A Hands-On Laboratory for Intelligent Control Courses

Abstract

:1. Introduction

- The first is a geographical shift from high-income western countries to the strong emerging economies of Asia and Latin America.

- The second trend is a movement towards open curricula adapted to social needs.

- The third trend is the motivation to deliver an integrated student-centered learning experience on a large scale.

2. Fuzzy Logic Background

- Fuzzy identifiers are easy to implement.

- Multiple input and output variables can be added in MIMO systems.

- It has lower computational cost than other artificial intelligence techniques.

- It delivers quick responses in most control processes.

- The universe of discourse is defined as the set X of all the possible values that a given variable x can take.

- A fuzzy set is a set that can partially contain elements, that is, the property that an element x belongs to the set A can be true with a partial degree of truth.

- A crisp set is the conventional set and only considers whether or not an element belongs to it, which means that it is a binary set.

- Let A be a fuzzy set and let be a value of the universal set; the membership function described in Equation (1) indicates the degree of belonging of said value to a fuzzy set.

2.1. Operations with Fuzzy Sets

- Commutativity: .

- Monotonicity: if and .

- Identity element: .

- Associativity: .

- Commutativity: .

- Monotonicity: if and .

- Identity element: .

- Associativity: .

- is a continuous function.

- Monotonicity: If , then .

- Involution:

2.2. Fuzzification

2.3. Rules

2.4. Defuzzification

3. Project Description and Methodology

4. Practical Sequence

4.1. DAQ Construction

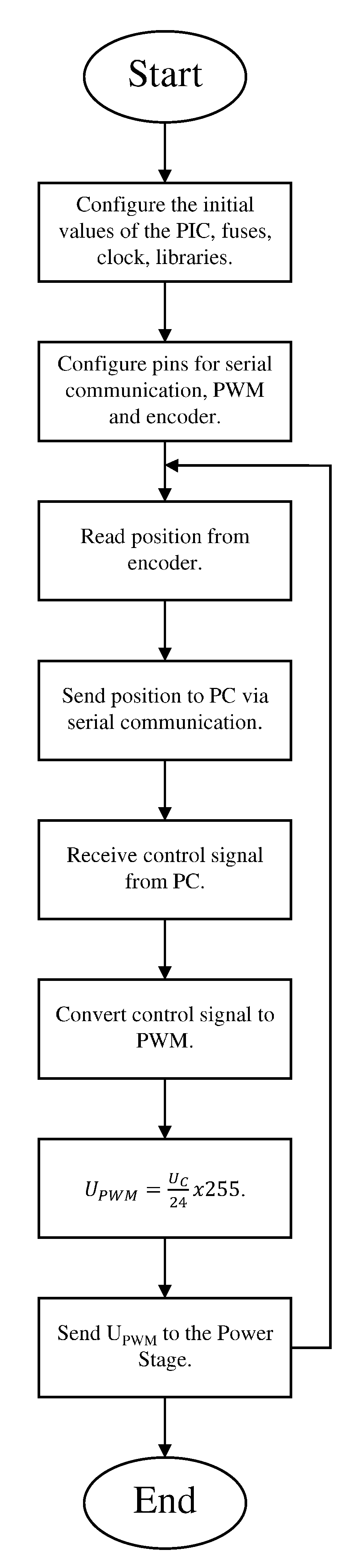

4.2. PIC Programming

4.3. Library for Membership Functions

4.4. Control Loop Construction

- Operating voltage 5–27 V

- Motor speed control through PWM frequency up to 25 kHz

- Control in both directions of the motor

- Maximum current capacity up to 30 A

- An operating voltage of 5–24 V of direct current

- A resolution of 1024 PPR

- Z signal that can be easily adjusted

- It has protection against short circuits

- Maximum current consumption of 70 mA

- Three exit signs A, B and Z

- Open collector output configuration

- Maximum frequency response of 100 kHz

- insulation resistance

4.5. Design of the Fuzzy Controller

4.6. Implementation of the Controller

- Two cores

- Two threads

- Processor Base Frequency of 2.10 GHz

- Cache 2 MB L3

- BusSpeed

5. Indicators

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Babatope, A.; Samuel, T.M.; Ajewole, P.I.; Anyanwu, O.M. Competence-driven engineering education: A case for T-shaped engineers and teachers. Int. J. Eval. Res. Educ. 2020, 9, 32. [Google Scholar] [CrossRef]

- Uskov, V.; Bakken, J.P.; Aluri, L.; Rachakonda, R.; Rayala, N.; Uskova, M. Smart pedagogy: Innovative teaching and learning strategies in engineering education. In Proceedings of the 2018 IEEE World Engineering Education Conference (EDUNINE), Buenos Aires, Argentina, 11–14 March 2018. [Google Scholar] [CrossRef]

- Choi, Y.; McClenen, C. Development of adaptive formative assessment system using computerized adaptive testing and dynamic bayesian networks. Appl. Sci. 2020, 10, 8196. [Google Scholar] [CrossRef]

- Crawley, E.; Malmqvist, J.; Ostlund, S.; Brodeur, D.; Edström, K. Rethinking Engineering Education: The CDIO Approach; Springer: Cham, Switzerland, 2014; pp. 9–10. [Google Scholar]

- Cunningham, C.M.; Kelly, G.J. Epistemic practices of engineering for education. Sci. Educ. 2017, 101, 486–505. [Google Scholar] [CrossRef]

- Feisel, L.D.; Rosa, A.J. The role of the laboratory in undergraduate engineering education. J. Eng. Educ. 2005, 94, 121–130. [Google Scholar] [CrossRef]

- Walther, J.; Miller, S.E.; Sochacka, N.W. A model of empathy in engineering as a core skill, practice orientation, and professional way of being. J. Eng. Educ. 2017, 106, 123–148. [Google Scholar] [CrossRef]

- Gunckel, K.L.; Tolbert, S. The imperative to move toward a dimension of care in engineering education. J. Res. Sci. Teach. 2018, 55, 938–961. [Google Scholar] [CrossRef]

- Burt, B.A.; Williams, K.L.; Palmer, G.J.M. It takes a village: The role of emic and etic adaptive strengths in the persistence of black men in engineering graduate programs. Am. Educ. Res. J. 2018, 56, 39–74. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y. Discussion on the teaching reform of the automatic control theory. In Proceedings of the 3rd International Conference on Science and Social Research, Tianjin, China, 14–15 June 2014; Atlantis Press: Paris, France, 2014. [Google Scholar] [CrossRef] [Green Version]

- Cheng, H.; Hao, L.; Luo, Z.; Wang, F. Establishing the connection between control theory education and application: An arduino based rapid control prototyping approach. Int. J. Learn. Teach. 2016, 2. [Google Scholar] [CrossRef] [Green Version]

- Han, S.; Capraro, R.; Capraro, M.M. How science, technology, engineering, and mathematics (STEM) project-based learning (PBL) affects high, middle, and low achievers differently: The impact of student factors on achievement. Int. J. Sci. Math. Educ. 2014, 13, 1089–1113. [Google Scholar] [CrossRef]

- Trusty, J.; Niles, S.G. High-School Math Courses and Completion of the. Bachelor’s Degree. Bachelor’s Thesis, Professional School Counseling, Alexandria, VA, USA, 2003; pp. 99–107. [Google Scholar]

- Hart, G.E.; Cottle, P.D. Academic backgrounds and achievement in college physics. Phys. Teach. 1993, 31, 470–475. [Google Scholar] [CrossRef]

- Koh, M.Y.; Koh, H.C. The determinants of performance in an accountancy degree programme. Account. Educ. 1999, 8, 13–29. [Google Scholar] [CrossRef]

- Petriz Mayen, M.A.; Barona Ríos, C.; López Villareal, R.M.; Quiroz González, J. Niveles de desempeño y actitudes hacia las matemáticas en estudiantes de la licenciatura en administración en una universidad estatal mexicana. Rev. Mex. Investig. Super. Educ. 2010, 15, 1223–1249. [Google Scholar]

- Zamfiroiu, A.; Constantinescu, D.; Zurini, M.; Toma, C. Secure learning management system based on user behavior. Appl. Sci. 2020, 10, 7730. [Google Scholar] [CrossRef]

- Moradi, M.H.; Katebi, M.R.; Johnson, M.A. Robust MIMO PID tuning method. In Proceedings of the International Conference on Control Applications, Glasgow, UK, 18–20 September 2002. [Google Scholar] [CrossRef]

- Odry, Á.; Fullér, R.; Rudas, I.J.; Odry, P. Fuzzy control of self-balancing robots: A control laboratory project. Comput. Appl. Eng. Educ. 2020, 28, 512–535. [Google Scholar] [CrossRef]

- Odry, Á.; Fullér, R.; Rudas, I.J.; Odry, P. Kalman filter for mobile-robot attitude estimation: Novel optimized and adaptive solutions. Mech. Syst. Signal Process. 2018, 110, 569–589. [Google Scholar] [CrossRef]

- Odry, A.; Fuller, R. Comparison of optimized PID and fuzzy control strategies on a mobile pendulum robot. In Proceedings of the 2018 IEEE 12th International Symposium on Applied Computational Intelligence and Informatics (SACI), Timisoara, Romania, 17–19 May 2018. [Google Scholar] [CrossRef]

- Stefanovic, M. The objectives, architectures and effects of distance learning laboratories for industrial engineering education. Comput. Educ. 2013, 69, 250–262. [Google Scholar] [CrossRef]

- Soares, F.; Leao, C.P.; Carvalho, V.; Vasconcelos, R.M.; Costa, S. Automation and control remote laboratory: A pedagogical tool. Int. J. Electr. Eng. Educ. 2014, 51, 54–67. [Google Scholar] [CrossRef] [Green Version]

- Swart, A.J. Student usage of a learning management system at an open distance learning institute: A case study in electrical engineering. Int. J. Electr. Eng. Educ. 2015, 52, 142–154. [Google Scholar] [CrossRef]

- Rampazzo, M.; Cervato, A.; Beghi, A. Remote refrigeration system experiments for control engineering education. Comput. Appl. Eng. Educ. 2017, 25, 430–440. [Google Scholar] [CrossRef]

- Parkhomenko, A.; Parkhomenko, A.; Tabunshchyk, G.; Henke, K.; Wuttke, H.D. The remote labs as an effective tool of inclusive engineering education. In Proceedings of the 2018 XIV-th International Conference on Perspective Technologies and Methods in MEMS Design (MEMSTECH), Lviv, Ukraine, 18–22 April 2018. [Google Scholar] [CrossRef]

- Davidovitch, L.; Parush, A.; Shtub, A. Simulation-based learning in engineering education: Performance and transfer in learning project management. J. Eng. Educ. 2006, 95, 289–299. [Google Scholar] [CrossRef]

- Akkoyun, O. New simulation tool for teaching-learning processes in engineering education. Comput. Appl. Eng. Educ. 2017, 25, 404–410. [Google Scholar] [CrossRef]

- Kezunovic, M.; Abur, A.; Huang, G.; Bose, A.; Tomsovic, K. The role of digital modeling and simulation in power engineering education. IEEE Trans. Power Syst. 2004, 19, 64–72. [Google Scholar] [CrossRef] [Green Version]

- Balamuralithara, B.; Woods, P.C. Virtual laboratories in engineering education: The simulation lab and remote lab. Comput. Appl. Eng. Educ. 2009, 17, 108–118. [Google Scholar] [CrossRef]

- Alhalabi, W. Virtual reality systems enhance students’ achievements in engineering education. Behav. Inf. Technol. 2016, 35, 919–925. [Google Scholar] [CrossRef]

- Salah, B.; Abidi, M.; Mian, S.; Krid, M.; Alkhalefah, H.; Abdo, A. Virtual reality-based engineering education to enhance manufacturing sustainability in industry 4.0. Sustainability 2019, 11, 1477. [Google Scholar] [CrossRef] [Green Version]

- Franzoni, V.; Milani, A.; Mengoni, P.; Piccinato, F. Artificial intelligence visual metaphors in E-Learning interfaces for learning analytics. Appl. Sci. 2020, 10, 7195. [Google Scholar] [CrossRef]

- Garduno-Aparicio, M.; Rodriguez-Resendiz, J.; Macias-Bobadilla, G.; Thenozhi, S. A multidisciplinary industrial robot approach for teaching mechatronics-related courses. IEEE Trans. Educ. 2018, 61, 55–62. [Google Scholar] [CrossRef]

- Cruz-Miguel, E.E.; Rodríguez-Reséndiz, J.; García-Martínez, J.R.; Camarillo-Gómez, K.A.; Pérez-Soto, G.I. Field-programmable gate array-based laboratory oriented to control theory courses. Comput. Appl. Eng. Educ. 2019, 27, 1253–1266. [Google Scholar] [CrossRef] [Green Version]

- Inelmen, E.; Inelmen, E.; Ibrahim, A.A. A new approach to teaching fuzzy logic system design. In Fuzzy Sets and Systems—IFSA 2003, Proceedings of the 10th International Fuzzy Systems Association World Congress, Istanbul, Turkey, 30 June–2 July 2003; Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2003; pp. 79–86. [Google Scholar] [CrossRef]

- Akcayol, M.A.; Elmas, C.; Erdem, O.A.; Kurt, M. An educational tool for fuzzy logic controller and classical controllers. Comput. Appl. Eng. Educ. 2004, 12, 126–135. [Google Scholar] [CrossRef]

- Ibrahim, D.; Alshanableh, T. An undergraduate fuzzy logic control lab using a line following robot. Comput. Appl. Eng. Educ. 2009, 19, 639–646. [Google Scholar] [CrossRef]

- Almohammadi, K.; Hagras, H.; Yao, B.; Alzahrani, A.; Alghazzawi, D.; Aldabbagh, G. A type-2 fuzzy logic recommendation system for adaptive teaching. Soft Comput. 2015, 21, 965–979. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.-X. Design and analysis of fuzzy identifiers of nonlinear dynamic systems. IEEE Trans. Autom. Control 1995, 40, 11–23. [Google Scholar] [CrossRef]

- Amendola, C.A.M.; Gonzaga, D.P. Fuzzy-logic control system of a variable-speed variable-pitch wind-turbine and a double-fed induction generator. In Proceedings of the Seventh International Conference on Intelligent Systems Design and Applications (ISDA 2007), Rio de Janeiro, Brazil, 20–24 October 2007. [Google Scholar] [CrossRef]

- Mamdani, E.H. Application of fuzzy algorithms for control of simple dynamic plant. Proc. Inst. Electr. Eng. 1974, 121, 1585–1588. [Google Scholar] [CrossRef]

- Takagi, T.; Sugeno, M. Fuzzy identification of systems and its applications to modeling and control. IEEE Trans. Syst. Man Cybern. 1985, SMC-15, 116–132. [Google Scholar] [CrossRef]

- Kouro, S.; Musalem, R. Control mediante lógica difusa. Téc. Mod. Autom. 2002, 1, 1–7. [Google Scholar]

- Rafa, S.; Larabi, A.; Barazane, L.; Manceur, M.; Essounbouli, N.; Hamzaoui, A. Implementation of a new fuzzy vector control of induction motor. ISA Trans. 2014, 53, 744–754. [Google Scholar] [CrossRef]

- Torres, H. DAQ for Fuzzy Controller. 2020. Available online: https://github.com/Htorres07/FuzzyController/tree/main/DAQ (accessed on 29 November 2020).

- Torres, H. GUI for Fuzzy Controller. 2020. Available online: https://github.com/Htorres07/FuzzyController/tree/main/GUI (accessed on 29 November 2020).

| Ref./Year | Study Area | Contribution to the Field |

|---|---|---|

| [27]/2006 | Simulation environment | The work presents empirical findings on the impact of maintaining and reviewing the learning history in a dynamic and interactive simulation environment of engineering education. |

| [22]/2013 | Laboratories for distance | The objective of the paper is to present the fundamental objectives of learning through distance learning laboratories as well as the special issues connected with these labs, including their effectiveness. |

| [23]/2014 | Perception study | The paper exposes a study to evaluate perception of the students of the development and use of remote Control and Automation training kits in Portugal. |

| [24]/2015 | Learning management system | The purpose of this article is to highlight student usage of a learning management system in electrical engineering at an open distance learning institute. |

| [28]/2017 | Simulation-based software | In this study, new simulation-based software developed for educational purposes is introduced. |

| Device | Description |

|---|---|

| Controller | A fuzzy controller works in a similar way to a conventional system: it accepts an input value, performs some calculations and generates an output value. |

| DAQ | The DAQ takes the signal received from the encoder and performs its conditioning so that it can be compared with the reference position. Additionally, it converts the signal to the controller output and converts it to a PWM signal for the power stage. |

| Power Stage | The power stage operates on the motor, in it is the H bridge that regulates the operation of the motor. Its operation is determined by the on or off of the different switches. |

| Motor | The motor is the final action target. Through this element, the angular position of the shaft is regulated. |

| Encoder | It allows coding the mechanical movement of the motor in different types of electrical impulses: binary digital, analog based on a wave, pulses, etc. In this way, the encoder is the interface between the motor and the controller. |

| Practice | Descriptions | Time (h) |

|---|---|---|

| 1. DAQ construction. | The student develops the acquisition card using a PIC and its physical circuit necessary to read encoder and implement PWM, in addition to performing serial communication. | 2 |

| 2. Library creation for membership functions in C language. | The student develops the library needed to mathematically represent the membership functions and facilitate their application in the main code. | 2 |

| 3. Control loop construction. | The student creates the control loop by selecting the required power stage and using the previously developed DAQ. | 4 |

| 4. Design of the fuzzy controller. | The student designs the controller defining the input and output variables, as well as the required membership functions and finally the defuzzification process. | 8 |

| 5. Implementation of the controller. | The student develops the main code for the implementation of the previously designed controller. | 8 |

| Parameters | Values |

|---|---|

| Nominal voltage | 12 V |

| No-load speed | 2220 RPM |

| No-load current | 200 mA |

| Nominal speed | 1810 RPM |

| Nominal torque | 276 mNm |

| Nominal current | 2.94 A |

| Starting current | 16.6 A |

| Initial torque | 1660 mNm |

| Max. efficiency | 77% |

| Resistance (R) | 1.44 |

| Inductance (L) | 0.56 mH |

| Pin Number | Pin Name | Description |

|---|---|---|

| 1 | RPWM | PWM signal to turn right |

| 2 | LPWM | PWM signal to turn left |

| 3 | R_EN | Enable turn right |

| 4 | L_EN | Enable turn right |

| 5 | R_IS | Over-current alarm |

| 6 | L_IS | Over-current alarm |

| 7 | VCC | Supply voltage |

| 8 | GND | Ground |

| Error/Weight | Very Negative (emn) | Negative (en) | Zero (ecero) | Positive (ep) | Very Positive (emp) |

|---|---|---|---|---|---|

| Light (pl) | smp | sp | scero | sn | sn |

| Normal (pn) | smp | sp | scero | sn | smn |

| Heavy (pp) | smp | scero | scero | smn | smn |

| Specific Indicators | Criteria | Grade | |||

|---|---|---|---|---|---|

| 90–100 | 70–89 | 60–69 | 0–59 | ||

| I. The ability to identify and formulate complex engineering problems. | a. Basic knowledge about control theory. b. Identification of the position control problem. c. Basics of different controllers. d. Controller proposal. | abcd | abc | ac | a |

| II. The ability to acquire and apply new knowledge as needed. | e. Knowledge about control loops. f. Knowledge of the types of fuzzy logic. g. Knowledge about fuzzification h. Applications of membership functions. i. Knowledge of fuzzy rules. j. Knowledge about defuzzification. | efghij | eghij | 1. efgh 2. efgi 3. efgj | efg |

| III. The ability to design experiment and conduct standard tests, measurements and experiments, as well as analyze and interpret the results. | k. Design of the fuzzy controller. l. Sensor implementation. m. Power stage implementation. n. Control stage implementation. o. Interpretation of results. p. Conclusions. | klmnop | 1. klmno 2. klmnp | 1. klm 2. kln | kl |

| IV. The ability to understand and apply programming languages | q. Microcontrollers programming r. Knowledge of the rs232 protocol in c language s. Construction of the program for the controller t. Perform code optimization, verification and debugging | qrst | 1. qrs 2. qrt | qr | q |

| V. The ability to apply written, oral and graphical communication in well-defined technical and non-technical environments, as well as the ability to identify and use appropriate technical literature | u. Write the experiment report. v. Add good quality images. w. Add and explain the necessary equations. x. Explain the results and conclusions. | uvwx | 1. uvw 2. uvx | 1. uv 2. uw 3. ux | u |

| Specific Indicator | 2018(2) | 2019(1) | 2019(2) | 2020(1) |

|---|---|---|---|---|

| I | 60 | 70 | 70 | 80 |

| II | 60 | 80 | 80 | 90 |

| III | 65 | 80 | 70 | 90 |

| IV | 75 | 75 | 70 | 80 |

| V | 80 | 80 | 90 | 90 |

| Total average | 68 | 77 | 76 | 86 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres-Salinas, H.; Rodríguez-Reséndiz, J.; Estévez-Bén, A.A.; Cruz Pérez, M.A.; Sevilla-Camacho, P.Y.; Perez-Soto, G.I. A Hands-On Laboratory for Intelligent Control Courses. Appl. Sci. 2020, 10, 9070. https://doi.org/10.3390/app10249070

Torres-Salinas H, Rodríguez-Reséndiz J, Estévez-Bén AA, Cruz Pérez MA, Sevilla-Camacho PY, Perez-Soto GI. A Hands-On Laboratory for Intelligent Control Courses. Applied Sciences. 2020; 10(24):9070. https://doi.org/10.3390/app10249070

Chicago/Turabian StyleTorres-Salinas, Hugo, Juvenal Rodríguez-Reséndiz, Adyr A. Estévez-Bén, M. A. Cruz Pérez, P. Y. Sevilla-Camacho, and Gerardo I. Perez-Soto. 2020. "A Hands-On Laboratory for Intelligent Control Courses" Applied Sciences 10, no. 24: 9070. https://doi.org/10.3390/app10249070