A Critical Review on the Influence of Fine Recycled Aggregates on Technical Performance, Environmental Impact and Cost of Concrete

Abstract

1. Introduction

2. State-of-Art Review

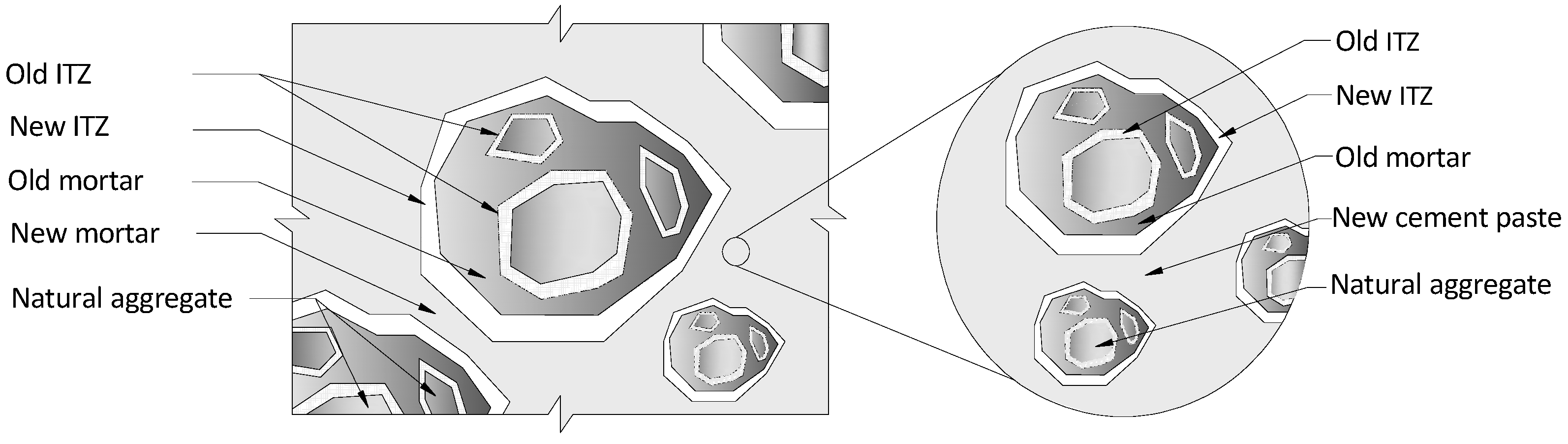

2.1. General Parameters Affecting the Performance of RFA in Concrete

2.1.1. Recycling Process

2.1.2. Particle Size

2.1.3. Quality of the Source Material

2.2. The Effect of Varying RFA Incorporation Ratio on Concrete Performance

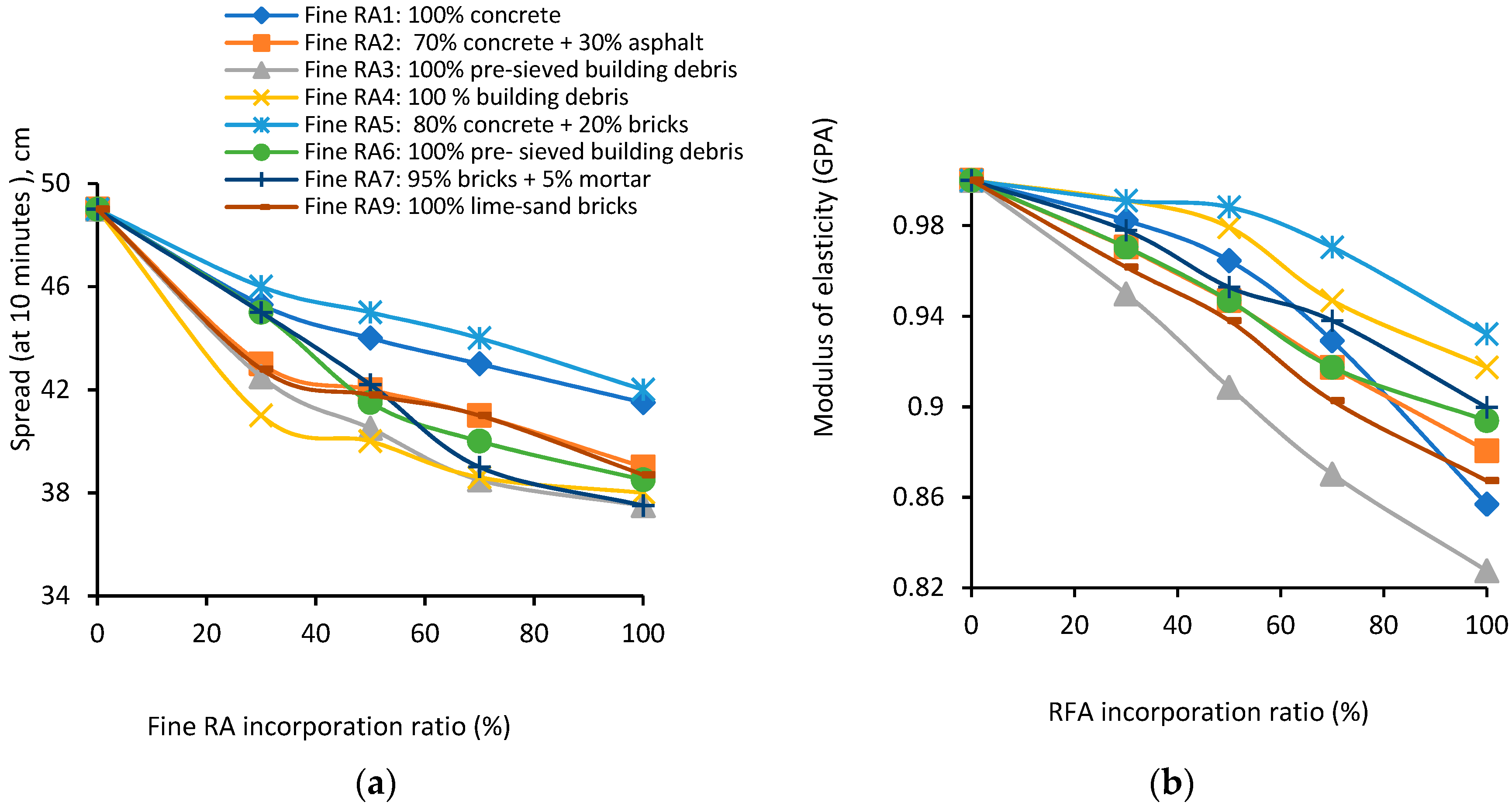

2.2.1. Workability

2.2.2. Bulk Fresh Density

2.2.3. Compressive Strength

2.2.4. Modulus of Elasticity

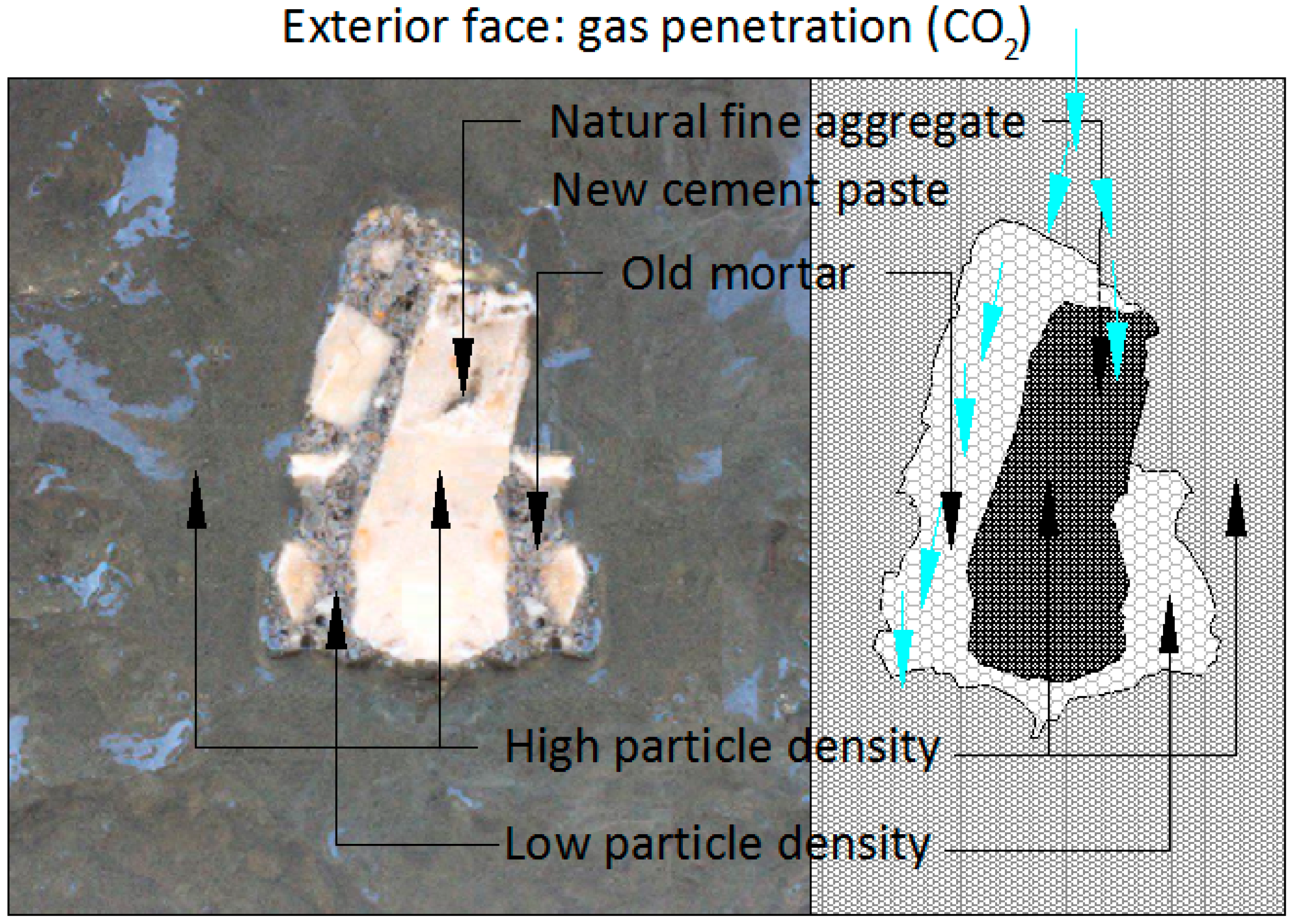

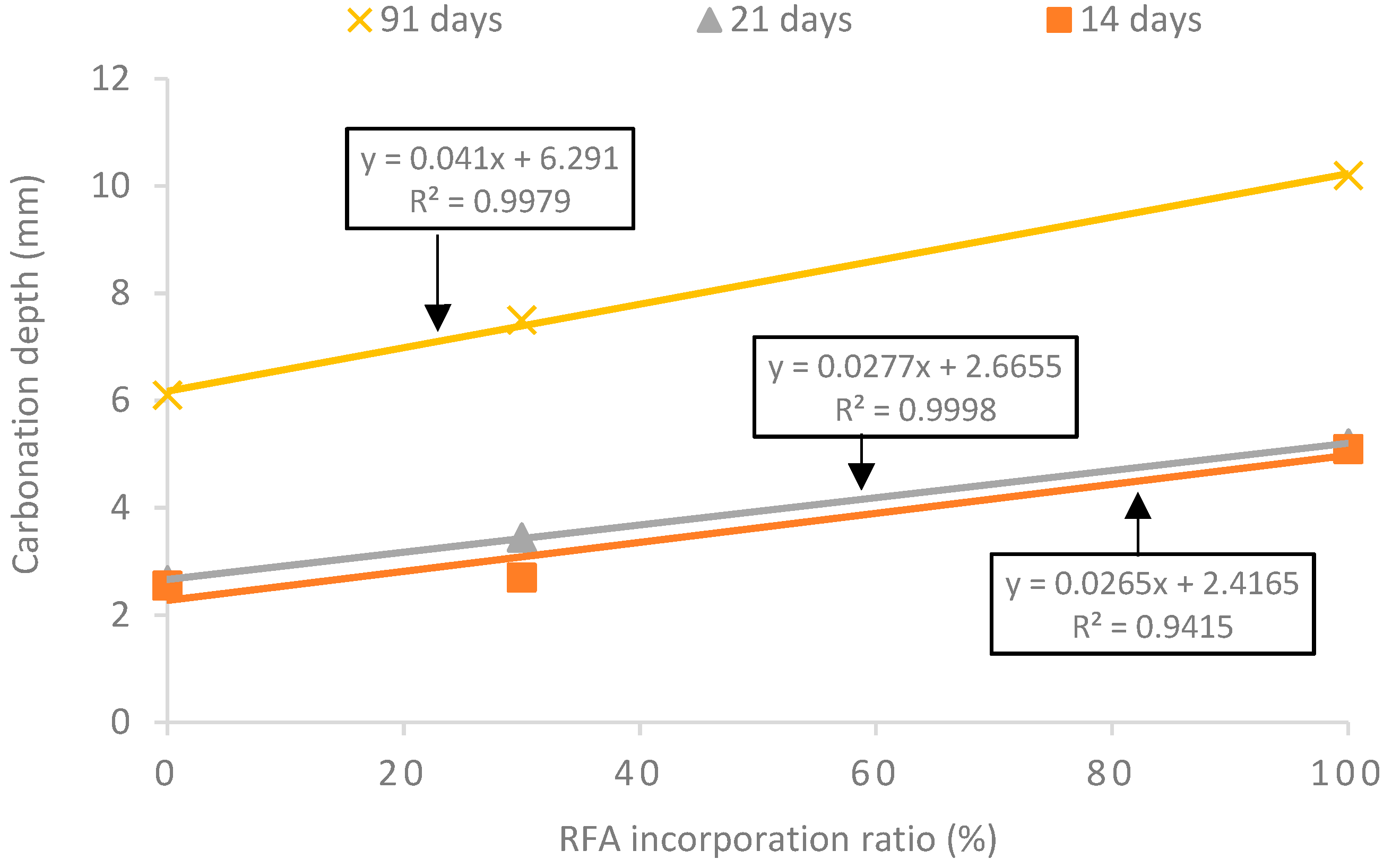

2.2.5. Carbonation Resistance

2.2.6. Chloride Penetration Resistance

2.3. The Effect of Varying RFA Incorporation Ratio on Environmental Impact of Concrete

2.3.1. Toxicity of Raw Materials for Concrete

2.3.2. Life Cycle Assessment of RFA in Concrete

2.4. The Effect of Varying RFA Incorporation Ratio on Economic Impact of Concrete

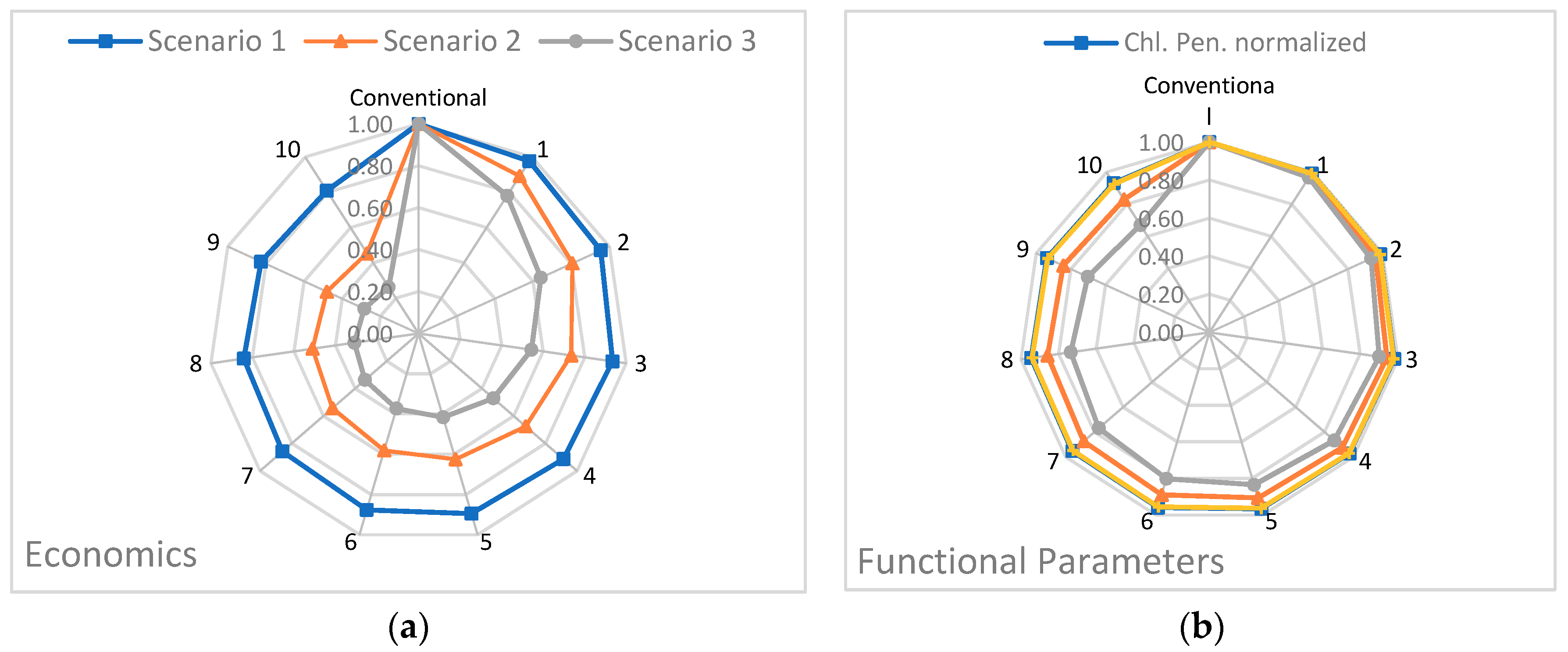

3. Sustainability Assessment of RFA Incorporation Ratio Based on Multi Criteria Decision Analysis

- Compressive strength = 30 MPa

- Expected maximum carbonation Depth = 20 mm

- Permeability to chlorides = 10 × 10−12 m2/s

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, P.; Xia, B.; Zhao, X. The importance of use and end-of-life phases to the life cycle greenhouse gas (GHG) emissions of concrete—A review. Renew. Sustain. Energy Rev. 2014, 37, 360–369. [Google Scholar] [CrossRef]

- Estanqueiro, B.; Silvestre, J.; de Brito, J.; Pinheiro, M. Environmental life cycle assessment of coarse natural and recycled aggregates for concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Freedonia. World Construction Aggregates, in No 2838; The Freedonia Group: Cleveland, OH, USA, 2012; Available online: https://www.freedoniagroup.com/industry-study/world-construction-aggregates-2838.htm (accessed on 5 January 2020).

- Dhir, R.; Paine, K. Value Added Sustainable Use of Recycled and Secondary Aggregates in Concrete. Indian Concr. J. 2010, 84, 7–26. [Google Scholar]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental evaluation of green concretes versus conventional concrete by means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Tu, A.; Chen, C.; Lehman, D.E. Mechanical properties, durability, and life-cycle assessment of concrete building blocks incorporating recycled concrete aggregates. J. Clean. Prod. 2018, 199, 136–149. [Google Scholar] [CrossRef]

- Ossa, A.; García, J.L.; Botero, E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Rodríguez-Robles, D.; van den Heede, P.; de Belie, N. 9—Life Cycle Assessment Applied to Recycled Aggregate Concrete. In New Trends in Eco-Efficient and Recycled Concrete; De Brito, J., Agrela, F., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 207–256. [Google Scholar]

- Suárez Silgado, S.; Valdiviezo, L.C.; Domingo, S.G.; Roca, X. Multi-criteria decision analysis to assess the environmental and economic performance of using recycled gypsum cement and recycled aggregate to produce concrete: The case of Catalonia (Spain). Resour. Conserv. Recycl. 2018, 133, 120–131. [Google Scholar] [CrossRef]

- EU. Directive 2008/98/CE N, The European Parliament and the Council on waste and repealing certain Directives. Off. J. Eur. Union 2008, 28. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008L0098 (accessed on 5 January 2020).

- Arora, S.; Singh, P. Analysis of flexural fatigue failure of concrete made with 100% coarse recycled concrete aggregates. Constr. Build. Mater. 2016, 102, 782–791. [Google Scholar] [CrossRef]

- Silva, R.; De Brito, J.; Dhir, R. Establishing a relationship between modulus of elasticity and compressive strength of recycled aggregate concrete. J. Clean. Prod. 2016, 112, 2171–2186. [Google Scholar] [CrossRef]

- Tošić, N.; Marinković, S.; Pecić, N.; Ignjatović, I.; Dragaš, J. Long-term behaviour of reinforced beams made with natural or recycled aggregate concrete and high-volume fly ash concrete. Constr. Build. Mater. 2018, 176, 344–358. [Google Scholar] [CrossRef]

- Tošić, N.D.; Marinković, S.B.; Ignjatović, I.S.; Bajat, B.J.; Pejović, M.P. Experimental Setup for Measuring Long-Term Behavior of Green Reinforced Concrete Beams; Springer International Publishing: Cham, Switzerland, 2018. [Google Scholar]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Korre, A.; Durucan, S. Life Cycle Assessment of Aggregates. EVA025-Final Report: Aggregates Industry Life Cycle Assessment Model: Modelling Tools and Case Studies; Waste & Resources Action Programme: Oxon, UK, 2009. [Google Scholar]

- Kurda, R. Sustainable Development of Cement-Based Materials: Application to Recycled Aggregates Concrete. Ph.D. Thesis, Instituto Superior Técnico—University of Lisbon, Lisbon, Portugal, 2017. Available online: http://bibliotecas.utl.pt/cgi-bin/koha/opac-detail.pl?biblionumber=520154 (accessed on 5 December 2019).

- Marinković, S.; Radonjanin, V.; Malesev, M.; Ignjatovic, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, T.; Silva, R.V.; de Brito, J.; Fernández, J.M.; Esquinas, A.R. Mechanical and durability performance of mortars with fine recycled concrete aggregates and reactive magnesium oxide as partial cement replacement. Cem. Concr. Compos. 2020, 105, 103420. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J. Reinforced recycled aggregate concrete slabs: Structural design based on Eurocode 2. Eng. Struct. 2020, 204, 110047. [Google Scholar] [CrossRef]

- Masood, B.; Elahi, A.; Barbhuiya, S.; Ali, B. Mechanical and durability performance of recycled aggregate concrete incorporating low calcium bentonite. Constr. Build. Mater. 2020, 237, 117760. [Google Scholar] [CrossRef]

- Gettu, R.; Pillai, R.G.; Santhanam, M.; Basavaraj, A.S.; Rathnarajan, S.; Dhanya, B. Sustainability-based decision support framework for choosing concrete mixture proportions. Mater. Struct. 2018, 51, 165. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. A comparative study of the mechanical and life cycle assessment of high-content fly ash and recycled aggregates concrete. J. Build. Eng. 2020, 101173. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. CONCRETop method: Optimization of concrete with various incorporation ratios of fly ash and recycled aggregates in terms of quality performance and life-cycle cost and environmental impacts. J. Clean. Prod. 2019, 226, 642–657. [Google Scholar] [CrossRef]

- Boudali, S.; Kerdal, D.E.; Ayed, K.; Abdulsalam, B.; Soliman, A.M. Performance of self-compacting concrete incorporating recycled concrete fines and aggregate exposed to sulphate attack. Constr. Build. Mater. 2016, 124, 705–713. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Geng, Y.; Wang, Q.; Zhang, S. Prediction of the elastic modulus and the splitting tensile strength of concrete incorporating both fine and coarse recycled aggregate. Constr. Build. Mater. 2019, 215, 332–346. [Google Scholar] [CrossRef]

- Behera, M.; Minocha, A.K.; Bhattacharyya, S.K. Flow behavior, microstructure, strength and shrinkage properties of self-compacting concrete incorporating recycled fine aggregate. Constr. Build. Mater. 2019, 228, 116819. [Google Scholar] [CrossRef]

- Vinay Kumar, B.M.; Ananthan, H.; Balaji, K.V.A. Experimental studies on utilization of recycled coarse and fine aggregates in high performance concrete mixes. Alex. Eng. J. 2018, 57, 1749–1759. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J. Water absorption and electrical resistivity of concrete with recycled concrete aggre-gates and fly ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Fan, C.-C.; Huang, R.; Hwang, H.; Chao, S.-J. Properties of concrete incorporating fine recycled aggregates from crushed concrete wastes. Constr. Build. Mater. 2016, 112, 708–715. [Google Scholar] [CrossRef]

- Velay-Lizancos, M.; Martinez-Lage, I.; Azenha, M.; Granja, J.; Vazquez-Burgo, P. Concrete with fine and coarse recycled aggregates: E-modulus evolution, compressive strength and non-destructive testing at early ages. Constr. Build. Mater. 2018, 193, 323–331. [Google Scholar] [CrossRef]

- Singh, N.; Singh, S.P. Evaluating the performance of self compacting concretes made with recycled coarse and fine aggregates using non destructive testing techniques. Constr. Build. Mater. 2018, 181, 73–84. [Google Scholar] [CrossRef]

- Geng, Y.; Zhao, M.; Yang, H.; Wang, Y. Creep model of concrete with recycled coarse and fine aggregates that accounts for creep development trend difference between recycled and natural aggregate concrete. Cem. Concr. Compos. 2019, 103, 303–317. [Google Scholar] [CrossRef]

- Leite, M.B.; Santana, V.M. Evaluation of an experimental mix proportion study and production of concrete using fine recycled aggregate. J. Build. Eng. 2019, 21, 243–253. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Lehman, D.E.; Geng, Y.; Kuder, K. Time-dependent drying shrinkage model for concrete with coarse and fine recycled aggregate. Cem. Concr. Compos. 2020, 105, 103426. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J. Carbonation of concrete made with high amount of fly ash and recycled concrete aggregates for utilization of CO2. J. CO2 Util. 2019, 29, 12–19. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, F.; Xu, L.; Zhao, H. Effect of elevated temperatures and cooling methods on strength of concrete made with coarse and fine recycled concrete aggregates. Constr. Build. Mater. 2019, 210, 540–547. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mater. 2020, 236, 117540. [Google Scholar] [CrossRef]

- Gayarre, F.L.; Pérez, J.G.; Pérez, C.L.-C.; López, M.S.; Martínez, A.L. Life cycle assessment for concrete kerbs manufactured with recycled aggregates. J. Clean. Prod. 2016, 113, 41–53. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Kim, S.; Yun, H. Evaluation of the bond behavior of steel reinforcing bars in recycled fine aggregate concrete. Cem. Concr. Compos. 2014, 46, 8–18. [Google Scholar] [CrossRef]

- Lee, S. Influence of recycled fine aggregates on the resistance of mortars to magnesium sulfate attack. Waste Manag. 2009, 29, 2385–2391. [Google Scholar] [CrossRef]

- Wegen, G.; Haverkort, R. Recycled construction and demolition waste as a fine aggregate for concrete. In Proceedings of the International Symposium on Sustainable Construction: Use of Recycled Concrete Aggregate, London, UK, 11–12 November 1998; pp. 333–346. [Google Scholar]

- Song, I.H.; Ryou, J.S. Hybrid techniques for quality improvement of recycled fine aggregate. Constr. Build. Mater. 2014, 72, 56–64. [Google Scholar] [CrossRef]

- Chisholm, D. Best Practice Guide for the Use of Recycled Aggregates in New Concrete; Cement & Concrete Association of New Zealand: Wellington, New Zealand, 2011; pp. 31–34. [Google Scholar]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Chan, C. Use of Recycled Aggregate in Shotcrete and Concrete 193. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 1998. [Google Scholar]

- Kou, C.; Poon, S. Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- Leite, M. Evaluation of the Mechanical Properties of Concrete Produced with Recycled Aggregates from Construction and Demolition Wastes. Ph.D. Thesis, Federal University of Rio Grande do Sul, Rio Grande do Sul, Porto Alegre, Brasil, 2001. [Google Scholar]

- Müeller, A.; Winkler, A. Characteristics of processed concrete rubble. In Sustainable Construction: Use of Recycled Concrete Aggregate; Dhir, R.K., Henderson, N.A., Limbachiya, M.C., Eds.; Thomas Telford: London, UK, 1998; pp. 109–119. [Google Scholar]

- Sérifou, M.; Sbartaï, M.; Yotte, S.; Boffoué, O.; Emeruwa, E.; Bos, F. A Study of Concrete Made with Fine and Coarse Aggregates Recycled from Fresh Concrete Waste. J. Constr. Eng. 2013, 2013, 317182. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; de Brito, J.; Martínez-Abella, F.; González-Taboada, I.; Silva, P. Study of the rheology of self-compacting concrete with fine recycled concrete aggregates. Constr. Build. Mater. 2015, 96, 491–501. [Google Scholar] [CrossRef]

- Cartuxo, F.; De Brito, J.; Evangelista, L.; Jiménez, R.; Ledesma, F. Rheological behaviour of concrete made with fine recycled concrete aggregates—Influence of the superplasticizer. Constr. Build. Mater. 2015, 89, 36–47. [Google Scholar] [CrossRef]

- Evangelista, L.; Guedes, M.; De Brito, J.; Ferro, C.; Pereira, F. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Hasaba, S.; Kawamura, M.; Toriik, K.; Takemoto, K. Drying shrinkage and durability of concrete made of recycled concrete aggregates. Transl. Jpn. Concr. Inst. 1981, 3, 55–60. [Google Scholar]

- Kikushi, M.; Dosho, Y.; Narikawa, M.; Miura, T. Application of recycled aggregate concrete for structural concrete. Part 1—Experimental study on the quality of recycled aggregate and recycled aggregate concrete. In Sustainable Construction: Use of Recycled Concrete Aggregate, Proceedings of the International Symposium on Sustainable Construction: Use of Recycled Concrete Aggregate, London, UK, 11–12 November 1998; University of Dundee: Dundee, Scotland, 1998; pp. 55–68. [Google Scholar]

- Levy, S.; Helene, P. Durability of concrete mixed with fine recycled aggregates. Exacta 2007, 5, 25–34. [Google Scholar] [CrossRef]

- Lin, Y.; Tyan, Y.; Chang, T.; Chang, C. An assessment of optimal mixture for concrete made with recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 1373–1380. [Google Scholar] [CrossRef]

- Schoon, J.; De-Buysser, K.; Driessche, I.; Belie, N.D. Fines extracted from recycled concrete as alternative raw material for Portland cement clinker production. Cem. Concr. Compos. 2015, 58, 70–80. [Google Scholar] [CrossRef]

- Sim, J.; Park, C. Compressive strength and resistance to chloride ion penetration and carbonation of recycled aggregate concrete with varying amount of fly ash and fine recycled aggregate. Waste Manag. 2011, 31, 2352–2360. [Google Scholar] [CrossRef]

- Uygunoğlu, T.; Topcu, I.; Gencel, O.; Brostow, W. The effect of fly ash content and types of aggregates on the properties of pre-fabricated concrete interlocking blocks (PCIBs). Constr. Build. Mater. 2012, 30, 180–187. [Google Scholar] [CrossRef]

- Wang, Z. The Effects of Aggregate Moisture Conditions on Rheological Behaviors of High-Workability Mortar Prepared with Fine Recycled-Concrete Aggregate. Master’s Thesis, Graduate Council of Texas State University, San Marcos, TX, USA, 2012. [Google Scholar]

- Yaprak, H.; Aruntas, H.; Demir, I.; Simsek, O.; Durmus, G. Effects of the fine recycled concrete aggregates on the concrete properties. Int. J. Phys. Sci. 2011, 6, 2455–2461. [Google Scholar]

- Zega, J.; Maio, A.D. Use of recycled fine aggregate in concretes with durable requirements. Waste Manag. 2011, 31, 2336–2340. [Google Scholar] [CrossRef]

- Solyman, M. Classification of Recycled Sands and Their Applications as Fine Aggregates for Concrete and Bituminous Mixtures. Klassifizierung von Recycling-Brechsanden und Ihre Anwendungen Für Beton und Für Straßenbaustoffe 196. Ph.D. Thesis, Kassel University Press, Kassel, Germany, 2005. Available online: https://books.google.pt/books?id=CCyAbpG3OTwC&printsec=frontcover#v=onepage&q&f=false (accessed on 5 January 2020).

- Geng, J.; Sun, J. Characteristics of the carbonation resistance of recycled fine aggregate concrete. Constr. Build. Mater. 2013, 49, 814–820. [Google Scholar] [CrossRef]

- Kim, K.; Shin, M.; Cha, S. Combined effects of recycled aggregate and fly ash towards concrete sustainability. Constr. Build. Mater. 2013, 48, 499–507. [Google Scholar] [CrossRef]

- Somna, R.; Jaturapitakkul, C.; Amde, A.M. Effect of ground fly ash and ground bagasse ash on the durability of recycled aggregate concrete. Cem. Concr. Compos. 2012, 34, 848–854. [Google Scholar] [CrossRef]

- Pereira, P. Structural Concrete with Incorporated Recycled Concrete Fine Aggregates: Influence of Superplasticizers on the Mechanical Behaviour (Translated from Portuguese) 144. Master’s Thesis, Instituto Superior Técnico, Lisbon, Portugal, 2010. [Google Scholar]

- Ramos, D. Freeze Thaw Resistance of Concrete Produced with Fine Recycled Concrete Aggregates 135. Master’s Thesis, Universidade de Lisboa/Instituto Superior Técnico, Lisbon, Portugal, 2014. (In Portuguess). [Google Scholar]

- Mukai, T.; Kikuchi, M.; Koizumi, H. Fundamental Study on Bond Properties between Recycled Aggregate Concrete and Steel Bars; Cement Association of Japan: Tokyo, Japan, 1978; Volume 32. [Google Scholar]

- Hansen, C.; Narud, H. Strength of recycled concrete made from crushed concrete coarse aggregate. Concr. Int. 1983, 5, 79–83. [Google Scholar]

- Buck, A. Recycled concrete as a source of aggregate. ACI Mater. J. 1977, 74, 212–219. [Google Scholar]

- Malhotra, M. Use of recycled concrete as a new aggregate. In Proceedings of the Symposium on Energy and Resource Conservation in the Cement and Concrete Industry, Ottawa, ON, Canada, 21–23 October 1978. CANMET Report no. 76-8. [Google Scholar]

- Ravindarajah, S.; Tam, T. Properties of concrete made with crushed concrete as coarse aggregate. Mag. Concr. Res. March 1985, 29–38. [Google Scholar] [CrossRef]

- Bogas, A.; de Brito, J.; Ramos, D. Freeze-thaw resistance of concrete produced with fine recycled concrete aggregates. J. Clean. Prod. 2016. [Google Scholar] [CrossRef]

- Hurlbert, S.H. The ancient black art and transdisciplinary extent of pseudoreplication. J. Comp. Psychol. 2009, 123, 434. [Google Scholar] [CrossRef] [PubMed]

- Silva, R. Use of Recycled Aggregates from Construction and Demolition Wastes in the Production of Structural Concrete 274. Ph.D. Thesis, Department of Civil Engineering, Universidade de Lisboa, Instituto Superior Técnico, Lisboa, Portugal, 2015. [Google Scholar]

- Khatib, M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Katz, A. Properties of concrete made with recycled aggregate from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Ahmed, S. Properties of concrete containing recycled fine aggregate and fly ash. In Proceedings of the Concrete 2011 Conference, Perth, Australia, 12 October 2011. [Google Scholar]

- EuroLightCon. Tensile Strength as Design Parameter—Economic Design and Construction with Light Weight Aggregate Concrete. Document BE96-3942/R32; European Union—Brite EuRam III: Luxembourg, 2000. [Google Scholar]

- Pereira, P.; Evangelista, L.; de Brito, J. The effect of superplasticizers on the mechanical performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2012, 34, 1044–1052. [Google Scholar] [CrossRef]

- Cabral, A.; Schalch, V.; Molin, D.; Ribeiro, J. Mechanical properties modelling of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 421–430. [Google Scholar] [CrossRef]

- Cartuxo, F. Concrete with Fine Recycled Concrete Aggregates: Influence of Superplasticizers on the Durability Related Performance (Translated from Portuguese) 232. Master’s Thesis, Universidade de Lisboa/Instituto Superior Técnico, Lisboa, Portugal, 2013. [Google Scholar]

- Basheer, L.; Cleland, D.; Kropp, J. Assessment of the durability of concrete from its permea-tion properties—A review. Constr. Build. Mater. 2001, 15, 93–103. [Google Scholar] [CrossRef]

- Levy, M.; Helene, P. Durability of recycled aggregates concrete: A safe way to sustainable development. Cem. Concr. Res. 2004, 34, 1975–1980. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology, 2nd ed.; Pearson, Prentice Hall: London, UK, 2010; ISBN 9780273732198. [Google Scholar]

- Barbudo, A.; Galvín, A.P.; Agrela, F.; Ayuso, J.; Jiménez, J.R. Correlation analysis between sulphate content and leaching of sulphates in recycled aggregates from construction and demolition wastes. Waste Manag. 2012, 32, 1229–1235. [Google Scholar] [CrossRef]

- Engelsen, C.; Lund, O.; Breedveld, G.; Mehus, J.; Petkovic, G.; Håøya, A. Leaching characteristic of unbound recycled aggregates: Preliminary study and ongoing research. In Proceedings of the 5th International Conference on the Environmental and Technical Implications of Construction with Alternative Materials, San Sebastian, Spain, 4–6 June 2003; Available online: https://www.vegvesen.no/_attachment/110361/binary/192280 (accessed on 10 January 2020).

- Durão, V.; Silvestre, J.D.; Ricardo, M.; de Brito, J. Assessment and communication of the environmental performance of construction products in Europe: Comparison between PEF and EN 15804 compliant EPD schemes. Resour. Conserv. Recycl. 2020, 156, 104703. [Google Scholar] [CrossRef]

- Pinheiro, M. Environment and Sustainable Construction; Rev.; Correia, F., Branco, F., Guedes, M., Eds.; Instituto do Ambiente: Amadora, Portugal, 2006. (In Portuguess) [Google Scholar]

- Hafez, H.; Kurda, R.; Cheung, W.M.; Nagaratnam, B. A Systematic Review of the Discrepancies in Life Cycle Assessments of Green Concrete. Appl. Sci. 2019, 9, 4803. [Google Scholar] [CrossRef]

- Sagastume Gutiérrez, A.; Eras, J.J.C.; Gaviria, C.A.; van Caneghem, J.; Vandecasteele, C. Improved selection of the functional unit in environmental impact assessment of cement. J. Clean. Prod. 2017, 168, 463–473. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Optimizing recycled concrete containing high volume of fly ash in terms of the embodied energy and chloride ion resistance. J. Clean. Prod. 2018, 194, 735–750. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Environmental life cycle assessment of concrete made with fine recycled concrete aggregates. In SB07 Lisbon—Sustainable Construction, Materials and Practices: Challenge of the Industry for the New Millennium; In-House Publishing: Rotterdam, The Netherlands, 2008; 6p. [Google Scholar]

- Weil, M.; Jeske, U.; Schebek, L. Closed-loop recycling of construction and demolition waste in Germany in view of stricter environmental threshold values. Waste Manag. Res. 2006, 24, 197–206. [Google Scholar] [CrossRef] [PubMed]

- Knoeri, C.; Sanyé-Mengual, E.; Althaus, H. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Braga, A. Comparative Analysis of the Life Cycle Assessment of Conventional and Recycled Aggregate Concrete 112. Master’s Thesis, Instituto Superior Técnico—University of Lisbon, Lisbon, Portugal, 2015. Available online: https://fenix.tecnico.ulisboa.pt/cursos/mec/dissertacao/846778572210846 (accessed on 10 December 2019). (In Portuguese).

- Tošić, N.; Marinković, S.; Dašić, T.; Stanić, M. Multicriteria optimization of natural and recycled aggregate concrete for structural use. J. Clean. Prod. 2015, 87, 766–776. [Google Scholar] [CrossRef]

- Sjunnesson, J. Life Cycle Assessment of Concrete. Master’s Thesis, Department of Technology and Society, Lund University, Lund, Sweden, 2005. [Google Scholar]

- Göswein, V.; Gonçalves, A.; Silvestre, J.D.; Freire, F.; Habert, G.; Kurda, R. Transportation matters—Does it? GIS-based comparative environmental assessment of concrete mixes with cement, fly ash, natural and recycled aggregates. Resour. Conserv. Recycl. 2018, 137, 1–10. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, M.; Xie, H.; Wang, Y. Assessment of CO2 emissions and cost in fly ash concrete. In Environment, Energy and Applied Technology, Proceedings of the 2014 International Conference on Frontier of Energy and Environment Engineering (ICFEEE 2014), Taiwan, 6–7 December 2014; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Yang, K.-H.; Seo, E.-A.; Jung, Y.-B.; Tae, S.-H. Effect of ground granulated blast-furnace slag on life-cycle environmental impact of concrete. J. Korea Concr. Inst. 2014, 26, 13–21. [Google Scholar] [CrossRef]

- Mateus, R.; Neiva, S.; Bragança, L.; Mendonça, P.; Macieira, M. Sustainability assessment of an innovative lightweight building technology for partition walls–comparison with conventional technologies. Build. Environ. 2013, 67, 147–159. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Comparative sustainability assessment of binary blended concretes using Supplementary Cementitious Materials (SCMs) and Ordinary Portland Cement (OPC). J. Clean. Prod. 2019, 220, 445–459. [Google Scholar] [CrossRef]

| Equation | Notes | Reference |

|---|---|---|

| Taking into account the w/c ratio; replacement ratio; quality RFA. Effective w/c ratio considered 0.55 and correlation factors a and b equal to 4.228 and 0.22, respectively, with a coefficient of determination R2 = 0.916. The equation was developed based on Model code [83] | [84] | |

| Relationship between compressive strength and modulus of elasticity. The equation can be used to determine RFA and CRA concrete, taking into account the modulus of elasticity of RFA concrete 10% lower than that of CRA concrete | [85] | |

| The relationship between compressive strength and modules of elasticity. With a coefficient of determination R2 = 0.80 | Literature review |

| LCA Boundaries | Life Cycle Stages | Life Cycle Stage | |

|---|---|---|---|

| Cradle to gate | Product stage (A1–A3) | A1 | Raw material extraction and processing, processing of secondary material input |

| A2 | Transport to the manufacturer | ||

| A3 | Manufacturing | ||

| Gate to grave | Construction process stage (A4–A5) | A4 | Transport to the building site |

| A5 | Installation into the building | ||

| Use stage—information modules related to the building fabric (B1–B5) | B1 | Use or application of the installed product | |

| B2 | Maintenance | ||

| B3 | Repair | ||

| Use stage—information modules related to the operation of the building (B4–B5) | B4 | Operational energy use | |

| B5 | Operational water use | ||

| End-of-life stage (C1–C4) | C1 | De-construction, demolition | |

| C2 | Transport to waste processing | ||

| C3 | Waste processing for reuse, recovery and/or recycling (3R) | ||

| C4 | Disposal | ||

| Source | Country | ADP | GWP | ODP | POCP | AP | EP | Pe-NRe |

|---|---|---|---|---|---|---|---|---|

| kg Sb eq | kg CO2 eq | kg CFC−11 eq | kg C2H4 eq | kg SO2 eq | kg PO4−3 eq | MJ | ||

| Natural Fine Aggregates | ||||||||

| Braga [102] | Portugal | 3.37 × 10−10 | 9.87 × 10−3 | 1.71 × 10−11 | 2.80 × 10−6 | 4.58 × 10−5 | 1.08 × 10−5 | 1.35 × 10−1 |

| 1.24 × 10−9 | 2.79 × 10−2 | 2.26 × 10−10 | 9.06 × 10−6 | 1.59 × 10−4 | 3.54 × 10−5 | 3.92 × 10−1 | ||

| 1.09 × 10−9 | 2.44 × 10−2 | 2.43 × 10−10 | 7.83 × 10−6 | 1.44 × 10−4 | 3.18 × 10−5 | 3.44 × 10−1 | ||

| 1.39 × 10−9 | 3.14 × 10−2 | 2.09 × 10−10 | 1.03 × 10−5 | 1.75 × 10−4 | 3.90 × 10−5 | 4.41 × 10−1 | ||

| Tošić et al. [103] | Serbia | 1.43 × 10−3 | 2.78 × 10−7 | 1.64 × 10−5 | 2.02 × 10−6 | 1.48 × 10−05 | ||

| 2.12 × 10−3 | 4.15 × 10−7 | 2.42 × 10−5 | 3.01 × 10−6 | 2.19 × 10−5 | ||||

| Korre and Durucan [16] | UK | 9.30 × 10−4 | 1.06 × 10−10 | 4.58 × 10−7 | 5.85 × 10−6 | 4.35 × 10−7 | ||

| 3.29 × 10−3 | 4.50 × 10−10 | 1.20 × 10−6 | 1.89 × 10−5 | 1.07 × 10−6 | ||||

| 2.16 × 10−3 | 3.19 × 10−10 | 7.35 × 10−1 | 1.20 × 10−5 | 6.87 × 10−7 | ||||

| 1.85 × 10−3 | 2.14 × 10−10 | 9.85 × 10−7 | 1.03 × 10−5 | 5.90 × 10−7 | ||||

| 3.79 × 10−2 | 8.50 × 10−6 | 5.40 × 10−5 | 6.77 × 10−4 | 1.04 × 10−4 | ||||

| 3.80 × 10−2 | 1.78 × 10−10 | 5.40 × 10−5 | 6.77 × 10−4 | 1.04 × 10−4 | ||||

| Marinkovic’ et al. [18] | Serbia | 1.43 × 10−3 | 2.82 × 10−7 | 1.64 × 10−5 | 2.02 × 10−6 | |||

| Sjunnesson [104] | Sweden | 1.60 × 10−3 | 1.70 × 10−6 | 7.80 × 10−7 | 3.00 × 10−2 | |||

| 7.00 × 10−4 | 3.80 × 10−10 | 5.00 × 10−5 | 1.24 × 10−3 | |||||

| Average | 1.01 × 10−9 | 1.23 × 10−2 | 8.50 × 10−7 | 4.90 × 10−2 | 1.36 × 10−4 | 2.58 × 10−5 | 1.68 × 10−1 | |

| Recycled Fine Aggregates | ||||||||

| Braga [102] | Portugal | 2.12 × 10−10 | 7.44 × 10−3 | 1.60 × 10−10 | 2.14 × 10−6 | 4.05 × 10−5 | 9.28 × 10−6 | 1.08 × 10−1 |

| Tošić et al. [103] | Serbia | 2.28 × 10−3 | 7.03 × 10−7 | 2.49 × 10−5 | 3.01 × 10−6 | 2.59 × 10−5 | ||

| 3.38 × 10−3 | 1.18 × 10−6 | 3.61 × 10−5 | 4.34 × 10−6 | 3.95 × 10−5 | ||||

| Korre and Durucan [16] | UK | 2.42 × 10−3 | 2.83 × 10−10 | 8.00 × 10−7 | 1.21 × 10−5 | 7.06 × 10−7 | ||

| Marinkovic´ et al. [18] | Serbia | 1.74 × 10−3 | 3.40 × 10−7 | 2.00 × 10−5 | 2.47 × 10−6 | |||

| Average | 2.12 × 10−10 | 3.45 × 10−3 | 2.22 × 10−10 | 1.03 × 10−6 | 2.67 × 10−5 | 3.96 × 10−6 | 3.60 × 10−2 | |

| Lorry/Maximum Capacity (Tonnes) | Baseline CML Method | Cumulative Energy Demand | |||||

|---|---|---|---|---|---|---|---|

| ADP | GWP | ODP | POCP | AP | EP | P X10-NRe | |

| kg Sb eq | kg CO2 eq | kg CFC−11 eq | kg C2H4 eq | kg SO2 eq | kg PO4−3 eq | MJ | |

| Articulated-lorry transport/27 t | 1.98 × 10−12 | 4.98 × 10−5 | 1.01 × 10−13 | 1.59 × 10−8 | 2.24 × 10−7 | 5.14 × 10−8 | 6.73 × 10−4 |

| Lorry−transport/17.3 t | 2.62 × 10−12 | 6.57 × 10−5 | 1.33 × 10−13 | 2.24 × 10−8 | 3.11 × 10−7 | 7.20 × 10−8 | 9.27 × 10−4 |

| Environmental Indicators | NA (Average) | NA/km | RFA (Average) | RFA/km | Equation for Y (Impact for 1 kg of Fine Aggregates Concrete Based on % Incorporation (X) of RFA | |

|---|---|---|---|---|---|---|

| ADP | kg Sb eq | 1.01 × 10−9 | 9.47 × 10−12 | 2.12 × 10−10 | 1.70 × 10−12 | Y = (D2 × 1.7 × 10−12 − D1 × 9.47 × 10−12) X + D1 × 9.47 × 10−12 |

| GWP | kg CO2 eq | 1.23 × 10−2 | 1.15 × 10−4 | 3.45 × 10−3 | 2.76 × 10−5 | Y= (D2 × 2.76 × 10−5 − D1 × 1.15 × 10−4) X + D1 × 1.15 × 10−4 |

| ODP | kg CFC−11 eq | 8.50 × 10−7 | 7.97 × 10−9 | 2.22 × 10−10 | 1.78 × 10−12 | Y = (D2 × 1.78 × 10−12 − D1 × 7.97 × 10−9) X + D1 × 7.97 × 10−9 |

| POCP | kg C2H4 eq | 4.90 × 10−2 | 4.59 × 10−4 | 1.03 × 10−6 | 8.24 × 10−9 | Y = (D2 × 8.24 × 10−9 − D1 × 4.59 × 10−4) X + D1 × 4.59 × 10−4 |

| AP | kg SO2 eq | 1.36 × 10−4 | 1.28 × 10−6 | 2.67 × 10−5 | 2.14 × 10−7 | Y= (D2 × 2.14 × 10−7 − D1 × 1.28 × 10−6) X + D1 × 1.28 × 10−6 |

| EP | kg PO4−3 eq | 2.58 × 10−5 | 2.42 × 10−7 | 3.96 × 10−6 | 3.17 × 10−8 | Y= (D2 × 3.17 × 10−8 − D1 × 2.42 × 10−7) X + D1 × 2.47 × 10−7 |

| PE-NRe | MJ | 1.68 × 10−1 | 1.58 × 10−3 | 3.60 × 10−2 | 2.88 × 10−4 | Y = (D2 × 2.88 × 10−4 − D1 × 1.58 × 10−3) X + D1 × 2.88 × 10−3 |

| Parameter | Empirical Function of Incorporation Ratio X (%) for the RFA in the Concrete Mix | Weights (%) | |

|---|---|---|---|

| Y (Functional) | Yfc = Fci – 0.022X | 25 | 33.3 |

| 25 | |||

| YCD = D90D + 0.041X | 25 | ||

| Ycl (PCl2/PCl1) = 1 + 0.0033X | 25 | ||

| Y (Environmental) | YADP = (D2 × 1.7 × 10−12 − D1 × 9.47 × 10−12) X + D1 × 9.47 × 10−12 | 14.3 | 33.3 |

| YGWP= (D2 × 2.65 × 10−5 − D1 × 1.16 × 10−4) X + D1 × 1.16 × 10−4 | 14.3 | ||

| YODP = (D2 × 1.77 × 10−12 −D1 × 2 × 10−12) X + D1 × 2 × 10−12 | 14.3 | ||

| YPOCP = D2 × 8.26 × 10−9 − D1 × 9.42 × 10−8) X + D1 × 9.42 × 10−8 | 14.3 | ||

| YAP= (D2 × 2.14 × 10−7 − D1 × 1.27 × 10−6) X + D1 × 1.27 × 10−6 | 14.3 | ||

| YEP= (D2 × 3.17 × 10−8 − D1 × 2.41 × 10−7) X + D1 × 2.41 × 10−7 | 14.3 | ||

| YPe-NRe= (D2 × 2.88 × 10−4 − D1 × 1.57 × 10−3) X + D1 × 1.57 × 10−3 | 14.3 | ||

| Y (Economic) | Yeconomic = 3.5 × D1 + X × (0.045 × D2 – 3.5 × D1) | 100 | 33.3 |

| Alternatives | X (%) | Functional | Scenario 1 | Scenario 2 | Scenario 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Environmental | Economic | Single Score | Environmental | Economic | Single Score | Environmental | Economic | Single Score | |||

| NA | 0% | 1.00 | 0.13 | 1.00 | 0.71 | 0.27 | 1.00 | 0.76 | 0.43 | 1.00 | 0.81 |

| 1 | 10 | 0.98 | 0.14 | 0.98 | 0.70 | 0.28 | 0.89 | 0.72 | 0.44 | 0.78 | 0.74 |

| 2 | 20 | 0.97 | 0.16 | 0.96 | 0.69 | 0.30 | 0.81 | 0.69 | 0.47 | 0.64 | 0.69 |

| 3 | 30 | 0.95 | 0.17 | 0.93 | 0.69 | 0.32 | 0.74 | 0.67 | 0.49 | 0.54 | 0.66 |

| 4 | 40 | 0.93 | 0.19 | 0.91 | 0.68 | 0.34 | 0.68 | 0.65 | 0.52 | 0.47 | 0.64 |

| 5 | 50 | 0.92 | 0.22 | 0.89 | 0.68 | 0.37 | 0.63 | 0.64 | 0.56 | 0.42 | 0.63 |

| 6 | 60 | 0.90 | 0.25 | 0.88 | 0.68 | 0.41 | 0.58 | 0.63 | 0.61 | 0.37 | 0.63 |

| 7 | 70 | 0.89 | 0.30 | 0.86 | 0.68 | 0.47 | 0.54 | 0.63 | 0.66 | 0.34 | 0.63 |

| 8 | 80 | 0.87 | 0.38 | 0.84 | 0.70 | 0.55 | 0.51 | 0.65 | 0.74 | 0.31 | 0.64 |

| 9 | 90 | 0.86 | 0.52 | 0.83 | 0.73 | 0.70 | 0.48 | 0.68 | 0.84 | 0.28 | 0.66 |

| 10 | 100 | 0.84 | 1.00 | 0.81 | 0.88 | 1.00 | 0.45 | 0.76 | 1.00 | 0.26 | 0.70 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hafez, H.; Kurda, R.; Kurda, R.; Al-Hadad, B.; Mustafa, R.; Ali, B. A Critical Review on the Influence of Fine Recycled Aggregates on Technical Performance, Environmental Impact and Cost of Concrete. Appl. Sci. 2020, 10, 1018. https://doi.org/10.3390/app10031018

Hafez H, Kurda R, Kurda R, Al-Hadad B, Mustafa R, Ali B. A Critical Review on the Influence of Fine Recycled Aggregates on Technical Performance, Environmental Impact and Cost of Concrete. Applied Sciences. 2020; 10(3):1018. https://doi.org/10.3390/app10031018

Chicago/Turabian StyleHafez, Hisham, Reben Kurda, Rawaz Kurda, Botan Al-Hadad, Rasheed Mustafa, and Barham Ali. 2020. "A Critical Review on the Influence of Fine Recycled Aggregates on Technical Performance, Environmental Impact and Cost of Concrete" Applied Sciences 10, no. 3: 1018. https://doi.org/10.3390/app10031018

APA StyleHafez, H., Kurda, R., Kurda, R., Al-Hadad, B., Mustafa, R., & Ali, B. (2020). A Critical Review on the Influence of Fine Recycled Aggregates on Technical Performance, Environmental Impact and Cost of Concrete. Applied Sciences, 10(3), 1018. https://doi.org/10.3390/app10031018