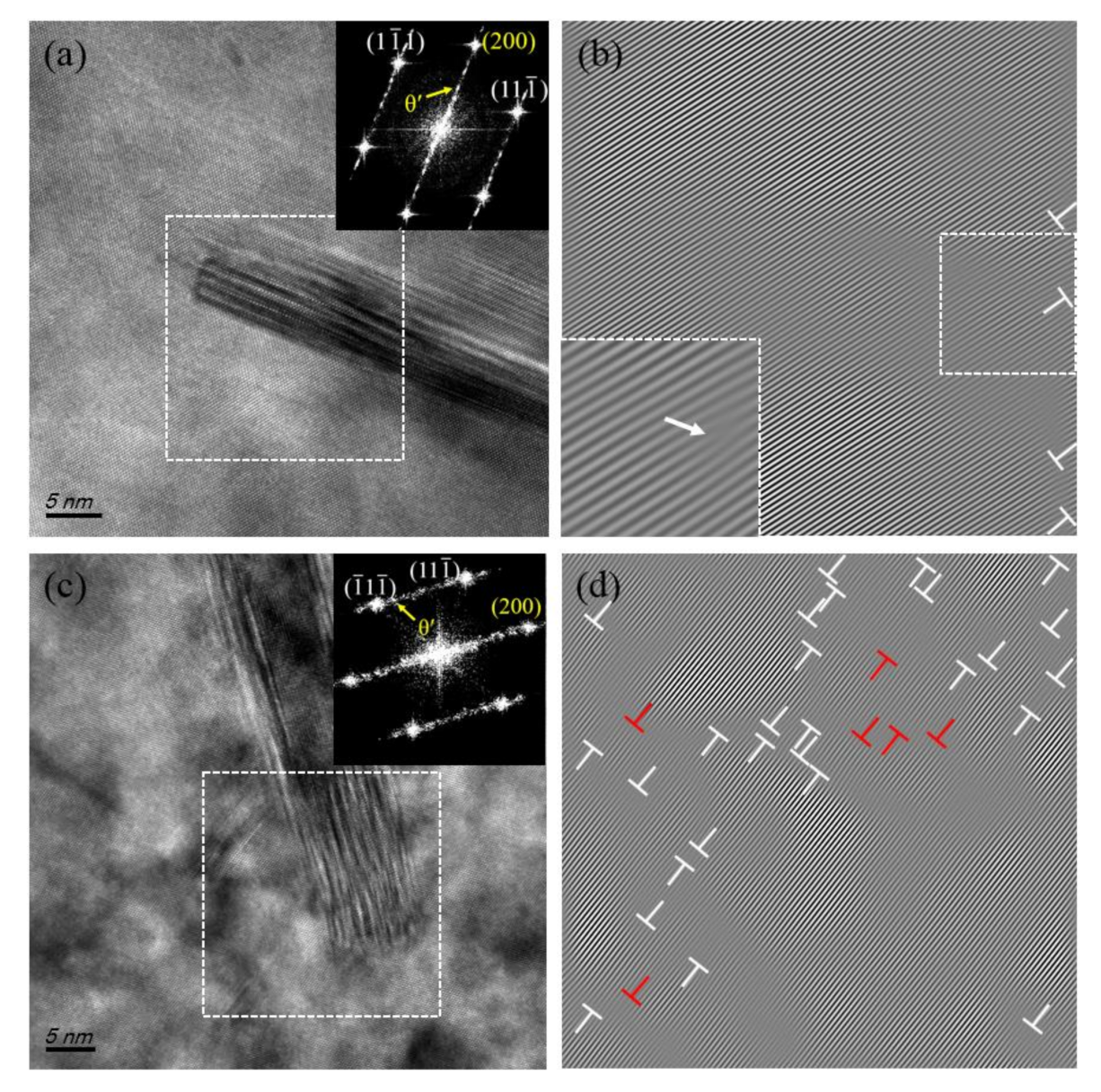

3.2.2. TEM Microstructures

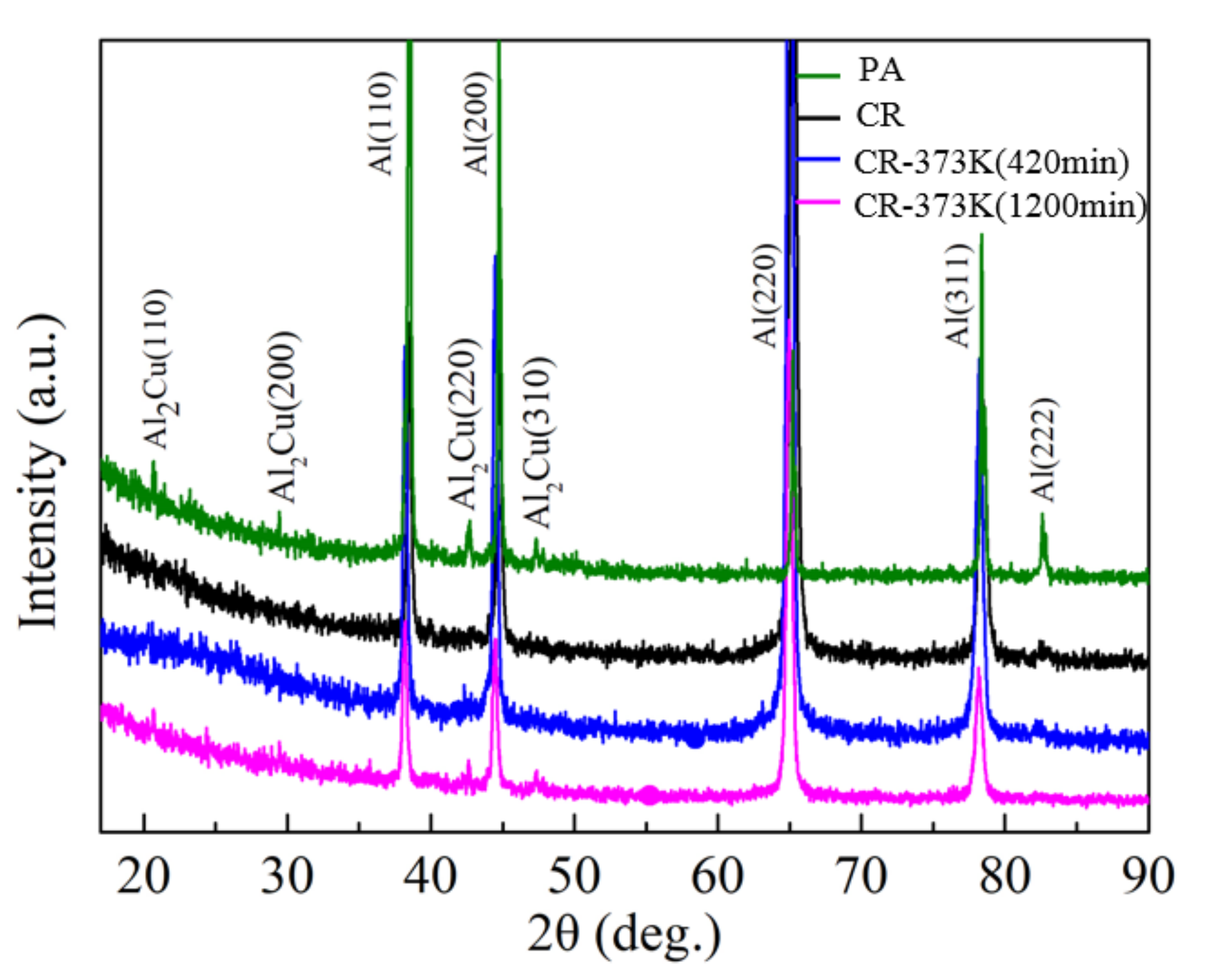

3.2.3. XRD Analysis

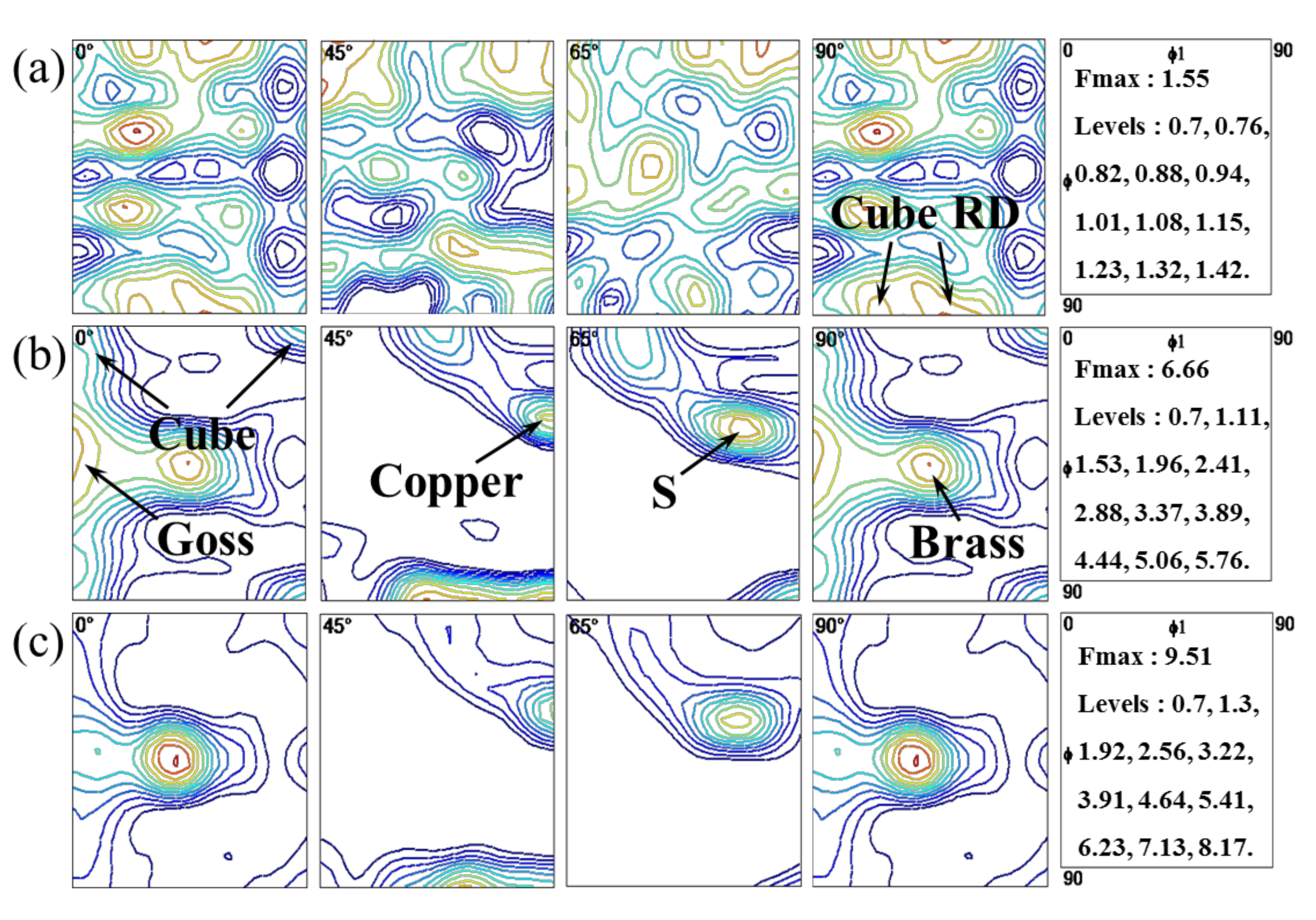

3.2.4. Texture Evolution

4. Discussion

4.1. The Formation of Composite Nanostructures in the Al-Cu-Mn Alloy

4.2. The Mechanism by Which Composite Nanostructures Influence Strength

4.3. The Mechanism by Which Composite Nanostructures Influence Ductility

5. Conclusions

- (1)

- The remaining T phase after ST effectively promoted the accumulation of dislocations during deformation. The high density dislocations promoted the formation of nanosized precipitates and ultrafine grains/nanograins in the postaging process, which significantly improved the strength of the CR samples.

- (2)

- Optimization of the postaging process improved the ductility of the CR samples. The nanoscale precipitated phases generated during the low-temperature aging not only compensated for a decrease in strength caused by a reduction in the dislocation density but also improved the work-hardening ability by pinning and accumulating dislocations. At the same time, the reduction in the dislocation density also increased the work-hardening rate.

- (3)

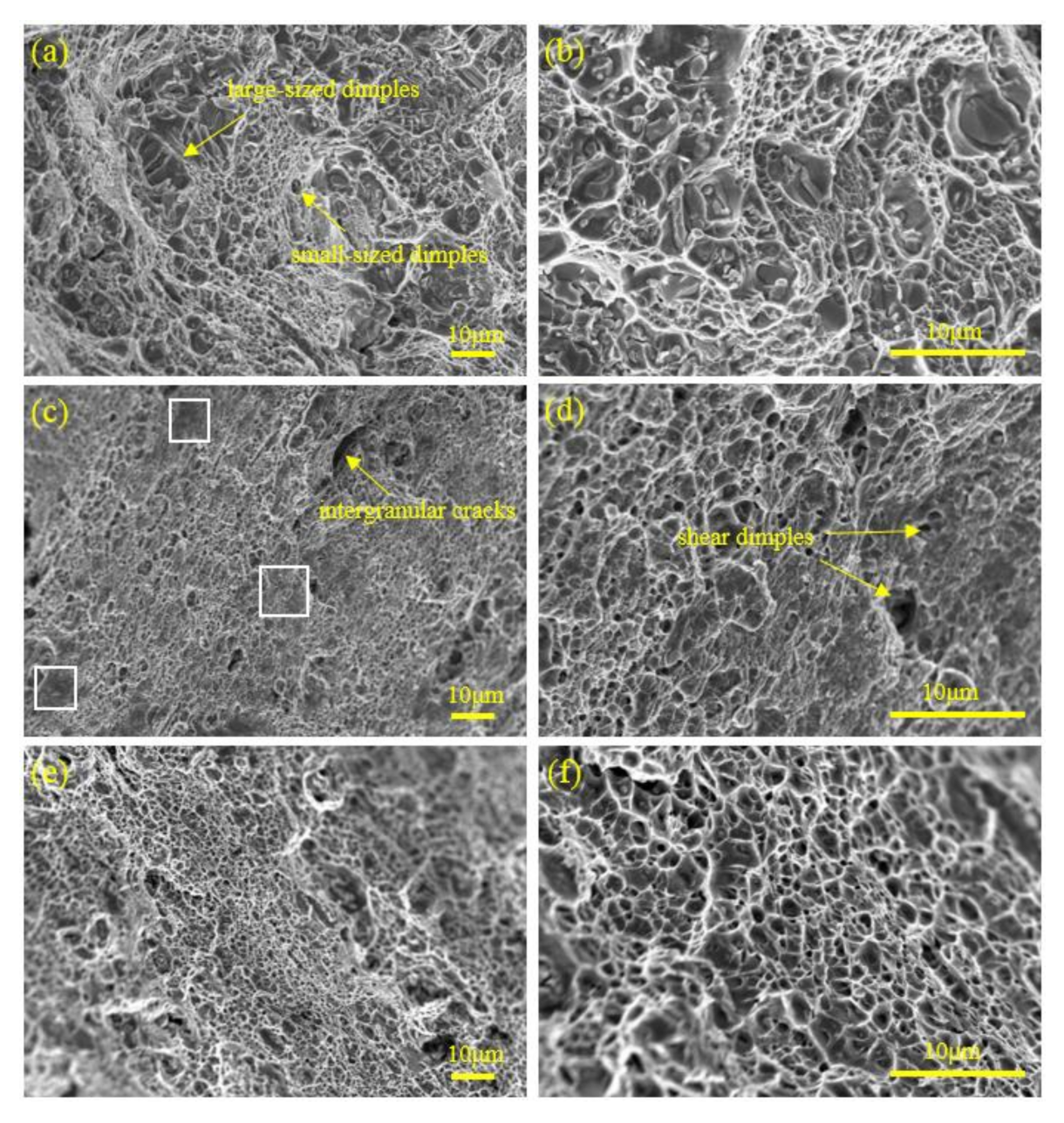

- Tensile fractures of the CR-373K (1200 min) samples mainly occurred via transgranular fractures induced by dimples.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ivanov, K.V.; Ovcharenko, V.E. Structural features of ultrafine-grained aluminum processed through accumulative roll bonding providing improved mechanical properties and thermal stability. Mater. Sci. Eng. A 2020, 775, 138988. [Google Scholar] [CrossRef]

- Yu, H.L.; Su, L.; Lu, C.; Tieu, K.; Li, H.; Li, J.; Godbole, A.; Kong, C. Enhanced mechanical properties of ARB-processed aluminum alloy 6061 sheets by subsequent asymmetric cryorolling and ageing. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2016, 674, 256–261. [Google Scholar] [CrossRef] [Green Version]

- Howeyze, M.; Eivani, A.R.; Arabi, H.; Jafarian, H.R. Effects of deformation routes on the evolution of microstructure, texture and tensile properties of AA5052 aluminum alloy. Mater. Sci. Eng. A 2018, 732, 120–128. [Google Scholar] [CrossRef]

- Braga, D.P.; Camilo-Magalhes, D.C.; Kliauga, A.M.; Della-Rovere, C.A.; Sordi, V.L. Microstructure, mechanical behavior and stress corrosion cracking susceptibility in ultrafine-grained Al-Cu alloy. Mater. Sci. Eng. A 2020, 773, 138865. [Google Scholar] [CrossRef]

- Okeke, U.; Yilmazer, H.; Sato, S.; Boehlert, C.J. Strength enhancement of an aluminum alloy through high pressure torsion. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2019, 760, 195–205. [Google Scholar] [CrossRef]

- Zha, M.; Li, Y.; Mathiesen, R.H.; Bjørge, R.; Roven, H.J. Microstructure evolution and mechanical behavior of a binary Al-7Mg alloy processed by equal-channel angular pressing. Acta Mater. 2006, 84, 42–54. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, M.; Zhou, F.; Ma, E. High tensile ductility in a nanostructured metal. Nature 2002, 419, 912–915. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Bingert, J.F.; Liao, X.Z.; Cui, B.Z.; Han, K.; Sergueeva, A.V.; Amiya, K. Simultaneously Increasing the Ductility and Strength of Ultra-Fine-Grained Pure Copper. Adv. Mater. 2006, 18, 2949–2953. [Google Scholar] [CrossRef]

- Dao, M.; Lu, L.; Shen, Y.F.; Suresh, S. Strength, strain-rate sensitivity and ductility of copper with nanoscale twins. Acta Mater. 2006, 54, 5421–5432. [Google Scholar] [CrossRef]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef] [Green Version]

- Horita, Z.; Ohashi, K.; Fujita, T.; Kaneko, K.; Langdon, T.G. Achieving High Strength and High Ductility in Precipitation-Hardened Alloys. Adv. Mater. 2005, 17, 1599–1602. [Google Scholar] [CrossRef]

- Cheng, S.; Ma, E. Simultaneously Increasing the Ductility and Strength of Nanostructured Alloys. Adv. Mater. 2006, 18, 2280–2283. [Google Scholar]

- Bunge, H.J.; Morris, P.R. Texture Analysis in Materials Science: Mathematical Methods; Butterworths: London, UK, 1982. [Google Scholar]

- Tang, J.G.; Zhang, X.M.; Deng, Y.L.; Du, Y.X.; Chen, Z.Y. Texture decomposition with particle swarm optimization method. Comput. Mater. Sci. 2006, 38, 395–399. [Google Scholar] [CrossRef]

- Williamson, G.K.; Hall, W.H. X-ray line broadening from filed aluminum and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, M.; Jiang, H.; Li, H.; Li, S. Effect of artificial ageing on strength and ductility of an Al-Cu-Mg-Mn alloy subjected to solutionizing and room-temperature rolling. Mater. Charact. 2020, 165, 110383. [Google Scholar] [CrossRef]

- Seidman, D.N.; Marquis, E.A.; Dunand, D.C. Precipitation strengthening at ambient and elevated temperatures of heat-treatable Al(Sc) alloys. Acta Mater. 2002, 50, 4021–4035. [Google Scholar] [CrossRef]

- Vulf, B.K.; Chernov, M.N. Influence of ternary intermetallic compounds on the heat resistance of deformed aluminium alloys (in Russian). Tsvet. Metall. 1960, 2, 147–152. [Google Scholar]

- Polesya, A.F.; Kovalenko, V.V. Phase diagram of rapidly solidified Al–Cu-Mn alloys. Russ. Metall. 1970, 1, 114–117. [Google Scholar]

- Feng, Z.Q.; Yang, Y.Q.; Huang, B.; Li, M.H.; Chen, Y.X.; Ru, J.G. Crystal substructures of the rotation-twinned T (Al 20 Cu 2 Mn 3) phase in 2024 aluminum alloy. J. Alloys Compd. 2014, 583, 445–451. [Google Scholar] [CrossRef]

- Cheng, S.; Zhao, Y.H.; Zhu, Y.T.; Ma, E. Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation. Acta Mater. 2007, 55, 5822–5832. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Zhang, Y. Effects of cold predeformation on dissolution of second-phase Al 2 Cu particles during solution treatment of 2219 Al-Cu alloy forgings. Mater. Charact. 2018, 135, 18–24. [Google Scholar] [CrossRef]

- Rakhmonov, J.; Liu, K.; Pan, L.; Breton, F.; Chen, X.G. Enhanced mechanical properties of high-temperature-resistant Al-Cu cast alloy by microalloying with Mg. J. Alloys Compd. 2020, 827, 154305. [Google Scholar] [CrossRef]

- Xu, P.; Luo, H. Improving the ductility of nanostructured Al alloy using strongly textured nano-laminated structure combined with nano-precipitates. Mater. Sci. Eng. A 2016, 675, 323–337. [Google Scholar] [CrossRef]

- Li, H.; Chen, P.; Wang, Z.; Zhu, F.; Song, R.; Zheng, Z. Tensile properties, microstructures and fracture behaviors of an Al-Zn-Mg-Cu alloy during ageing after solution treating and cold-rolling. Mater. Sci. Eng. A 2019, 742, 798–812. [Google Scholar] [CrossRef]

- Gu, J.; Wang, X.; Bai, J.; Ding, J.; Williams, S.; Zhai, Y.; Liu, K. Deformation microstructures and strengthening mechanisms for the wire+arc additively manufactured Al-Mg4.5Mn alloy with inter-layer rolling. Mater. Sci. Eng. A 2018, 712, 292–301. [Google Scholar] [CrossRef]

- Starink, M.J.; Wang, S.C. A model for the yield strength of overaged Al–Zn–Mg–Cu alloys. Acta Mater. 2003, 51, 5131–5150. [Google Scholar] [CrossRef] [Green Version]

- Song, R.; Wei, H.; Zheng, Z.; Wang, Z.; Fang, B. Effects of re-ageing treatment on microstructure and tensile properties of solution treated and cold-rolled Al-Cu-Mg alloys. Mater. Sci. Eng. A 2016, 650, 254–263. [Google Scholar]

- Wu, X.; Tao, N.; Hong, Y.; Xu, B.; Lu, J.; Lu, K. Microstructure and evolution of mechanically-induced ultrafine grain in surface layer of AL-alloy subjected to USSP. Acta Mater. 2002, 50, 2075–2084. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Hansen, N. Hall-Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

| Alloy Sample | d/nm | ||

|---|---|---|---|

| CR | 16 | 0.18 | 1.4 × 1015 |

| CR-373K (420 min) | 51 | 0.21 | 5.0 × 1014 |

| CR-373K (1200 min) | 71 | 0.23 | 3.9 × 1014 |

| Alloy Sample | Cube (2.45) | Goss (2.45) | Brass (3.17) | S (3.33) | Copper (3.7) | Random (3.07) | Rolling Texture | MA |

|---|---|---|---|---|---|---|---|---|

| PA | 5.25 | 6.13 | 5.83 | 5.42 | 4.49 | 72.88 | 15.17 | 3.04 |

| CR | 6.89 | 10.80 | 11.56 | 36.67 | 10.93 | 23.15 | 59.16 | 3.14 |

| CR-373K (1200 min) | 6.50 | 10.10 | 15.19 | 33.77 | 12.53 | 21.91 | 61.49 | 3.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, K.; Yang, M.; Long, S.-l.; Li, B. The Effect of a Composite Nanostructure on the Mechanical Properties of a Novel Al-Cu-Mn Alloy through Multipass Cold Rolling and Aging. Appl. Sci. 2020, 10, 8109. https://doi.org/10.3390/app10228109

Feng K, Yang M, Long S-l, Li B. The Effect of a Composite Nanostructure on the Mechanical Properties of a Novel Al-Cu-Mn Alloy through Multipass Cold Rolling and Aging. Applied Sciences. 2020; 10(22):8109. https://doi.org/10.3390/app10228109

Chicago/Turabian StyleFeng, Ke, Ming Yang, Shao-lei Long, and Bo Li. 2020. "The Effect of a Composite Nanostructure on the Mechanical Properties of a Novel Al-Cu-Mn Alloy through Multipass Cold Rolling and Aging" Applied Sciences 10, no. 22: 8109. https://doi.org/10.3390/app10228109

APA StyleFeng, K., Yang, M., Long, S.-l., & Li, B. (2020). The Effect of a Composite Nanostructure on the Mechanical Properties of a Novel Al-Cu-Mn Alloy through Multipass Cold Rolling and Aging. Applied Sciences, 10(22), 8109. https://doi.org/10.3390/app10228109