A Modification of Offset Strip Fin Heatsink with High-Performance Cooling for IGBT Modules

Abstract

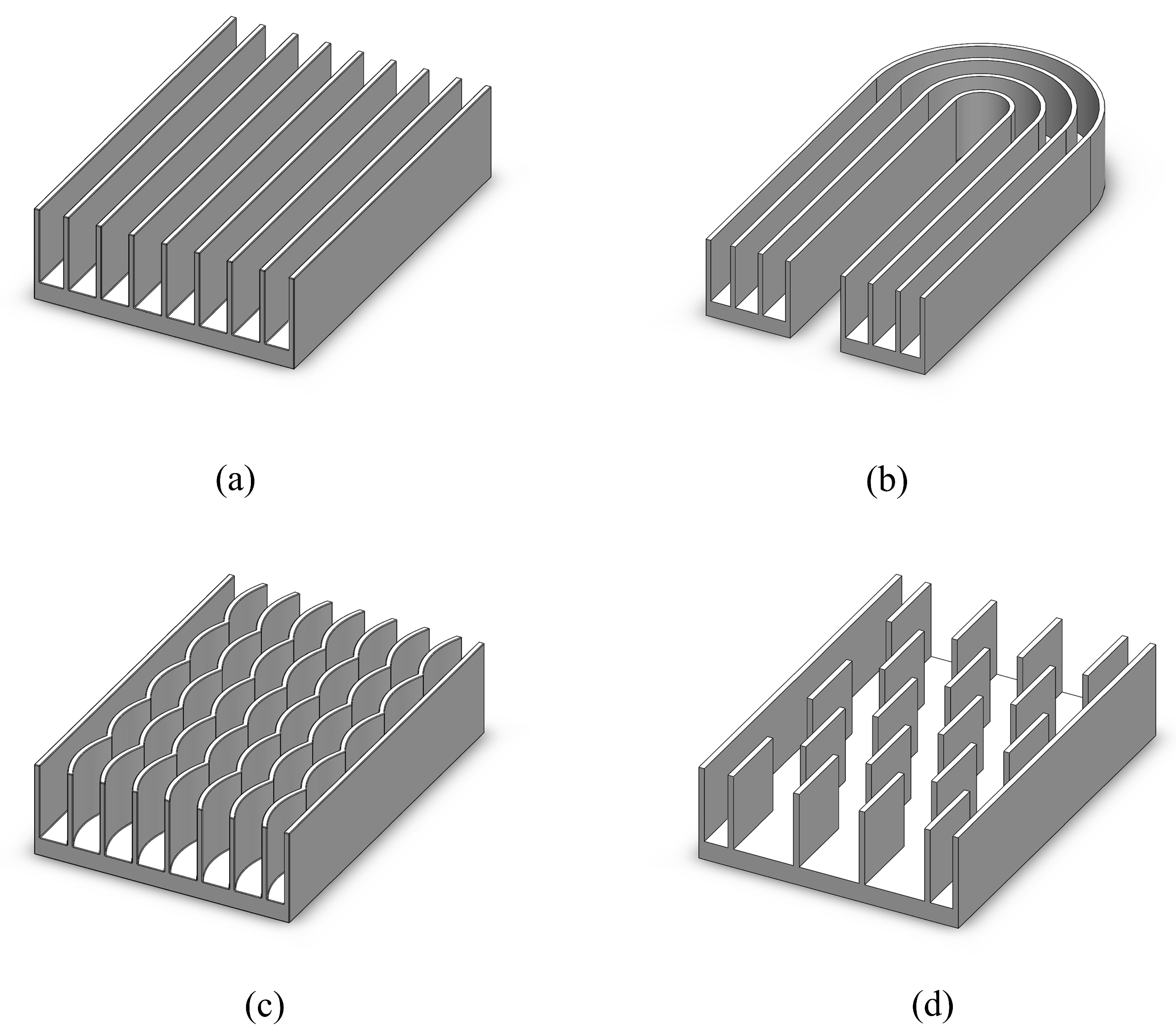

:1. Introduction

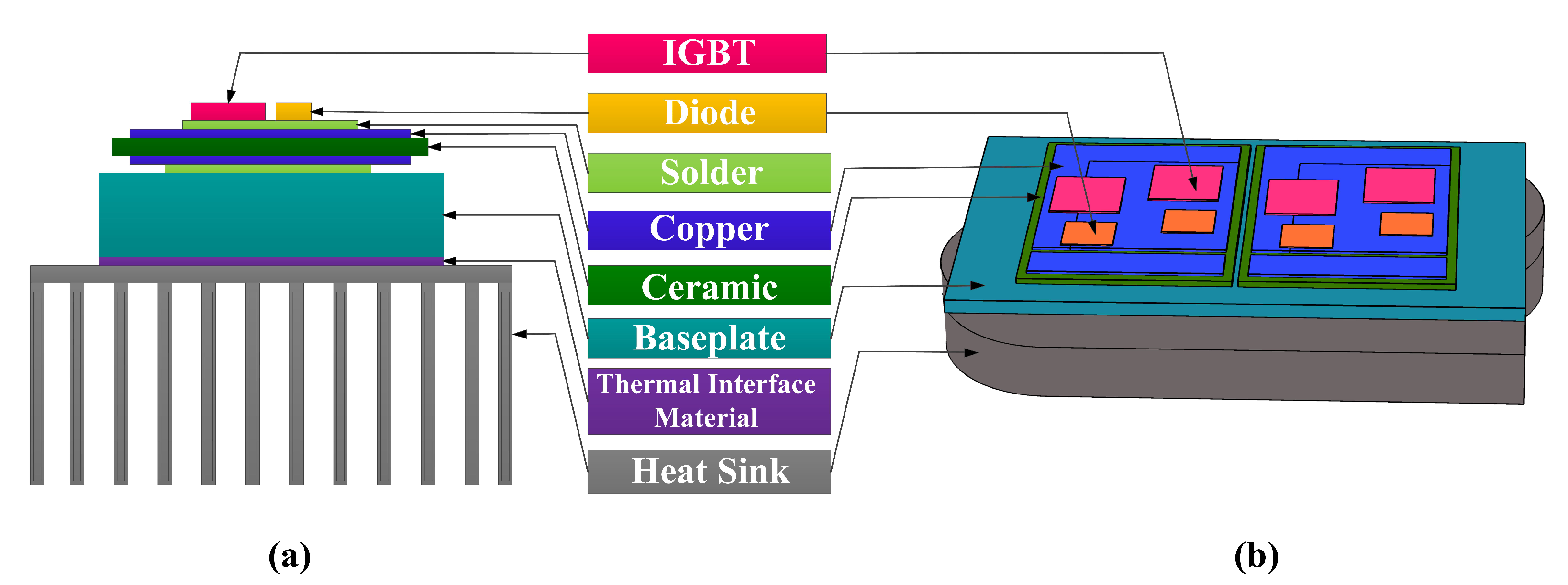

2. Numerical Details and Layouts for Analysis

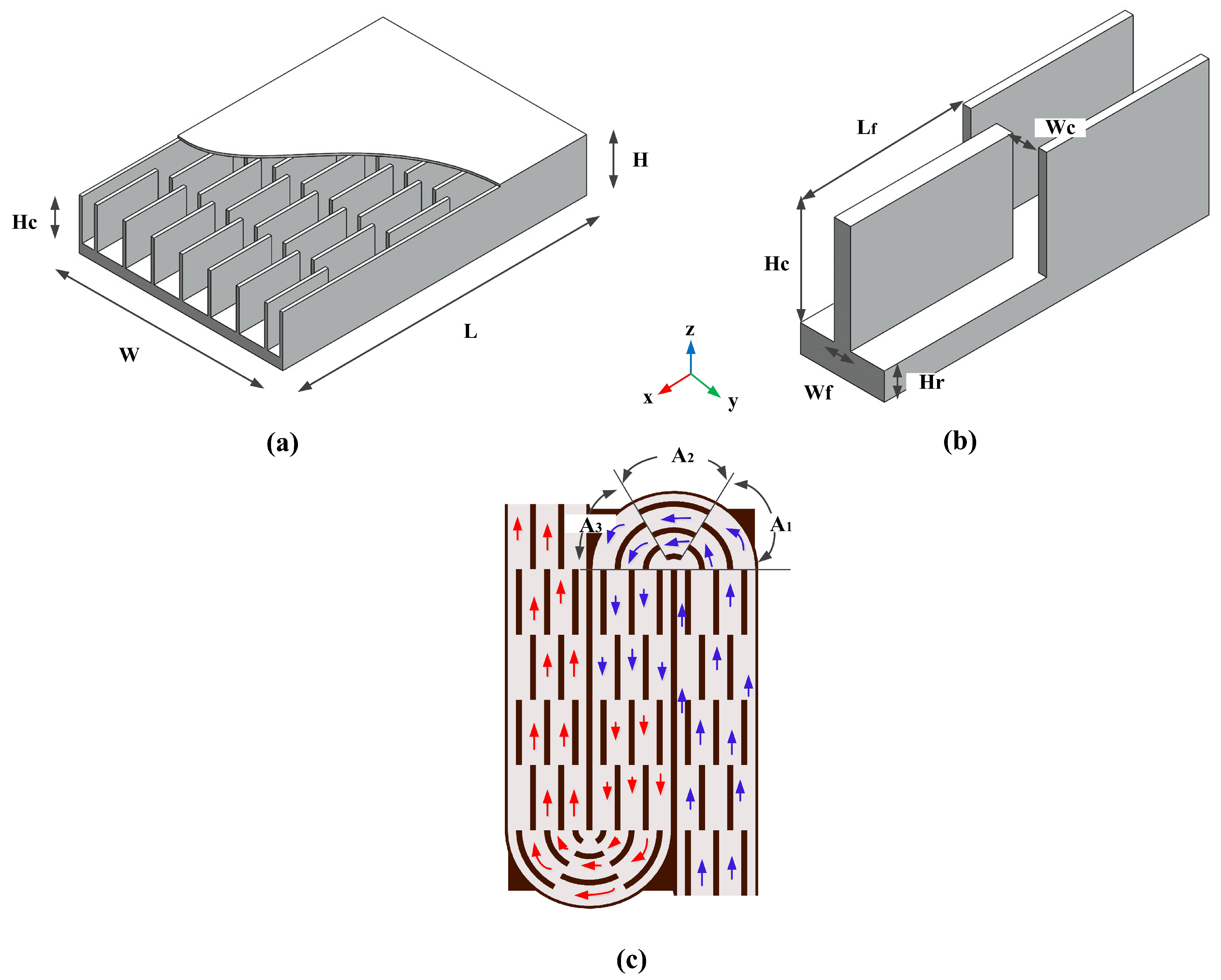

2.1. Computational Domain

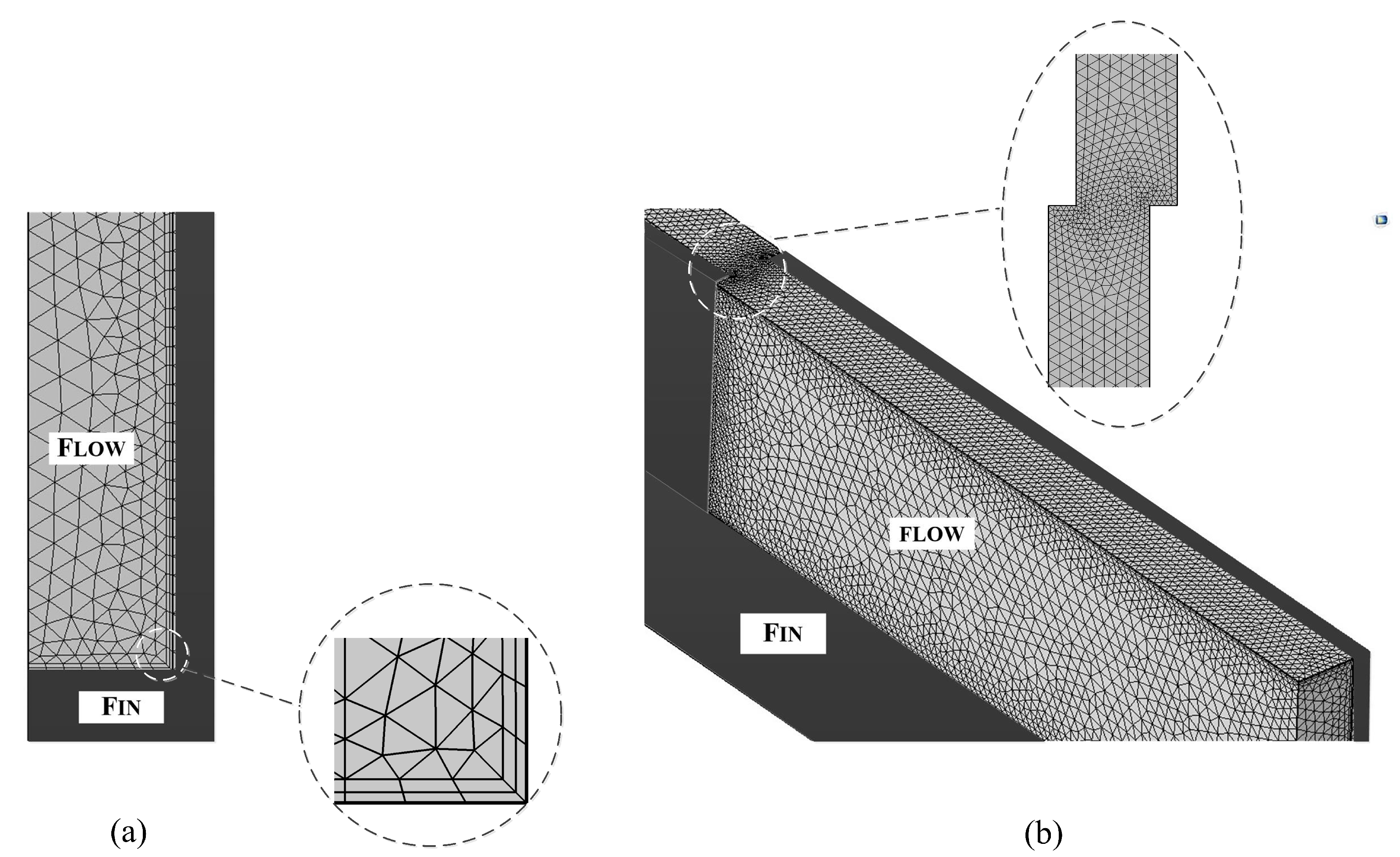

2.2. Grid Topology to Simulate

2.3. Richardson’s Extrapolation

3. Results and Discussion

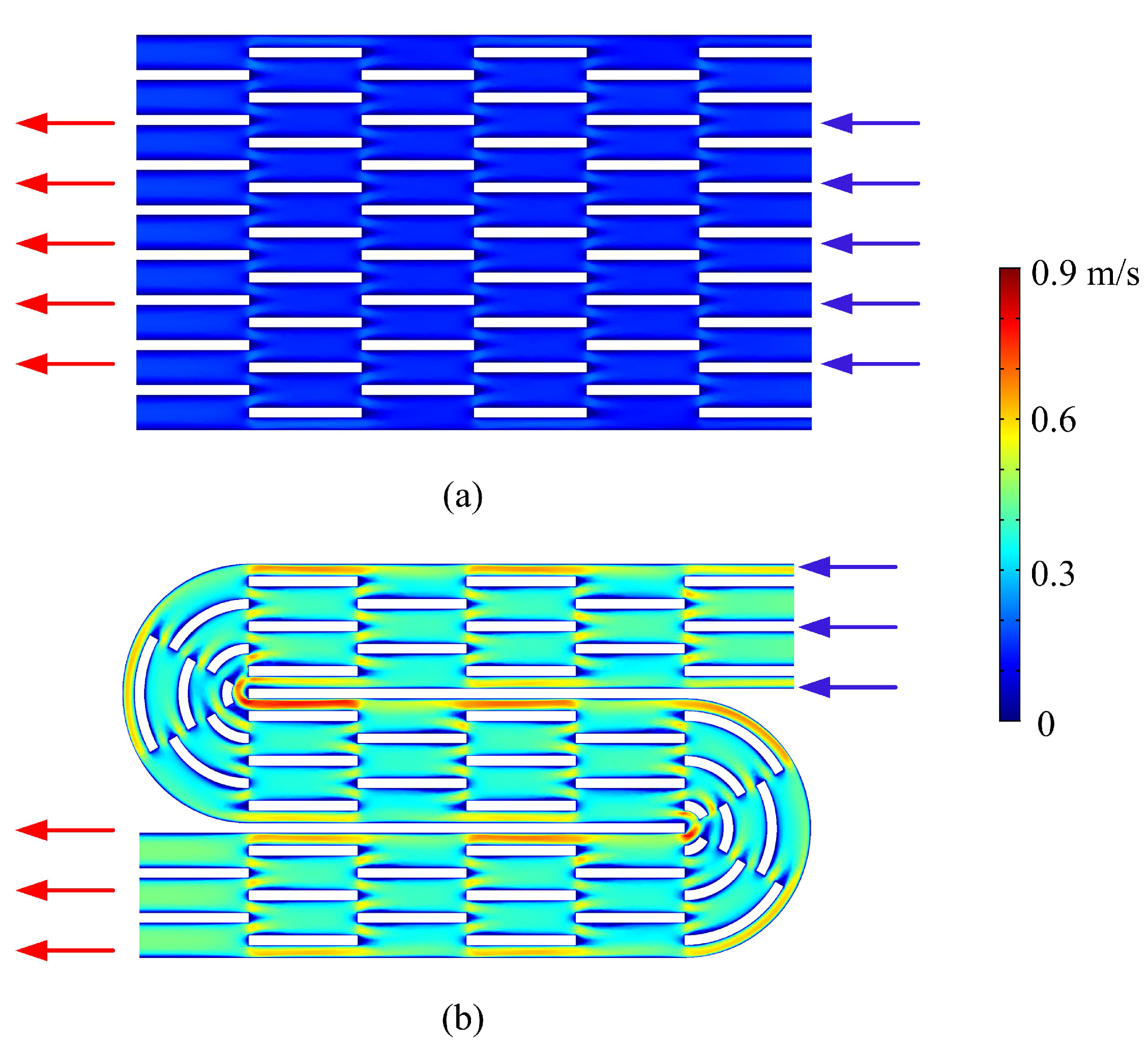

3.1. Velocity Distribution

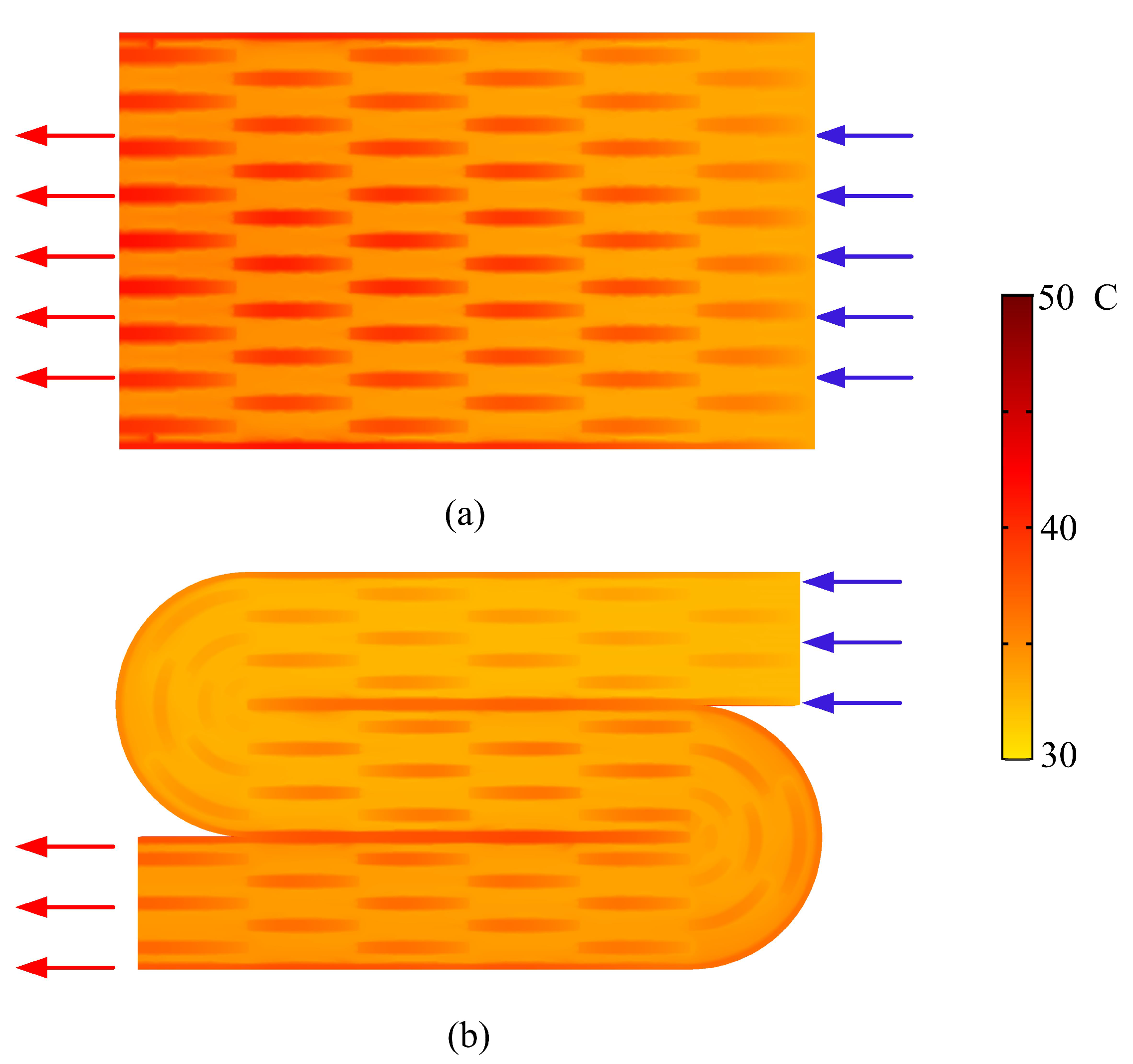

3.2. Temperature Uniformity

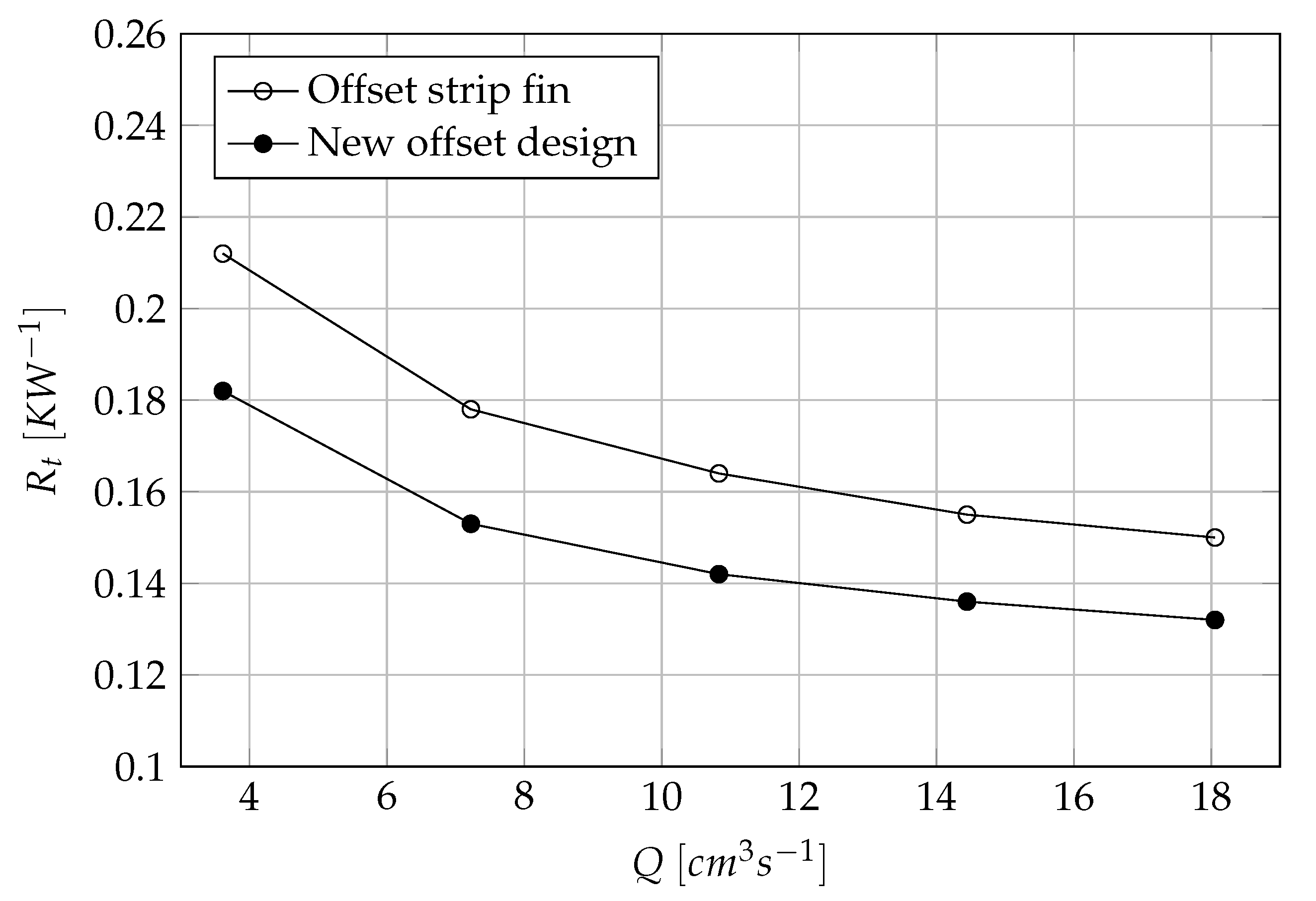

3.3. Thermal Resistance

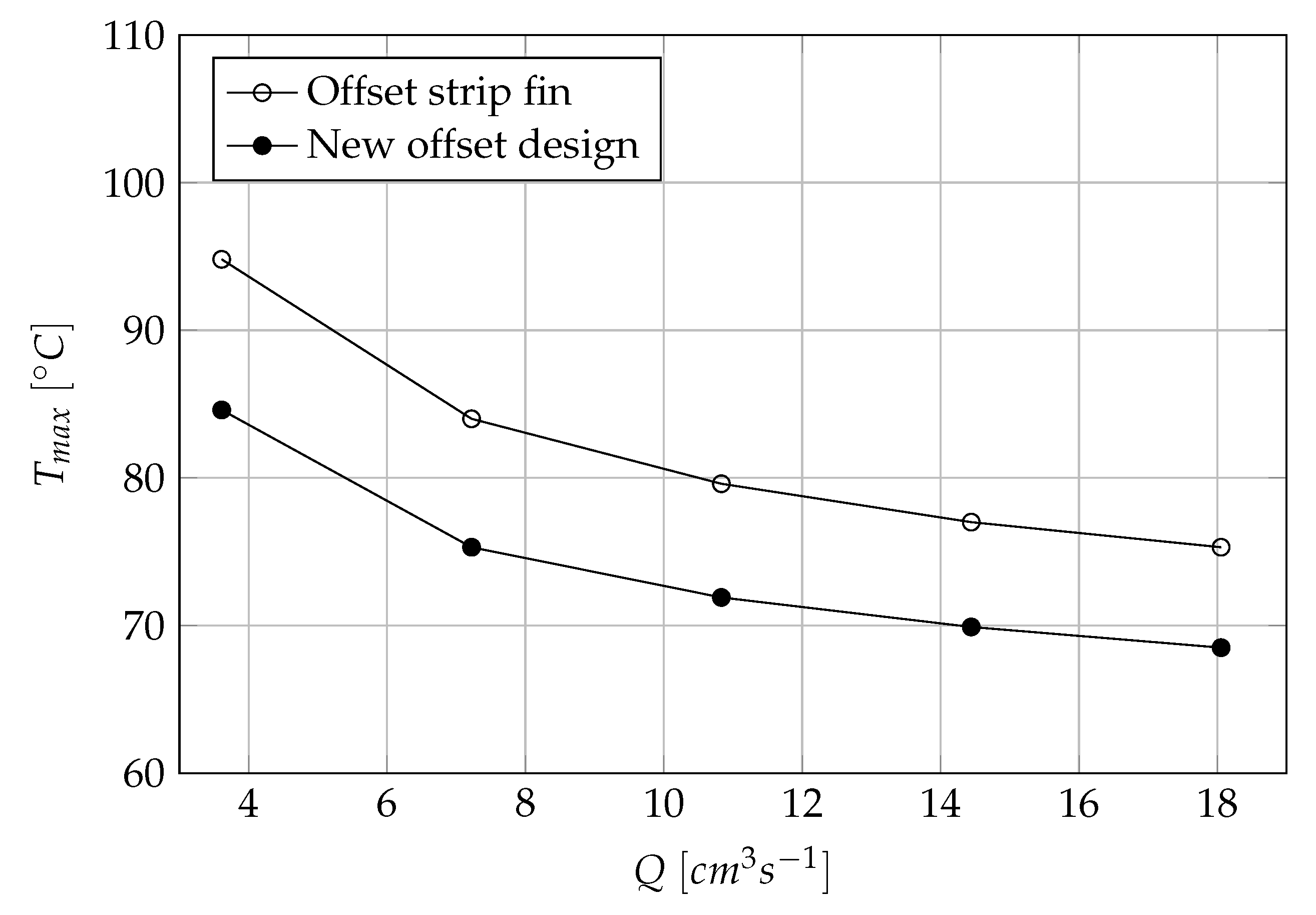

3.4. Maximum Chip Temperature

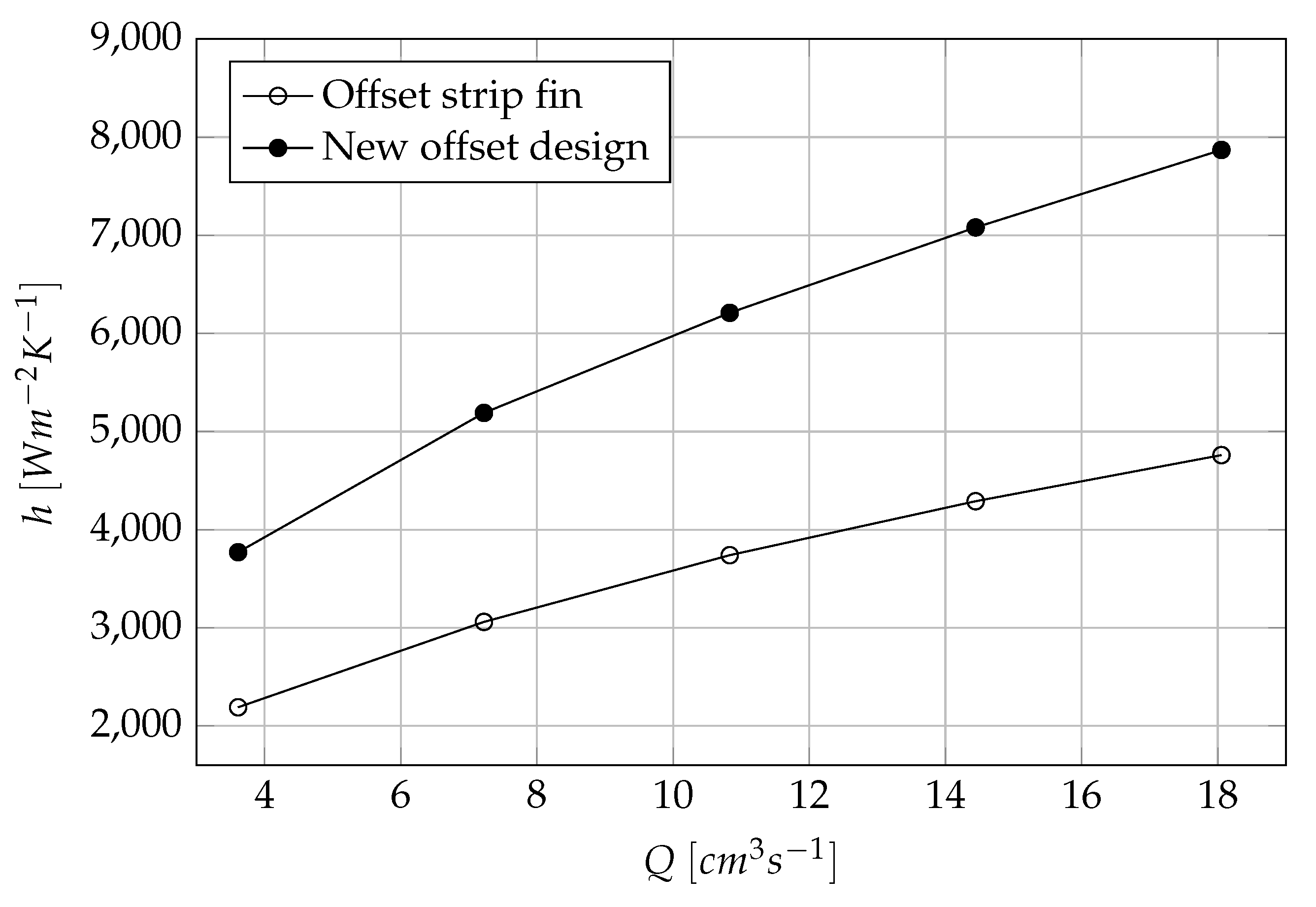

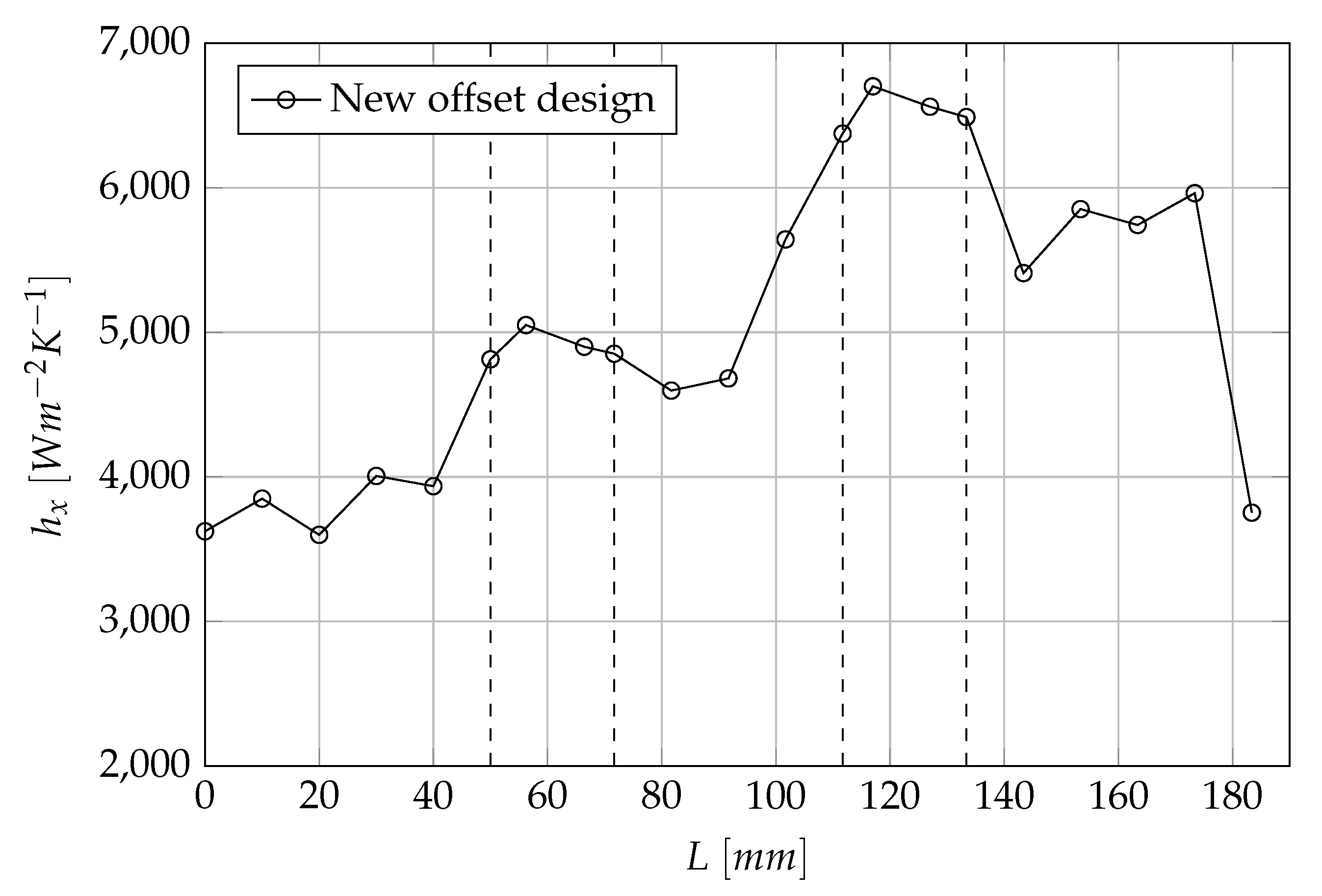

3.5. Heat Transfer Coefficient

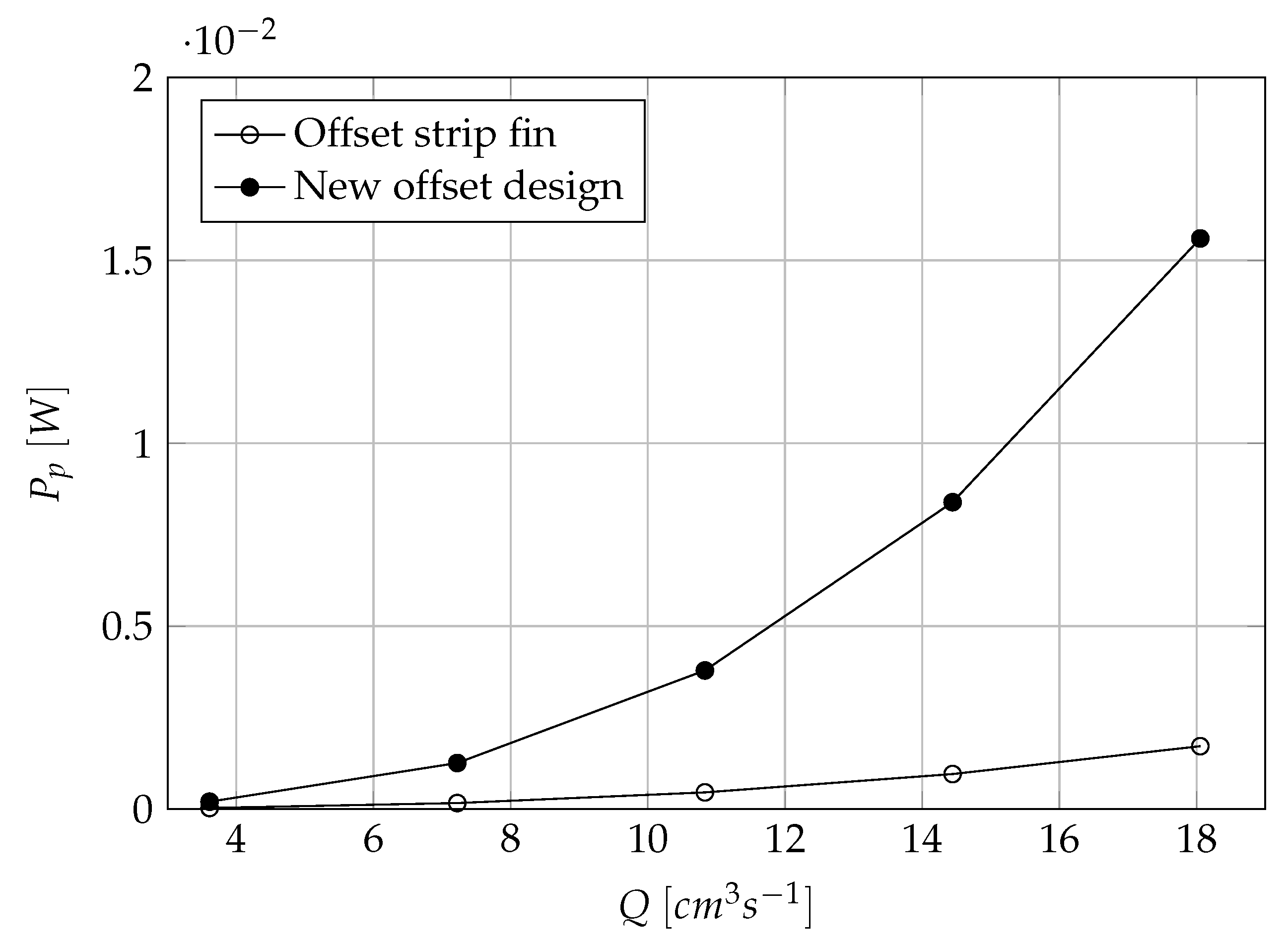

3.6. Pumping Power

4. Conclusions

- Heat transfer coefficient through this new design increased by 65–72% compared to offset strip fin.

- The line of the local heat transfer coefficients has non-linear distribution and are much higher at the second U-turn region. U-turns play a vital role on heat transfer performance.

- A decrease in the maximum temperature of heat source (in the range of 8–11%) can be seen in the new design compared to offset strip fin.

- Thermal resistance in the new design is lower than that in the offset strip fin (about 10–15%).

- Pressure drop is higher in the new design than the conventional one; and this is the drawback of this new design.

- The improved heat transfer performance results from the compound augmentation of the longer coolant passage, recirculation areas and vortices along the curvy fins, centrifugal forces in U-turns and the redeveloping boundary layer.

Author Contributions

Funding

Conflicts of Interest

References

- Shu, S.; Yang, H.; Tong, C.; Qiu, F. Fabrication of TiCx-TiB2/Al composites for application as a heat sink. Materials 2016, 9, 642. [Google Scholar] [CrossRef] [Green Version]

- Pang, L.; Wang, M.; Wang, W.; Liu, M.; Wang, J. Optimal thermal design of a stacked mini-channel heat sink cooled by a low flow rate coolant. Entropy 2013, 15, 4716–4731. [Google Scholar] [CrossRef] [Green Version]

- Oguntala, G.; Sobamowo, G.; Ahmed, Y.; Abd-Alhameed, R. Thermal Prediction of Convective-Radiative Porous Fin Heatsink of Functionally Graded Material Using Adomian Decomposition Method. Computation 2019, 7, 19. [Google Scholar] [CrossRef] [Green Version]

- Ma, L.; Zhao, X.; Sun, H.; Wu, Q.; Liu, W. Experimental study of single phase flow in a closed-loop cooling system with integrated mini-channel heat sink. Entropy 2016, 18, 128. [Google Scholar] [CrossRef] [Green Version]

- Bahman, A.S.; Blaabjerg, F. Optimization tool for direct water cooling system of high power IGBT modules. In Proceedings of the 18th European Conference on Power Electronics and Applications (EPE’16 ECCE Europe), Karlsruhe, Germany, 5–9 September 2016; pp. 1–10. [Google Scholar]

- Wang, Y.; Peles, Y. Subcooled flow boiling in a microchannel with a pin fin and a liquid jet in crossflow. Int. J. Heat Mass Transf. 2015, 86, 165–173. [Google Scholar] [CrossRef]

- Wu, T.; Wang, Z.; Ozpineci, B.; Chinthavali, M.; Campbell, S. Automated Heatsink Optimization for Air-Cooled Power Semiconductor Modules. IEEE Trans. Power Electr. 2019, 34, 5027–5031. [Google Scholar] [CrossRef]

- Nujukambari, A.Y.; Bahman, A.S.; Hærvig, J.; Sørensen, H. A Review: New Designs of Heat Sinks for Flow Boiling Cooling. In Proceedings of the 25th International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), Lecco, Italy, 25–27 September 2019; pp. 1–6. [Google Scholar]

- Mahmoudinezhad, S.; Rezaniakolaei, A.; Rosendahl, L.A. Experimental study on effect of operating conditions on thermoelectric power generation. Energy Procedia 2017, 142, 558–563. [Google Scholar] [CrossRef]

- Chang, Y.; Luo, H.; Iannuzzo, F.; Bahman, A.S.; Li, W.; He, X.; Blaabjerg, F. Compact Sandwiched Press-Pack SiC Power Module with Low Stray Inductance and Balanced Thermal Stress. IEEE Trans. Power Electr. 2019, 35, 2237–2241. [Google Scholar] [CrossRef]

- Pourfattah, F.; Arani, A.A.A.; Babaie, M.R.; Nguyen, H.M.; Asadi, A. On the thermal characteristics of a manifold microchannel heat sink subjected to nanofluid using two-phase flow simulation. Int. J. Heat Mass Transf. 2019, 143, 118518. [Google Scholar] [CrossRef]

- Bartoszewicz, J.; Bogusławski, L. Numerical analysis of the steam flow field in shell and tube heat exchanger. Arch. Thermodyn. 2016, 37, 107–120. [Google Scholar] [CrossRef] [Green Version]

- Jeng, T.M.; Tzeng, S.C. Numerical simulation of laminar forced convection of pin-fin heat-sink array in a Channel by Using Porous Approach. Appl. Sci. 2015, 5, 1846–1868. [Google Scholar] [CrossRef] [Green Version]

- Mohammed, H.A.; Gunnasegaran, P.; Shuaib, N.H. Influence of channel shape on the thermal and hydraulic performance of microchannel heat sink. Int. Commun. Heat Mass Transf. 2011, 38, 474–480. [Google Scholar] [CrossRef]

- Ndao, S.; Peles, Y.; Jensen, M.K. Multi-objective thermal design optimization and comparative analysis of electronics cooling technologies. Int. J. Heat Mass Transf. 2009, 52, 4317–4326. [Google Scholar] [CrossRef]

- Kim, H. Enhancement of critical heat flux in nucleate boiling of nanofluids: A state-of-art review. Nanoscale Res. Lett. 2011, 6, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Muzychka, Y.S.; Yovanovich, M.M. Modeling the f and j characteristics for transverse flow through an offset strip fin at low Reynolds number. J. Enhanc. Heat Transf. 2001, 8, 243–259. [Google Scholar] [CrossRef]

- Ranganayakulu, C.; Kabelac, S. Boiling of R134a in a plate-fin heat exchanger having offset fins. J. Heat Transf. 2015, 137, 121002. [Google Scholar] [CrossRef]

- Yang, F.; Dai, X.; Peles, Y.; Cheng, P.; Khan, J.; Li, C. Flow boiling phenomena in a single annular flow regime in microchannels (I): Characterization of flow boiling heat transfer. Int. J. Heat Mass Transf. 2014, 68, 703–715. [Google Scholar] [CrossRef]

- Wieting, A.R. Empirical correlations for heat transfer and flow friction characteristics of rectangular offset-fin plate-fin heat exchangers. J. Heat Transf. 1975, 97, 488–490. [Google Scholar] [CrossRef]

- Mochizuki, S.; Yagi, Y.; Yang, W.J. Transport phenomena in stacks of interrupted parallel-plate surfaces. Exp. Heat Transf. Int. J. 1987, 1, 127–140. [Google Scholar] [CrossRef]

- Joshi, H.M.; Webb, R.L. Heat transfer and friction in the offset stripfin heat exchanger. Int. J. Heat Mass Transf. 1987, 30, 69–84. [Google Scholar] [CrossRef]

- Manglik, R.M.; Bergles, A.E. Heat transfer and pressure drop correlations for the rectangular offset strip fin compact heat exchanger. Exp. Therm. Fluid Sci. 1995, 10, 171–180. [Google Scholar] [CrossRef]

- Meana-Fernández, A.; Fernández Oro, J.M.; Argüelles Díaz, K.M.; Galdo-Vega, M.; Velarde-Suárez, S. Application of Richardson extrapolation method to the CFD simulation of vertical-axis wind turbines and analysis of the flow field. Eng. Appl. Comput. Fluid Mech. 2019, 13, 359–376. [Google Scholar] [CrossRef] [Green Version]

- Hærvig, J.; Sørensen, K.; Condra, T.J. On the fully-developed heat transfer enhancing flow field in sinusoidally, spirally corrugated tubes using computational fluid dynamics. Int. J. Heat Mass Transf. 2017, 106, 1051–1062. [Google Scholar] [CrossRef] [Green Version]

- Bjerg, A.; Christoffersen, K.; Sørensen, H.; Hærvig, J. Flow structures and heat transfer in repeating arrangements of staggered rectangular winglet pairs by Large Eddy Simulations: Effect of winglet height and longitudinal pitch distance. Int. J. Heat Mass Transf. 2019, 131, 654–663. [Google Scholar] [CrossRef]

- Roache, P.J. A method for uniform reporting of grid refinement studies. ASME-PUBLICATIONS-FED 1993, 158, 109. [Google Scholar] [CrossRef]

- Chvála, A.; Donoval, D.; Šatka, A.; Molnár, M.; Marek, J.; Príbytný, P. Advanced methodology for fast 3-D TCAD device/circuit electrothermal simulation and analysis of power HEMTs. IEEE Trans. Electron Devices 2015, 62, 828–834. [Google Scholar] [CrossRef]

| Material | Density/kgm | Specific Heat/JkgK | Conductivity/WmK |

|---|---|---|---|

| Heatsink (Silicon) | 2330 | 705 | 140 |

| Baseplate (Copper) | 8954 | 384 | 395 |

| Ceramic (AlO) | 3890 | 880 | 35 |

| Solder | 2600 | 1200 | 3 |

| Thermal grease | 7370 | 220 | 57 |

| Description | Length × Width × Height |

|---|---|

| Diode | mm |

| Solder (under Diodes) | mm |

| IGBT | mm |

| Solder (under IGBTs) | mm |

| Copper | mm |

| Ceramic | mm |

| Solder (between copper and baseplate) | mm |

| Baseplate | mm |

| Thermal grease | mm |

| Sign | Description | Value |

|---|---|---|

| H | Heatsink height | 10 mm |

| Channel height | 6 mm | |

| Rib height | 4 mm | |

| W | Heatsink width | 36 mm |

| L | Heatsink length | 60 mm |

| Fin width | 0.86 mm | |

| Channel width | 1.14 mm | |

| Fin length | 10 mm | |

| Curve angle | 40° | |

| Curve angle | 100° | |

| Curve angle | 40° |

| Max Element Size | Min Element Size | Max Element Growth Rate | |

|---|---|---|---|

| Fluid domain | 5.12 mm | 0.64 mm | 1.45 |

| IGBT module domain | 1.5 mm | 0.448 mm | 1.15 |

| Wetted walls | 0.829 mm | 0.0897 mm | 1.1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yahyaee, A.; Bahman, A.S.; Blaabjerg, F. A Modification of Offset Strip Fin Heatsink with High-Performance Cooling for IGBT Modules. Appl. Sci. 2020, 10, 1112. https://doi.org/10.3390/app10031112

Yahyaee A, Bahman AS, Blaabjerg F. A Modification of Offset Strip Fin Heatsink with High-Performance Cooling for IGBT Modules. Applied Sciences. 2020; 10(3):1112. https://doi.org/10.3390/app10031112

Chicago/Turabian StyleYahyaee, Ali, Amir Sajjad Bahman, and Frede Blaabjerg. 2020. "A Modification of Offset Strip Fin Heatsink with High-Performance Cooling for IGBT Modules" Applied Sciences 10, no. 3: 1112. https://doi.org/10.3390/app10031112

APA StyleYahyaee, A., Bahman, A. S., & Blaabjerg, F. (2020). A Modification of Offset Strip Fin Heatsink with High-Performance Cooling for IGBT Modules. Applied Sciences, 10(3), 1112. https://doi.org/10.3390/app10031112