Thermal Exchange and Skid Resistance of Chip Seal with Various Aggregate Types and Morphologies

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

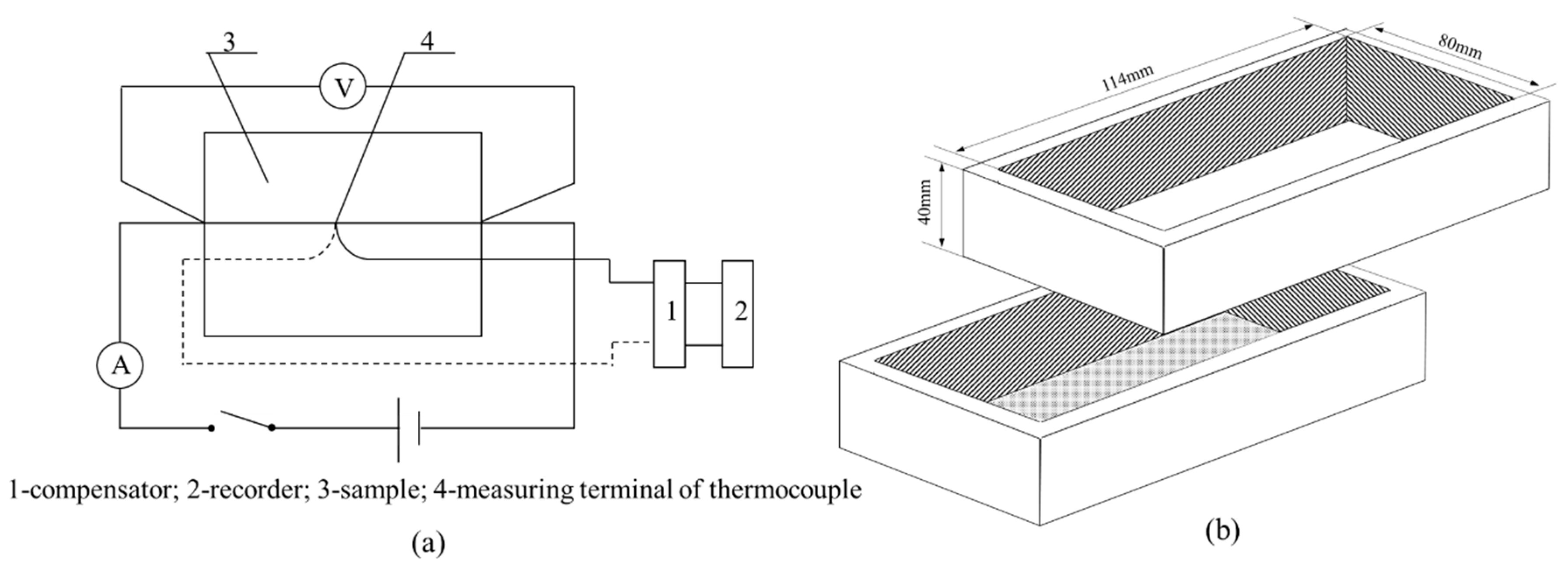

2.2. Thermal Conductivity and Chemical Composition of Aggregate

2.3. Thermal Exchange of Chip Seal

2.4. Aggregate Morphology Features

2.5. Performance of Chip Seal

2.5.1. Surface Features

2.5.2. Aggregate Retention Performance

3. Results and Discussion

3.1. Properties of Aggregates

3.1.1. Thermal Behavior

3.1.2. Chemical and Phase Compositions

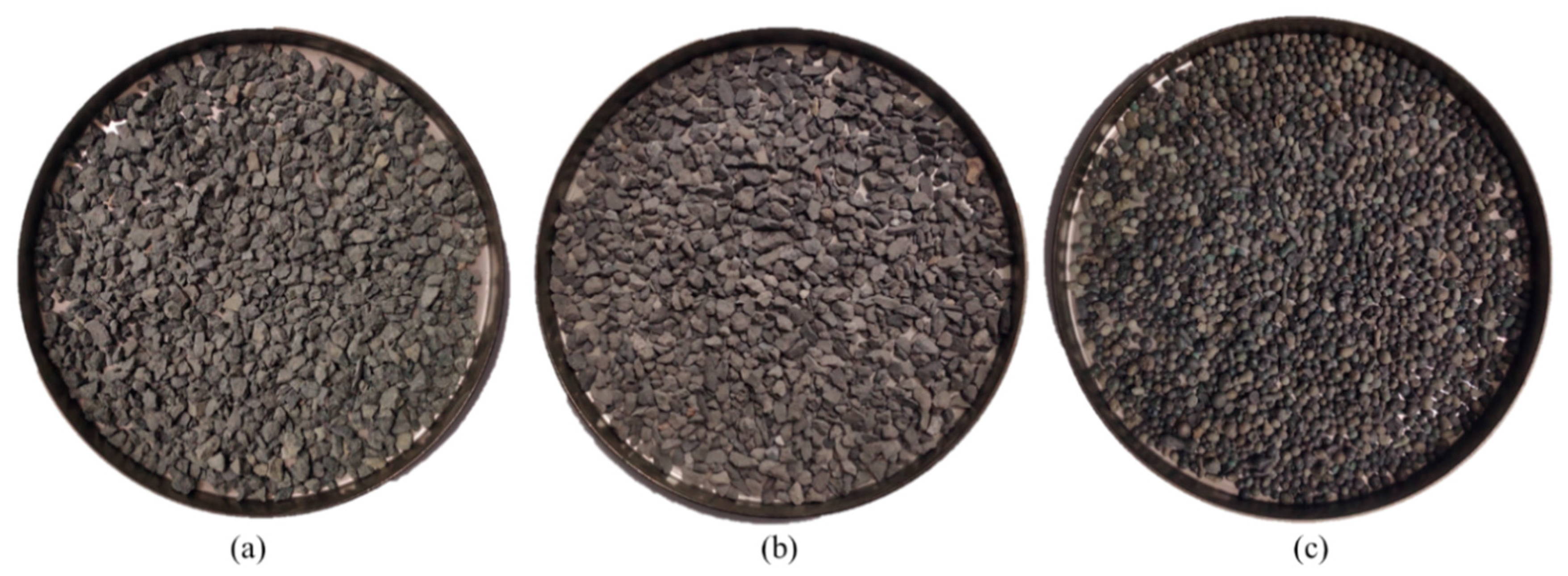

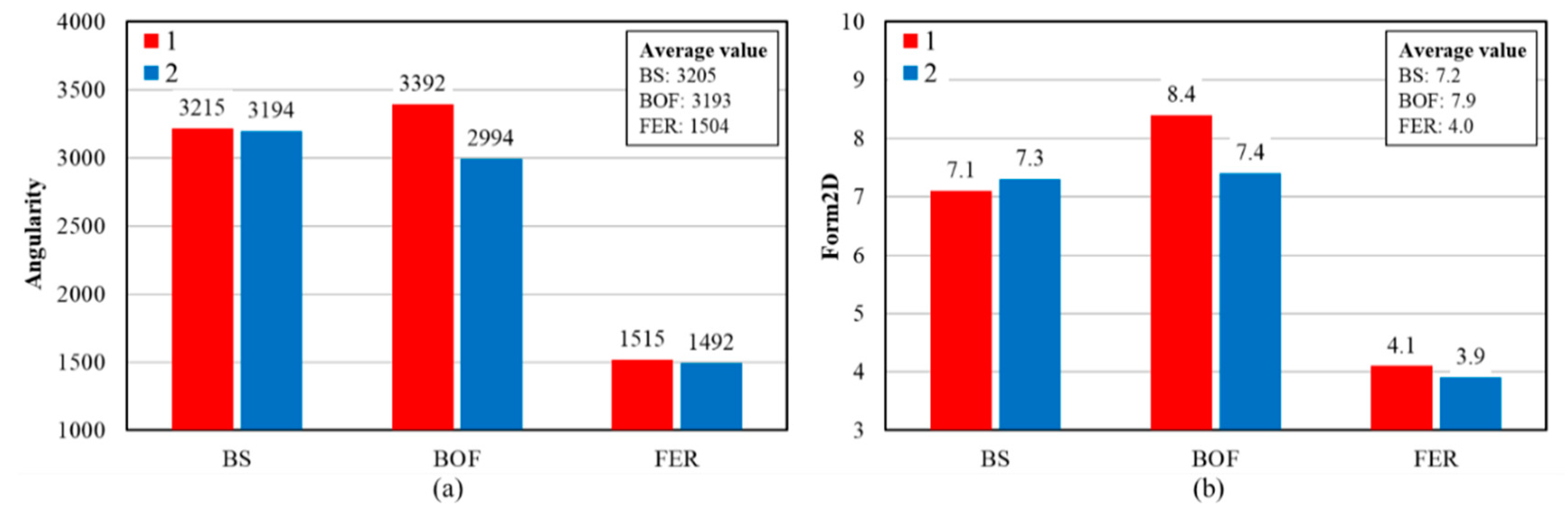

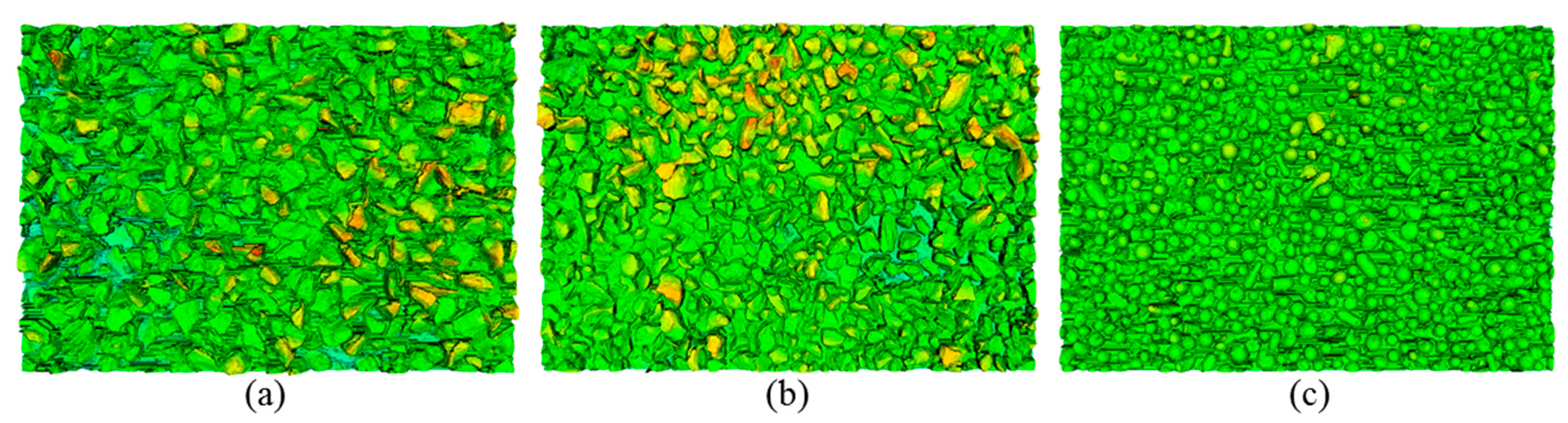

3.1.3. Morphology

3.2. Properties of Chip Seal

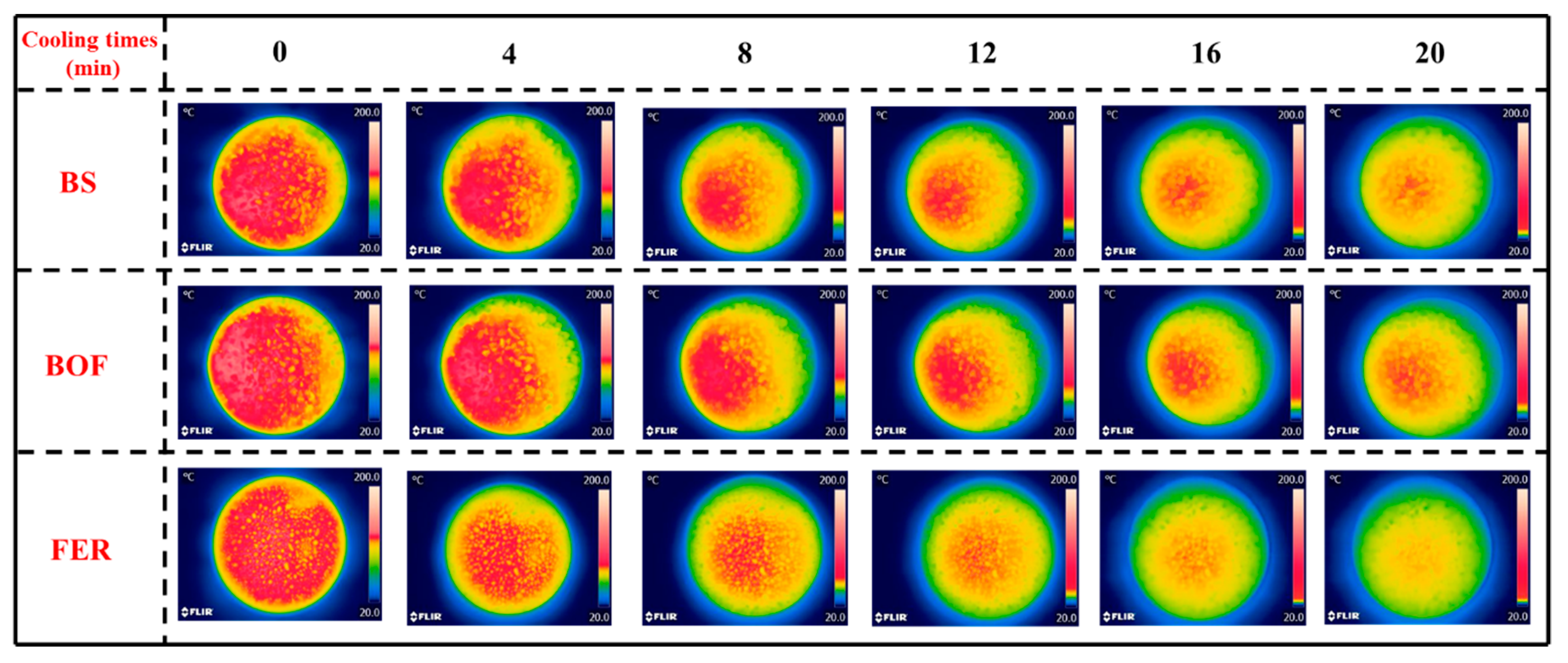

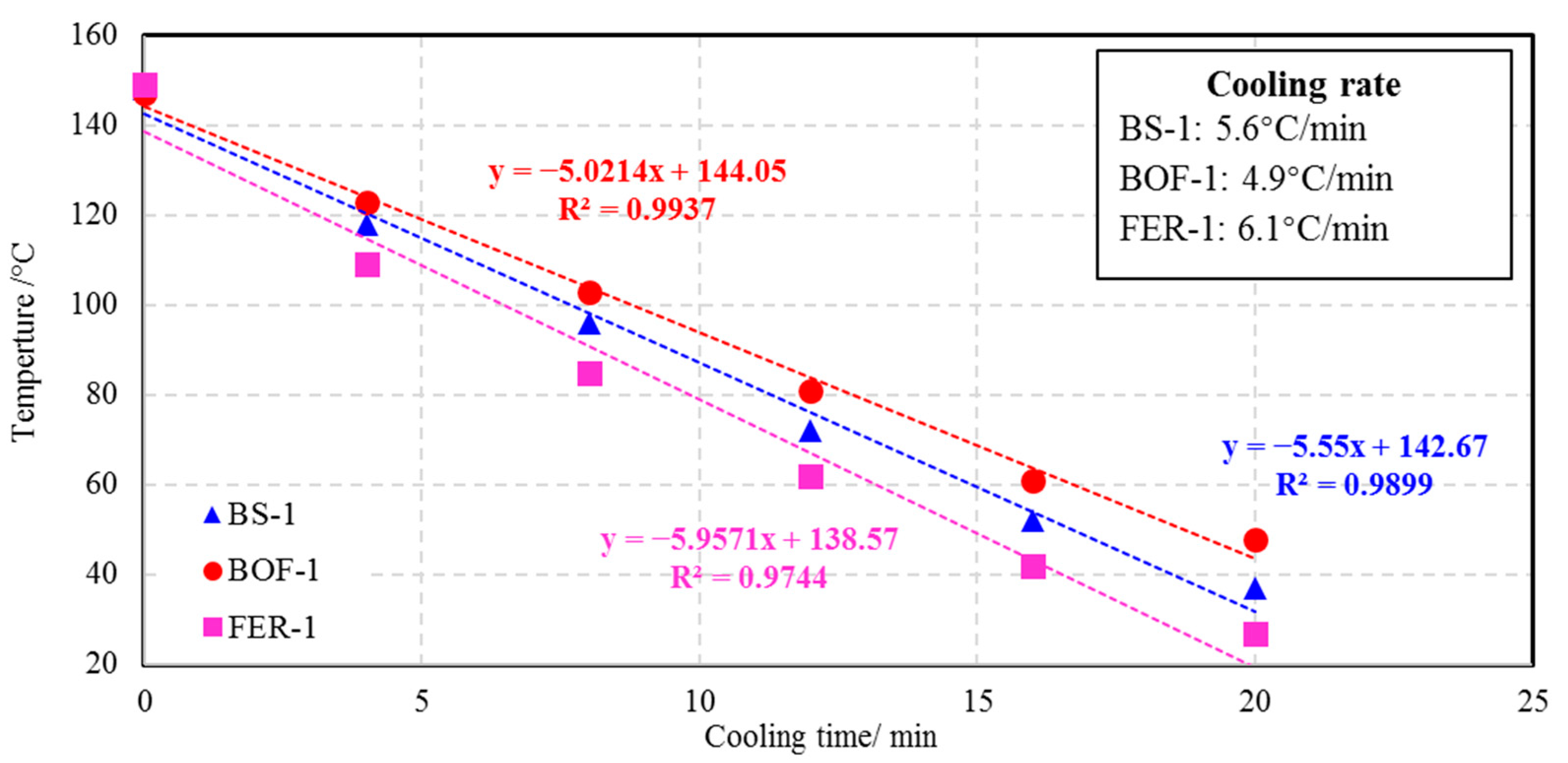

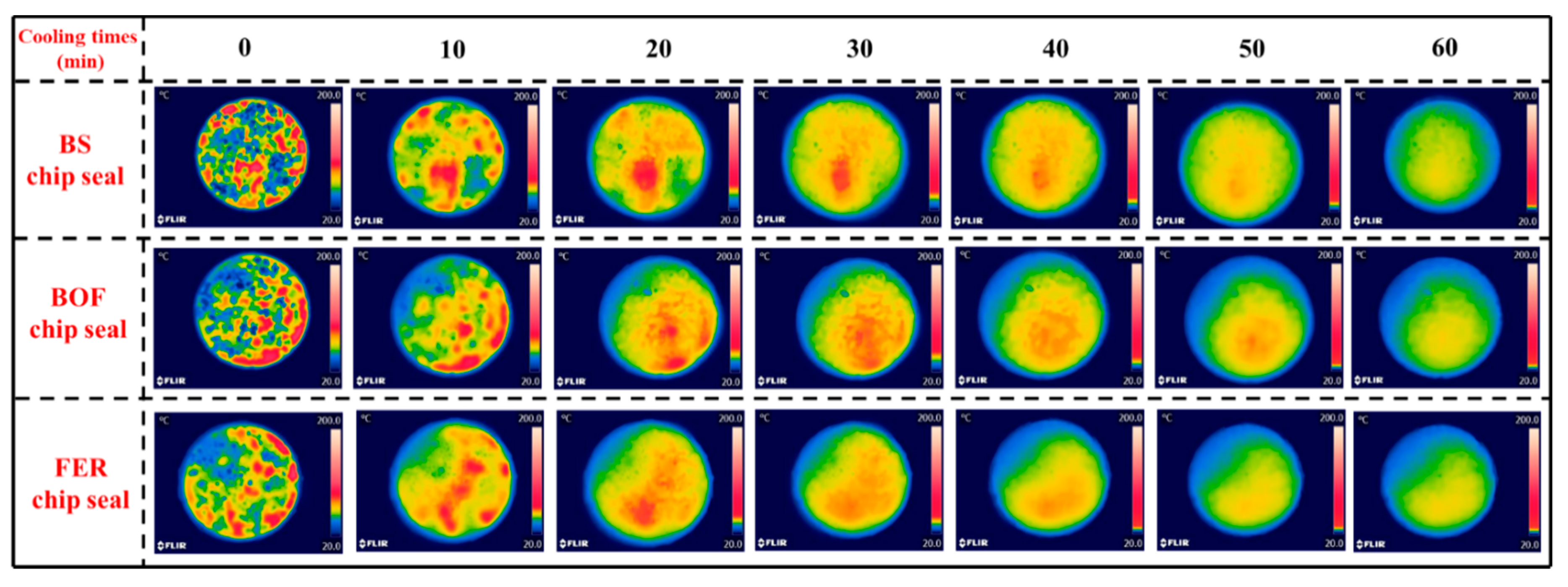

3.2.1. Thermal Exchange of Chip Seal

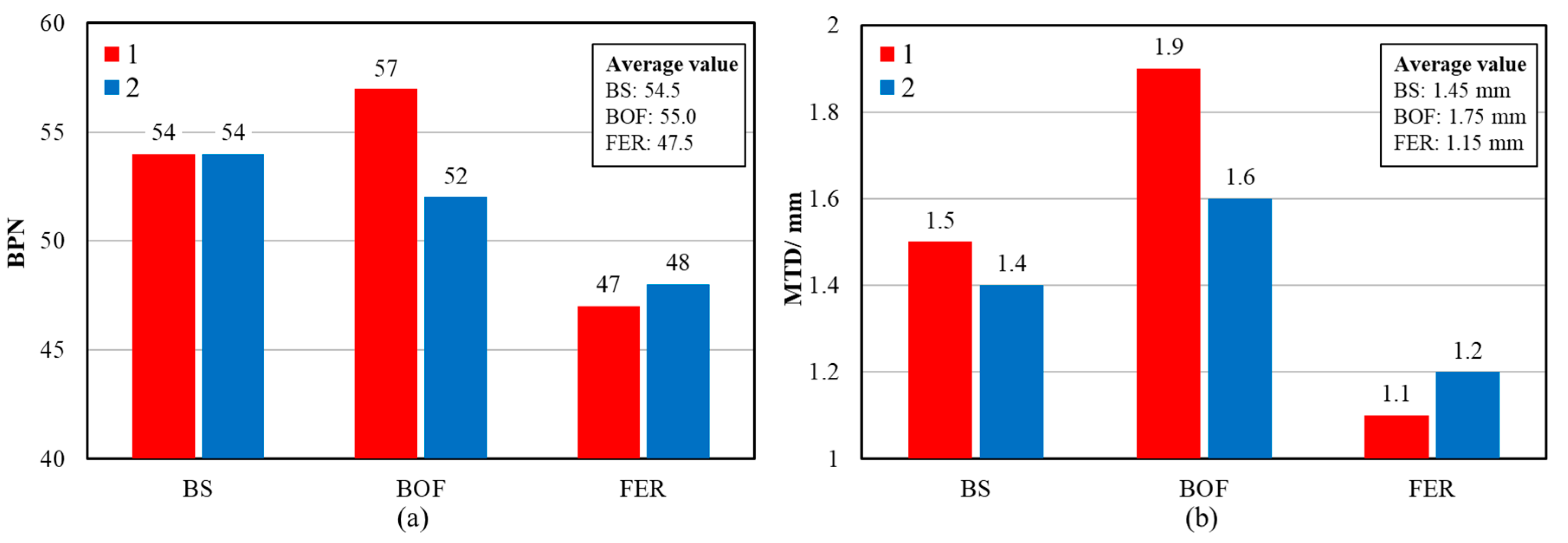

3.2.2. BPN and Texture Depth

3.2.3. Aggregate Loss

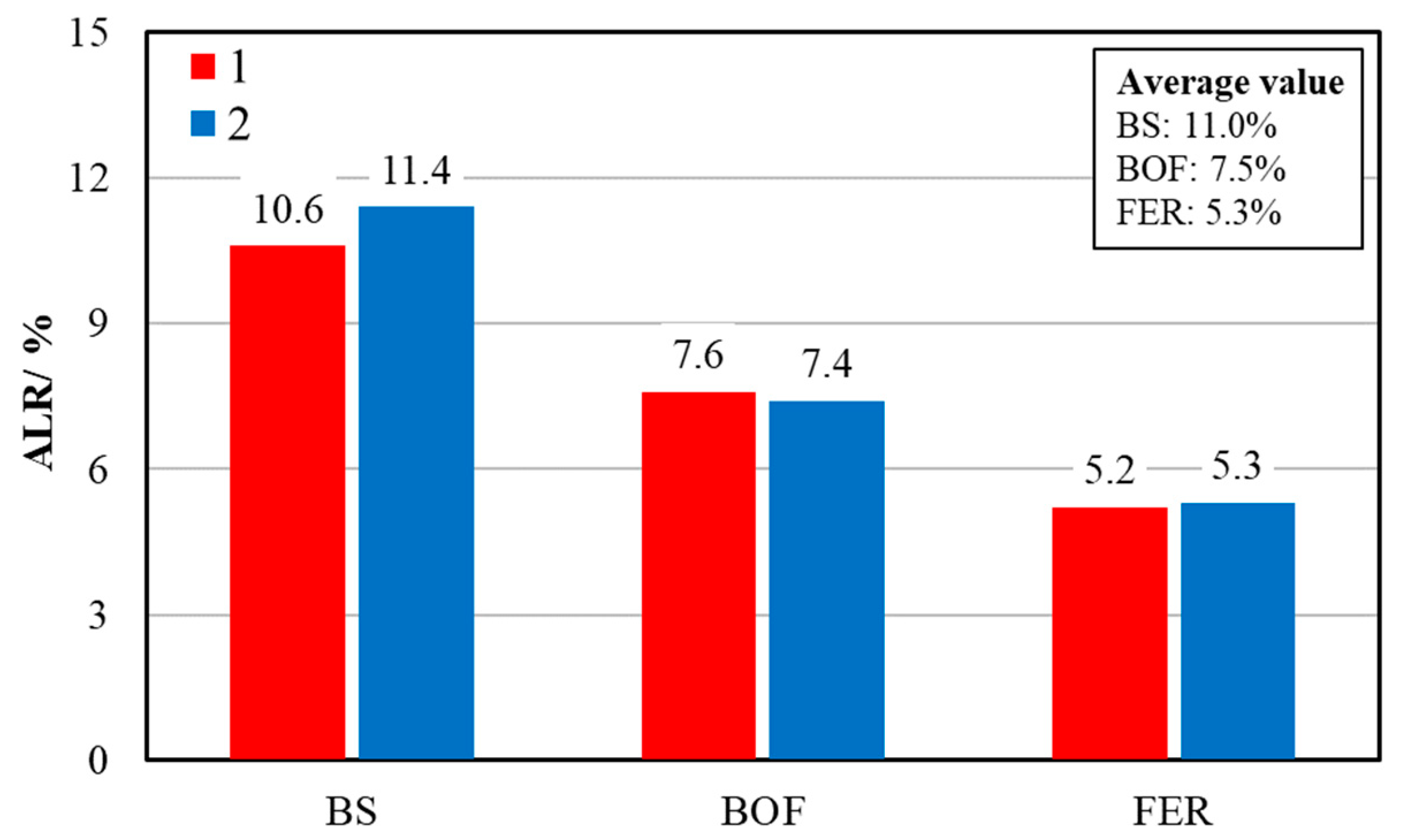

4. Conclusions

- The relative ranking of aggregate types according to thermal conductivity places BOF slag as the lowest and FER slag as the highest, with the basalt falling in between. The differences in thermal behavior can be attributed to the various chemical compositions.

- The morphologies of FER slag are more rounded and circular than those of the BS and BOF slag due to the air-granulated treatment methods, and BOF slag has the most abundant morphological features among the aggregates.

- The thermal exchange performances of chip seal made of FER slag are better than those of BOF slag and basalt. The recycling of FER slag as aggregate in chip seal can allow the chip seal to resume traffic about ten minutes earlier than original samples.

- The BPN and MTD values of chip seal made of FER slag are the worst among the three kinds of aggregate. However, they still meet the requirements of the specification, although they are less than those of ordinary aggregates.

- FER slag offers the best aggregate retention performance due to its spherical particles and alkaline surface. It can reduce the friction force and strengthen the interface bond between aggregate and asphalt.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xue, Y.; Wu, S.; Hou, H.; Zha, J. Experimental investigation of basic oxygen furnace slag used as aggregate in asphalt mixture. J. Hazard. Mater. 2006, 138, 261–268. [Google Scholar] [CrossRef] [PubMed]

- Amelian, S.; Manian, M.; Abtahi, S.M.; Goli, A. Moisture sensitivity and mechanical performance assessment of warm mix asphalt containing by-product steel slag. J. Clean. Prod. 2018, 176, 329–337. [Google Scholar] [CrossRef]

- Skaf, M.; Manso, J.M.; Aragon, A.; Fuente-Alonso, J.A.; Ortega-Lopez, V. Eaf slag in asphalt mixes: A brief review of its possible re-use. Resour. Conserv. Recycl. 2017, 120, 176–185. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Sengoz, B. Evaluation of steel slag coarse aggregate in hot mix asphalt concrete. J. Hazard. Mater. 2009, 165, 300–305. [Google Scholar] [CrossRef]

- Jiao, W.X.; Sha, A.M.; Liu, Z.Z.; Jiang, W.; Hu, L.Q.; Li, X.Z. Utilization of steel slags to produce thermal conductive asphalt concretes for snow melting pavements. J. Clean. Prod. 2020, 261, 121197. [Google Scholar] [CrossRef]

- Wan, J.M.; Wu, S.P.; Xiao, Y.; Fang, M.J.; Song, W.; Pan, P.; Zhang, D. Enhanced ice and snow melting efficiency of steel slag based ultra-thin friction courses with steel fiber. J. Clean. Prod. 2019, 236, 117613. [Google Scholar] [CrossRef]

- Fang, F.T.; Chong, Y.C.; Nyunt, T.T.; Loi, S.S. Development of environmentally sustainable pavement mix. Int. J. Pavement Res. Technol. 2013, 6, 440–446. [Google Scholar]

- Kehagia, F. Skid resistance performance of asphalt wearing courses with electric arc furnace slag aggregates. Waste Manag. Res. 2009, 27, 288–294. [Google Scholar] [CrossRef]

- Aziz, M.M.A.; Hainin, M.R.; Yaacob, H.; Ali, Z.; Chang, F.L.; Adnan, A.M. Characterisation and utilisation of steel slag for the construction of roads and highways. Mater. Res. Innov. 2014, 18, 255–259. [Google Scholar] [CrossRef]

- Kavussi, A.; Qazizadeh, M.J. Fatigue characterization of asphalt mixes containing electric arc furnace (eaf) steel slag subjected to long term aging. Constr. Build. Mater. 2014, 72, 158–166. [Google Scholar] [CrossRef]

- Cui, P.; Wu, S.; Xiao, Y.; Wang, F.; Wang, F. Quantitative evaluation of active based adhesion in aggregate-asphalt by digital image analysis. J. Adhes. Sci. Technol. 2019, 33, 1544–1557. [Google Scholar] [CrossRef]

- Ji, X.; Hou, J.; Liu, Y.; Liu, J. Effect of cao-feo-mno system solid solution on the hydration activity of tri-component f-cao in steel slag. Constr. Build. Mater. 2019, 225, 476–484. [Google Scholar] [CrossRef]

- Wan, J.; Wu, S.; Xiao, Y.; Chen, Z.; Zhang, D. Study on the effective composition of steel slag for asphalt mixture induction heating purpose. Constr. Build. Mater. 2018, 178, 542–550. [Google Scholar] [CrossRef]

- Ameri, M.; Hesami, S.; Goli, H. Laboratory evaluation of warm mix asphalt mixtures containing electric arc furnace (eaf) steel slag. Constr. Build. Mater. 2013, 49, 611–617. [Google Scholar] [CrossRef]

- Wasiuddin, N.M.; Marshall, A.; Saltibus, N.E.; Saber, A.; Abadie, C.; Mohammad, L.N. Use of sweep test for emulsion and hot asphalt chip seals: Laboratory and field evaluation. J. Test. Eval. 2013, 41, 289–298. [Google Scholar] [CrossRef]

- Mcleod, N.W. A general method of design for seal coats and surface treatments. Proc. Assoc. Asph. Paving Technol. 1969, 38, 1969. [Google Scholar]

- Xiao, Y.; Wang, F.; Cui, P.; Lei, L.; Lin, J.; Yi, M. Evaluation of fine aggregate morphology by image method and its effect on skid-resistance of micro-surfacing. Materials 2018, 11, 920. [Google Scholar] [CrossRef]

- Cui, P.; Xiao, Y.; Yan, B.; Li, M.; Wu, S. Morphological characteristics of aggregates and their influence on the performance of asphalt mixture. Constr. Build. Mater. 2018, 186, 303–312. [Google Scholar] [CrossRef]

- Bessa, I.S.; Castelo Branco, V.T.F.; Soares, J.B.; Nogueira Neto, J.A. Aggregate shape properties and their influence on the behavior of hot-mix asphalt. J. Mater. Civ. Eng. 2015, 27, 04014212. [Google Scholar] [CrossRef]

- Bessa, I.S.; Franco Castelo Branco, V.T.; Soares, J.B. Evaluation of polishing and degradation resistance of natural aggregates and steel slag using the aggregate image measurement system. Road Mater. Pavement Des. 2014, 15, 385–405. [Google Scholar] [CrossRef]

- Kumbargeri, Y.S.; Boz, I.; Kutay, M.E. Investigating the effect of binder and aggregate application rates on performance of chip seals via digital image processing and sweep tests. Constr. Build. Mater. 2019, 222, 213–221. [Google Scholar] [CrossRef]

- Lee, J.; Lee, J.; Kim, Y.R.; Mun, S. A comparison study of friction measurements for chip seal. J. Test. Eval. 2012, 40, 603–611. [Google Scholar] [CrossRef]

- Kumbargeri, Y.; Boz, I.; Kutay, M.E.; Heidelberg, A. A study on the effects of aggregate shape and percent embedment on chip seal performance via image-based finite element analysis. Int. J. Pavement Eng. 2019, 21, 1002–1011. [Google Scholar] [CrossRef]

- Zhao, Z.G.; Qu, X.L.; Li, F.X.; Wei, J.X. Effects of steel slag and silica fume additions on compressive strength and thermal properties of lime-fly ash pastes. Constr. Build. Mater. 2018, 183, 439–450. [Google Scholar] [CrossRef]

- Xu, H.; Wu, S.; Li, H.; Zhao, Y.; Lv, Y. Study on recycling of steel slags used as coarse and fine aggregates in induction healing asphalt concretes. Materials 2020, 13, 889. [Google Scholar] [CrossRef]

- Coenen, A.R.; Kutay, M.E.; Sefidmazgi, N.R.; Bahia, H.U. Aggregate structure characterisation of asphalt mixtures using two-dimensional image analysis. Road Mater. Pavement Des. 2012, 13, 433–454. [Google Scholar] [CrossRef]

- Takeda, M.; Onishi, T.; Nakakubo, S.; Fujimoto, S. Physical properties of iron-oxide scales on si-containing steels at high temperature. Mater. Trans. 2009, 50, 2242–2246. [Google Scholar] [CrossRef]

- Uz, V.E.; Gokalp, I. The effect of aggregate type, size and polishing levels to skid resistance of chip seals. Mater. Struct. 2017, 50, 126. [Google Scholar] [CrossRef]

- Wang, F.; Cui, P.D.; Zhang, X.S.; Yunusa, M.; Xiao, Y. Profile features of emulsified asphalt mixture containing steel slag based on laser scanning. Materials 2020, 13, 2679. [Google Scholar] [CrossRef]

| Sample ID | BS-1 | BS-2 | BOF-1 | BOF-2 | FER-1 | FER-2 | Method |

|---|---|---|---|---|---|---|---|

| Specific gravity (g/cm3) | 2.65 | 2.68 | 3.15 | 3.21 | 2.98 | 3.02 | ASTM C127 |

| Sand equivalent (%) | 68 | 66 | 74 | 75 | 79 | 78 | ASTM D419 |

| Water absorption ratio (%) | 0.42 | 0.49 | 1.35 | 1.69 | 1.07 | 1.14 | ASTM C127 |

| Soundness by Na2SO4 (%) | 2.96 | 3.02 | 2.34 | 2.25 | 1.86 | 1.97 | ASTM C88 |

| Polished stone value | 48 | 44 | 68 | 62 | 57 | 54 | EN 1097-8 |

| Materials | MgO/% | Al2O3/% | SiO2/% | CaO/% | Fe2O3/% | Others/% |

|---|---|---|---|---|---|---|

| BS-1 | 7.1 | 15.4 | 50.0 | 8.6 | 14.5 | 4.4 |

| BOF-1 | 5.1 | 1.8 | 25.5 | 47.4 | 13.6 | 6.6 |

| FER-1 | 6.1 | 3.1 | 16.0 | 36.6 | 27.6 | 10.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, M.; Wu, S.; Cui, P.; Yang, T.; Lv, Y. Thermal Exchange and Skid Resistance of Chip Seal with Various Aggregate Types and Morphologies. Appl. Sci. 2020, 10, 8192. https://doi.org/10.3390/app10228192

Wei M, Wu S, Cui P, Yang T, Lv Y. Thermal Exchange and Skid Resistance of Chip Seal with Various Aggregate Types and Morphologies. Applied Sciences. 2020; 10(22):8192. https://doi.org/10.3390/app10228192

Chicago/Turabian StyleWei, Minghua, Shaopeng Wu, Peide Cui, Tianyuan Yang, and Yang Lv. 2020. "Thermal Exchange and Skid Resistance of Chip Seal with Various Aggregate Types and Morphologies" Applied Sciences 10, no. 22: 8192. https://doi.org/10.3390/app10228192

APA StyleWei, M., Wu, S., Cui, P., Yang, T., & Lv, Y. (2020). Thermal Exchange and Skid Resistance of Chip Seal with Various Aggregate Types and Morphologies. Applied Sciences, 10(22), 8192. https://doi.org/10.3390/app10228192