Optimization of Parameters for the Cutting of Wood-Based Materials by a CO2 Laser

Abstract

:1. Introduction

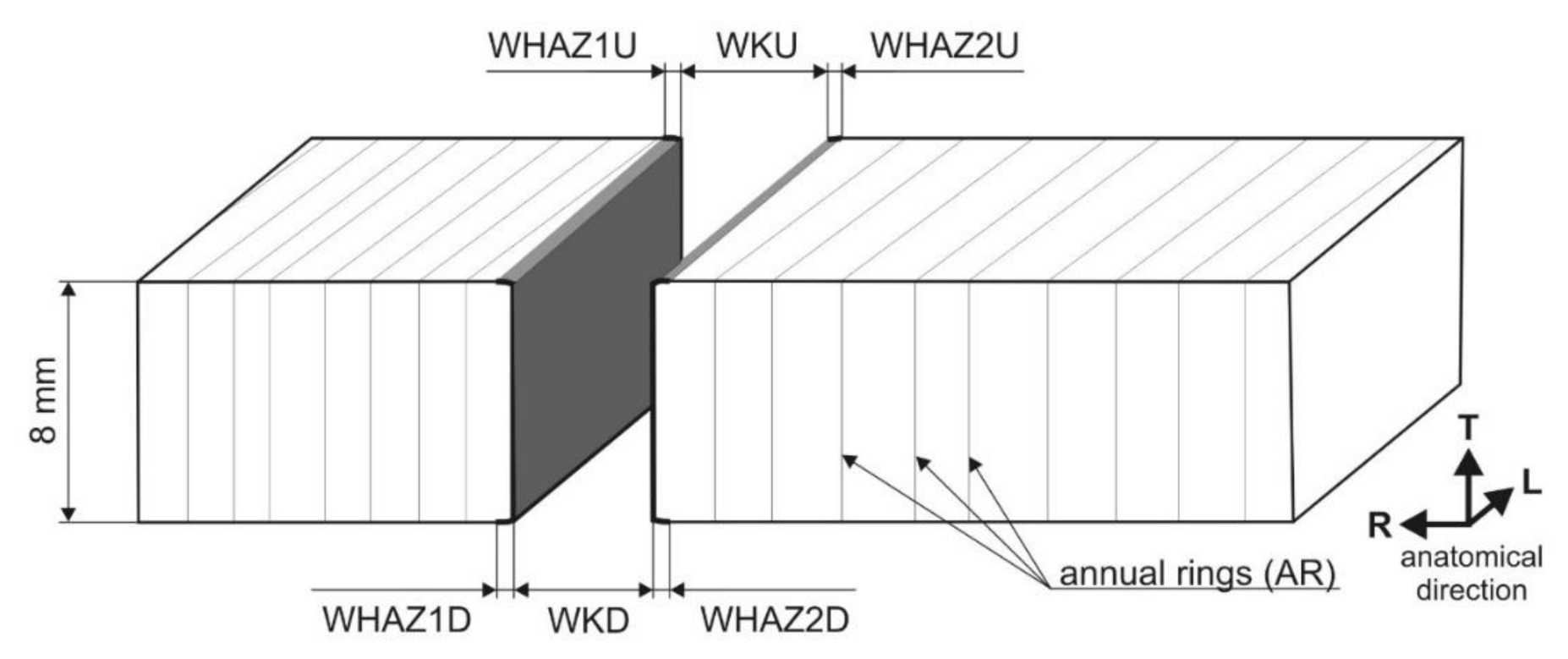

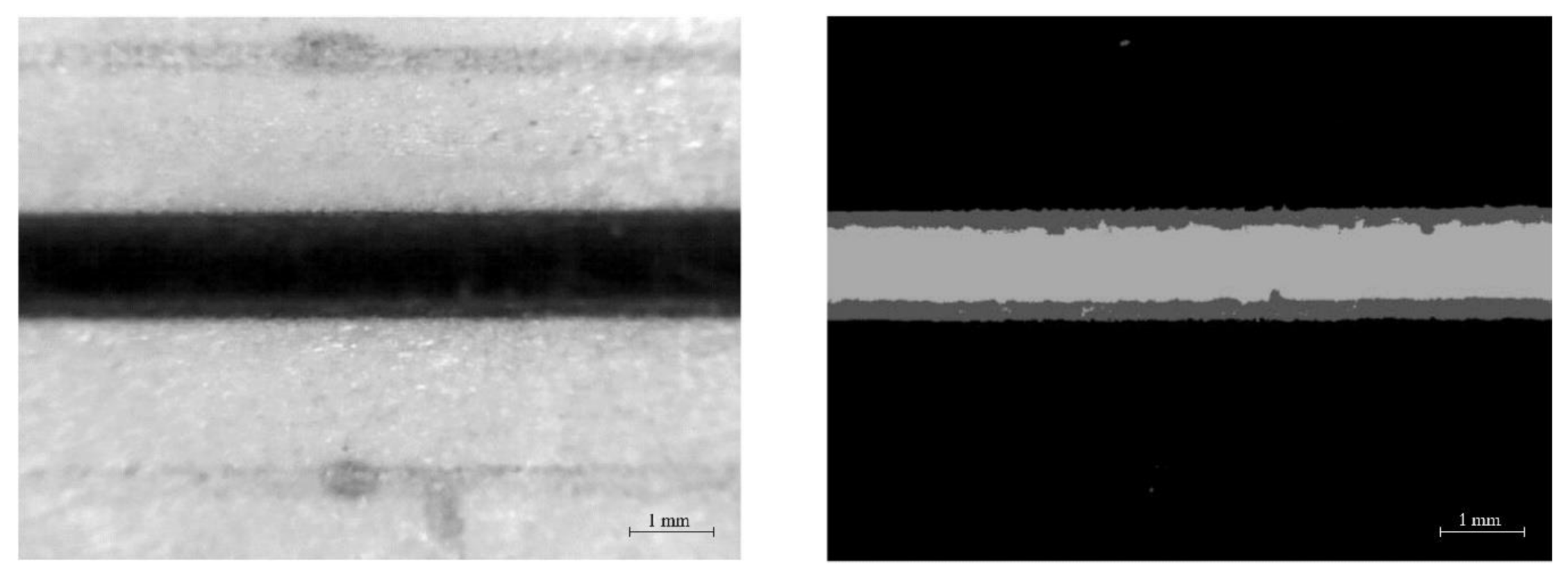

2. Materials and Methods

3. Results and Discussion

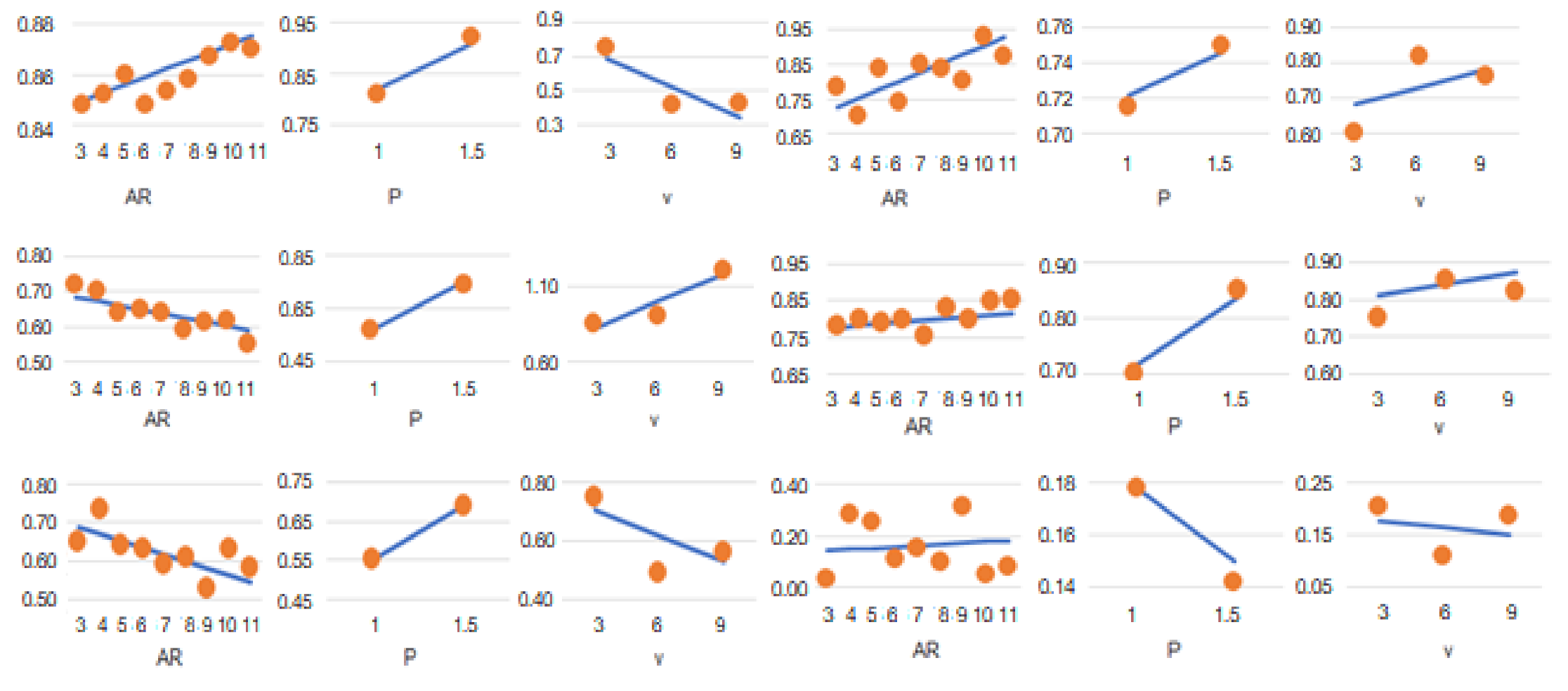

3.1. Analysis of Variance and Regression Analysis

3.2. Optimal Parameter Settings of the Investigated Process

− 0.25323·V − 0.29207·P − 0.05862·AR = min,

0.08067·V + 0.19104·P + 0.02398·AR = min,

0.03693·V + 0.81739·P + 0.06392·AR = min,

0.05375·V + 0.00574·P + 0.01209·AR = min,

− 0.51849·P – 0.03579·AR = min,

0.23656·V + 1.17681·P + 0.10382·AR = 1.

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Masoud, F.; Sapuan, S.; Mohd Ariffin, M.K.A.; Nukman, Y.; Bayraktar, E. Cutting Processes of Natural Fiber-Reinforced Polymer Composites. Polymers 2020, 12, 1332. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, K.; Yahagi, H.; Wada, M.; Kameyama, T.; Kawakami, M.; Furukawa, H.; Adachi, K. Enormously Low Frictional Surface on Tough Hydrogels Simply Created by Laser-Cutting Process. Technologies 2018, 6, 82. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Wei, J.; Ma, Z.; Song, P.; Ma, J.; Zhao, Y.; Huang, Z.; Zhang, M.; Yang, F.; Wang, X. The Fabrication of Micro/Nano Structures by Laser Machining. Nanomaterials 2019, 9, 1789. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abidou, D.; Yusoff, N.; Nazri, N.; Awang, M.A.O.; Hassan, M.A.; Sarhan, A.A.D. Numerical simulation of metal removal in laser drilling using radial point interpolation method. Eng. Anal. Bound. Elem. 2017, 77, 89–96. [Google Scholar] [CrossRef]

- Mukherjee, K.T.; Grendzwell, P.A.A.; McMillin, C.W. Gas-flow parameters in laser cutting of wood–nozzle design. For. Prod. J. 1990, 40, 39–42. [Google Scholar]

- Khan, P.A.A.; Cherif, M.; Kudapa, S.; Barnekov, V.; Mukherjee, K. High Speed, High Energy Automated Machining of Hardwoods by Using a Carbon Dioxide Laser: ALPS; Laser Institute of America: Orlano, FL, USA, 1991; Volume 2, pp. 238–252. [Google Scholar]

- Barcikowski, S.; Koch, G.; Odermatt, J. Characterisation and modification of the heat affected zone during laser material processing of wood and wood composites. Holz Roh Werkst. 2006, 64, 94–103. [Google Scholar] [CrossRef]

- Huber, H.E.; McMillin, C.W.; Rasher, A. Economics of cutting wood parts with a laser under optical image analyzer control. For. Prod. J. 1982, 32, 16–21. [Google Scholar]

- Belforte, D.A. Non-metal cutting. Ind. Laser Rev. 1998, 13, 11–13. [Google Scholar]

- Powell, J.; Ellis, G.; Menzies, I.A.; Scheyvaerts, P.F. CO2 laser cutting of non-metallic materials. In Proceedings of the 4th International Conference Lasers in Manufacturing, Birmingham, UK, 12–14 May 1987. [Google Scholar]

- Wieloch, G.; Pohl, P. Use of laser in the furniture industry. In Proceedings of the Laser Technology IV: Research Trends, Instrumentation, and Applications in Metrology and Materials Processing, Szczecin, Poland, 1 March 1995; Volume 2202, pp. 604–607. [Google Scholar]

- Pires, M.C. Plywood inlays through CO2 laser cutting. In Proceedings of the CO2 Laser and Applications, Los Angeles, CA, USA, 28 July 1989; Volume 1042, pp. 97–102. [Google Scholar]

- Kúdela, J.; Kubovský, I.; Andrejko, M. Surface properties of beechwood after CO2 laser engraving. Coatings 2020, 10, 77. [Google Scholar] [CrossRef] [Green Version]

- Kúdela, J.; Kubovský, I.; Andrejko, M. Impact of different radiation forms on beech wood discolouration. Wood Res. 2018, 63, 923–934. [Google Scholar]

- Kubovský, I.; Kačík, F.; Veľková, V. The effects of CO2 laser irradiation on color and major chemical component changes in hardwoods. Bioresources 2018, 13, 2515–2529. [Google Scholar] [CrossRef]

- Kubovský, I.; Kačík, F.; Reinprecht, L. The impact of UV radiation on the change of colour and composition of the surface of lime wood treated with a CO2 laser. J. Photochem. Photobiol. A Chem. 2016, 322, 60–66. [Google Scholar] [CrossRef]

- Kubovský, I.; Kačík, F. Colour and chemical changes of the lime wood surface due to CO2 laser thermal modification. Appl. Surf. Sci. 2014, 321, 261–267. [Google Scholar] [CrossRef]

- Sinn, G.; Chuchala, D.; Orlowski, K.; Tauble, P. Cutting model parameters from frame sawing of natural and impregnated Scots Pine (Pinus sylvestris L.). Eur. J. Wood Wood Prod. 2020, 78, 777–784. [Google Scholar] [CrossRef]

- Očkajová, A.; Kučerka, M.; Kminiak, R.; Krišťák, L’.; Igaz, R.; Réh, R. Occupational Exposure to Dust Produced When Milling Thermally Modified Wood. Int. J. Environ. Res. Public Health 2020, 17, 1478. [Google Scholar]

- Kučerka, M.; Očkajová, A. Thermowood and granularity of abrasive wood dust. Acta Fac. Xylologiae Zvolen 2018, 60, 43–51. [Google Scholar]

- Gaff, M.; Razaei, F.; Sikora, A.; Hýsek, Š.; Sedlecký, M.; Ditommaso, G.; Corleto, R.; Kamboj, G.; Sethy, A.; Vališ, M.; et al. Interactions of monitored factors upon tensile glue shear strength on laser cut wood. Compos. Struct. 2020, 234, 111679. [Google Scholar] [CrossRef]

- Martinez-Conde, A.; Krenke, T.; Frybort, S.; Muller, U. Review: Comparative analysis of CO2 laser and conventional sawing for cutting of lumber and wood-based materials. Wood Sci. Technol. 2017, 51, 943–966. [Google Scholar] [CrossRef]

- Pinkowski, A.; Krauss, A.; Sydor, M. The effect of spiral grain on energy requirement of plane milling od Scots pine (Pinus sylvestris L.) wood. Bioresources 2016, 11, 1930–2126. [Google Scholar]

- Vlckova, M.; Gejdos, M.; Nemec, M. Analysis of vibration in wood chipping process. Akustika 2017, 28, 106–110. [Google Scholar]

- Suchomel, J.; Belanova, K.; Gejdos, M.; Nemec, M.; Danihelova, A.; Maskova, Z. Analysis of Fungi in Wood Chip Storage Piles. Bioresources 2014, 9, 4410–4420. [Google Scholar] [CrossRef]

- Sydor, M.; Rogozinski, T.; Stuper-Szablewska, K.; Starczewski, K. The Accuracy of Holes Drilled in the Side Surface of Plywood. Bioresources 2020, 15, 117–129. [Google Scholar]

- Barcík, Š.; Kvietková, M.; Gašparík, M.; Kminiak, R. Influence of technological parameters on lagging size in cutting process of solid wood by abrasive water jet. Wood Res. 2013, 58, 627–636. [Google Scholar]

- Igaz, R.; Kminiak, R.; Krišťák, L’.; Němec, M.; Gergel’, T. Methodology of Temperature Monitoring in the Process of CNC Machining of Solid Wood. Sustainability 2018, 11, 95. [Google Scholar] [CrossRef] [Green Version]

- Eltawahni, H.A.; Rossini, N.S.; Dassisti, M.; Alrashed, K.; Aldaham, T.A.; Benyounis, K.Y.; Olabi, A.G. Evaluation and optimization of laser cutting parameters for plywood materials. Opt. Lasers Eng. 2013, 51, 1029–1043. [Google Scholar] [CrossRef] [Green Version]

- Orlowski, K.; Chuchala, D.; Muzinski, T.; Barariski, J.; Banski, A.; Rogozinski, T. The effect of wood drying method on the granularity of sawdust obtained during the sawing process using the frame sawing machine. Acta Fac. Xylologiae Zvolen 2019, 61, 83–92. [Google Scholar]

- Rogozinski, T.; Wilkowski, J.; Gorski, J.; Szymanowski, K.; Podziewski, P.; Czarniak, P. Technical note: Fine particles content in dust created in CNC milling of selected wood composites. Wood Fiber Sci. 2017, 49, 461–469. [Google Scholar]

- Hlaskova, L.; Orlowski, K.; Kopecky, Z.; Jedinak, M. Sawing Processes as a Way of Determining Fracture Toughness and Shear Yield Stresses of Wood. Bioresources 2015, 10, 5381–5394. [Google Scholar] [CrossRef] [Green Version]

- Marková, I.; Mračková, E.; Očkajová, A.; Ladomerský, J. Granulometry of selected wood dust species of dust from orbital sanders. Wood Res. 2016, 61, 983–992. [Google Scholar]

- Igaz, R.; Gajtanska, M. The influence of water vapour concentration in CO2 laser active region on output power of emited beam. Acta Fac. Tech. 2014, 19, 35–40. [Google Scholar]

- Gajtanska, M.; Igaz, R.; Krišťák, L’.; Ružiak, I. Contamination of CO2 Laser Mixture; Technical University in Zvolen Publishing: Zvolen, Slovakia, 2014. [Google Scholar]

- Gajtanska, M.; Suja, J.; Igaz, R.; Krišťák, L’.; Ružiak, I. CO2 Laser Cutting of Spruce Wood; Technical University in Zvolen Publishing: Zvolen, Slovakia, 2015. [Google Scholar]

- Antov, P.; Neykov, N. Costs of occupational accidents in the Bulgarian woodworking and furniture industry. In Proceedings of the 3rd International Scientific Conference Wood Technology & Product Design, Ohrid, Republic of Macedonia, 11–14 September 2017; Volume III, pp. 213–221. [Google Scholar]

- Brezin, V.; Antov, P. Engineering Ecology, 1st ed.; Publishing House of the UF: Sofia, Bulgaria, 2015; 259p. [Google Scholar]

- Li, L.; Mazumder, J. A study of the mechanism of laser cutting of wood. For. Prod. J. 1992, 41, 53–59. [Google Scholar]

- Barnekov, V.G.; Huber, H.A.; McMillin, C.W. Laser machining wood composites. For. Prod. J. 1989, 39, 76–78. [Google Scholar]

- Grad, L.; Mozina, J. Optodynamic studies of Er: YAG laser interaction with wood. Appl. Surf. Sci. 1998, 127, 973–986. [Google Scholar] [CrossRef]

- Hattori, N. Laser processing of wood. Mokuzai Gakkaishi 1995, 41, 703–709. [Google Scholar]

- Riveiro, A.; Quintero, F.; Boutinguiza, M.; del Val, J.; Comesana, R.; Lusquinos, F.; Pou, J. Laser Cutting: A Review on the Influence of Assist Gas. Materials 2019, 12, 157. [Google Scholar] [CrossRef] [Green Version]

- Piili, H.; Hirvikaki, M.; Salminen, A. Repeatability of laser cutting of uncoated and coated boards. In Proceedings of the NOLAMP, Copenhagen, Denmark, 24–26 August 2009. [Google Scholar]

- Lum, K.C.P.; Hg, S.L.; Black, I. CO2 laser cutting of MDF: Determination of process parameter settings. Opt. Laser Technol. 2000, 32, 67–76. [Google Scholar] [CrossRef]

- Powell, J. CO2 Laser Cutting, 2nd ed.; Springer-Verlag: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Eltawahni, H.A.; Olabi, A.G.; Benyounis, K.Y. Investigating the CO2 laser cutting parameters of MDF wood composite material. Opt. Laser Technol. 2011, 43, 648–659. [Google Scholar] [CrossRef] [Green Version]

- Barnekov, V.G.; McMillin, C.W.; Huber, H.A. Factors influencing laser cutting of wood. For. Prod. J. 1986, 36, 55–58. [Google Scholar]

- Lum, K.C.P.; Hg, S.L.; Black, I. CO2 laser cutting of MDF, Estimation of power distribution. J. Opt. Laser Technol. 2000, 32, 77–87. [Google Scholar] [CrossRef]

- Antov, P.; Mantanis, G.I.; Savov, V. Development of Wood Composites from Recycled Fibres Bonded with Magnesium Lignosulfonate. Forests 2020, 11, 613. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Mantanis, G.; Neykov, N. Medium-density fibreboards bonded with phenol-formaldehyde resin and calcium lignosulfonate as an eco-friendly additive. J. Wood Mater. Sci. Eng. 2020. [Google Scholar] [CrossRef]

- Tayal, M.; Barnekov, V.; Mukherjee, K. Focal point location in laser machining of thick hard wood. J. Mater. Sci. Lett. 1994, 13, 644–646. [Google Scholar] [CrossRef]

- Nukman, Y.; Saiful, R.I.; Azuddin, M.; Aznijar, A.Y. Selected Malaysian Wood CO2 Laser Cutting Parameters and Cut Quality. Am. J. Appl. Sci. 2008, 5, 990–996. [Google Scholar]

- McMillin, W.C.; Harry, J.E. Laser Machining of Southern Pine. For. Prod. J. 1971, 21, 24–37. [Google Scholar]

- Quintero, F.; Riveiro, A.; Lusquinos, F.; Comesana, R.; Pou, J. CO2 laser cutting of phenolic resin boards. J. Mater. Process. Technol. 2011, 211, 1710–1718. [Google Scholar] [CrossRef]

- Quintero, F.; Riveiro, A.; Lusquinos, F.; Comesana, R.; Pou, J. Feasibility study on the laser cutting of phenolic resin boards. Phys. Procedia 2011, 12, 578–583. [Google Scholar] [CrossRef] [Green Version]

- Zhou, B.H.; Mahdavian, S.M. Experimental and theoretical analyses of cutting nonmetallic materials by low power CO2 laser. J. Mater. Process. Technol. 2004, 146, 188–192. [Google Scholar] [CrossRef]

- Moradi, M.; Mehrabi, O.; Azdast, T.; Benyounis, K.Y. Enhancement of low power CO2 laser cutting process for injection molded polycarbonate. Opt. Laser Technol. 2017, 96, 208–218. [Google Scholar] [CrossRef]

- Choudhury, I.A.; Shirley, S. Laser cuting of polymeric materials: An experimental investigation. Opt. Laser Technol. 2010, 42, 503–508. [Google Scholar] [CrossRef]

- Yang, C.B.; Deng, C.S.; Chiang, H.L. Combining the Taguchi method with artificial neural network to construct a prediction model of a CO2 laser cutting experiment. Int. J. Adv. Manuf. Technol. 2012, 59, 1103–1111. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Shehabeldeen, T.A.; Zhou, J.; Showaib, E.; Elaziz, M.A. Prediction of laser cutting parameters for polymethylmethacrylate sheets using random vector functional link network integrated with equilibrium optimizer. J. Intell. Manuf. 2020. [Google Scholar] [CrossRef]

- Alizadeh, A.; Omrani, H. An integrated multi response Taguchi- neural network- robust data envelopment analysis model for CO2 laser cutting. Measurement 2019, 131, 69–78. [Google Scholar] [CrossRef]

- Dubey, A.K.; Yadava, V. Laser beam machining: A review. Int. J. Mach. Tools Manuf. 2008, 48, 609–628. [Google Scholar] [CrossRef]

- Radovanovic, M.; Madic, M. Experimental investigations of CO2 laser cut quality: A review. Nonconv. Technol. Rev. 2011, 4, 35–42. [Google Scholar]

- Hernandez-Castaneda, C.J.; Sezer, K.H.; Li, L. The effect of moisture content in fibre laser cutting of pine wood. Opt. Lasers Eng. 2011, 49, 1139–1152. [Google Scholar] [CrossRef]

- Prakash, S.; Kumar, S. Experimental investigation and analytical modeling of multi-pass CO2 laser processing on PMMA. Precis. Eng. 2017, 49, 220–234. [Google Scholar] [CrossRef]

- Jianying, S.; Yun, Z. FEM Simulation Technologies of Laser Cutting Wood Board Based on ANSYS. Adv. Mater. Res. 2010, 113, 1629–1631. [Google Scholar]

- Polak, M.; Chmelickova, H.; Vasicek, L. Numerical modeling of laser treatment of metal and nonmetal materials. In Proceedings of the 13th Polish-Czech-Slovak Conference on Wave and quantum Aspects of Contemporary Optics, Krzyzowa, Poland, 21 November 2003; Volume 5259, pp. 303–307. [Google Scholar] [CrossRef]

- Yang, C.; Jiang, T.; Yu, Y.; Dun, G.; Ma, Y.; Liu, J. Study of surface quality of wood processed by water-jet assisted nanosecond laser. Bioresources 2018, 13, 3125–3134. [Google Scholar] [CrossRef]

- Yang, C.; Jiang, T.; Yu, Y.; Bai, Y.; Song, M.; Miao, Q.; Ma, Y.; Liu, J. Water-jet assisted nanosecond laser microcutting of norheast China ash wood: Experimental study. Bioresources 2019, 14, 128–138. [Google Scholar]

- Hardalov, C.M.; Christov, C.G.; Mihalev, M.S. Numerical modeling of laser machining on the ceramic surface. AU J. Technol. 2006, 9, 163–171. [Google Scholar]

- Modest, F.M. Laser Machining of Ablating/Decomposing Materials–Through Cutting and Drilling Models; ICALEO: Quebec, Canada, 1996. [Google Scholar]

- Roggero, G.; Scotti, F.; Piuri, V. Quality analysis measurement for laser cutting. In Proceedings of the 2001 International Workshop on Virtual and Intelligent Measurement Systems, Budapest, Hungary, 20–20 May 2001. [Google Scholar]

- Bianco, N.; Manca, O.; Nardini, S.; Tamburino, S. Transient Heat Conduction in Solids Irradiated by a Moving Heat Source. Defect Diffus. Forum 2009, 283, 358–363. [Google Scholar] [CrossRef]

- Babiak, M.; Orech, J.; Kleskeňová, M. Temperature distribution in wood heated by scanning gaussian laser beam. Wood Res. 1986, 108, 1–15. [Google Scholar]

- Yilbas, B. Laser Cutting Qualitz Assesment and Thermal Efficiency Analysis. J. Mater. Process. Technol. 2004, 155, 2106–2115. [Google Scholar] [CrossRef]

- ISO 13061-1:2014. Physical and Mechanical Properties of Wood. Test Methods for Small Clear Wood Specimens. Part 1: Determinantion of Moisture Content for Physical and Mechanical Tests; International Organization for Standardization: Geneva, Swittzerland, 2014. [Google Scholar]

- ISO 13061-2:2014. Physical and Mechanical Properties of Wood. Test Methods for Small Clear Wood Specimens. Part 2: Determination of Density for Physical and Mechanical Tests; International Organization for Standardization: Geneva, Swittzerland, 2014. [Google Scholar]

- Dhanachandra, N.; Manglem, K.; Chanu, Y.J. Image Segmentation Using K–means Clustering Algorithm and Subtractive Clustering Algorithm. Procedia Comput. Sci. 2015, 54, 764–771. [Google Scholar] [CrossRef] [Green Version]

- Moallem, P.; Razmjooy, N. Adaptive Particle Swarm Optimization. J. Appl. Res. Technol. 2012, 5, 703–712. [Google Scholar]

- Ready, J.F.; Farson, D.F.; Feeley, T. LIA Handbook of Laser Materials Processing; Laser Institute of America, Magnolia Publishing: Orlando, FL, USA; Springer Nature: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Liu, Q.; Yang, C.; Xue, B.; Miao, Q.; Liu, J. Processing Technology and Experimental Analysis of Gas-assisted Laser Cut Micro Thin Wood. Bioresources 2020, 15, 5366–5378. [Google Scholar]

- Asibu, E.K. Principles of Laser Materials Processing; John Wiley and Sons: New York, NY, USA, 2009. [Google Scholar]

- Arai, T.; Hayashi, D. Factors affecting the Laser processing of wood. 1. Effects of mechanical laser parameters on machinability. Mokuzai Gakkaishi 1992, 38, 350–356. [Google Scholar]

- Arai, T.; Hayashi, D. Factors affecting the Laser processing of wood. 2. Effects of material parameters on machinability. Mokuzai Gakkaishi 1994, 40, 497–503. [Google Scholar]

- Peters, C.C.; Banas, C.M. Cutting wood and wood-base products with a multikilowatt CO2 laser. For. Prod. J. 1977, 27, 41–45. [Google Scholar]

- Pędzik, M.; Bednarz, J.; Kwidziński, Z.; Rogoziński, T.; Smardzewski, J. The Idea of Mass Customization in the Door Industry Using the Example of the Company Porta KMI Poland. Sustainability 2020, 12, 3788. [Google Scholar] [CrossRef]

- Potkany, M.; Gejdoš, M.; Debnár, M. Sustainable Innovation Approach for Wood Quality Evaluation in Green Business. Sustainability 2018, 10, 2984. [Google Scholar] [CrossRef] [Green Version]

- Němec, F.; Lorincová, S.; Hitka, M.; Turinská, L. The Storage Area Market in the Particular Territory. Nase More 2015, 62, 131–138. [Google Scholar] [CrossRef] [Green Version]

- Lorincová, S.; Schmidtová, J.; Balážová, Z. Perception of the corporate culture by managers and blue collar workers in Slovak wood-processing businesses. Acta Fac. Xylologiae Zvolen 2016, 58, 149–163. [Google Scholar]

- Potkany, M.; Hitka, M. Utilization of contribution margin in the costing system in the production of components for wood working machines. Drv. Ind. 2009, 60, 101–110. [Google Scholar]

| Factor | Min. Value | Max. Value | Levels Number | Factor Levels | Unit | Type |

|---|---|---|---|---|---|---|

| AR | 3 | 11 | 9 | 3, 4, 5, 6, 7, 8, 9, 10, 11 | - | random |

| P | 100 | 150 | 2 | 100, 150 | W | controlled |

| V | 3 | 9 | 3 | 3, 6, 9 | mm·s−1 | controlled |

| Reaction | Box-Cox Transformation |

|---|---|

| WKU* | 1 + (WKU−0.569 − 1)/(−0.569·0.847226−1.569) |

| WHAZU* | 1 + (WHAZU0.134 − 1)/(0.134·0.172185−0.866) |

| WKD* | 1 + (WKD0.206 − 1)/(0.206·0.460085−0.794) |

| WHAZD* | 1 + (WHAZD−0.605 − 1)/(−0.605·0.169228−1.605) |

| WKR* | 1 + (WKR0.372 − 1)/(0.372·0.543049−0.628) |

| B* | 1 + (B2.049 − 1)/(2.049·46.42581.049) |

| WKU* | WHAZU* | WKD* | WHAZD* | WKR* | B* | |

|---|---|---|---|---|---|---|

| Average | 0.8566 | 0.1741 | 0.5524 | 0.2192 | 0.6337 | 0.4688 |

| Standard deviation | 0.1761 | 0.0657 | 0.2093 | 0.1471 | 0.1709 | 0.0079 |

| Variation coefficient | 20.55% | 37.75% | 37.88% | 67.14% | 26.97% | 16.74% |

| Displacement coefficient | −0.42 | 2.344 | 1.964 | 4.685 | 1.452 | −1.328 |

| Peak coefficient | −1.256 | −0.1885 | −0.5222 | 2.288 | −1.079 | −0.657 |

| 95% confidence interval for the average | <0.8085; 0.9046> | <0.1561; 0.1920> | <0.4953; 0.6095> | <0.1179; 0.2593> | <0.5870; 0.6803> | <0.4474; 0.4902> |

| 95% confidence interval for the standard deviation | <0.148; 0.2174> | <0.0553; 0.0811> | <0.1759; 0.2583> | <0.1237; 0.1816> | <0.1437; 0.2110> | <0.0660; 0.0969> |

| Response | WKU* | WHAZU* | WKD* | WHAZD* | WKR* | B* |

|---|---|---|---|---|---|---|

| Factor | Coeff. | Coeff. | Coeff. | Coeff. | Coeff. | Coeff. |

| AR | 0.0031 | 0.0021 | −0.0112 | 0.0003 | −0.0177 | 0.00487 |

| P | 0.1762 | 0.0451 | 0.3501 | 0.2583 | 0.2847 | −0.05437 |

| V | −0.0586 | 0.0168 | −0.061 | −0.0110 | −0.0304 | −0.00415 |

| Constant | 0.9691 | 0.5613 | 0.6486 | 0.5189 | 0.5699 | 0.22126 |

| R2 | 71.76% | 49.14% | 84.65% | 46.51% | 46.74% | 2.73% |

| Response | WKU* | WHAZU* | WKD* | WHAZD* | WKR* | B* |

|---|---|---|---|---|---|---|

| Factor | Coeff. | Coeff. | Coeff. | Coeff. | Coeff. | Coeff. |

| AR | −0.05862 | 0.02398 | 0.06392 | 0.01209 | 0.10382 | −0.03579 |

| P | −0.29207 | 0.19104 | 0.81739 | 0.00574 | 1.17681 | −0.51849 |

| V | −0.25323 | 0.08067 | 0.03693 | −0.05375 | 0.23656 | −0.15057 |

| AR2 | 0.00526 | −0.00142 | 0.00034 | −0.00349 | −0.00263 | 0.00107 |

| AR*P | −0.00745 | 0.00257 | −0.05651 | 0.02135 | −0.05468 | 0.01333 |

| AR*V | 0.00032 | −0.00108 | −0.00208 | 0.00121 | −0.00352 | 0.00172 |

| P*V | 0.08847 | −0.02749 | −0.02015 | 0.01778 | −0.09821 | 0.06385 |

| V2 | 0.00695 | −0.00193 | −0.00489 | 0.00099 | −0.09964 | 0.00467 |

| Constant | 1.96353 | 0.23073 | −0.13999 | −0.78817 | −1.01551 | 1.04444 |

| R2 | 85.88% | 56.49% | 87.93% | 50.50% | 62.53% | 29.40% |

| Parameter | Goal | Cutting Kerf Width (mm) Reference | Cutting Kerf Width (mm) Optimal | Improvement (%) |

|---|---|---|---|---|

| WKU* | min | 0.715 | 0.627 | 12.3 |

| WKD* | min | 0.591 | 0.416 | 29.6 |

| WKR* | 1 | 0.528 | 0.670 | 21.1 |

| WHAZU* | min | 0.786 | 0.764 | 2.7 |

| WHAZD* | min | 0.808 | 0.679 | 16 |

| B* | min | 0.117 | 0.144 | - |

| Goal | Cutting Kerf Width (mm) | Suitability | AR | P (W) | V (mm·s−1) | |

|---|---|---|---|---|---|---|

| WKU* (WKU) | min | 0.627 (0.565) | 0.92 | 3 | 100 | 9 |

| WKD* (WKD) | min | 0.327 (0.334) | 0.92 | 11 | 100 | 9 |

| WKR* (WKR) | 1 | 0.853 (0.853) | 0.92 | 3 | 150 | 3 |

| WHAZU* (WHAZU) | min | 0.663 (0.113) | 0.92 | 3 | 100 | 3 |

| WHAZD* (WHAZD) | min | 0.679 (0.093) | 0.88 | 3 | 100 | 9 |

| B* (B) | min | 0.117 (33.245) | 0.69 | 3 | 150 | 9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kubovský, I.; Krišťák, Ľ.; Suja, J.; Gajtanska, M.; Igaz, R.; Ružiak, I.; Réh, R. Optimization of Parameters for the Cutting of Wood-Based Materials by a CO2 Laser. Appl. Sci. 2020, 10, 8113. https://doi.org/10.3390/app10228113

Kubovský I, Krišťák Ľ, Suja J, Gajtanska M, Igaz R, Ružiak I, Réh R. Optimization of Parameters for the Cutting of Wood-Based Materials by a CO2 Laser. Applied Sciences. 2020; 10(22):8113. https://doi.org/10.3390/app10228113

Chicago/Turabian StyleKubovský, Ivan, Ľuboš Krišťák, Juraj Suja, Milada Gajtanska, Rastislav Igaz, Ivan Ružiak, and Roman Réh. 2020. "Optimization of Parameters for the Cutting of Wood-Based Materials by a CO2 Laser" Applied Sciences 10, no. 22: 8113. https://doi.org/10.3390/app10228113

APA StyleKubovský, I., Krišťák, Ľ., Suja, J., Gajtanska, M., Igaz, R., Ružiak, I., & Réh, R. (2020). Optimization of Parameters for the Cutting of Wood-Based Materials by a CO2 Laser. Applied Sciences, 10(22), 8113. https://doi.org/10.3390/app10228113