The Analysis of Key Technologies for Sustainable Machine Tools Design

Abstract

:1. Introduction

1.1. Sustainable Manufacturing and Design

1.2. Challenges and Opportunities of Sustainable Machine Tool Design

- High performance;

- High energy consumption;

- High carbon manufacturing systems;

- Environmental burden;

- Waste volumes;

- Economy efficiency;

- Public health;

- Social benefits.

- What is sustainable design of machine tools?

- How to design sustainable machine tools?

- What degree of sustainability performance is there for machine tools?

2. Research Methodology

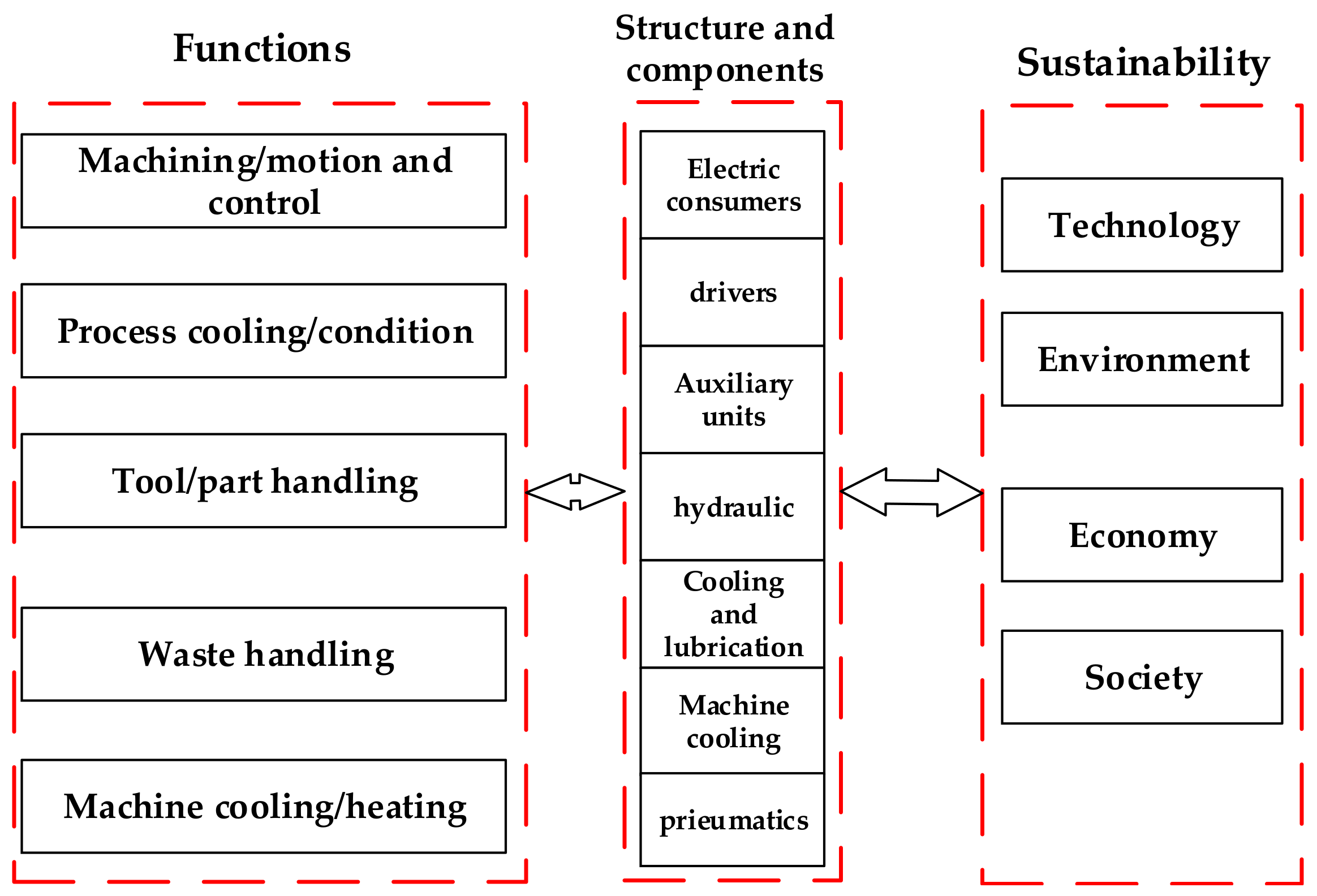

3. Dimension of Sustainable Machine Tools

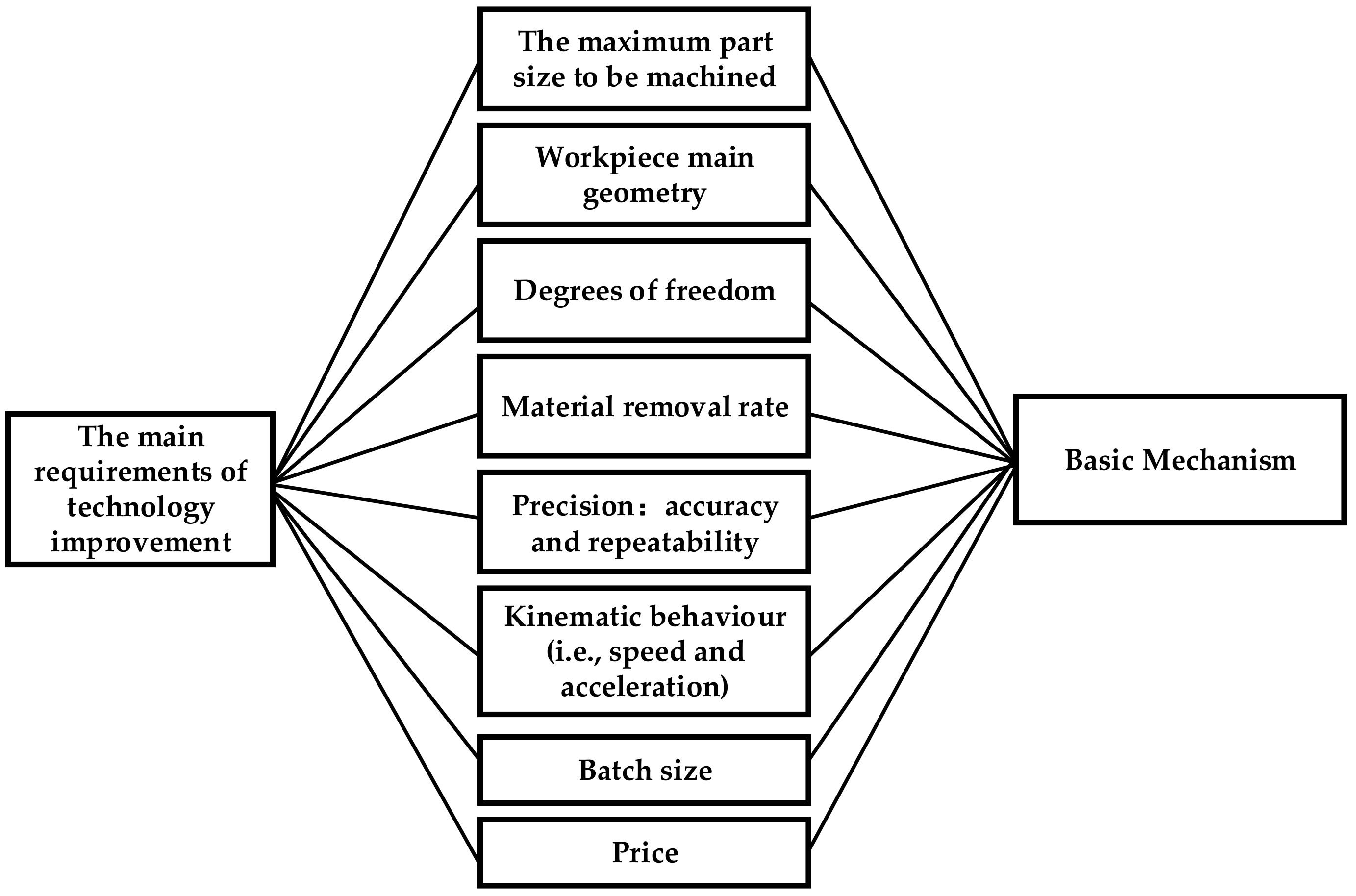

3.1. Technology Factors

3.2. Environmental Factors

3.2.1. Energy Efficiency

3.2.2. Resource Efficiency

3.2.3. Waste

3.2.4. Carbon Emission

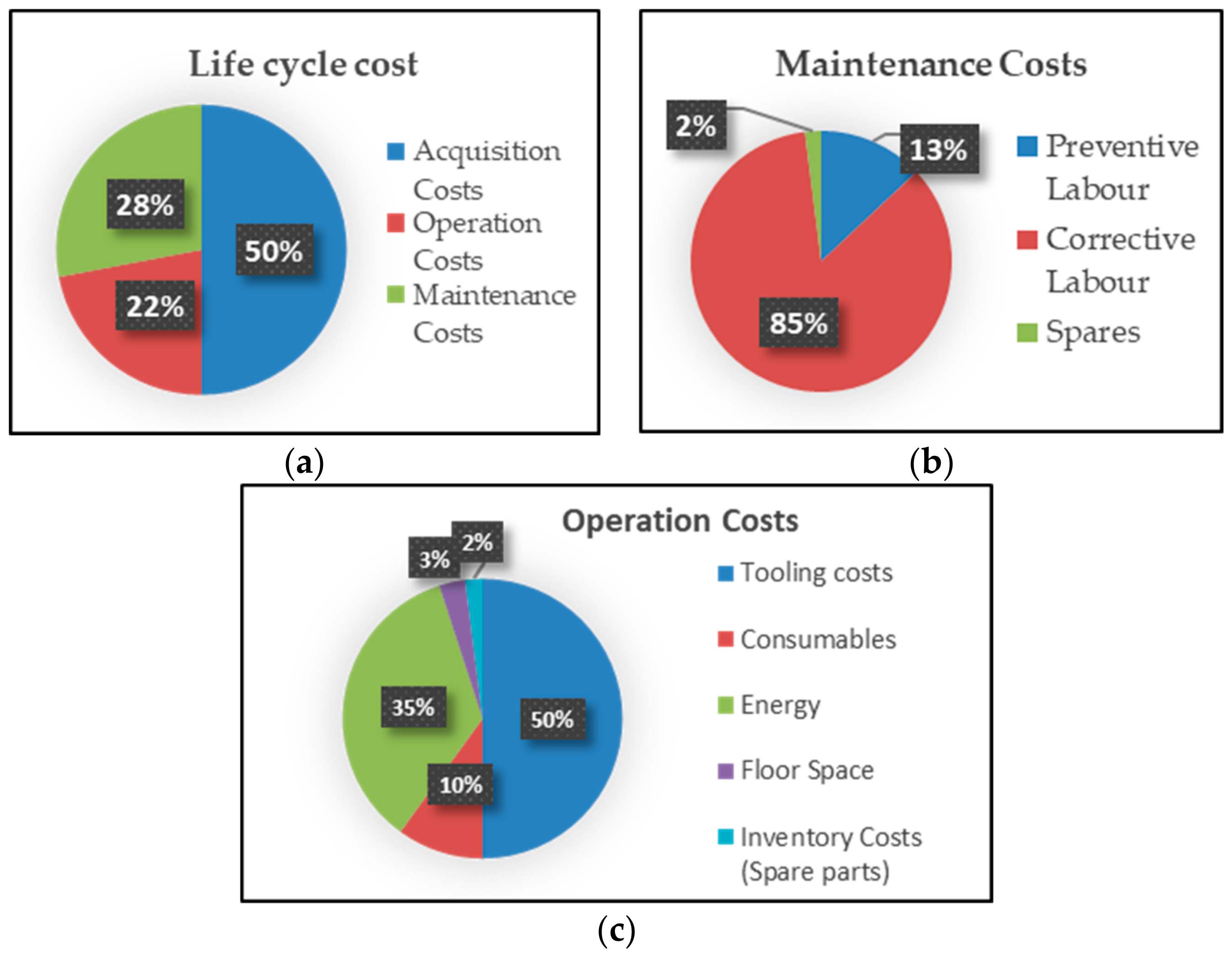

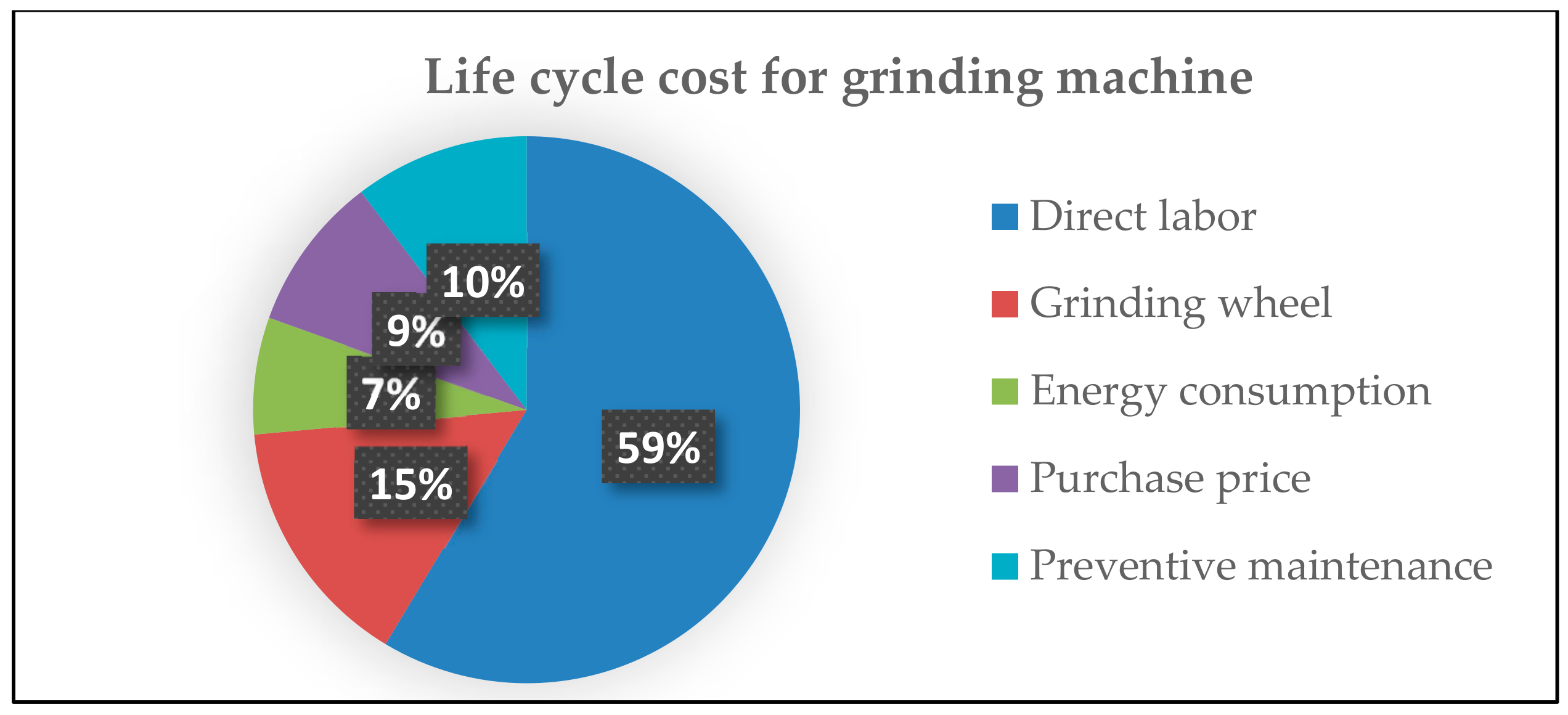

3.3. Economic Factors

3.4. Social Factors

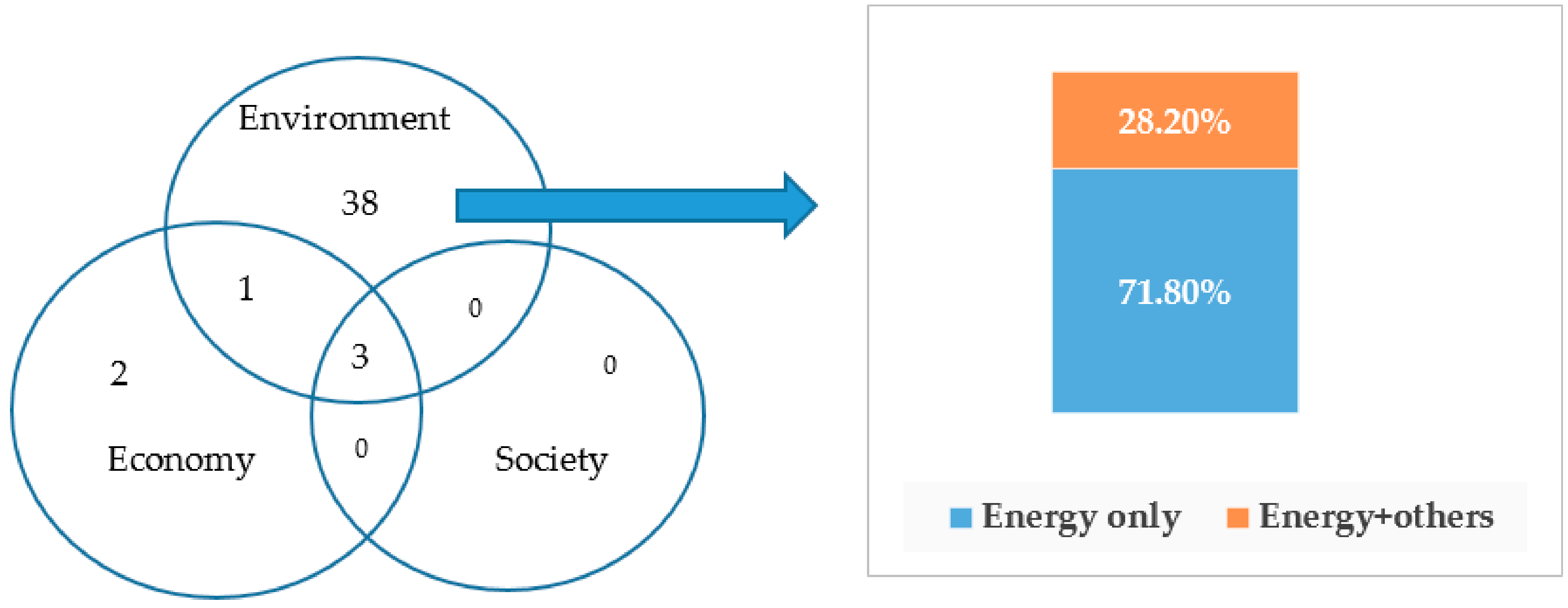

3.5. The Analysis Result

4. Strategies and Technologies for Sustainable Design of Machine Tools

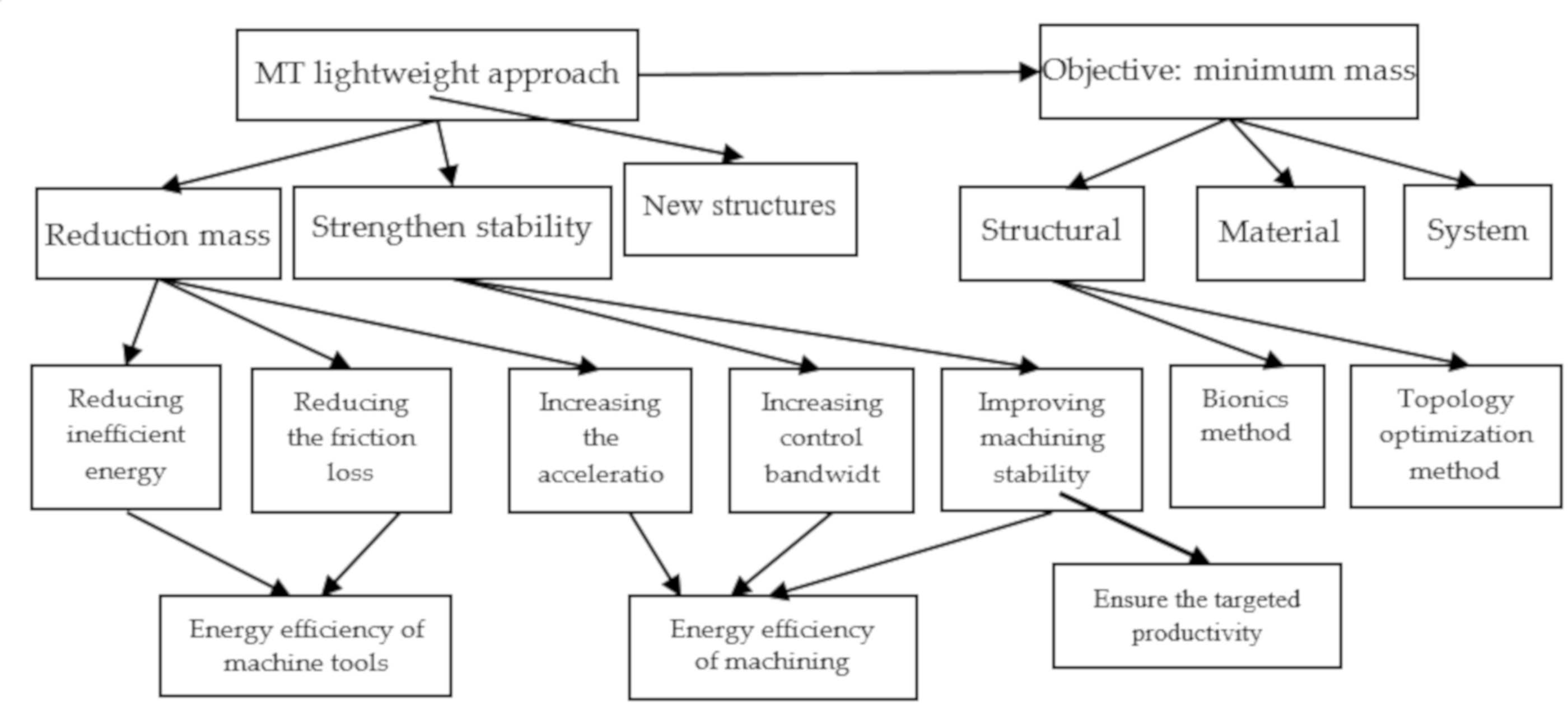

4.1. Lightweight Techniques of Structural Components

- (1)

- Machine tool moving parts are light as possible for reducing driving power, increasing energy efficiency, and decreasing production and transport costs.

- (2)

- The structure components should have enough effective stiffness in order to guarantee machining precision.

- (3)

- The structure components should have good damping and vibration reduction performance avoiding chatter to improve the metal cutting rate.

4.2. Structure Principle

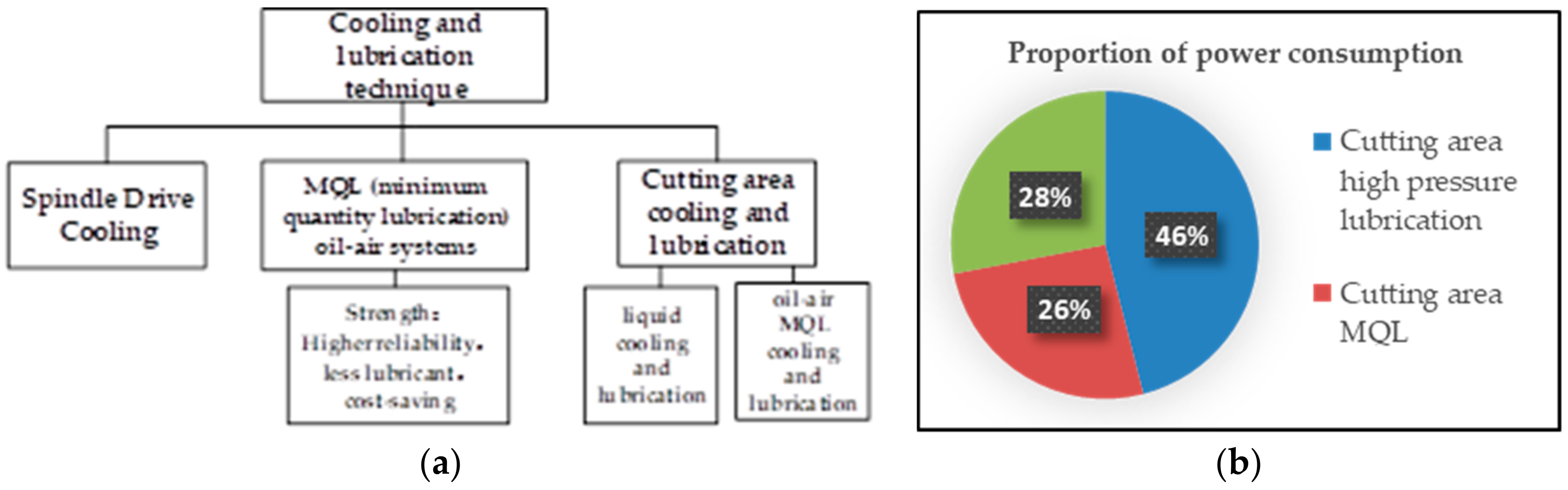

4.3. Cooling and Lubrication Technique

4.4. Reuse Techniques for Outdated Machine Tools

4.5. Sustainable Strategy for Machining Process

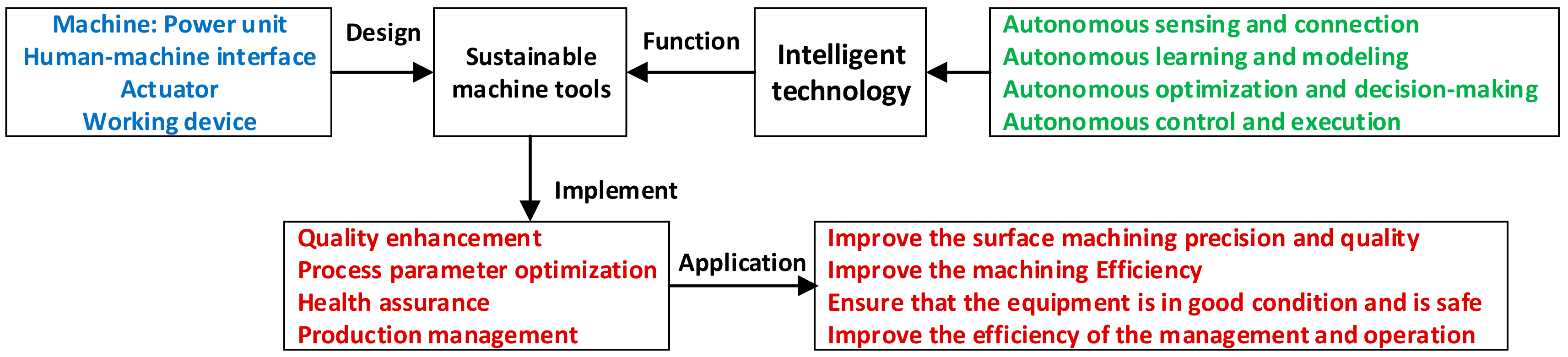

4.6. Other Technologies

5. Conclusions and Future Research Directions

- (1)

- The partial design strategies such as light weight and modular design to integrated sustainable design method have three sustainability dimensions.

- (2)

- The sustainability assessment method for machine tools to support decision-making in the early design stage. The two categories, however, are faced with the issue of considering three sustainable design dimensions simultaneously in different life cycle stages.

- (3)

- Most research focuses on the environmental burden especially energy efficiency, while sustainable product design underscored the importance of three sustainability dimensions under the condition of functional attributes.

- (4)

- The key techniques are categorized into light weight, modular design, and cooling and lubricant system, which have benefits in sustainable machine tool design in different life cycle stages.

- (5)

- Furthermore, sustainability assessment used by machine tools are described as LCA (Life cycle assessment), LCC (Life cycle cost) and LCSA (Life cycle social assessment), which should be used conveniently and relate to design parameter in early design stage. Currently, the research focuses on one or two factors for achieving sustainable design and manufacturing for machine tools.

- (1)

- The simulation technique contributes to design efficiency before manufacturing process, use and end-of-life.

- (2)

- With the development of new types of sensor, wireless monitoring technology will be used to monitor the state of machine tool usage including energy consumption, failure diagnosis, coolant fluids and lubricant oil, and so on.

- (3)

- The uniform standardization for the energy efficiency of machine tools should be developed based on standard components in order to make accurate judgments.

- (4)

- The network environment will provide more opportunities for collecting existing MT data used to improve the next generation or new product designs.

Author Contributions

Funding

Conflicts of Interest

References

- Gbededo, M.A.; Liyanage, K.; Garza-Reyes, J.A. Towards a Life Cycle Sustainability Analysis: A Systematic Review of Approaches to Sustainable Manufacturing. J. Clean. Prod. 2018, 184, 1002–1015. [Google Scholar] [CrossRef] [Green Version]

- Ahmad, S.; Wong, K.Y.; Ming, L.T.; Wong, W.P. Sustainable product design and development: A review of tools, applications and research prospects. Resour. Conserv. Recycl. 2018, 132, 49–61. [Google Scholar] [CrossRef]

- Kishawy, H.A.; Hegab, H.; Saad, E. Design for Sustainable Manufacturing: Approach, Implementation, and Assessment. Sustainability 2018, 10, 3604. [Google Scholar] [CrossRef] [Green Version]

- Avram, O.I.; Xirouchakis, P. Evaluating the use phase energy requirements of a machine tool system. J. Clean. Prod. 2011, 19, 699–711. [Google Scholar] [CrossRef]

- Diaz-Elsayed, N.; Dornfeld, D.; Horvath, A. A comparative analysis of the environmental impacts of machine tool manufacturing facilities. J. Clean. Prod. 2015, 95, 223–231. [Google Scholar] [CrossRef]

- European Union. Directive 2009/125/EC of the European Parliament and of the Council of 21 October 2009 Establishing A Framework for the Setting of Ecodesign Requirements for Energy-Related Products (Recast); Official Journal of the European Union: London, UK, 2009. [Google Scholar]

- European Union. Directive 2005/32/EC of the European Parliament and of the Council of 6 July 2005 Establishing A Framework for the Setting of Ecodesign Requirements for Energy-Using Products; Official Journal of the European Union: London, UK, 2005. [Google Scholar]

- Calleja-Ochoa, A.; Gonzalez-Barrio, H.; Polvorosa-Teijeiro, R.; Lopez-De La Calle Marcaide, L. Multitasking machines: Evolution, resources, processes and scheduling. DYNA 2017, 92, 637–642. [Google Scholar]

- Machine Tools—Environmental Evaluation of Machine Tools—Part 1: Design Methodology for Energy-Efficient Machine Tools; ISO 14955-1.2017; BSI Standards Publication: Lugano, Switzerland, 2017.

- Schudeleit, T.; Züst, S.; Weiss, L.; Wegener, K. The Total Energy Efficiency Index for machine tools. Energy 2016, 102, 682–693. [Google Scholar] [CrossRef]

- Zhou, L.; Li, J.; Li, F.; Meng, Q.; Li, J.; Xu, X. Energy consumption model and energy efficiency of machine tools: A comprehensive literature review. J. Clean. Prod. 2016, 112, 3721–3734. [Google Scholar] [CrossRef]

- Triebe, M.J.; Mendisa, G.P.; Zhao, F.; Sutherlanda, J.W. Understanding energy consumption in a machine tool through energy mapping. Procedia CIRP 2018, 69, 259–264. [Google Scholar] [CrossRef]

- Mert, G.; Bohr, C.; Waltemode, S.; Aurich, J.C. Increasing the Resource Efficiency of Machine Tools by Life Cycle Oriented Services. Procedia CIRP 2014, 15, 176–181. [Google Scholar] [CrossRef] [Green Version]

- Posselt, G.; Kellens, K.; Thiede, S.; Renaldi; Herrmann, C.; Dewulf, W.; Duflou, J.R. Combining Machine Tool Builder and Operator Perspective towards Energy and Resource Efficiency in Manufacturing. In Re-Engineering Manufacturing for Sustainability; Springer: Singapore, 2013; pp. 209–214. [Google Scholar]

- Chen, J.L.; Su, W.L.; Huang, H.C. Method and Calculation Tool for Carbon Footprint Assessment of Machine Tool. In Re-Engineering Manufacturing for Sustainability; Springer: Singapore, 2013; pp. 330–343. [Google Scholar]

- Oleaga, I.; Pardo, C.; Zulaika, J.J.; Bustillo, A. A machine-learning based solution for chatter prediction in heavy-duty milling machines. Measurement 2018, 128, 34–44. [Google Scholar] [CrossRef]

- Jovane, F.; Yoshikawa, H.; Alting, L.; Boër, C.R.; Westkamper, E.; Williams, D. The incoming global technological and industrial revolution towards competitive sustainable manufacturing. CIRP Ann. Manuf. Technol. 2008, 57, 641–659. [Google Scholar] [CrossRef]

- Gutowski, T.; Dahmus, J.; Thiriez, A.; Branham, M.; Jones, A. A thermodynamic characterization of manufacturing processes. In Proceedings of the 2007 IEEE International Symposium, Orlando, FL, USA, 7–10 May 2007; pp. 137–142. [Google Scholar]

- Huang, J.; Jin, L.; Zhang, C. Mathematical Modeling and a Hybrid NSGA-II Algorithm for Process Planning Problem Considering Machining Cost and Carbon Emission. Sustainability 2017, 9, 1769. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Jiang, P. Sustainability Evaluation of Process Planning for Single CNC Machine Tool under the Consideration of Energy-Efficient Control Strategies Using Random Forests. Sustainability 2019, 11, 3060. [Google Scholar] [CrossRef] [Green Version]

- Shin, S.J.; Woo, J.; Rachuri, S.; Meilanitasari, P. Standard Data-Based Predictive Modeling for Power Consumption in Turning Machining. Sustainability 2018, 10, 598. [Google Scholar] [CrossRef] [Green Version]

- Kono, D.; Nishio, S.; Yamaji, I.; Matsubara, A. A method for stiffness tuning of machine tool supports considering contact stiffness. Int. J. Mach. Tools Manuf. 2015, 90, 50–59. [Google Scholar] [CrossRef] [Green Version]

- Schöggl, J.P.; Baumgartner, R.J.; Hofer, D. Improving sustainability performance in early phases of product design: A checklist for sustainable product development tested in the automotive industry. J. Clean. Prod. 2016, 140, 1602–1617. [Google Scholar] [CrossRef]

- Brundage, M.P.; Bernstein, W.Z.; Hoffenson, S.; Chang, Q.; Nishi, H. Analyzing environmental sustainability methods for use earlier in the product lifecycle. J. Clean. Prod. 2018, 187, 877–892. [Google Scholar] [CrossRef]

- Mori, K.; Bergmann, B.; Konoa, D.; Denkenac, B.; Matsubara, A. Energy efficiency improvement of machine tool spindle cooling system with on–off control. CIRP J. Manuf. Sci. Technol. 2019, 25, 14–21. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, L.; Peng, T.; Jia, S. An Improved Scheduling Approach for Minimizing Total Energy Consumption and Makespan in a Flexible Job Shop Environment. Sustainability 2019, 11, 179. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Wu, W. Investigation of Drilling Machinability of Compacted Graphite Iron under Dry and Minimum Quantity Lubrication (MQL). Metals 2019, 9, 1095. [Google Scholar] [CrossRef] [Green Version]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Graessler, I.; Yang, X. Product life cycle cost approach for modular lightweight design. Procedia CIRP 2019, 84, 1048–1053. [Google Scholar] [CrossRef]

- Hayasaka, T.; Minoura, K.; Ishizaki, K.; Shamotoa, E.; Sencer, B. A lightweight interpolation algorithm for short-segmented machining tool paths to realize vibration avoidance, high accuracy, and short machining time. Precis. Eng. 2019, 59, 1–17. [Google Scholar] [CrossRef]

- Schweizer, M.L.; Nair, R. A practical guide to systematic literature reviews and meta-analyses in infection prevention: Planning, challenges, and execution. Am. J. Infect. Control 2017, 45, 1292–1294. [Google Scholar] [CrossRef]

- Avram, O.; Stroud, I.; Xirouchakis, P. A multi-criteria decision method for sustainability assessment of the use phase of machine tool systems. Int. J. Adv. Manuf. Technol. 2011, 53, 811–828. [Google Scholar] [CrossRef] [Green Version]

- Azkarate, A.; Ricondo, I.; PãRez, A.; Martã Nez, P. An assessment method and design support system for designing sustainable machine tools. J. Eng. Des. 2011, 22, 165–179. [Google Scholar] [CrossRef]

- López de Lacalle, L.N.; Lamikiz, A. Machine Tools for High Performance Machining; Springer: London, UK, 2009. [Google Scholar]

- Sato, R.; Noguchi, S.; Hokazono, T.; Nishida, I.; Shirase, K. Time domain coupled simulation of machine tool dynamics and cutting forces considering the influences of nonlinear friction characteristics and process damping. Precis. Eng. 2020, 61, 103–109. [Google Scholar] [CrossRef]

- Archenti, A.; Laspas, T. Accuracy and Performance Analysis of Machine Tools. In Metrology, Precision Manufacturing; Springer: Singapore, 2019; pp. 1–30. [Google Scholar]

- Eisele, C.; Schrems, S.; Abele, E. Energy-Efficient Machine Tools through Simulation in the Design Process. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 258–262. [Google Scholar]

- Taha, Z.; Rostam, S. A hybrid fuzzy AHP-PROMETHEE decision support system for machine tool selection in flexible manufacturing cell. J. Intell. Manuf. 2012, 23, 2137–2149. [Google Scholar] [CrossRef]

- Wei, Y.; Hua, Z.; Zhi-Gang, J.; Hon, K.K.B. A new multi-source and dynamic energy modeling method for machine tools. Int. J. Adv. Manuf. Technol. 2018, 95, 4485–4495. [Google Scholar] [CrossRef]

- Zhang, Y. Energy efficiency techniques in machining process: A review. Int. J. Adv. Manuf. Technol. 2014, 71, 1123–1132. [Google Scholar]

- Environmental Management—Integrating Environmental Aspects into Product Design and Development; ISO/TR 14062; ISO: Geneva, Switzerland, 2002.

- Yoon, H.S.; Kim, E.S.; Kim, M.S.; Lee, J.Y.; Lee, G.B.; Ahn, S.H. Towards greener machine tools—A review on energy saving strategies and technologies. Renew. Sustain. Energy Rev. 2015, 48, 870–891. [Google Scholar] [CrossRef]

- Gontarz, A.; Schudeleit, T.; Wegener, K. Framework of a Machine Tool Configurator for Energy Efficiency. Procedia CIRP 2015, 26, 706–711. [Google Scholar] [CrossRef] [Green Version]

- Neugebauer, R.; Wabner, M.; Rentzsch, H.; Ihlenfeldt, S. Structure principles of energy efficient machine tools. CIRP J. Manuf. Sci. Technol. 2011, 4, 136–147. [Google Scholar] [CrossRef]

- Abele, E.; Sielaff, T.; Schiffler, A.; Rothenbücher, S. Analyzing Energy Consumption of Machine Tool Spindle Units and Identification of Potential for Improvements of Efficiency. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 280–285. [Google Scholar]

- Hu, S.; Liu, F.; He, Y.; Peng, B. Characteristics of Additional Load Losses of Spindle System of Machine Tools. J. Adv. Mech. Des. Syst. Manuf. 2010, 4, 1221–1233. [Google Scholar] [CrossRef] [Green Version]

- Schudeleit, T.; Züst, S.; Wegener, K. Energy equivalents to quantify the total electricity consumption of factory-integrated machine tools. Int. J. Adv. Manuf. Technol. 2017, 90, 3239–3247. [Google Scholar] [CrossRef]

- Kara, S.; Li, W. Unit process energy consumption models for material removal processes. CIRP Ann. Manuf. Technol. 2011, 60, 37–40. [Google Scholar] [CrossRef]

- Rivero, A.; López de Lacalle, L.N.; Penalva, M.L. Tool wear detection in dry high-speed milling based upon the analysis of machine internal signals. Mechatronics 2008, 18, 627–633. [Google Scholar] [CrossRef]

- Bordin, A.; Sartori, S.; Bruschi, S.; Ghiotti, A. Experimental investigation on the feasibility of dry and cryogenic machining as sustainable strategies when turning ti6al4v produced by additive manufacturing. J. Clean. Prod. 2017, 142, 4142–4151. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. Evaluation of cryogenic cooling and minimum quantity lubrication effects on machining GLARE laminates using design of experiments. J. Clean. Prod. 2016, 135, 533–548. [Google Scholar] [CrossRef]

- Wang, P.J.; Liu, Y.; Ong, S.K.; Nee, A.Y.C. Modular Design of Machine Tools to Facilitate Design for Disassembly and Remanufacturing. Procedia CIRP 2014, 15, 443–448. [Google Scholar]

- Hondo, H. Life cycle GHG emission analysis of power generation systems: Japanese case. Energy 2005, 30, 2042–2056. [Google Scholar] [CrossRef]

- Tao, Y.; Li, H.; Wen, Z.; Chen, H.; Xu, W.; Evans, S. A hybrid scenario analysis for the selection of future greenhouse gas emissions reduction technologies in China’s oil and gas industry. J. Clean. Prod. 2019, 223, 14–24. [Google Scholar] [CrossRef]

- Chetan; Ghosh, S.; Rao, P.V. Comparison between sustainable cryogenic techniques and nano-MQL cooling mode in turning of nickel-based alloy. J. Clean. Prod. 2019, 231, 1036–1039. [Google Scholar] [CrossRef]

- Li, B.; Cao, H.; Yan, J.; Jafar, S. A life cycle approach to characterizing carbon efficiency of cutting tools. Int. J. Adv. Manuf. Technol. 2017, 93, 1–9. [Google Scholar] [CrossRef]

- Uhlmann, E.; Lang, K.D.; Prasol, L.; Thom, S.; Peukert, B. Sustainable Solutions for Machine Tools. In Sustainable Manufacturing; Springer International Publishing: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Singh, G.; Gill, S.S.; Dogra, M. Techno-economic analysis of blanking punch life improvement by environment friendly cryogenic treatment. J. Clean. Prod. 2017, 143, 1060–1068. [Google Scholar] [CrossRef]

- Mulyana, T.; Rahim, E.A.; Md Yahaya, S.N. The influence of cryogenic supercritical carbon dioxide cooling on tool wear during machining high thermal conductivity steel. J. Clean. Prod. 2017, 164, 950–962. [Google Scholar] [CrossRef]

- Grguraš, D.; Sterle, L.; Krajnik, P.; Pušavec, P. A novel cryogenic machining concept based on a lubricated liquid carbon dioxide. Int. J. Mach. Tools Manuf. 2019, 145, 103456. [Google Scholar] [CrossRef]

- Mia, M.; Gupta, M.K.; Lozano, J.A.; Carou, D.; Pimenov, D.Y.; Królczyk, G.; MashoodKhan, A.; RanjanDhar, N. Multi-objective optimization and life cycle assessment of eco-friendly cryogenic n2 assisted turning of ti-6al-4v. J. Clean. Prod. 2019, 210, 121–133. [Google Scholar] [CrossRef]

- Götze, U.; Koriath, H.J.; Kolesnikov, A.; Lindner, R.; Paetzold, J. Integrated methodology for the evaluation of the energy- and cost-effectiveness of machine tools. CIRP J. Manuf. Sci. Technol. 2012, 5, 151–163. [Google Scholar] [CrossRef]

- Enparantza, R.; Revilla, O.; Azkarate, A.; Zendoia, J. A Life Cycle Cost Calculation and Management System for Machine Tools. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belguim, 31 May–2 June 2006; pp. 717–721. [Google Scholar]

- Züst, S.; Züst, R.; Schudeleit, T.; Wegener, K. Development and Application of an Eco-design Tool for Machine Tools. Procedia CIRP 2016, 48, 431–436. [Google Scholar] [CrossRef] [Green Version]

- Schudeleit, T.; Züst, S.; Wegener, K. Methods for evaluation of energy efficiency of machine tools. Energy 2015, 93, 1964–1970. [Google Scholar] [CrossRef]

- Salonitis, K.; Ball, P. Energy efficient manufacturing from machine tools to manufacturing. Procedia CIRP 2013, 7, 634–639. [Google Scholar] [CrossRef] [Green Version]

- Zein, A.; Li, W.; Herrmann, C.; Kara, S. Energy Efficiency Measures for the Design and Operation of Machine Tools: An Axiomatic Approach. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin, Germany, 2011; pp. 274–279. [Google Scholar]

- Kroll, L.; Blau, P.; Wabner, M.; Frieß, U.; Eulitz, J.; Klärner, M. Lightweight components for energy-efficient machine tools. CIRP J. Manuf. Sci. Technol. 2011, 4, 148–160. [Google Scholar] [CrossRef]

- Li, L.; Yu, S.; Tao, J.; Li, L. A FBS-based energy modelling method for energy efficiency-oriented design. J. Clean. Prod. 2017, 172, 1–13. [Google Scholar] [CrossRef]

- Ding, X.; Chen, Y.; Liu, W. Optimal design approach for eco-efficient machine tool bed. Int. J. Mech. Mater. Des. 2010, 6, 351–358. [Google Scholar] [CrossRef]

- Li, W.; Zein, A.; Kara, S.; Herrmann, C. An Investigation into Fixed Energy Consumption of Machine Tools. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin, Germany, 2011; pp. 268–273. [Google Scholar]

- Gonzalez, A. Machine Tool Utilisation Phase: Costs and Environmental Impacts with a Life Cycle View. Ind. Ecol. 2007. [Google Scholar] [CrossRef] [Green Version]

- Behrendt, T.; Zein, A.; Min, S. Development of an energy consumption monitoring procedure for machine tools. CIRP Ann. Manuf. Technol. 2012, 61, 43–46. [Google Scholar] [CrossRef]

- Mohammadi, A.; Züst, S.; Mayr, J.; Blaser, P.; Sonne, M.R. A methodology for online visualization of the energy flow in a machine tool. CIRP J. Manuf. Sci. Technol. 2017, 19, 138–146. [Google Scholar] [CrossRef]

- Vijayaraghavan, A.; Dornfeld, D. Automated energy monitoring of machine tools. CIRP Ann.Manuf. Technol. 2010, 59, 21–24. [Google Scholar] [CrossRef] [Green Version]

- Balogun, V.A.; Aramcharoen, A.; Mativenga, P.T.; Blaser, P.; Sonne, M.R. Impact of Machine Tools on the Direct Energy and Associated Carbon Emissions for a Standardized NC Toolpath. In Proceedings of the CIRP International Conference on Life Cycle Engineering, Singapore, 17–19 April 2013; pp. 197–202. [Google Scholar]

- Braun, S.; Heisel, U. Simulation and Prediction of Process-Oriented Energy Consumption of Machine Tools. In Leveraging Technology for a Sustainable World; Springer: Berlin/Heidelberg, Germany, 2012; pp. 245–250. [Google Scholar]

- Draganescu, F.; Gheorghe, M.; Doicin, C.V. Models of machine tool efficiency and specific consumed energy. J. Mater. Process. Technol. 2003, 141, 9–15. [Google Scholar] [CrossRef]

- Lee, W.; Lee, C.Y.; Min, B.K. Simulation-based energy usage profiling of machine tool at the component level. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 183–189. [Google Scholar] [CrossRef] [Green Version]

- Brecher, C.; Triebs, J.; Jasper, D. Energy Efficient Solutions for Hydraulic Units of Machine Tools. In Re-Engineering Manufacturing for Sustainability; Springer: Singapore, 2013; pp. 191–196. [Google Scholar]

- Brecher, C.; Bäumler, S.; Jasper, D.; Triebs, J. Energy Efficient Cooling Systems for Machine Tools. In Leveraging Technology for A Sustainable World; Springer: Berlin/Heidelberg, Germany, 2012; pp. 239–244. [Google Scholar]

- Mori, M.; Fujishima, M.; Inamasu, Y.; Oda, Y. A study on energy efficiency improvement for machine tools. CIRP Ann. Manuf. Technol. 2011, 60, 145–148. [Google Scholar] [CrossRef]

- Chen, J.L.; Chen, Y.B.; Huang, H.C. Quantifying the Life Cycle Water Consumption of a Machine Tool. Procedia CIRP 2015, 29, 498–501. [Google Scholar] [CrossRef]

- Zeng, D.; Cao, H.J.; Jafar, S.; Tan, Y.F.; Su, S. A Life Cycle Ecological Sensitivity Analysis Method for Eco-Design Decision Making of Machine Tool. In Proceedings of the 25th CIRP Life Cycle Engineering (LCE) Conference, Copenhagen, Denmark, 30 April–2 May 2018. [Google Scholar]

- Azevedo, M.; Oliveira, M.; Pereira, J.P.; Reis, A. Comparison of two LCA Methodologies in the Machine-Tools Environmental Performance Improvement Process. In Glocalized Solutions for Sustainability in Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 1818–1825. [Google Scholar]

- Zendoia, J.; Woy, U.; Ridgway, N.; Pajula, T.; Unamuno, G. A specific method for the life cycle inventory of machine tools and its demonstration with two manufacturing case studies. J. Clean. Prod. 2014, 78, 139–151. [Google Scholar] [CrossRef]

- Narita, H. Environmental Burden Analyzer for Machine Tool Operations and Its Application. In Manufacturing System; InTech Open: London, UK, 2012. [Google Scholar]

- Kamal, A.; Al-Ghamdi, S.G.; Koc, M. Revaluing the costs and benefits of energy efficiency: A systematic review. Energy Res. Soc. Sci. 2019, 54, 68–84. [Google Scholar] [CrossRef]

- Urbikain, G.; Campa, F.J.; Zulaika, J.J.; Lópezde Lacalle, L.N.; Alonso, M.A.; Collado, V. Preventing chatter vibrations in heavy-duty turning operations in large horizontal lathes. J. Sound Vib. 2015, 340, 317–330. [Google Scholar] [CrossRef]

- Ansoategui, I.; Campa, F.J.; Carolina, L.; Mikel, D. Influence of the machine tool compliance on the dynamic performance of the servo drives. Int. J. Adv. Manuf. Technol. 2016, 90, 1–13. [Google Scholar] [CrossRef]

- Zulaika, J.J.; Campa, F.J.; Lacalle, L.N.L.D. An integrated process–machine approach for designing productive and lightweight milling machines. Int. J. Mach. Tools Manuf. 2011, 51, 591–604. [Google Scholar] [CrossRef]

- Neugebauer, R.; Wabner, M.; Ihlenfeldt, S.; Frieß, U.; Schneider, F.; Schubert, F. Bionics Based Energy Efficient Machine Tool Design. Procedia CIRP 2012, 3, 561–566. [Google Scholar] [CrossRef]

- Möhring, H.C. Materials in machine tool structures. CIRP Ann. Manuf. Technol. 2015, 64, 725–748. [Google Scholar] [CrossRef]

- Edem, I.F.; Balogun, V.A.; Mativenga, P.T. An investigation on the impact of toolpath strategies and machine tool axes configurations on electrical energy demand in mechanical machining. Int. J. Adv. Manuf. Technol. 2017, 92, 2503–2509. [Google Scholar] [CrossRef]

- Brecher, C.; Esser, M.; Witt, S. Interaction of manufacturing process and machine tool. CIRP Ann. Manuf. Technol. 2009, 58, 588–607. [Google Scholar] [CrossRef]

- Padayachee, J.; Bright, G. Modular machine tools: Design and barriers to industrial implementation. J. Manuf. Syst. 2012, 31, 92–102. [Google Scholar] [CrossRef]

- Li, P.; Liu, J.; Liu, S. Topological Variable-Density Algorithm Based Design Method for Lightweight Machine Tools. In Electrical Power Systems and Computers; Springer: Berlin/Heidelberg, Germany, 2011; Volume 99, pp. 957–963. [Google Scholar]

- Xiang, D.; Wang, H.L.; Jiang, L.F.; Duan, G.H.; Zhang, H.C. Design for Saving Energy and Material Based On Energy Flow Analysis of Electromechanical Products. In Proceedings of the 16th CIRP International Conference on Life Cycle Engineering, Cairo, Egypt, 4–6 May 2009; pp. 125–130. [Google Scholar]

- Peukert, B.; Benecke, S.; Clavell, J.; Neugebauer, S.; Nissen, N.F.; Uhlmann, E. Addressing sustainability and flexibility in manufacturing via smart modular machine tool frames to support sustainable value creation. Procedia CIRP 2015, 29, 514–519. [Google Scholar] [CrossRef]

- Sonego, M.; Echeveste, M.E.S.; Debarba, H.G. The role of modularity in sustainable design: A systematic review. J. Clean. Prod. 2018, 176, 196–209. [Google Scholar] [CrossRef]

- Xirouchakis, P. Machine Tool Cooling and Lubrication in the Use Phase, Report; Swiss Federal Institute of Technology: Zürich, Switzerland, 2017. [Google Scholar]

- Osman, K.A.; Özgür Ünver, H.; Şeker, U. Application of minimum quantity lubrication techniques in machining process of titanium alloy for sustainability: A review. Int. J. Adv. Manuf. Technol. 2019, 100, 2311–2332. [Google Scholar] [CrossRef]

- Rotella, G.; Lu, T.; Settineri, L.; Dillon, O.W., Jr.; Jawahir, I.S. Dry and Cryogenic Machining: Comparison from the Sustainability Perspective. In Sustainable Manufacturing; Springer: Berlin/Heidelberg, Germany, 2011; pp. 95–100. [Google Scholar]

- Goindi, G.S.; Sarkar, P.; Sarkar, P. Dry Machining: A Step towards Sustainable Machining—Challenges and Future Directions. J. Clean. Prod. 2017, 165, 1557–1571. [Google Scholar] [CrossRef]

- Sharif, M.N.; Pervaiz, S.; Deiab, I. Potential of alternative lubrication strategies for metal cutting processes: A review. Int. J. Adv. Manuf. Technol. 2017, 89, 2447–2479. [Google Scholar] [CrossRef]

- Abbas, A.T.; Gupta, M.K.; Soliman, M.S.; Mia, M.; Pimenov, D.Y. Sustainability assessment associated with surface roughness and power consumption characteristics in nano-fluid mql assisted turning of aisi 1045 steel. Int. J. Adv. Manuf. Technol. 2019, 105, 1311–1327. [Google Scholar] [CrossRef]

- Abdalla, H.S.; Baines, W.; Mcintyre, G.; Slade, C. Development of novel sustainable neat-oil metal working fluids for stainless steel and titanium alloy machining. Part 1. formulation development. Int. J. Adv. Manuf. Technol. 2007, 34, 21–33. [Google Scholar] [CrossRef]

- Uhlmann, E.; Thom, S.; Ehricke, M. Application of Spindle Speed Increaser as Sustainable Solution to Upgrade Machine Tools. Procedia Manuf. 2017, 8, 680–685. [Google Scholar] [CrossRef]

- Du, Y.B.; Cao, H.J.; Liu, F.; Li, C.B.; Chen, X. An integrated method for evaluating the remanufacturability of used machine tool. J. Clean. Prod. 2012, 20, 82–91. [Google Scholar] [CrossRef]

- Younas, M.; Jaffery, S.H.I.; Khan, M.; Khan, M.A.; Ahmad, R.; Mubashar, A.; Ali, L. Multi-objective optimization for sustainable turning Ti6Al4V alloy using grey relational analysis (GRA) based on analytic hierarchy process (AHP). Int. J. Adv. Manuf. Technol. 2019, 105, 1175–1188. [Google Scholar] [CrossRef]

- Xiong, Y.; Wu, J.; Deng, C.; Wang, Y. Machining process parameters optimization for heavy-duty CNC machine tools in sustainable manufacturing. Int. J. Adv. Manuf. Technol. 2013, 18, 1–10. [Google Scholar] [CrossRef]

- Hu, L.; Liu, W.; Xu, K.; Peng, T.; Yang, H.; Tang, R. Turning part design for joint optimisation of machining and transportation energy consumption. J. Clean. Prod. 2019, 232, 67–78. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, Y.; Dong, H.; Zhang, K.; Lv, L.; Zhang, X.; Zheng, C.; Ji, R. Parameters optimization for sustainable machining of ti6al4v using a novel high-speed dry electrical discharge milling. Int. J. Adv. Manuf. Technol. 2017, 90, 2733–2740. [Google Scholar] [CrossRef]

- Camposeco-Negrete, C.; de Dios Calderón-Nájera, J. Sustainable machining as a mean of reducing the environmental impacts related to the energy consumption of the machine tool: A case study of aisi 1045 steel machining. Int. J. Adv. Manuf. Technol. 2019, 102, 27–41. [Google Scholar] [CrossRef]

- Chen, X.; Li, C.; Jin, Y.; Li, L. Optimization of cutting parameters with a sustainable consideration of electrical energy and embodied energy of materials. Int. J. Adv. Manuf. Technol. 2018, 96, 775–788. [Google Scholar] [CrossRef] [Green Version]

- Kaynak, Y. Evaluation of machining performance in cryogenic machining of inconel 718 and comparison with dry and mql machining. Int. J. Adv. Manuf. Technol. 2014, 72, 919–933. [Google Scholar] [CrossRef]

- Rendi, K.; Thirumalai, K.S.; Saood, A.; Dwi, A.N.; Gandjar, K.; Tae, J.K. Experimental and analytical study of ultrasonic elliptical vibration cutting on aisi 1045 for sustainable machining of round-shaped microgroove pattern. Int. J. Adv. Manuf. Technol. 2018, 98, 2031–2055. [Google Scholar]

- Peng, T.; Xu, X. Energy-efficient machining systems: A critical review. Int. J. Adv. Manuf. Technol. 2014, 72, 1389–1406. [Google Scholar] [CrossRef]

- Shojaeipour, S. Sustainable manufacturing process planning. Int. J. Adv. Manuf. Technol. 2015, 78, 1347–1360. [Google Scholar] [CrossRef]

- Tigane, M.; Dahane, M.; Boudhar, M. Multi objective approach for deteriorating jobs scheduling for a sustainable manufacturing system. Int. J. Adv. Manuf. Technol. 2019, 101, 1939–1957. [Google Scholar] [CrossRef]

- Warsi, S.S.; Agha, M.H.; Ahmad, R.; Jaffery, S.H.I.; Khan, M. Sustainable turning using multi-objective optimization: A study of al 6061 t6 at high cutting speeds. Int. J. Adv. Manuf. Technol. 2019, 100, 843–855. [Google Scholar] [CrossRef]

- Jia, S.; Yuan, Q.; Cai, W.; Lv, J.; Hu, L. Establishing prediction models for feeding power and material drilling power to support sustainable machining. Int. J. Adv. Manuf. Technol. 2019, 100, 2243–2253. [Google Scholar] [CrossRef]

- Vijayaraghavan, V.; Castagne, S. Sustainable manufacturing models for mass finishing process. Int. J. Adv. Manuf. Technol. 2016, 86, 49–57. [Google Scholar] [CrossRef]

- Jiang, Z.; Gao, D.; Lu, Y.; Kong, L.; Shang, Z. Electrical energy consumption of cnc machine tools based on empirical modeling. Int. J. Adv. Manuf. Technol. 2019, 100, 2255–2267. [Google Scholar] [CrossRef]

- Shen, N.; Cao, Y.; Li, J.; Zhu, K.; Zhao, C. A practical energy consumption prediction method for CNC machine tools: Cases of its implementation. Int. J. Adv. Manuf. Technol. 2018, 99, 2915–2927. [Google Scholar] [CrossRef]

- Kim, J.; Hwangbo, H. Sensor-based real-time detection in vulcanization control using machine learning and pattern clustering. Sensors 2018, 18, 3123. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Hwangbo, H. Real-time early warning system for sustainable and intelligent plastic film manufacturing. Sustainability 2019, 11, 1490. [Google Scholar] [CrossRef] [Green Version]

- Cheng, J.; Chen, W.; Tao, F.; Lin, C.L. Industrial IoT in 5G environment towards smart manufacturing. J. Ind. Inf. Integr. 2018, 10, 10–19. [Google Scholar] [CrossRef]

- Ren, S.; Zhang, Y.; Liu, Y.; Sakao, T.; Huisingh, D.; Almeida, C.M.V.B. A comprehensive review of big data analytics throughout product lifecycle to support sustainable smart manufacturing: A framework, challenges and future research directions. J. Clean. Prod. 2019, 210, 1343–1365. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Hu, P.; Zhou, H.; Yang, J.; Xie, J.; Jiang, Y.; Hao, Z.; Zhang, C. Toward Intelligent Machine Tool. Intell. Mach. Tool Eng. 2019, 5, 679–690. [Google Scholar]

- Liu, W.; Kong, C.; Niu, Q.; Jiang, J.; Zhou, X. A method of NC machine tools intelligent monitoring system in smart factories. Robot. Comput. Integr. Manuf. 2020, 61, 101842. [Google Scholar] [CrossRef]

- Kim, H.; Jung, W.K.; Choi, I.G.; Ahn, S.H. A Low-Cost Vision-Based Monitoring of Computer Numerical Control (CNC) Machine Tools for Small and Medium-Sized Enterprises (SMEs). Sensors 2019, 19, 4506. [Google Scholar] [CrossRef] [Green Version]

- Böhl, S.; Weikert, S.; Wegener, K. Enhancing Signal Quality of Capacitive Displacement Measurements in Machine Tool Environments. J. Manuf. Mater. Process. 2019, 3, 76–99. [Google Scholar]

- Lee, W.J.; Mendis, G.P.; Sutherland, J.W. Development of an Intelligent Tool Condition Monitoring System to Identify Manufacturing Tradeoffs and Optimal Machining Conditions. Procedia Manuf. 2019, 33, 256–263. [Google Scholar] [CrossRef]

- Chang, C.W.; Lee, H.W.; Liu, C.H. A review of artificial intelligence algorithms used for smart machine tools. Inventions 2018, 3, 41. [Google Scholar] [CrossRef] [Green Version]

- Yao, Y.; Liu, M.; Du, J.; Zhou, L. Design of a machine tool control system for function reconfiguration and reuse in network environment. Robot. Comput. Integr. Manuf. 2019, 56, 117–126. [Google Scholar] [CrossRef]

- Chen, K.S.; Yu, C.M.; Hsu, T.H.; Cai, S.R.; Chiou, K.C. A Model for Evaluating the Performance of the Bearing Manufacturing Process. Appl. Sci. 2019, 9, 3105. [Google Scholar] [CrossRef] [Green Version]

- Ji, Q.; Li, C.; Zhu, D.; Jin, Y.; Lv, Y.; He, J. Structural design optimization of moving component in CNC machine tool for energy saving. J. Clean. Prod. 2020, 246, 118976. [Google Scholar] [CrossRef]

- Brecher, C.; Utsch, P.; Klar, R.; Wenzel, C. Compact design for high precision machine tools. Int. J. Mach. Tools Manuf. 2010, 50, 328–334. [Google Scholar] [CrossRef]

- Ashworth, S.; Fairclough, J.P.A.; Takikawa, Y.; Scaife, R.; Ghadbeigi, H.; Kerrigan, K.; Meredith, J. Effects of machine stiffness and cutting tool design on the surface quality and flexural strength of edge trimmed carbon fibre reinforced polymers. Compos. Part A Appl. Sci. Manuf. 2019, 119, 88–100. [Google Scholar] [CrossRef]

| Dimension | Criteria for Machine Tools | Corresponding Influence Factors | Process Level |

|---|---|---|---|

| 1. Technology | Precision | Positioning accuracy | Cutting force |

| Flexibility | Tool storage capacity | Surface roughness | |

| CNC (Computer Numerical Control) type | |||

| Part complexity | |||

| Number of pallets | |||

| 2. Environment | Power/Energy | Idle power | Cutting power |

| Total rated power | |||

| Part program energy | |||

| Emissions control | Mist collector | Cutting fluid consumption Air quality | |

| Enclosure type | |||

| Material | Material selection | ||

| 3. Economy | Productivity | Spindle maximum speed | Tool life |

| Tool-to-tool time | |||

| Rapid feed rate | |||

| Cost | Initial cost | Machining time | |

| Maintenance cost | |||

| Operational cost | |||

| 4. Society | Safety | Safety | |

| User-friendliness | Easiness of programming | User-friendliness | |

| Support in manual operations | |||

| Ergonomics | Ergonomics |

| Environment | Economy | Society | Integrated Method | ||

|---|---|---|---|---|---|

| Specific strategy | Energy | Life cycle [10,64,65,66] | Use cost [72] | ||

| Design stage [37,44,67,68,69,70] | |||||

| Complete machine [12,23,71] | |||||

| Use stage [4,13,72,73,74,75,76,77,78] | |||||

| Partial components [45,79,80,81,82] | |||||

| Resource | [13,83] | ||||

| Carbon emission | [15,76] | ||||

| Review | Energy-saving | [11,42] | |||

| Integrated strategy | [5,14,78,84,85,86,87] | Life cycle cost [63] | [32,33,57] | ||

| Interaction between environment and economy | Energy-and cost-effectiveness | [62,88] | |||

| Sustainability for Environment | Sustainability for Economy | Sustainability for Society | |

|---|---|---|---|

| Production | Raw material reducing | Material cost reducing | - |

| Energy efficiency increasing | process cost reducing | ||

| Use | Energy efficiency increasing | Energy cost reducing | - |

| Productivity increasing | |||

| End-of-life | Recycle, waste reducing | Disposal cost reducing | - |

| Sustainability for Environment | Sustainability for Economy | Sustainability for Society | |

|---|---|---|---|

| Production | Material | Manufacturing cost | - |

| Carbon emission | Fair wage | ||

| Variety | |||

| Supply Chain | |||

| Manufacture | |||

| Use | Maintenance | Maintenance cost | Operator safety and health |

| Repairability | |||

| Upgrades | |||

| Functionality | |||

| Services | |||

| End-of-life | Recycle, reuse, remanufacture, updated | Recycle, reuse, remanufacture, updated | Operator safety and health |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, C.; Huang, S. The Analysis of Key Technologies for Sustainable Machine Tools Design. Appl. Sci. 2020, 10, 731. https://doi.org/10.3390/app10030731

Feng C, Huang S. The Analysis of Key Technologies for Sustainable Machine Tools Design. Applied Sciences. 2020; 10(3):731. https://doi.org/10.3390/app10030731

Chicago/Turabian StyleFeng, Chunhua, and Shi Huang. 2020. "The Analysis of Key Technologies for Sustainable Machine Tools Design" Applied Sciences 10, no. 3: 731. https://doi.org/10.3390/app10030731

APA StyleFeng, C., & Huang, S. (2020). The Analysis of Key Technologies for Sustainable Machine Tools Design. Applied Sciences, 10(3), 731. https://doi.org/10.3390/app10030731