A Review of the Flow-Induced Noise Study for Centrifugal Pumps

Abstract

:1. Introduction

2. The Generation Mechanism and Propagation Route of Flow-Induced Noise

3. Study Methodologies

3.1. Theoretical Study of Hydrodynamic Noise

3.2. Numerical Simulation Study

3.3. Experimental Measurement Study

4. The Study about the Distribution Characteristics of Flow-Induced Noise

4.1. Noise Source Identification and Comparison

4.2. Frequency Response Analysis of Flow-Induced Noise

4.3. Directivity Characteristics Analysis of Sound Field

4.4. Noise Changing Characteristics Analysis under Various Operating Conditions

5. Noise Optimization Design of Centrifugal Pumps

6. Outlook for Future Study

- (1)

- Analysis model establishment of the generation, distribution and propagation mechanism for flow-induced noise. The analysis of the propagation mechanism of flow-induced noise, which has been proved that it is affected by the synergy of flow and sound fields in the process of fluid flow [131], is not involved in current study of the flow-induced noise of centrifugal pumps. It is beneficial for the prevention and control of flow-induced noise to establish the analysis model of the generation, distribution and propagation mechanism for flow-induced noise. The analysis model could be used for systematically analyzing the generation mechanism, the proportions of noise sources with different properties, the spatial-temporal distribution characteristics and the propagation characteristics of flow-induced noise.

- (2)

- Development of high precision and fast numerical simulation method. There are three-dimensional steady and transient iterative calculation processes in the numerical simulation of flow-induced noise, which are tedious and time-consuming. To obtain high precision results, a large amount of grid system is required. Predictably, the development of high precision and fast simulation method could promote the study of flow-induced noise.

- (3)

- Noise visualization experiment. To acquire the spatial distribution and dynamic changing characteristics of the flow-induced noise of centrifugal pumps more accurately, the real-time measurement of the whole sound field of centrifugal pumps should be conducted by developing the noise visualization technology.

7. Conclusions

- (1)

- The flow-induced noise of centrifugal pumps is related to various complex flow phenomena. During the normal operating condition, the noise induced by rotor-stator interaction is the main component of overall noise. The rotor-stator interaction could cause the frequency response characteristics that are dominated by characteristic frequencies in a low frequency range. The cavitation could inhibit the rotor-stator interaction to some extent. With the development of cavitation, the frequency response characteristics of flow-induced noise that are dominated by characteristic frequencies weaken and the noise level in a high frequency range increases gradually. In addition, when the flow-induced noise generates inside centrifugal pumps, the noise could not only propagate to the inlet and outlet pipes but also propagate to the external environment, namely the internal flow noise and external radiation noise, respectively.

- (2)

- Theoretical study, numerical simulation and experimental measurement are the main methodologies to analyze the flow-induced noise of centrifugal pumps. Theoretical study analyzes the subject through the governing equation level. Because of the obscurity of the theoretical study, the theoretical conclusions are always combined with numerical simulation. Numerical simulation is currently the most popular and versatile method to analyze the flow-induced noise by combining the Lighthill acoustic analogy theory with CFD and taking the acoustic-vibration-coupling effect into consideration, but the numerical simulation results need to be verified by experiment. For experimental measurement, the flow-induced noise could be directly measured but the measurement object and mode are relatively monotonous and the measurement results are affected by mechanical vibration.

- (3)

- The analysis of the distribution characteristics of flow-induced noise mainly includes the noise source identification and comparison, the frequency response analysis, the directivity characteristics of sound field and the noise changing characteristics under various operating conditions. The main noise source region is located near the volute tongue and the volute dipole source has more contribution to internal flow noise compared with the impeller dipole source. Besides the dipole source, the vibration of pump structures induced by unsteady flow fluctuations is also a kind of noise source and it makes the biggest contribution to external radiation noise. Under the influence of a noise source, specific frequency response characteristics of flow-induced noise are formed and the internal flow noise shows a trend of fluctuating downward with the increase of frequency, while the maximum of external radiation noise appears between 1000 and 2000 Hz. Based on the frequency response analysis results, directivity characteristics could be obtained. The internal flow noise and external radiation noise show the similar dipole directivity characteristics and the noise level near the tongue is higher than that far away from the tongue. The internal flow noise and external radiation noise increase with the growth of rotational speed. With the growth of flow rate, the internal flow noise reaches a minimum at rated operating conditions generally and increases at off-design conditions, while the external radiation noise increases gradually. Besides the effects of rotational speed and flow rate on noise, the medium temperature could also affect the noise level.

- (4)

- As the final goal of the flow-induced noise study of centrifugal pumps, the noise optimization design is mainly realized by changing the pump structures to reduce the rotor-stator interaction intensity. However, different structures have different effects on the flow-induced noise. Therefore, it is required to consider the impacts of various structure variables and to combine the evaluation criteria of noise with that of hydraulic performance, then carry out multi-objective comprehensive optimization design.

- (5)

- Based on the current study status, the in-depth study of the generation mechanism of flow-induced noise, the improvement of the fluid-vibration-acoustic-coupling method, the analysis model establishment of the generation, distribution and propagation mechanism for flow-induced noise and the development of high precision and fast numerical simulation method, as well as the development of noise visualization experiment need to be focused in future.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| CFD | Computational Fluid Dynamics |

| fb | Blade-passing frequency (Hz) |

| fs | Shaft-passing frequency (Hz) |

| n | Number of frequencies (-) |

| NPSHa | Available net positive suction head (m) |

| NYLON | Aliphatic polyamides (-) |

| p’ | Instantaneous sound pressure (Pa) |

| Pe | Effective sound pressure (Pa) |

| Pref | Reference sound pressure (Pa) |

| PEEK | Polyetheretherketone (-) |

| PSD | Power spectral density (Pa2) |

| PTFE | Polytetrafluoroethylene (-) |

| SPL | Sound Pressure Level (dB) |

| STD | Standard deviation (-) |

| T | Several rotational periods (s) |

| TSPL | Total Sound Pressure Level (dB) |

| 316L | One kind of anti-corrosion stainless steel (-) |

References

- China Environmental Noise Prevention and Control Annual Report. Available online: http://www.mee.gov.cn/hjzl/sthjzk/hjzywr/ (accessed on 26 December 2019). (In Chinese)

- Short, A.E.; Short, K.T.; Holdgate, A.; Ahern, N.; Morris, J. Noise levels in an Australian emergency department. Australas. Emerg. Nurs. J. 2011, 14, 26–31. [Google Scholar] [CrossRef]

- Environmental Noise Guidelines for the European Region. Available online: http://www.euro.who.int/en/health-topics/environment-and-health/noise/publications/2018/environmental-noise-guidelines-for-the-european-region-2018 (accessed on 10 October 2018).

- Jurevicius, D.; Evans, T.; Stead, M. A New Approach to Implementing Facade Treatments in Context of the South Australian Road Traffic Noise Guidelines. Acoust. Aust. 2016, 44, 263–271. [Google Scholar] [CrossRef]

- Gerges, S.N. Noise control policy in Brazil and South America. J. Acoust. Soc. Am. 2012, 131, 3328. [Google Scholar] [CrossRef]

- Reuter, E.L. Applications of automatic equipment identification to studies of rail noise and vibration in North America. J. Acoust. Soc. Am. 2016, 140, 3094. [Google Scholar] [CrossRef]

- Ma, K.; Wong, H.; Mac, C. Dental environmental noise evaluation and health risk model construction to dental professionals. Int. J. Environ. Res. Public Health 2017, 14, 1084. [Google Scholar] [CrossRef] [Green Version]

- Gorica, M.; Branko, Z.; Lack, L. A review of the potential impacts of wind farm noise on sleep. Acoust. Aust. 2018, 46, 87–97. [Google Scholar]

- Kamp, I.V.; Berg, F.V.D. Health Effects Related to Wind Turbine Sound, Including Low-Frequency Sound and Infrasound. Acoust. Aust. 2018, 46, 31–57. [Google Scholar] [CrossRef] [Green Version]

- Goelzer, B.; Hansen, C.H.; Sehrndt, G.A. Occupational Exposure to Noise Evaluation, Prevention and Control; World Health Organization: Geneva, Switzerland, 2001; pp. 80–81. [Google Scholar]

- Jiang, A.; Zhang, Z.; Zhang, Y.; Hua, H. Review and outlook of studying on noise of centrifugal pumps. J. Vib. Shock 2011, 30, 77–84. (In Chinese) [Google Scholar]

- Chu, S.; Dong, R.; Katz, J. Relationship between unsteady flow, pressure fluctuation, and noise in a centrifugal pump—Part A: Use of PDV data to compute the pressure field. J. Fluid Eng. 1995, 117, 24–29. [Google Scholar] [CrossRef]

- Chu, S.; Dong, R.; Katz, J. Relationship between unsteady flow, pressure fluctuation, and noise in a centrifugal pump—Part B: Effects of blade-tongue interactions. J. Fluid Eng. 1995, 117, 30–35. [Google Scholar] [CrossRef]

- José, G.; Joaquín, F.; Eduardo, B.; Carlos, S. Numerical simulation of the dynamic effects due to impeller-volute interaction in a centrifugal pump. J. Fluid. Eng. 2002, 124, 348–355. [Google Scholar]

- Brennen, C.E. Cavitation and Bubble Dynamics; Cambridge University Press: New York, NY, USA, 2014; pp. 59–83. [Google Scholar]

- Li, Y.; Feng, G.; Li, X.; Si, Q.; Zhu, Z. An experimental study on the cavitation vibration characteristics of a centrifugal pump at normal flow rate. J. Mech. Sci. Technol. 2018, 32, 4711–4720. [Google Scholar] [CrossRef]

- Georgios, M.; Nilla, K.D.; George, A.; Ioannis, A.; Dimitrios, P. Experimental analysis of cavitation in a centrifugal pump using acoustic emission, vibration measurements and flow visualization. Eup. J. Mech. B-Fluid. 2019, 75, 300–311. [Google Scholar]

- Choi, J.S.; Mclaughlin, D.K.; Thompson, D.E. Experiments on the unsteady flow field and noise generation in a centrifugal pump impeller. J. Sound Vib. 2003, 263, 493–514. [Google Scholar] [CrossRef]

- Heng, Y. Numerical and Experimental Study on Flow-Induced Noise in Centrifugal Pumps. Master’s Thesis, Jiangsu University, Zhenjiang, China, June 2014. (In Chinese). [Google Scholar]

- Si, Q.; Yuan, S.; Yuan, J.; Liang, Y. Investigation on flow-induced noise impacted by backflow in low specific speed centrifugal pumps. Adv. Mech. Eng. 2013. [Google Scholar] [CrossRef]

- Yang, J.; Yuan, S.; Pei, J.; Zhang, J. Overview of rotating stall in centrifugal pumps with vaned diffuser. J. Drain. Irrig. Mach. Eng. 2015, 33, 369–373. (In Chinese) [Google Scholar]

- Guo, X. Research on Rotating Stall Characteristics in Centrifugal Pumps. Master’s Thesis, China Agricultural University, Beijing, China, June 2015. (In Chinese). [Google Scholar]

- Afshar, M.H.; Rohani, M. Water hammer simulation by implicit method of characteristic. Int. J. Pres. Ves. Pip. 2008, 85, 851–895. [Google Scholar] [CrossRef]

- Ismaier, A.; Schlücker, E. Fluid dynamic interaction between water hammer and centrifugal pumps. Nucl. Eng. Des. 2009, 239, 3151–3154. [Google Scholar] [CrossRef]

- Du, G.; Zhu, Z.; Gong, X. Fundamentals of Acoustics, 3rd ed.; Nanjing University Press: Nanjing, China, 2012; pp. 124–128. (In Chinese) [Google Scholar]

- Guo, R.; Li, R.; Zhang, R. Reconstruction and Prediction of Flow Field Fluctuation Intensity and Flow-Induced Noise in Impeller Domain of Jet Centrifugal Pump Using Gappy POD Method. Energies 2019, 12, 111. [Google Scholar] [CrossRef] [Green Version]

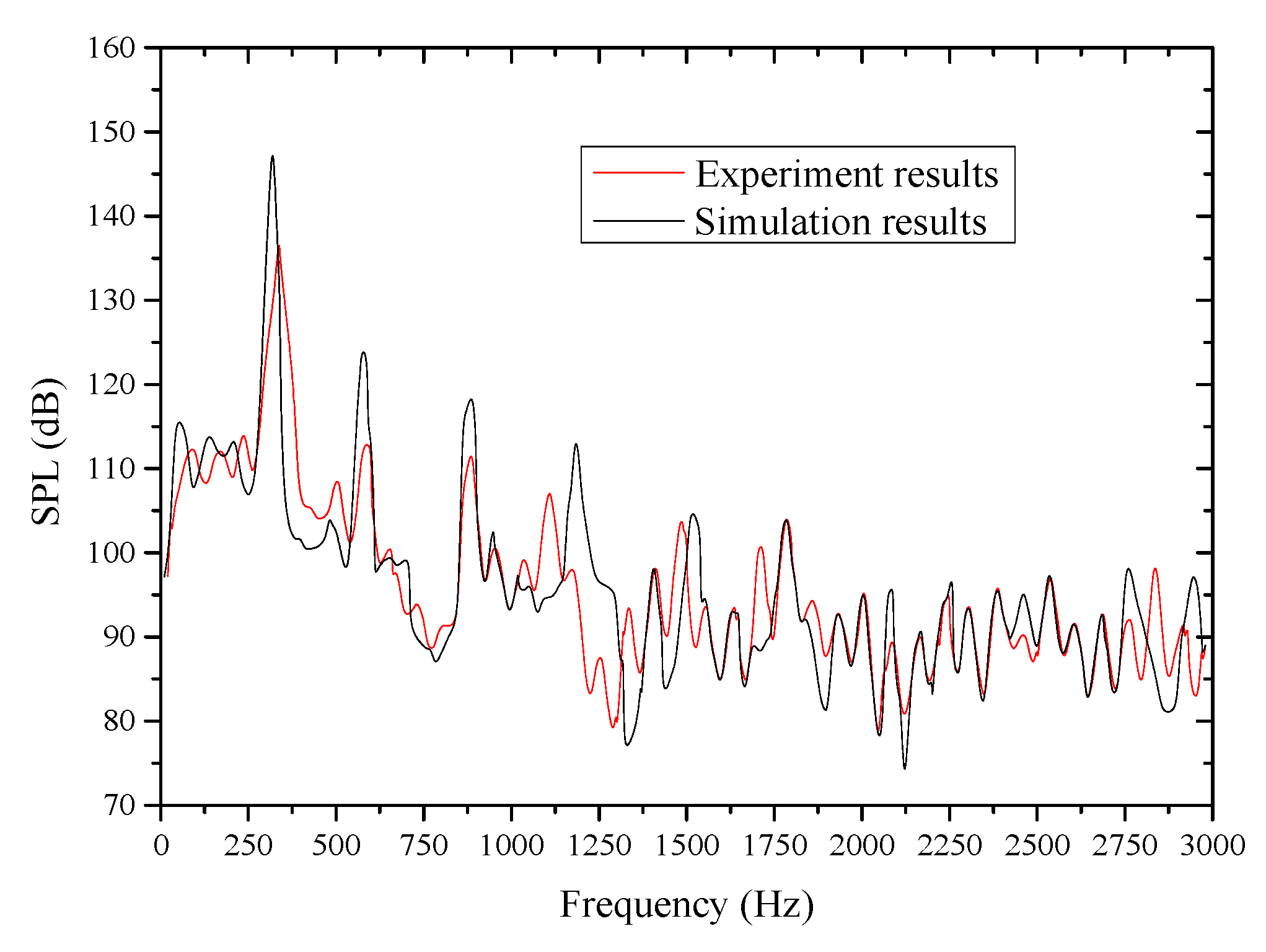

- Rui, X.; Zhao, Y. Numerical simulation and experimental research of flow-induced noise for centrifugal pumps. J. Vibroeng. 2016, 18, 622–636. [Google Scholar]

- McNulty, P.J.; Pearsall, I.S. Cavitation Inception in Pumps. J. Fluid Eng. 1982, 104, 99–104. [Google Scholar] [CrossRef]

- Li, Y.; Liu, H.; Wang, K.; Chen, K. Research on cavitation induced noise feature of marine centrifugal pump under various cavitation numbers. Water Resour. Power 2017, 35, 162–165. (In Chinese) [Google Scholar]

- Lu, J.; Yuan, S.; Yuan, J. Research on the noise induced by cavitation under the asymmetric cavitation condition in a centrifugal pump. In Proceedings of the 9th International Symposium on Cavitation, Lausanne, Switzerland, 6–10 December 2015. [Google Scholar]

- Wang, Y.; Zhao, Y.; Dong, L.; Dai, C.; Liu, H.; Xu, H. Cavitation characteristics of ultra-low specific speed centrifugal pump based on fluid-acoustic coupling method. T. Chin. Soc. Agric. Mach. 2017, 48, 114–123. (In Chinese) [Google Scholar]

- Dong, R.; Chu, S.; Katz, J. Effect of Modification to Tongue and Impeller Geometry on Unsteady Flow, Pressure Fluctuations, and Noise in a Centrifugal Pump. J. Turbomach. 1997, 119, 506–515. [Google Scholar] [CrossRef] [Green Version]

- Mattia, B.; Emiliano, M. Incipient cavitation detection in external gear pumps by means of vibroacoustic measurements. Measurement 2018, 129, 51–61. [Google Scholar]

- Qing, B.; Yu, B.; Lan, W.; Hu, J. Measurement of cavitation noise in centrifugal pump. J. Drain. Irrig. Mach. Eng. 2016, 34, 198–203. (In Chinese) [Google Scholar]

- Valentino, C.; Fabio, B.; Gianfranco, F.; Riccardo, F.; Felice, A.P.; Michele, S. A control system for preventing cavitation of centrifugal pumps. In Proceedings of the 73rd Conference of the Italian Thermal Machines Engineering Association, Pisa, Italy, 12–14 September 2018. [Google Scholar]

- Lu, D. Experimental Study on Flow-Noise of Centrifugal Pump in Variable Working Condition. Master’s Thesis, Shandong University, Jinan, China, June 2017. (In Chinese). [Google Scholar]

- Tu, Y. Hamiton Method and Its Application for Aeroacoustics. Ph.D. Thesis, Huazhong University of Science and Technology, Wuhan, China, May 2013. (In Chinese). [Google Scholar]

- Lighthill, M.J. On sound generated aerodynamically. I General theory. Proc. R. Soc. Lond. Ser. A 1952, 211, 564–587. [Google Scholar]

- Ffowcs Williams, J.E.; Hawkings, D.L. Sound generation by turbulence and surfaces in arbitrary motion. Philos. Trans. R. Soc. A 1969, 264, 321–342. [Google Scholar]

- Ffowcs Williams, J.E.; Hawkings, D.L. Theory relating to the noise of rotating machinery. J. Sound Vib. 1969, 10, 10–21. [Google Scholar] [CrossRef]

- Powell, A. Theory of vortex sound. J. Acoust. Soc. Am. 1964, 36, 177–195. [Google Scholar] [CrossRef]

- Howe, M.S. Contributions to the theory of aerodynamic sound with application to excess jet noise and the theory of the flute. J. Fluid Mech. 1975, 71, 625–673. [Google Scholar] [CrossRef]

- Takaishi, T.; Miyazawa, M.; Kato, C. A computational method of evaluating noncompact sound based on vortex sound theory. J. Acoust. Soc. Am. 2007, 121, 1353–1361. [Google Scholar] [CrossRef]

- Schram, C.; Hirschberg, A. Application of vortex sound theory to vortex-pairing noise: Sensitivity to errors in flow data. J. Sound Vib. 2003, 266, 1079–1098. [Google Scholar] [CrossRef]

- Liu, Q.; Qi, D.; Tang, H. Computation of aerodynamic noise of centrifugal fan using large eddy simulation approach, acoustic analogy, and vortex sound theory. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2007, 221, 1321–1332. [Google Scholar] [CrossRef]

- Zhang, N.; Xie, H.; Wang, X.; Wu, B. Computation of vortical flow and flow induced noise by large eddy simulation with FW-H acoustic analogy and Powell vortex sound theory. J. Hydrodyn. 2016, 28, 255–266. [Google Scholar] [CrossRef]

- Hardin, J.C.; Pope, D.S. An acoustic/viscous splitting technique for computational aeroacoustics. Theor. Comp. Fluid. Dyn. 1994, 6, 323–340. [Google Scholar] [CrossRef]

- Wen, Z.; Jens, N.S. Comment on the Aeroacoustic Formulation of Hardin and Pope. AIAA J. 1999, 37, 141–143. [Google Scholar]

- Langthjem, M.A.; Olhoff, N. A numerical study of flow-induced noise in a two-dimensional centrifugal pump. Part I. Hydrodynamics. J. Fluid Struct. 2004, 19, 349–368. [Google Scholar] [CrossRef]

- Langthjem, M.A.; Olhoff, N. A numerical study of flow-induced noise in a two-dimensional centrifugal pump. Part II. Hydroacoustics. J. Fluid Struct. 2004, 19, 369–386. [Google Scholar] [CrossRef]

- Tu, J.; Gan, L.; Ma, S.; Zhang, H. Flow Noise Characteristics Analysis of Underwater High-Speed Vehicle Based on LES/FW-H Coupling Model. Acoust. Aust. 2019, 47, 91–104. [Google Scholar] [CrossRef]

- Rona, A.; Dosoky, M.F.F.E.I.; Adebayo, D.S. A hybrid RANS model of wing-body junction flow. Eur. J. Mech. B-Fluid 2020, 79, 283–296. [Google Scholar] [CrossRef]

- Yuan, S.; Si, Q.; Xue, F.; Yuan, J.; Zhang, J. Numerical calculation of internal flow-induced noise in centrifugal pump volute. J. Drain. Irrig. Mach. Eng. 2011, 29, 93–98. (In Chinese) [Google Scholar]

- Zhang, N.; Liu, X.; Gao, B.; Wang, X.; Xia, B. Effects of modifying the blade trailing edge profile on unsteady pressure pulsations and flow structures in a centrifugal pump. Int. J. Heat Fluid Flow 2019, 75, 227–238. [Google Scholar] [CrossRef]

- Posa, A.; Lippolis, A. Effect of working conditions and diffuser setting angle on pressure fluctuations within a centrifugal pump. Int. J. Heat Fluid Flow 2019, 75, 44–60. [Google Scholar] [CrossRef]

- Yang, J.; Liu, J.; Liu, X.; Xie, T. Numerical Study of Pressure Pulsation of Centrifugal Pumps with the Compressible Mode. J. Therm. Sci. 2019, 28, 106–114. [Google Scholar] [CrossRef]

- Chen, J.; Wang, Y.; Liu, H.; Shao, C.; Zhang, X. Internal flow and analysis of its unsteady characteristics in centrifugal pump with ultra-low specific-speed. J. Drain. Irrig. Mach. Eng. 2018, 36, 377–383. (In Chinese) [Google Scholar]

- Zhu, Y. Study on Unsteady Vortex Characteristics of Centrifugal Pump Based on DDES Model. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, May 2018. (In Chinese). [Google Scholar]

- Yang, Q. Numerical Simulation and Analysis on the Internal Flow in Centrifugal Pump Based on Different Turbulence Models. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, June 2010. (In Chinese). [Google Scholar]

- Wagner, C.A.; Hüttl, T.; Sagaut, P. Large-Eddy Simulation for Acoustics; Cambridge University Press: New York, NY, USA, 2007; pp. 167–232. [Google Scholar]

- Liu, H.; Ding, J.; Wang, Y.; Tan, M.; Xu, H. Numerical simulation of hydrodynamic noise in centrifugal pump based on LES. J. Mech. Eng. 2013, 49, 177–183. (In Chinese) [Google Scholar] [CrossRef]

- Fu, J.; Wang, Y.; Jin, S.; Li, L. Applicability of LES and DES in fluid dynamic noise prediction. J. Huazhong Univ. Sci. Tech. (Nat. Sci. Ed.) 2015, 43, 66–70. (In Chinese) [Google Scholar]

- Lu, F.; Qi, D.; Wang, X.; Zhou, Z.; Zhou, H. A numerical optimization on the vibroacoustics of a centrifugal fan volute. J. Sound Vib. 2012, 331, 2365–2385. [Google Scholar] [CrossRef]

- Chen, J.; He, Y.; Gui, L.; Wang, C.; Chen, L.; Li, Y. Aerodynamic noise prediction of a centrifugal fan considering the volute effect using IBEM. Appl. Acoust. 2018, 132, 182–190. [Google Scholar] [CrossRef]

- Pan, Y.; Li, Y.; Huang, M.; Liao, Y.; Liang, D. Noise source identification and transmission path optimization for noise reduction of an axial piston pump. Appl. Acoust. 2018, 130, 283–293. [Google Scholar] [CrossRef]

- Dong, L.; Dai, C.; Lin, H.; Chen, Y. Noise comparison of centrifugal pump operating in pump and turbine mode. J. Cent. South. Univ. 2018, 25, 2733–2753. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, Y.; Wang, X.; Zhu, R.; Qiu, W.; Fang, J. Experimental and simulation methods of flow noise on pipeline oil pumps. J. Drain. Irrig. Mach. Eng. 2017, 35, 645–651. (In Chinese) [Google Scholar]

- Si, Q.; Yuan, S.; Yuan, J.; Yang, J. Flow-induced Noise Calculation of Centrifugal Pumps Based on CFD/CA Method. J. Mech. Eng. 2013, 49, 177–184. (In Chinese) [Google Scholar] [CrossRef]

- Tan, Y.; Wang, H.; Yang, A.; Wang, Z.; Xu, X. Numerical prediction of hydrodynamic noise for a centrifugal pump. J. Univ. Shanghai Sci. Technol. 2011, 33, 90–94. (In Chinese) [Google Scholar]

- Wang, Z.; Yang, A.; Dai, R. Numerical prediction of the flow-induced noise of centrifugal pump. J. Mech. Eng. 2012, 48, 162–167. (In Chinese) [Google Scholar] [CrossRef]

- Dai, C.; Kong, F.; Feng, Z.; Bai, Y. Numerical and experimental investigation of flow-induced noise in centrifugal pump as turbine. J. Huazhong Univ. Sci. Tech. (Nat. Sci. Ed.) 2014, 42, 17–21. (In Chinese) [Google Scholar]

- Dong, L.; Dai, C.; Kong, F.; Fu, L.; Xia, B. Flow-induced exterior noise characteristics of a centrifugal pump as a turbine and different noise contribution analysis. J. Vib. Shock 2016, 35, 168–174. (In Chinese) [Google Scholar]

- Cai, J.; Pan, J.; Andrew, G. Experimental study of the pressure fluctuation around the volute tongue of a centrifugal pump at variable rotating speed. Fluid Mach. 2015, 43, 13–16. (In Chinese) [Google Scholar]

- Si, Q.; Yuan, J.; Yuan, S.; Wang, W.; Zhu, L.; Gérard, B. Numerical Investigation of Pressure Fluctuation in Centrifugal Pump Volute Based on SAS Model and Experimental Validation. Adv. Mech. Eng. 2014. [Google Scholar] [CrossRef] [Green Version]

- Zhang, N.; Yang, M.; Gao, B.; Li, Z.; Ni, D. Experimental and numerical analysis of unsteady pressure pulsation in a centrifugal pump with slope volute. J. Mech. Sci. Technol. 2015, 29, 4231–4238. [Google Scholar] [CrossRef]

- Shi, B.; Wei, J.; Zhang, Y. A novel experimental facility for measuring internal flow of Solid-liquid two-phase flow in a centrifugal pump by PIV. Int. J. Multiphas. Flow 2017, 89, 266–276. [Google Scholar] [CrossRef]

- Shi, B.; Wei, J.; Zhang, Y. Phase discrimination and a high accuracy algorithm for PIV image processing of particle–fluid two-phase flow inside high-speed rotating centrifugal slurry pump. Flow Meas. Instrum. 2015, 45, 93–104. [Google Scholar] [CrossRef]

- Zhang, N.; Gao, B.; Li, Z.; Ni, D.; Jiang, Q. Unsteady flow structure and its evolution in a low specific speed centrifugal pump measured by PIV. Exp. Therm. Fluid Sci. 2018, 97, 133–144. [Google Scholar] [CrossRef]

- Tan, M.; Wang, Y.; Liu, H.; Wu, X.; Wang, K. Effects of number of blades on flow induced noise vibration and noise of centrifugal pumps. J. Drain. Irrig. Mach. Eng. 2012, 30, 131–135. (In Chinese) [Google Scholar]

- Liu, H.; Wang, Y.; Yuan, S.; Tan, M. Effects of impeller outlet width on the vibration and noise from centrifugal pumps induced by flow. J. Huazhong Univ. Sci. Tech. (Nat. Sci. Ed.) 2012, 40, 123–127. (In Chinese) [Google Scholar]

- Wang, Y.; Liu, H.; Liu, D.; Wang, J.; Wu, X. Effects of vane wrap angle on flow induced vibration and noise of centrifugal pumps. T. Chin. Soc. Agric. Eng. 2013, 29, 72–77. (In Chinese) [Google Scholar]

- Wang, Y.; Liu, Q.; Liu, D.; Wang, J.; Tang, X. Analysis of flow induced vibration and noise in centrifugal pumps with different blade inlet incidence angle. Fluid Mach. 2013, 41, 1–4. (In Chinese) [Google Scholar]

- Zhou, H.; Mao, Y.; Zhang, Q.; Zhao, C.; Qi, D.; Diao, Q. Vibro-acoustics of a pipeline centrifugal compressor part I. Experimental study. Appl. Acoust. 2018, 131, 112–128. [Google Scholar] [CrossRef]

- Yuan, S.; Yang, Y.; Yuan, J.; Luo, Y. Measurement system design of flow-induced noise in centrifugal pumps. Drain. Irrig. Mach. 2009, 27, 10–14. (In Chinese) [Google Scholar]

- Si, Q.; Yuan, S.; Yuan, J. Experimental study on the influence of impeller-tongue gap on the performance and flow-induced noise characteristics of centrifugal pumps. J. Vib. Shock 2016, 35, 164–168. (In Chinese) [Google Scholar]

- Wang, H.; Xu, X.; Yang, A.; Wang, F.; Tan, Y. Numerical simulation of flow noise in axial-flow pump. J. Drain. Irrig. Mach. Eng. 2011, 29, 199–203. (In Chinese) [Google Scholar]

- Huang, H.; Liu, H.; Wang, Y.; Jiang, L.; Shao, C. Effect of inclined trailing edge of blade on vibration and hydrodynamic noise of marine centrifugal pump. J. Vib. Shock 2015, 34, 195–200. (In Chinese) [Google Scholar]

- Liu, H.; Dai, H.; Ding, J.; Tan, M.; Wang, Y.; Huang, H. Numerical and experimental studies of hydraulic noise induced by surface dipole sources in a centrifugal pump. J. Hydrodyn. 2016, 28, 43–51. [Google Scholar] [CrossRef]

- Guo, C.; Wang, J.; Gao, M. A Numerical Study on the Distribution and Evolution Characteristics of an Acoustic Field in the Time Domain of a Centrifugal Pump Based on Powell Vortex Sound Theory. Appl. Sci. 2019, 9, 5018. [Google Scholar] [CrossRef] [Green Version]

- He, T.; Zhong, R.; Sun, Y. Numerical method on hydrodynamic noise of centrifugal pump. J. Ship Mech. 2012, 16, 449–455. (In Chinese) [Google Scholar]

- Dong, L.; Dai, C.; Kong, F.; Fu, L.; Cao, R. Flow-induced Noise Characteristic and Contribution to Interior Noise for Centrifugal Pump as Turbine. J. Mech. Eng. 2016, 52, 184–192. (In Chinese) [Google Scholar] [CrossRef]

- Ye, X.; Pei, J.; Li, C.; Liu, Z. Experimental Study on Nosie Characteristics of Centrifugal Pump Based on Near-Field Acoustic Pressure Method. Chin. J. Power Eng. 2013, 33, 375–380. (In Chinese) [Google Scholar]

- Guo, C.; Gao, M.; Lu, D.; Guan, H. Experimental Study on Radiation Noise Frequency Characteristics of a Centrifugal Pump with Various Rotational Speeds. Appl. Sci. 2018, 8, 796. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Yuan, S.; Yuan, J.; Si, Q.; Pei, J. Numerical and Experimental Study on Flow-induced Noise at Blade-passing Frequency in Centrifugal Pumps. Chin. J. Mech. Eng. 2014, 27, 606–614. [Google Scholar] [CrossRef]

- Si, Q.; Sheng, G.; Heng, Y.; Cui, Q.; Huang, K. Numerical simulation for flow-induced noise in a centrifugal pump based on Lighthill acoustic analogy theory. J. Vib. Shock 2018, 37, 84–90. (In Chinese) [Google Scholar]

- Gao, M.; Dong, P.; Lei, S.; Turan, A. Computational Study of the Noise Radiation in a Centrifugal Pump When Flow Rate Changes. Energies 2017, 10, 221. [Google Scholar] [CrossRef] [Green Version]

- Lin, G. Study of Flow Induced Radiated Noise in a Multi-Stage Centrifugal Pump. Master’s Thesis, Jiangsu University, Zhenjiang, China, June 2017. (In Chinese). [Google Scholar]

- Guo, C.; Gao, M.; Lu, D.; Wang, K. An Experimental Study on the Radiation Noise Characteristics of a Centrifugal Pump with Various Working Conditions. Energies 2017, 10, 2139. [Google Scholar] [CrossRef] [Green Version]

- Dong, P.; Gao, M.; Guan, H.; Lu, D.; Song, K.; Sun, F. Numerical simulation for variation law of volute radiated noise in centrifugal pumps under variable rotating speed. J. Vib. Shock 2017, 36, 128–133. (In Chinese) [Google Scholar]

- Si, Q.; Wang, B.; Yuan, J.; Huang, K.; Lin, G.; Wang, C. Numerical and Experimental Investigation on Radiated Noise Characteristics of the Multistage Centrifugal Pump. Processes 2019, 7, 793. [Google Scholar] [CrossRef] [Green Version]

- Guo, C.; Gao, M.; Wang, J.; Shi, Y.; He, S. The effect of blade outlet angle on the acoustic field distribution characteristics of a centrifugal pump based on Powell vortex sound theory. Appl. Acoust. 2019, 155, 297–308. [Google Scholar] [CrossRef]

- Dong, L.; Dai, C.; Kong, F.; Fu, L.; Bai, Y. Impact of blade outlet angle on acoustic of centrifugal pump as turbine. Trans. Chin. Soc. Agric. Eng. 2015, 31, 69–75. (In Chinese) [Google Scholar]

- Wang, W. Research on Hydrodynamic Noise of Multistage Centrifugal Pump. Master’s Thesis, Jiangsu University, Zhenjiang, China, June 2016. (In Chinese). [Google Scholar]

- Liu, H.; Li, Y.; Wang, K.; Liu, Z. Study on radiated noise characteristics of multistage centrifugal pump under fluid excitation. J. Huazhong Univ. Sci. Tech. (Nat. Sci. Ed.) 2017, 45, 92–97. (In Chinese) [Google Scholar]

- Guo, R.; Li, R.; Zhang, R.; Song, Q. Characteristic analysis of exterior hydrodynamic noise of jetting centrifugal self-priming pump. J. Huazhong Unv. Sci. Tech. (Nat. Sci. Ed.) 2018, 46, 43–48. (In Chinese) [Google Scholar]

- You, C.; Zhang, G.; Wu, X. Numerical simulation study on flow-induced noises of centrifugal pump. Large Electr. Mach. Hydraul. Turbine 2019, 1, 64–68. (In Chinese) [Google Scholar]

- Guo, C.; Gao, M. Investigation on the flow-induced noise propagation mechanism of centrifugal pump based on flow and sound fields synergy concept. Manuscript in preparation. 2020. [Google Scholar]

- Rzentkowski, G.; Zbroja, S. Experimental characterization of centrifugal pumps as an acoustic source at the bladde-pasing frequency. J. Fluid. Struct. 2000, 14, 529–558. [Google Scholar] [CrossRef]

- Rzentkowski, G.; Zbroja, S. Acoustic characterization of a CANDU primary heat transport pump at the blade-passing frequency. Nucl. Eng. Des. 2000, 196, 63–80. [Google Scholar] [CrossRef]

- Ye, J. Research on Optimization of Vibration and Structural Noise of Centrifugal Pump. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2006. (In Chinese). [Google Scholar]

- Zhang, J.; Xia, S.; Ye, S.; Xu, B.; Song, W.; Zhu, S.; Tang, H.; Xiang, J. Experimental investigation on the noise reduction of an axial piston pump using free-layer damping material treatment. Appl. Acoust. 2018, 139, 1–7. [Google Scholar] [CrossRef]

- Liu, H.; Ding, J.; Dai, H.; Tan, M.; Tang, X. Numerical Research on Hydraulically Generated Vibration and Noise of a Centrifugal Pump Volute with Impeller Outlet Width Variation. Math. Probl. Eng. 2014. [Google Scholar] [CrossRef]

- Liu, H.; Ding, J.; Tan, M.; Cui, J.; Wang, Y. Analysis and experimental of centrifugal pump noise based on outlet width of impeller. T. Chin. Soc. Agric. Eng. 2013, 29, 66–73. (In Chinese) [Google Scholar]

- Feng, T.; Wang, J.; Wu, R. Research on the influence to the flow noise of centrifugal pumps with different gap between impeller and tongue. Food Mach. 2012, 28, 75–78. (In Chinese) [Google Scholar]

- Ma, Z.; Chen, E.; Guo, Y.; Yang, A. Numerical Simulation of the Influence of the Diameter at the Outlet of an Impeller on the Noise Level Induced by the Flow Inside a Centrifugal Pump. J. Eng. Therm. Energ. Power 2016, 31, 93–98. (In Chinese) [Google Scholar]

- Lang, D. Influence of Blade Outlet Angle on Flow Induced Noise Inside Centrifugal Pump. Master’s Thesis, University of Shanghai for Science and Technology, Shanghai, China, March 2013. (In Chinese). [Google Scholar]

- Ding, J.; Liu, H.; Wang, Y.; Tan, M.; Cui, J. Numerical study on the effect of blade outlet angle on centrifugal pump noise. J. Vib. Shock 2014, 33, 122–127. (In Chinese) [Google Scholar]

- Huang, J.; Geng, S.; Wu, R.; Liu, K.; Nie, C.; Zhang, H. Comparison of noise characteristics in centrifugal pumps with different types of impellers. Acta Acoust. 2010, 35, 113–118. (In Chinese) [Google Scholar]

- Dai, C.; Dong, L.; Kong, F.; Bai, Y.; Xia, B. Noise reduction by actively leaning blades in centrifugal pump as turbine. J. Shanghai Jiaotong Univ. 2016, 50, 575–582. (In Chinese) [Google Scholar]

- Wang, Y.; Huang, H.; Liu, H.; Wang, W.; Guo, B. Effect of inclined trailing edge of blade on exterior radiation noise of marine centrifugal pump. J. Drain. Irrig. Mach. Eng. 2015, 33, 104–110. (In Chinese) [Google Scholar]

- Lu, W.; Wang, Z.; Wu, W.; Shi, Y.; Zhou, S. Analysis and research of centrifugal pump vibration and noise based on rotate speed and the number of impeller blades. In Proceedings of the 5th International Conference on Mechanical Engineering and Mechanics, Yangzhou, China, 20–22 August 2014. [Google Scholar]

- Wang, Y.; Liu, H.; Yuan, S.; Liu, D.; Wang, J. Characteristics of cavitation vibration and noise in centrifugal pumps with different vane wrap angles. J. Drain. Irrig. Mach. Eng. 2013, 31, 390–394. (In Chinese) [Google Scholar]

- Wu, D.; Liu, Y.; Li, D.; Zhao, X.; Li, C. Effect of materials on the noise of a water hydraulic pump used in submersible. Ocean Eng. 2017, 131, 107–113. [Google Scholar] [CrossRef]

- Zhou, P.; Zhang, Q.; Shuai, Z.; Li, W. Inlet design and its influence on vibration and noise of centrifugal pump. J. Drain. Irrig. Mach. Eng. 2015, 33, 16–20. (In Chinese) [Google Scholar]

- Si, Q.; Yuan, J.; Heng, Y.; Yuan, S. Effects of cross-section and cut-water shapes of volute on flow induced noise in centrifugal pumps. J. Drain. Irrig. Mach. Eng. 2015, 33, 209–215. (In Chinese) [Google Scholar]

- Zhao, W. The Numerical Simulation of the Flow Noise in the Centrifugal Pump and Noise Optimization. Master’s Thesis, Huazhong University of Science and Technology, Wuhan, China, January 2013. (In Chinese). [Google Scholar]

- Dai, C. Flow-Induced Noise Characteristics for Centrifugal Pump as Turbine Theoretical, Numerical and Experimental Investigations. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, December 2014. (In Chinese). [Google Scholar]

- Lomakin, V.O.; Chaburko, P.S.; Kuleshova, M.S. Multi-criteria optimization of the flow of a centrifugal pump on energy and vibroacoustic characteristics. Procedia Eng. 2017, 176, 476–482. [Google Scholar] [CrossRef]

- Luo, B. The Research of Flow-Induced Noise of Underwater Pump and Optimal Design. Master’s Thesis, Jiangsu University, Zhenjiang, China, June 2017. (In Chinese). [Google Scholar]

- Zhang, J.; Jia, J.; Hu, R.; Wang, Y.; Cao, P. Flow noise of pipeline pump and bionic sound optimization. T. Chin. Soc. Agric. Mach. 2018, 49, 138–145. (In Chinese) [Google Scholar]

- Cao, Y.; Ke, H.; Lin, Y.; Zeng, M.; Wang, Q. Investigation on the flow noise propagation mechanism in pipelines of shell-and-tube heat exchangers based on synergy principle of flow and sound fields. Appl. Therm. Eng. 2017, 122, 339–349. [Google Scholar] [CrossRef]

| Flow Phenomena | References | Noise Generation Mechanism |

|---|---|---|

| Rotor-stator interaction | [12,13,14] | Periodic interference occurs between blade and volute. The flow passage width changes periodically, which causes periodic pressure fluctuations and noise. |

| Cavitation | [15,16,17] | The generated-bubbles due to cavitation implode in contact with solid surface in high pressure region, which induce pressure waves that result in the generation of noise. |

| Turbulence | [18,19] | Combined with the jet-wake effect at impeller outlet, the interaction between blade and high-speed fluid causes the blade acted by the unsteady load continuously and broadband noise is generated. |

| Back flow | [20] | Pre-rotation occurs at impeller inlet, strong eddy and eddy strip are formed. Then pressure fluctuations with low frequency are generated and further induce the low frequency noise. |

| Rotating stall | [21,22] | Under low flow rate condition, stall vortex is formed in impeller, which blocks the flow passage and induces low frequency noise. |

| Water hammer | [23,24] | Rapid change of flow velocity occurs, which could induce intermittent noise. |

| Sound Theory | Lighthill Acoustic Analogy Theory [38,39,40] | Vortex Sound Theory [41,42,43,44,45,46] | Acoustic/Viscous Splitting Theory [47,48] |

|---|---|---|---|

| Governing equation | Inhomogeneous sound wave equation with sound source. The left and right side items of the sound wave equation are wave operator and sound source, respectively. | Same as the form of the governing equation of “Lighthill acoustic analogy theory.” | Compressible perturbation equation of sound field is obtained by subtracting the incompressible N-S equation of flow field from compressible N-S equation based on variable separation method. |

| Sound source | Monopole, dipole and quadrupole sources. | The stretching of the vortex and the non-uniformity of fluid kinetic energy. | / |

| Advantages | It is suitable for the frequency response analysis and the distribution characteristics analysis of sound field in frequency domain and the improved calculation process has been formed. | The time-domain parameters of sound field could be obtained directly. It is suitable for the interpretation of the generation and distribution of flow-induced noise. | Same as the advantages of “Vortex sound theory.” |

| Shortages | Fluid viscosity is ignored. It could not explain the generation and distribution mechanism of flow-induced noise. | Fluid viscosity is ignored. The solution process is relatively complicated and the improved calculation process has not been formed. | The solution process is more complicated than that of “Vortex sound equation” and the improved calculation process has not been formed. |

| Study Object | References | Impact on Frequency Response Characteristics | Key Findings |

|---|---|---|---|

| Internal flow noise | [68,69] | The 2-order of fb is close to the 1-order of natural frequency, the SPL at 2-order of fb decreases. | The vibration of volute could cause the sound energy dissipation. Due to the reflection and scatter effects, the volute could prevent the internal noise from propagating to outside. |

| External radiation noise | [72] | The 2-order and 5-order of fb are close to the 1-order and 3-order of natural frequencies, the SPL at 2-order and 5-order of fb is higher. | The external radiation noise is the result of joint action of the internal pressure fluctuations and structure vibration. |

| Pump Structures | References | Key Findings |

|---|---|---|

| Impeller outlet width | [112,113] |

|

| Impeller diameter | [32,85,114,115] |

|

| Blade outlet angle | [102,116,117] |

|

| Blade type | [74,79,118,119,120,121] |

|

| Vane wrap angle | [81,122] |

|

| Blade inlet incidence angle | [82] |

|

| Structure material | [123] |

|

| Inlet shape | [124] |

|

| Volute shape | [125] |

|

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, C.; Gao, M.; He, S. A Review of the Flow-Induced Noise Study for Centrifugal Pumps. Appl. Sci. 2020, 10, 1022. https://doi.org/10.3390/app10031022

Guo C, Gao M, He S. A Review of the Flow-Induced Noise Study for Centrifugal Pumps. Applied Sciences. 2020; 10(3):1022. https://doi.org/10.3390/app10031022

Chicago/Turabian StyleGuo, Chang, Ming Gao, and Suoying He. 2020. "A Review of the Flow-Induced Noise Study for Centrifugal Pumps" Applied Sciences 10, no. 3: 1022. https://doi.org/10.3390/app10031022