1. Introduction

With the rapid development of the aerospace industry, remote sensing technology has been widely used in various fields of the national economy. At the same time, people put forward higher requirements for performances of space cameras [

1]. The requirements of high performances mean that the camera has a large aperture and long focal length, which inevitably leads to the increase of camera mass and launch cost. Therefore, it is necessary to optimize the optomechanical structures of the camera so that it achieves a high lightweight ratio and meets space performance requirements [

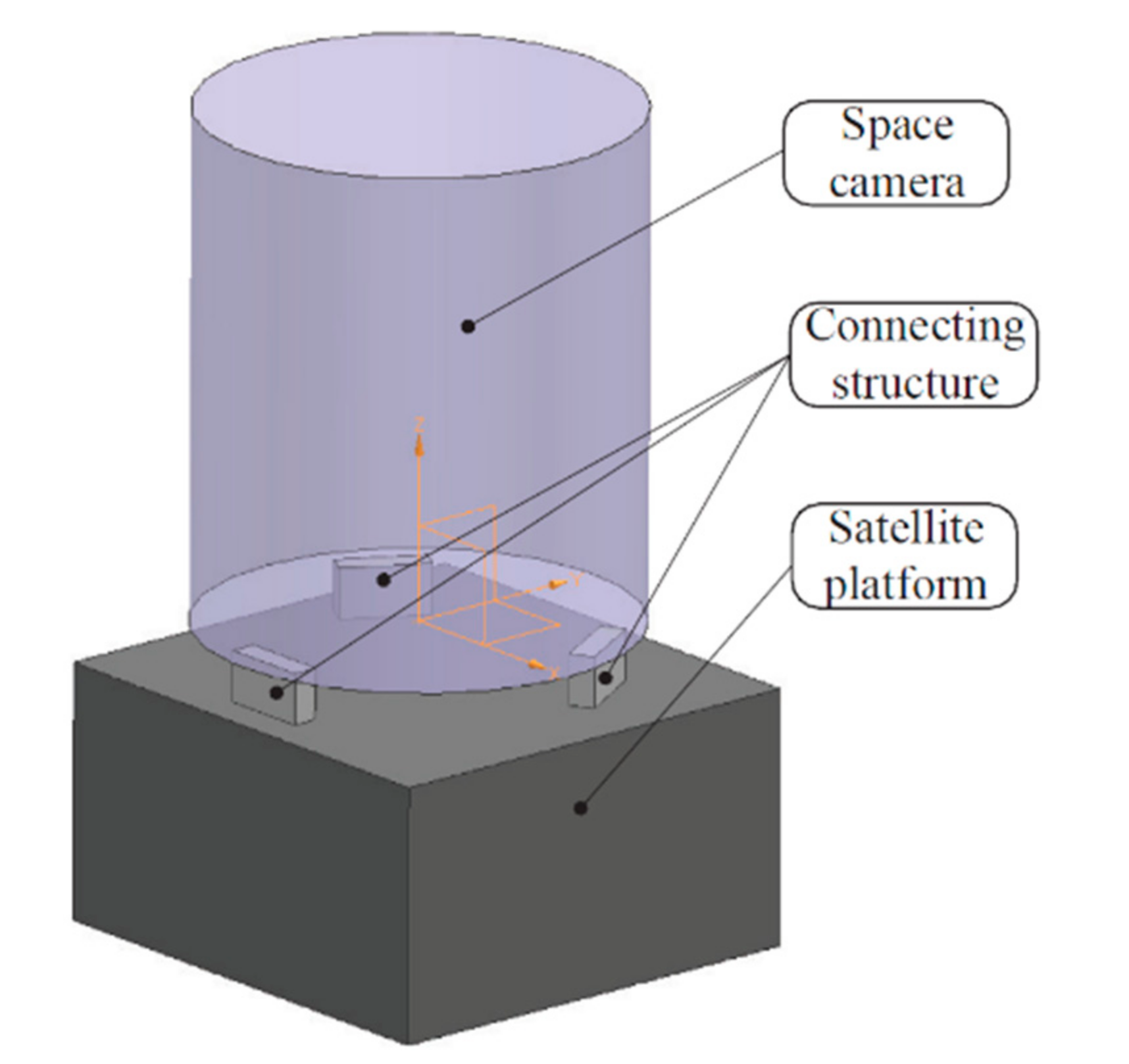

2]. The lightweight ratio of structures is the ratio of mass removed by optimization design to initial mass. The higher its value, the higher the lightness of the structure and the lower the launch cost of the space cameras. The spaceborne connecting structure of the space cameras provides installation interfaces for the space camera and satellite platform, and it reduces the influence of external loads on the camera. So, the optimization design of the connecting structure is very important for the development of a high-performance space camera.

So far, there are two main types of connection between a space camera and satellite platform: vertical installation and horizontal installation. Vertical installation has the advantages of uniform force, good static mechanical performance, and it is not easy to be affected by external loads. It is generally used in space cameras with high lightweight ratio and low structural stiffness requirements, such as the Skysat-1 video satellite launched by Skybox [

3], which is an American company, and Worldview series satellites developed by Digital Globe [

4]. Horizontal installation has advantages of a low centroid of the whole satellite and a high satellite fundamental frequency. It is generally used in space cameras with high stiffness requirements, such as the Sofia Space Telescope designed by the German Aerospace Center [

5]. In this paper, in order to ensure the suitable lightweight ratio of the camera and stability of mirrors, the vertical installation is adopted.

There have been a lot of research studies on the optomechanical design. Isaac Weingrod, from the Lockheed Martin Space Systems company, designed precise bipod flexible support structures for the optical elements of NASA’s IRIS spectrometer and realized the accurate installation of the optical elements. The bipod mounts successfully carried nine different optics through environmental testing and into orbit, which demonstrated the kinematic structures without fiction can be applied to most optic mount designs [

6]. Riva et al. proposed an optomechanical structure optimization method based on coupling sensitivity matrix analysis with an optimized telescope with an aperture of 600 mm and obtained a suitable lightweight ratio. Their idea is to reduce the number of iterations in a multi-variable structural optimization, taking advantage of the embedded sensitivity routines that are available both in FEA software and in ray-tracing software. It can be used simply for performance prediction or for optimization strategies [

7]. Mikio Kunita applied Genetic algorithm (GA) to the truss-type main support structure of a space camera and realized a lightweight design of the main support structure. Genetic algorithm is a powerful tool to optimize a multi-objective optimization problem. They developed an optimization program employing a GA in order to obtain the main support structure design, which satisfies an acceptable homologous deformation with lightweight [

8]. Yi-Cheng Chen et al. wrote a program to process the deformation data of mirror surface nodes into a root mean square (RMS) value and optimized the mirror and its support structure with the RMS value as an objective. They used FEA to determine mirror surface deformation; then, the deformation surface nodal data were transferred into Zernike polynomials through MATLAB optomechanical transfer codes to calculate the resulting optical path difference (OPD) and optical aberrations. By using their self-developed Tcl script, an optimum design of mirrors was achieved [

9]. These studies show the practicability of the kinematic structures without fiction in the optical machinery and the development of the multi-objective optimization design of optomechanical structures. However, these are designs based on the known structures. It is still necessary to explore the configuration design methods of optomechanical structures and further structural optimization design methods integrating optical metrics.

Topology optimization is one of the most effective methods in the structural conceptual design stage, which has attracted extensive attention in aerospace, automotive, and civil engineering. Some researchers have applied the topology optimization method to the design of optomechanical structures. Park et al. studied the topology optimization technology of a multispectral space camera, calculated the mass of its mirror and the sensitivity of the camera’s Strehl ratio by using the direct differentiation method, and obtained topology optimization results of mirrors under different mass constraints by an optimality criteria method [

10]. Rui et al. established a topology optimization model with the mirror shape error caused by gravity and thermal effects as an objective function and the first-order natural frequency of mirror assembly as a constraint condition. The results showed that this optimization method significantly improves the optical performance of the mirror assembly [

11]. These studies demonstrated the feasibility of topology optimization in the design of optomechanical structures.

In this paper, we present an optimization method considering the LOS drift for designing a connecting structure. Qualitative analysis for the camera LOS drift is conducted, and the LOS drift is decomposed into quantities that are easy to analyze. The initial configuration of the connecting structure is obtained by topology optimization considering the relative displacements between mirrors. The optimal size parameters are obtained with detailed parameters optimization. Finally, performance analysis and evaluation results verify the effectiveness of the optimization method.

4. Engineering Analysis and Performance Comparison

As a component of a space camera, the spaceborne connecting structure needs to have enough mechanical performances to withstand disturbance during ground transportation, rocket launching, and in-orbit operation. In order to verify the safety of the camera, it is necessary to conduct engineering analysis. First, we fixed the translation and rotation of screw hole element nodes at the bottom of the spaceborne connecting structure. Then, we analyzed the performances of the whole machine under static and dynamic loads, including the maximum displacement of the secondary mirror relative to the primary mirror, the wavefront error of the mirrors and the system, the mode information of the camera, and the acceleration response under random vibration load.

4.1. Static Analysis

Static analysis is the performance analysis of the camera under the action of 1 g of gravity and 4 °C temperature rise loads. The maximum displacement of the secondary mirror relative to the primary mirror has been obtained in

Section 3.2, as shown in

Table 3. In addition, the displacement of the mirrors’ surface nodes can be fitted by the Zernike polynomial. After removing the rigid body displacement and the defocus terms of the mirrors, the RMS values of the mirrors’ surface deformation are calculated to evaluate the mirror quality under static loads. The surface deformation nephogram is shown in

Figure 9. In order to evaluate the imaging quality of the camera, the rigid body displacements of the mirrors and surface deformation are input into the camera’s optical model, and the wavefront error of the system is obtained by using the ray-tracing method. The wavefront nephogram of the system is shown is

Figure 10. The RMS values of the surface error and system wavefront error are summarized in

Table 4.

From

Figure 9, the surface accuracy of the mirrors is good. After removing the rigid body displacements and defocus, the RMS values of the mirror surface error are about 1 nm. From

Figure 10, the wavefront error of the system is worst under 1 g of X-direction gravity, but it still meets the space application requirements, and the mirror performance and system performance are good under the temperature rise loads. The results showed that after installing the optimized connecting structure, the static performances of the system meets the design requirements.

4.2. Dynamic Analysis

In order to better verify the dynamic mechanical performance of the camera, random analysis of the camera was carried out. From

Section 3.2 in

Table 3, the fundamental frequency meets the design requirements, indicating that the dynamic stiffness of the camera is high enough to avoid resonance with a rocket carrier under the action of low-frequency sinusoidal excitation. The test conditions of random vibration are given by the technicians of rocket design, as shown in

Table 5. The dynamic analysis showed that the node with the largest acceleration excitation response is located at the edge of the primary mirror, which is set as the sampling point. The acceleration responses of the sampling point in the X, Y, and Z directions are summarized in

Table 6. The results show that the direction corresponding to the maximum response of the sampling point is the X direction (vertical to the optical axis), and the amplification factor is 4.71, which meets the mechanical performance requirements. It demonstrates that the dynamic performances of the system meet the engineering application.

4.3. Performance Comparison

In order to further evaluate the effect of the optimization method, a traditional bipod support structure (as shown in

Figure 11) is selected to contrast with the structures designed in this paper. The camera is mounted using the traditional structure in the same assembling method. Positions A, B, and C adopt the same configuration but with different flexible sizes, which are optimized by using size parametric optimization.

t1 and

t2 are set as the design variables. The objective and constraint functions are the same as those functions in Equation (5). After the convergence of optimization iteration, the optimized

t1 and

t2 are 12.5 mm and 9.8 mm, respectively. The optimization results of all responses are summarized in

Table 7.

The optimization results of the traditional structure show that after installing the traditional support structure, the first natural frequency meets the performance requirements, but the relative displacements between mirrors exceed the design requirements. In contrast, R1 and R5 for the optimized spaceborne connecting structure optimized in this paper are 35% and 42% smaller compared with the traditional structure under the action of 1 g of gravity. They are 43% and 29% smaller under the action of a temperature rise of 4 °C. Furthermore, the optimized connecting structures in this paper have a higher lightweight ratio. These demonstrate the effectiveness of the design method presented in this paper.

5. Conclusions

This paper presents an optimization design method for designing spaceborne connecting structures. Drift of line of sight (LOS) is the movement of an image point on the image plane under external loads. In order to meet the design requirements of the camera’s LOS drift under 1 g of gravity and a temperature rise load, the LOS drift was qualitatively analyzed. The main factor that affects the LOS drift is the relative displacements between the secondary mirror and primary mirror. The specific expressions of the relative displacements between mirrors were derived. In order to obtain the optimal configuration of the spaceborne connecting structure, a topology optimization model was established with the mass as the objective and the fundamental frequency and relative displacements between mirrors as constraints. The topology optimization model was solved by using MMA. Based on the topology optimization results, the sensitivity analysis of size parameters was carried out. The analysis result showed that the size parameters have an obvious influence on the performance of the system. To obtain the optimal size parameters combination, a size parameter optimization model was established, and it was solved by using GA. In order to further evaluate the effect of the optimization, engineering analysis was carried out. The performance was compared with the traditional flexible structure after size parameter optimization. The results showed that the camera mounted by the designed connecting structure in this paper has better comprehensive performance. The relative linear displacements and angular displacements between mirrors are within 10 μm and 10″ respectively, which meet the design requirements, and the lightweight ratio of the connecting structures reached 54%, which verifies the effectiveness of the proposed optimization design method.

In this paper, the relative displacements between mirrors were analyzed in detail, which is the main factor affecting the camera’s LOS drift. By integrating the relative displacements into the optimization design model of the spaceborne connecting structures, effective optimization results were obtained. If the other structures in the optomechanical system have an obvious influence on the camera’s LOS drift, this method can also be used for their optimization design, which can significantly improve the LOS stability and lightweight ratio of the structure. However, if a structure in the optomechanical system has little effect on the LOS drift, it should consider other targeted design methods and conduct specific analysis. The camera’s system performances also include other optical metrics such as optical transfer function and energy distribution. In the future, if the optical transfer function under external loads can be integrated in the optomechanical structure optimization, the design will be more effective.