Laboratory Validation of Surface-Initiated Transverse Cracking of Asphalt Pavement

Abstract

:1. Introduction

2. Methodology

- Test conditions need to be changed to ensure that cracking instead of permanent deformation is the dominant failure mechanism. Typically, asphalt mixture reacts as viscoelastic–plastic material under standard HWTD loading condition, since the test is performed at a relative high temperature (i.e., 50 °C) and low loading rate (52 passes per minute). To obtain asphalt material that responds as more elastic–brittle solid, the test temperature should be decreased to room level (i.e., 20–25 °C) or even lower (close to zero degrees), or the wheel load speed needs to be increased to a higher value that can simulate a fast-moving vehicle.

- Long-term aging of the specimen should be included, since it is a critical factor that affects both fatigue cracking and low-temperature thermal cracking [3,12,13]. The aging of asphalt mixture increases the stiffness of the material, reduces its ductility, and could negatively affect its resistance to fatigue-induced cracking [14,15]. It is also found that aging decreases the low-temperature cracking resistance of asphalt concrete pavement and increases the crack frequency [16].

- The base (or support) stiffness of the test specimen should be adjustable to match with the field pavement condition. Such adjustment can be achieved by placing rubber with different stiffness under the specimen. Typically, the potential for fatigue cracking initiation increases with the decrease of the base modulus [17].

- An extra chiller was connected to the equipment to maintain test temperature at around 20 °C.

- Wider loading rate range: maximum 70 passes per minute, which is faster than the standard wheel load speed (52 ± 2).

- Capable of including rubber base to adjust the support conditions.

2.1. Scale Down of Sample Size

2.2. Materials

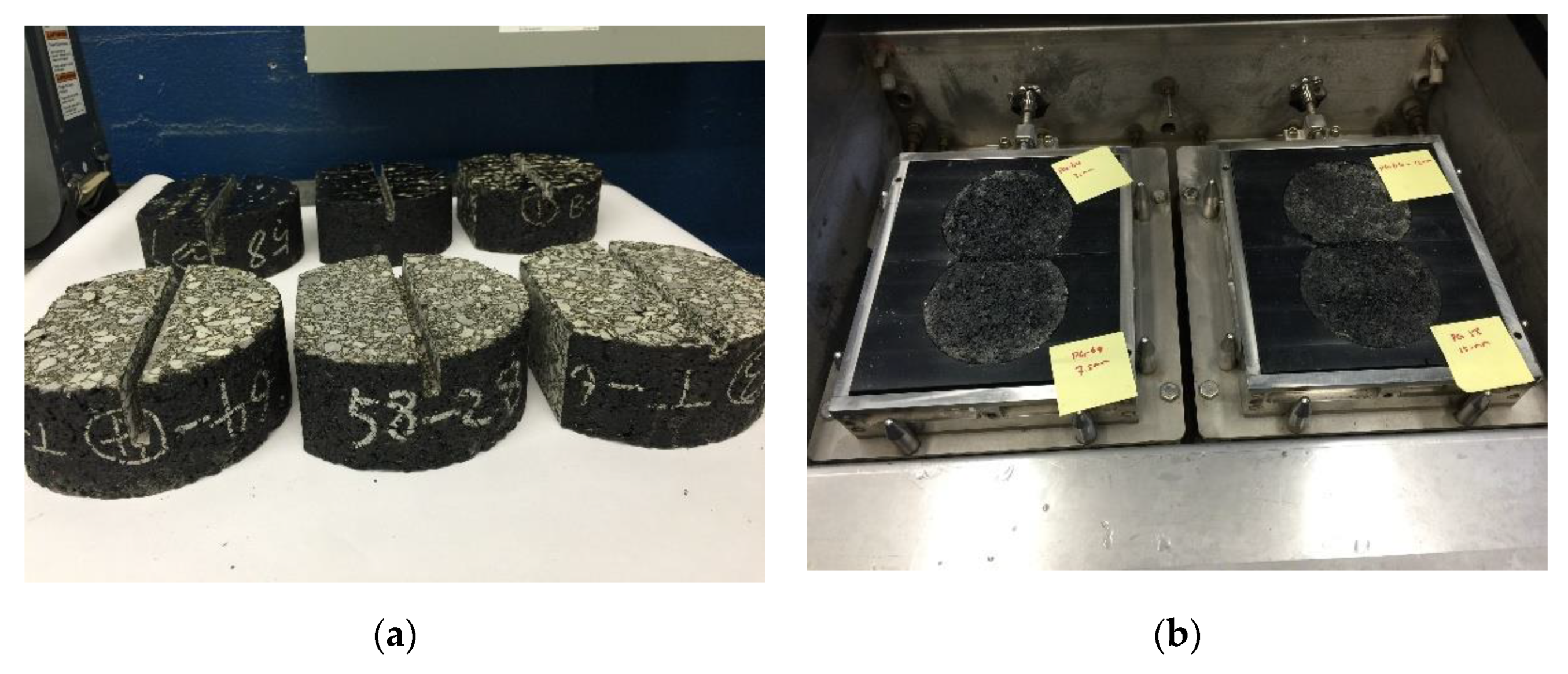

2.3. Specimen Preparation

2.4. Design of Test Condition

- Layer thickness: Layer thickness has been proved to affect top–down longitudinal cracking significantly [22]. As seen elsewhere [22], pavement thickness could be a critical factor that correlates to surface-initiated transverse cracking. Therefore, it is expected that the initiation of cracks can be observed at different wheel load repetitions by using varied specimen thicknesses. Therefore, HWT samples with different thicknesses are used, consisting of 1 inch, 1.5 inches, and 2.4 inches.

- Aging condition: Specimens with different degrees of aging (5-day aging, 10-day aging, and 15-day aging) are applied. Five-day aging at 85 °C is considered to be equivalent to long-term aging in the field pavement in accordance with AASHTO R30 [23]. Ten-day and 15-day agings are used to obtain asphalt mixture with even higher stiffness (more brittleness), which is critical for surface-initiated cracks, as suggested elsewhere [22].

- With or without existing notch: Some specimens have joints in the bottom layer, and this is simulated using a notch or saw cut (0.33 inch depth and 0.25 inch width). Both specimens with and without existing notches are used to evaluate the effects of existing notches on the property of surface-initiated transverse cracking.

- Weak base or strong base: For pavement under traffic load, the modulus of the base can greatly affect the stress magnitude at the pavement surface. Von Mises stress is the maximum octahedral shear stress; it takes into account the multiaxial stress state, including the shear when protentional failure location is near the pavement surface [24]. It was found that the higher the base modulus, the smaller the Von Mises stress value at the pavement surface. In contrast, the lower the base modulus, the higher the Von Mises stress value at the pavement surface [8]. The effect of base stiffness on pavement response has also been confirmed by other researchers as well [17,25]. Specifically, the sensitivity analysis of flexible pavement performance prediction to Mechanistic-Empirical Pavement Design Guide (MEPDG) design inputs shows that the top-down longitudinal cracking is very sensitive to base resilient modulus [25], a greater amount of longitudinal cracking is predicted if the lower base modulus is used. It is also pointed out that pavement with a lower base modulus is more prone to initiate top–down fatigue cracking [17]. Therefore, with a flexible base, it is expected that surface-initiated reflective cracking (SIRC) is easier to be simulated in the laboratory. SIRC refers to such cracks that initiate at the surface of the pavement layer in the transverse direction and propagate downward to match the existing transverse cracking, and there is no cracking in the intralayer. In this paper, rubber with an approximate stiffness range of 400–700 MN/m was placed under test specimen to simulate a weak base, as shown in Figure 2a, and the HWTD steel frame was used as a strong base instead of a rubber pad, as shown in Figure 2b.

- Binder performance grade (PG): Asphalt binder PG is used since it fully characterizes asphalt binders for different environmental and climatic conditions and is an important indicator for asphalt stiffness [26]. The binder PGs consisted in this study are PG 58-28 and PG 64-22.

2.5. Test Results and Analysis

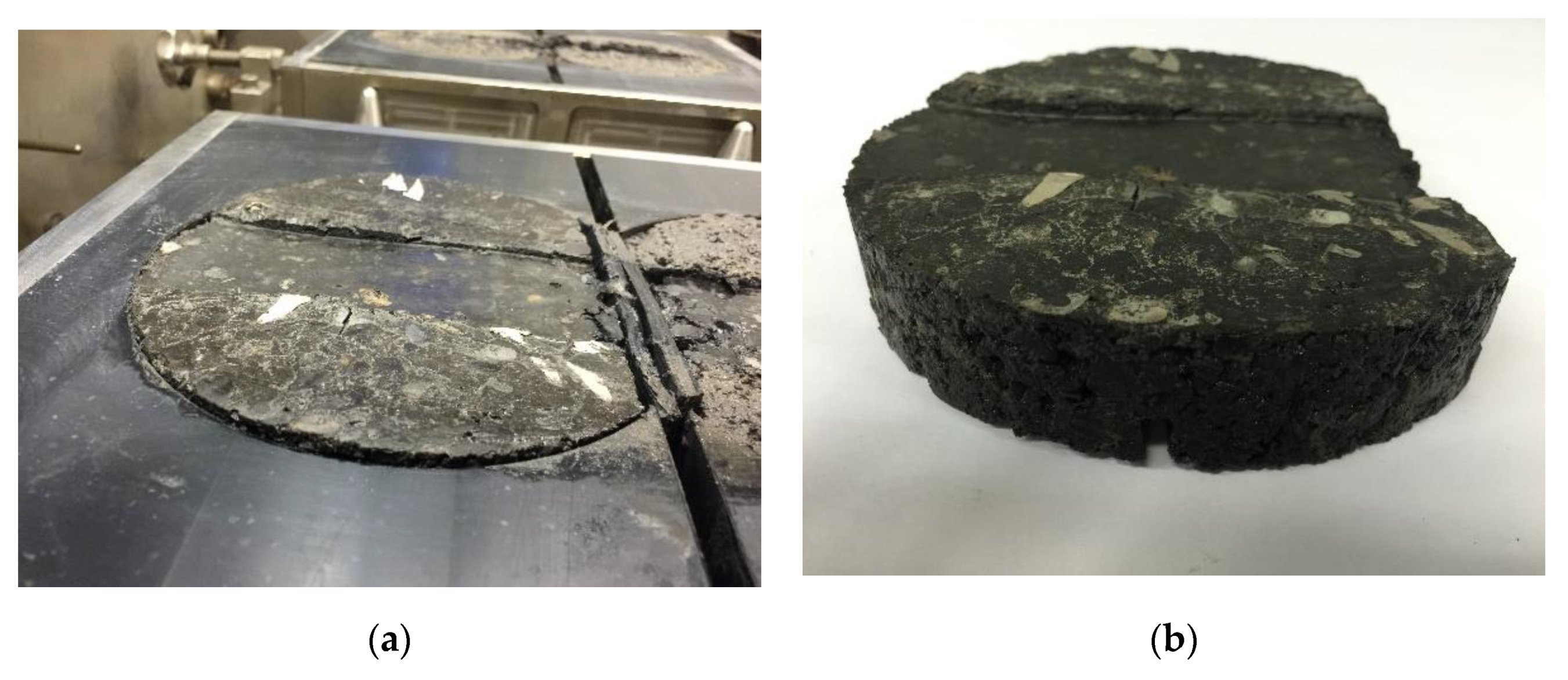

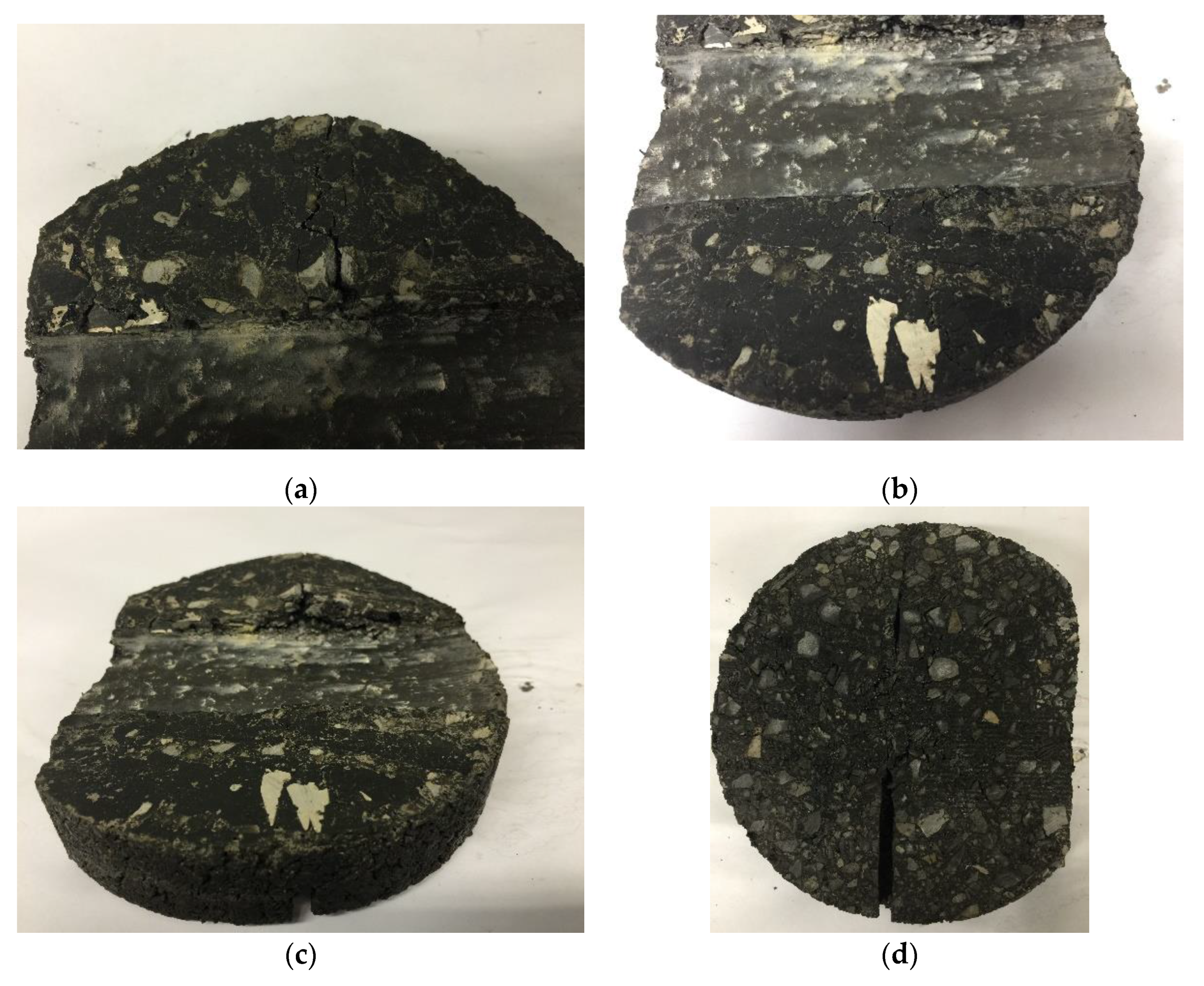

3. Testing with Observed SIRC

4. Potential Mechanism

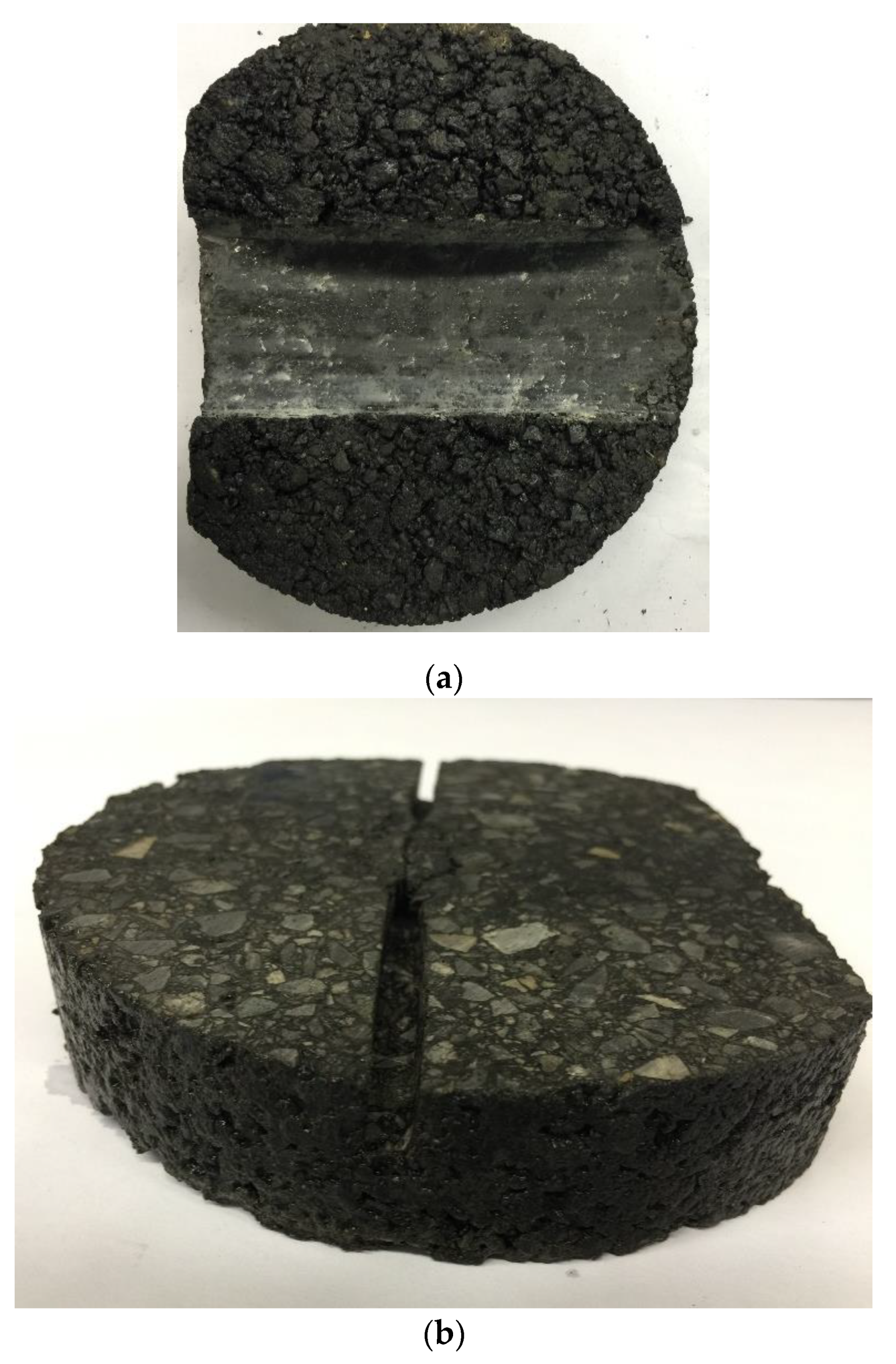

5. Testing without Observed SIRC

5.1. Without the Existing Notch

5.2. Aging Days

5.3. Base Stiffness

5.4. Binder PG

6. Summary of Crack Initiation Cycles and Rut Depth

7. Conclusions

- (1)

- The specimen thickness, base stiffness, material stiffness (aging effect), existing notch, and binder source are critical factors for surface-initiated transverse cracking. Specifically, laboratory tests indicate that such a crack type is seen easier for the softer base, stiffer asphalt mixture, with the existing transverse notch.

- (2)

- In terms of pavement thickness, although some studies in the literature indicate that thicker pavement may crack easier due to shear failure, laboratory tests indicate that specimens with thinner thickness (1 inch) takes less wheel load passes before the crack was observed. Two reasons could be used to explain this difference: (a) a thin specimen cannot be directly equal to field thin HMA layers, the scale-down factor needs to be considered in laboratory tests, and (b) sufficient thickness is important to shift the critical distress position to the surface of the pavement and lead to surface-initiated cracking. However, there may exist a threshold value, and if the value above the threshold, the pavement with thinner thickness is more prone to develop SIRC and cracks may appear with fewer traffic repetitions that need a further demonstration.

- (3)

- Surface-initiated transverse cracking can be induced under traffic load. Although the thermal load gradient (cooling cycles) could accelerate the development of the surface-initiated transverse cracking, the laboratory evaluation proved that such a crack type can be caused by repeated traffic load at intermediate temperature.

- (4)

- The possible mechanism that induces the surface-initiated transverse cracking is that with the existence of a transverse joint at the pavement bottom, it is possible that when the traffic load tracks back and forth in the middle of the road, a bending is induced in an upward direction near the load area. Therefore, tensile stress is caused on the pavement surface and tears the pavement apart under repeated wheel loads. Compression is caused on the pavement bottom surface and leads to the asphalt mixture squeezing together, which has been validated by the laboratory tests. Such bending may only occur when the base structure is relatively weak. If a strong base is applied, no bending is expected, and surface-initiated transverse cracking is not seen anymore. When the tensile stress is higher than the strength of the material, the crack initiates. The asphalt material with higher stiffness or brittleness may crack easier than soft material, since soft asphalt mixture can relax stress faster.

8. Recommendations

- (1)

- It is recommended to further explore this mechanism in the lab by introducing a discontinuity in the rubber pads instead of a notch to simulate an existing crack in the HMA bottom layer.

- (2)

- Use more replicates to see whether the phenomena are the same or not for other samples as well.

Author Contributions

Funding

Conflicts of Interest

References

- Vinson, T.S.; Janoo, V.C.; Ralph, C.G.H. Low Temperature and Thermal Fatigue Cracking; Transportation Research Board: Washington, DC, USA, 1989. [Google Scholar]

- Lytton, R.L.; Tsai, F.L.; Lee, S.I.; Luo, R.; Hu, S.; Zhou, F.J. Models for Predicting Reflection Cracking of Hot-Mix Asphalt Overlays; Transportation Research Board: Washington, DC, USA, 2010. [Google Scholar]

- Martin, A.E.; Arambula, E.; Cucalon, L.G.; Chowdhury, A.; Lytton, R.; Epps, J.; Estakhri, C.; Park, E.S. Evaluation of the Moisture Susceptibility of WMA Technologies; Transportation Research Board of the National Academies: Washington, DC, USA, 2014. [Google Scholar]

- Nesnas, K.; Nunn, M.E. A Thermal Pavement Response Model for Top-Down Reflection Cracking in Composite Pavements; Transportation Research Board: Washington, DC, USA, 2006. [Google Scholar]

- Nunn, M.E. An Investigation into Reflection Cracking in Composite Pavements. In Proceedings of the RILEM International Conference on Reflection Cracking, Liege, Belgium, 8–10 March 1989. [Google Scholar]

- Burt, A.R. M4 motorway, a composite pavement, surface cracking. Highw. Transp. 1987, 34, 16–19. [Google Scholar]

- Bennert, T.; Worden, M.; Turo, M. Field and laboratory forensic analysis of reflective cracking on Massachusetts Interstate 495. J. Transp. Res. Board 2009, 2126, 27–38. [Google Scholar] [CrossRef]

- Shen, S.H.; Zhang, W.G.; Wang, H.; Huang, H. Numerical Evaluation of Surface-initiated Cracking in Flexible Pavement Overlays with Field Observations. Road Mater. Pavement Des. 2016. [Google Scholar] [CrossRef]

- AASHTO T 324. Standard method of test for hamburg wheel-track testing of compacted hot-mix asphalt (HMA). In Standard Specificaitons for Transportation Materials and Methods of Sampling and Testing; American Association of State and Highway Transportation Officials: Washington, DC, USA, 2011. [Google Scholar]

- Aschenbrener, T. Investigation of Low Temperature Thermal Cracking in Hot Mix Asphalt; Transportation Research Board: Washington, DC, USA, 1995. [Google Scholar]

- Zhou, F.; Chen, D.H.; Scullion, T.; Bilyeu, J. Case Study: Evaluation of Laboratory Test Methods to Characterize Permanent Deformation Properties of Asphalt Mixes. Int. J. Pavement Eng. 2003, 4, 155–164. [Google Scholar] [CrossRef]

- Zhang, W.G.; Shen, S.H.; Basak, P.; Wen, H.F.; Wu, S.H.; Faheem, A.; Mohammad, L.N. Development of Predictive Models for Initiation and Propagation of Field Transverse Cracking. J. Transp. Res. Board 2015, 2524, 92–99. [Google Scholar] [CrossRef]

- Shen, S.H.; Zhang, W.G.; Shen, L.; Huang, H. A Statistical Based Framework for Predicting Field Cracking Performance of Asphalt Pavements: Application to Top-Down Cracking Prediction. Constr. Build. Mater. 2016, 116, 226–234. [Google Scholar] [CrossRef]

- Glover, C.J.; Davison, R.R.; Domke, C.H.; Ruan, Y.H.; Juristyarini, P.; Knorr, D.B.; Jung, S.H. Development of a New Method for Assessing Asphalt Binder Durability with Field Validation; Texas A&M Transportation Institute: College Station, TX, USA, 2005. [Google Scholar]

- Glover, C.; Liu, G.; Rose, A.; Tong, Y.; Gu, F.; Ling, M.; Arambula, E.; Estakhri, C.; Lytton, R. Evaluation of Binder Aging and Its Influence in Aging of Hot Mix Asphalt Concrete: Technical Report; Research and Technology Implementation Office, Texas Deptment of Transportation: Austin, TX, USA, 2014. [Google Scholar]

- Zhang, W.; Shen, S.; Wu, S.; Mohmmaad, L. Long-term Field Aging of Warm-Mix and Hot-Mix Asphalt Binders. J. Transp. Res. Board 2017, 2632, 140–149. [Google Scholar] [CrossRef]

- Hu, X.; Hu, S.; Walubita, L.F.; Sun, L. Investigation of Fatigue Cracking: Bottom-Up or Top-Down; Pavement Cracking: London, UK, 2008. [Google Scholar]

- de Fortier Smit, A.; Hugo, F.; Rand, D.; Powell, B. Model mobile load simulator testing at National Center for Asphalt Technology test track. Transp. Res. Rec. 2003, 1832, 182–190. [Google Scholar] [CrossRef]

- Zhang, W.; Bahadori, A.; Shen, S.; Wu, S.; Muhunthan, B.; Mohammad, L. Comparison of Laboratory and Field Asphatl Aging for Polymer-Modified and Warm-Mix Asphalt Binders. J. Mater. Civ. Eng. 2018, 30, 1–11. [Google Scholar] [CrossRef]

- Kim, S.M.; Hugo, F.; Roesset, J.M.; White, T.D. Dimensional Analysis of the Model Mobile Load Simulator Action on Pavements; Center for Transportation Research, The University of Texas: Austin, TX, USA, 1995. [Google Scholar]

- Ven, M.V.; Smit, A.D.; Jenkins, K.; Hugo, F. Scaled down APT Considerations for Viscoelastic Materials. J. Assoc. Asph. Paving Technol. 1998, 67, 602–622. [Google Scholar]

- Roque, R.; Zou, J.; Kim, Y.R.; Baek, C.; Thirunavukkarasu, S.; Underwood, B.S.; Guddati, M.N. Top-Down Cracking of Hot-Mix Asphalt Layers: Models for Initiation and Propagation; Transportation Research Board: Washington, DC, USA, 2010. [Google Scholar]

- Designation, A. R30, Mixture Conditioning of Hot Mix Asphalt (HMA); American Association of State Highway and Transportation Officials: Washington, DC, USA, 2002. [Google Scholar]

- Wang, H.; Ozer, H.; Al-Qadi, I.L.; Duarte, A.C. Analysis of near-surface cracking under critical loading conditions using uncracked and cracked pavement models. J. Transp. Eng. 2013, 139, 992–1000. [Google Scholar] [CrossRef]

- Schwartz, C.W.; Li, R.; Kim, S.H.; Ceylan, H.; Gopalakrishnan, K. Sensitivity Evaluation of MEPDG Performance Prediction; Transportation Research Board, National Research Council, National Academies: Washington, DC, USA, 2011. [Google Scholar]

- Gandhi, T.; Amirkhanian, S. Laboratory Simulation of Warm Mix Asphalt (WMA) Binder Aging Characteristics. In Airfield and Highway Pavements; American Society of Civil Engineers: Reston, VA, USA, 2008; pp. 195–204. [Google Scholar]

| Design Parameter | Mix Design #1 | Mix Design #2 |

|---|---|---|

| Asphalt PG | 58–28 | 64–22 |

| NMAS, in | 0.38 | 0.38 |

| Asphalt content, % | 5.9 | 5.8 |

| Gyration number | 75 | 75 |

| % voids @ Nmax | 4.0 | 4.0 |

| Gmb | 2.449 | 2.462 |

| Gmm | 2.551 | 2.527 |

| Aggregate Gsb | 2.78 | 2.74 |

| Design ESALs, million | 0.3 to <3 | 0.3 to <3 |

| Binder PG | Sample # | Layer Thickness, in. | Aging Condition | With or Without Existing Joint | Strong or Weak Base | Observed Crack |

|---|---|---|---|---|---|---|

| 64-22 | 1 | 1.0 | 10-day | With | Weak Base | Yes |

| 64-22 | 2 | 1.0 | 10-day | With | Weak Base | Yes |

| 64-22 | 3 | 1.5 | 10-day | With | Weak Base | Yes |

| 64-22 | 4 | 1.0 | 10-day | Without | Weak Base | No |

| 64-22 | 5 | 1.0 | 5-day | With | Weak Base | No |

| 64-22 | 6 | 1.0 | 5-day | With | Weak Base | No |

| 64-22 | 7 | 2.4 | 10-day | With | Strong Base | No |

| 64-22 | 8 | 2.4 | 10-day | With | Strong Base | No |

| 64-22 | 9 | 2.4 | 10-day | With | Strong Base | No |

| 58-28 | 10 | 1.0 | 10-day | With | Weak Base | No |

| 58-28 | 11 | 1.5 | 10-day | With | Weak Base | No |

| 58-28 | 12 | 1.0 | 15-day | With | Weak Base | No |

| Binder PG | Sample # | Observed Crack | Cycle at Crack Initiation | Rut Depth at Crack Initiation, mm | Total Test Cycle | Final Rut Depth, mm |

|---|---|---|---|---|---|---|

| 64-22 | 1 | Yes | 40,000 | 5.0 | 70,000 | 7.0 |

| 64-22 | 2 | Yes | 40,000 | 5.5 | 80,000 | 7.0 |

| 64-22 | 3 | Yes | 180,000 | 2.0 | 240,000 | 3.0 |

| 64-22 | 4 | No | N/A | N/A | 100,000 | 2.0 |

| 64-22 | 5 | No | N/A | N/A | 100,000 | 10.0 |

| 64-22 | 6 | No | N/A | N/A | 100,000 | 10.0 |

| 64-22 | 7 | No | N/A | N/A | 1,500,000 | 6.0 |

| 64-22 | 8 | No | N/A | N/A | 1,500,000 | 6.0 |

| 64-22 | 9 | No | N/A | N/A | 1,500,000 | 6.0 |

| 58-28 | 10 | No | N/A | N/A | 500,000 | 11.0 |

| 58-28 | 11 | No | N/A | N/A | 500,000 | 11.5 |

| 58-28 | 12 | No | N/A | N/A | 500,000 | 9.8 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Khan, A.R.; Shen, S.; Gao, Y. Laboratory Validation of Surface-Initiated Transverse Cracking of Asphalt Pavement. Appl. Sci. 2020, 10, 1002. https://doi.org/10.3390/app10031002

Zhang W, Khan AR, Shen S, Gao Y. Laboratory Validation of Surface-Initiated Transverse Cracking of Asphalt Pavement. Applied Sciences. 2020; 10(3):1002. https://doi.org/10.3390/app10031002

Chicago/Turabian StyleZhang, Weiguang, Ali Raza Khan, Shihui Shen, and Yingda Gao. 2020. "Laboratory Validation of Surface-Initiated Transverse Cracking of Asphalt Pavement" Applied Sciences 10, no. 3: 1002. https://doi.org/10.3390/app10031002

APA StyleZhang, W., Khan, A. R., Shen, S., & Gao, Y. (2020). Laboratory Validation of Surface-Initiated Transverse Cracking of Asphalt Pavement. Applied Sciences, 10(3), 1002. https://doi.org/10.3390/app10031002