Featured Application

This review aims to investigate the relevant literature regarding integrations of Building Information Modeling technology and the Last Planner® System in the construction execution phase. It is supposed to help scientists and practitioners to overview the state-of-the-art in terms of synergies between both approaches and devises a conceptual model for integration based on the review’s findings.

Abstract

Many researchers have stated that lean and building information modeling (BIM) have positive synergies. This integrative literature review aims at exploring this body of knowledge within the scope of combinations of BIM and the Last Planner® System, as an important Lean construction method, in the phase of construction execution. The research motivation is to find out whether a comprehensive understanding of how to take advantage of these synergies exists. Eventually, the question arises of how to condense this understanding—if existing—into a robust conceptual model for integration. As a theoretical backbone, we will make use of the original BIM-Lean interaction matrix. The hypothesis is that new BIM functionalities have been evolved since the first formulation of this interaction matrix almost 10 years ago. These new BIM functionalities cause new interactions with existing lean principles. We will focus on interactions that refer directly or indirectly to production planning and control and use them to find the most relevant literature for this review. Within the content analysis, as a part of this review, we focus on existing conceptual models and frameworks for integration of BIM and the Last Planner® System and reveal their shortcomings. Eventually, we will propose a new conceptual model.

1. Introduction

1.1. Starting Point

Except for a few scientific publications in the field of Lean Construction and digitization, both movements seem to be treated independently in the scientific context [1]. In recent years, the architectural, engineering, and construction (AEC) industry has been experiencing an ever-increasing wave of digitization. This is visible in this sector thanks to the adoption of building information modeling (BIM) [2]. BIM was originally conceived as the last generation of object-oriented CAD systems in which intelligent objects collectively represent the design of a building, coexisting in a single virtual structure. Over time, connotation has evolved with the term and is now also used to represent digital innovation in the construction sector [3].

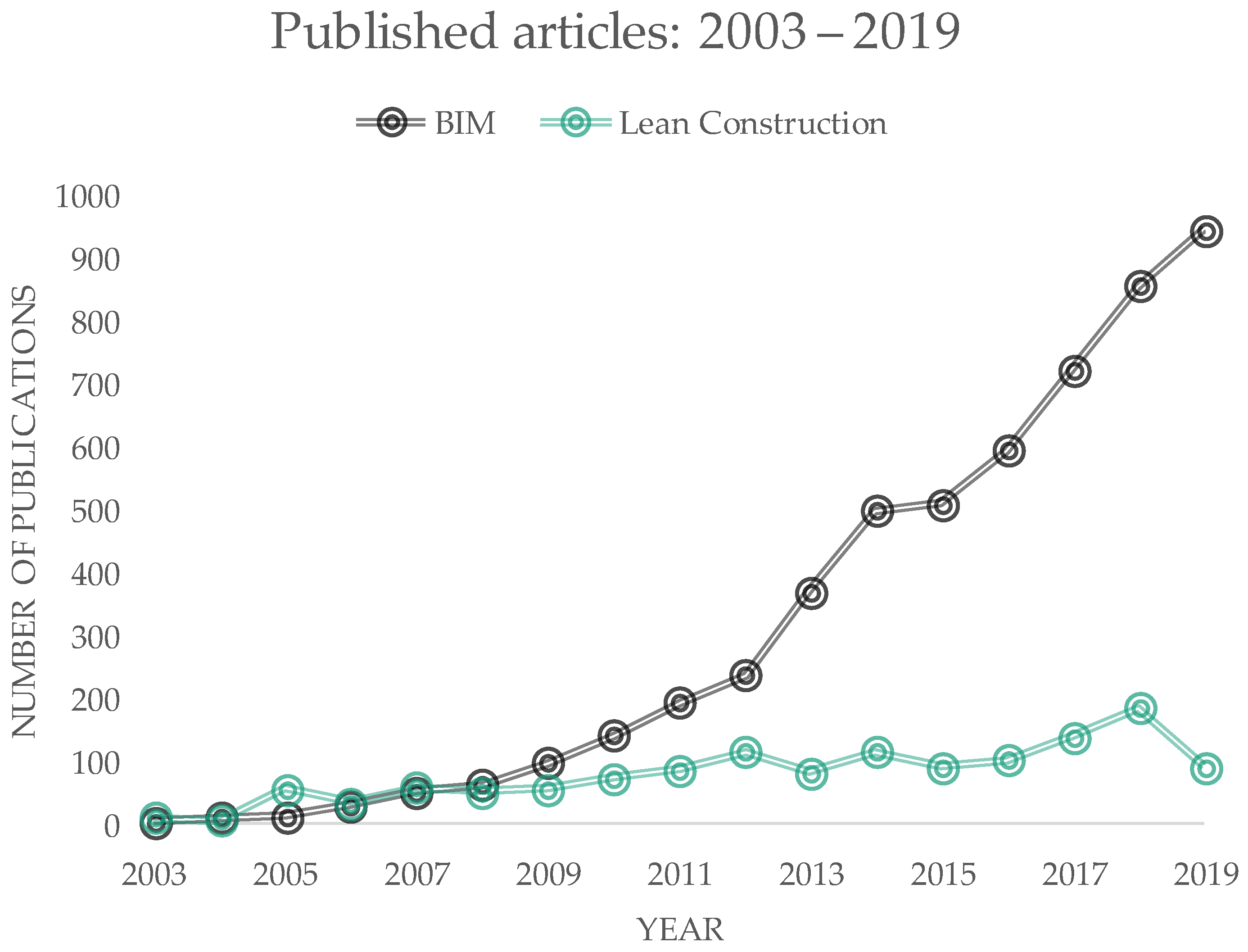

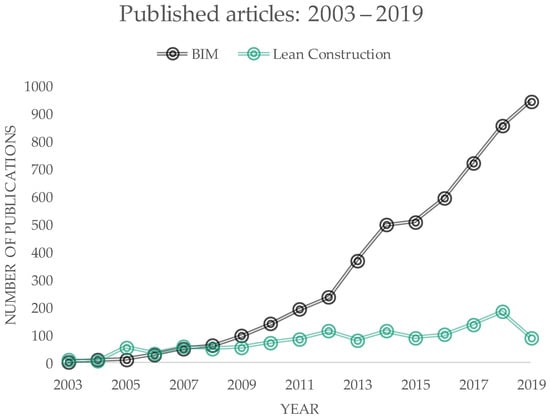

At the same time, the movement of lean construction management (LCM) has established itself on the level of construction process management as an adaptation of lean production from the automotive industry and is gaining more and more influence in today’s construction management practice [4]. This resulted among others in new methods for design and/or site management such e.g., the Last Planner® System (LPS) but also in holistic project management and delivery approaches, such as e.g., integrated project delivery (IPD) concepts [5]. The principles of lean philosophy are primarily aimed at maximizing value for the customer by eliminating non-value-adding activities referred to as waste [6,7]. In lean jargon, basically, everything that is not needed is considered as being waste [8]. BIM can help to define what is needed and thus help to identify and remove waste, since it can precisely—digitally—describe what, how much and in which quality is needed on-site. The latter refers already to an often-cited positive interaction of BIM and Lean [9,10,11]. These positive interactions—or in other words, synergies—are receiving more and more attention in both academia and practice [11]. This tendency of the growing importance of both movements can also be seen in the increasing number of scientific studies over the last 16 years in both fields BIM and Lean Construction as depicted in Figure 1.

Figure 1.

Building information modeling (BIM)/Lean construction papers published: 2003–2019; (data retrieved from the Scopus Database; search terms TITLE-ABS-KEY ((“building information modeling” or “building information modelling”))” and (“lean construction”))).

The indicator of scientific publications clearly shows the proactive role of the AEC-industry in the adoption of both BIM and LCM [12]. It can be also seen that especially the number of BIM publications is growing steadily and rapidly. On the one hand, this is due to the general trend towards digitization in our society today. On the other hand, it is also and particularly due to the pressure triggered by legal and social requirements to increase productivity and efficiency. This is why the discrepancy with other industry sectors is still very large, but the construction industry, however, accounts for a very important share of the economic performance of industrialized countries [12,13]. BIM is seen here as a key technology [14]. This is also made clear by the fact that in many countries BIM will be mandatory in the near future for the planning of public-sector projects [15].

In addition to the growing popularity of both approaches, it is important to emphasize that BIM and Lean are in principle independent of each other and could be used concurrently [16]. Nevertheless, the scientific community and also practitioners are certain that (new) BIM functionalities can generate numerous interaction effects with the existing principles of the lean philosophy. In most cases, these can be considered as positive synergies and thus add value to the construction industry [10].

Considering this potential added value of an integrated BIM-lean adaption, interest in combining both approaches has arisen in the scientific world in recent years. The resulting synergies have been brought to the surface, both through scientific-theoretical treatises [10,17,18,19] and by proposing BIM-Lean supporting IT systems [20,21,22,23].

On the theoretical side two works deserve special mention in this context.: the original work of Sacks et al. [10], who describe the combination of BIM functionalities and Lean principles in an interaction matrix, and its update from Oskouie et al. [9], which together form the basis of numerous scientific publications in the tension between BIM and Lean, we will make use of the original interaction matrix as a guideline for this literature review. More specifically, it will serve as an a-priori filter for the identification of relevant literature in the scoped area of BIM-LPS combinations in the construction phase. It will also help to analyze only papers dealing with on-site production that combine both approaches. The rationale for limiting this review to the Last Planner® System rather than considering lean construction, in general, is explained in more detail in Section 1.2.

On the one hand, this review aims at finding out to what extent the interactions that were attributed as “cannot be considered mature technology” in 2010, when the original interaction matrix was first published, have evolved over the last decade. In addition, it will be also analyzed where still existing gaps in terms of technology maturity could be closed with new BIM-Lean IT systems to be developed in the future.

On the other hand, we claim that within the last 10 years the BIM functionalities have expanded and that the possibilities of using the information available through BIM are no longer reserved for IT specialists only, but have also opened up for architects and engineers through the introduction of e.g., visual programming languages (VPL). Consequently, these new functionalities also result in new interactions with existing lean principles, which are formulated in this study and serve as a “lens” for this literature review, too.

In summary, and as a starting point for this literature review, it can be said that numerous studies have been published in the field of BIM–Lean interaction. The present inadequacy, however, is that there is much literature on synergies but—to our best knowledge—no summarizing review for the specific case of BIM-LPS integration in the phase of construction execution.

This study inserts in this niche and aims at disclosing the relevant body of knowledge within this scope. This goal is pursued by means of the research method “integrative review”, which will be guided by the original BIM–Lean interaction matrix as theoretical backing.

The body of this review article is organized as follows. Section 2 explains the applied research strategy for conducting this review. Section 3 provides the details of the followed review protocol allowing for replication of the procedure. Section 4 contains the actual results of the review in terms of a description of the final literature sample, a qualitative content analysis, and implications. Section 5 provides a final discussion on the findings and their potential meaning for practice. Section 6 concludes this study.

1.2. Research Question and Scope

This integrative literature review deals exclusively with the integration of the Last Planner® System and BIM in the construction execution phase.

This review, therefore, differs from other reviews about BIM and Lean [12,24] in its integrative nature, which resulted in the inference of a new conceptual model for integration and its focus on the Last Planner® System instead of dealing with the field of lean construction in general. The scope is limited to the execution phase, because Lean has started in the construction phase and is now moving towards lean design management [25], while BIM is widely accepted as a design method, hence first standards and norms exist for this phase [26]. However, there are still few guidelines for the beneficial use of BIM in construction execution processes, with a few exceptions like e.g., studies dealing with the design of BIM models for the sake of constructability [27,28], or proposals for so-called BIM-stations [29,30]. The motivation is, therefore, to make use of the complementary “maturity levels” within the two project phases and to combine BIM and lean—using the concrete example of the LPS—during construction execution.

This raises the following research questions, which will be addressed with the help of this integrative literature review: What is the current situation of conceptual models for the integration of BIM and LPS in the construction execution phase? Are there any models or frameworks that allow BIM data to be brought systematically, continuously and software vendor-neutral to the site enabling the application of LPS? If not, how do available models have to be adapted to achieve this goal? For this purpose, short introductions to BIM, LPS as well as BIM–lean interactions identified in the literature are given in the following sections.

1.3. Building Information Modeling

Building Information Modeling is a process for creating and managing the information of a building, infrastructure or facility through its life cycle [31]. One of the fundamental results of this process is the Building Information Model, the digital representation of all relevant aspects of the built edifice. This model is developed on the basis of the information that is inserted and updated collaboratively during the course of the project. This definition, given by the British NBS [32], highlights the three fundamental concepts that characterize BIM:

- BIM is a digital model, functioning as a container of data and information, which must be read, enriched, modified throughout the life cycle of a building, infrastructure or facility

- BIM is a process, or—in other words—a network of activities to manage the information contained within the models in order to use them beneficially

- BIM imposes collaboration, i.e., so that the information models are always up to date and usable, all operators must collaborate at appropriate times during the process and according to certain rules

BIM differs from the traditional CAD approach in that there is only one single place of editing—the BIM model itself—and no longer all plan deductions such as views, sections, and floor plans have to be adapted individually when changes are requested [33]. Azhar and Nadeem [33] point also out that BIM models are composed of intelligent and semantically structured objects such as walls or slabs whilst CAD drawings only represent geometry by means of interconnected lines or arcs.

Well-known benefits, such as automated clash detection, code checking, visualization by means of the help of augmented/virtual reality technology and enhanced collaboration among stakeholders becoming more and more exploited in the regular business of many practitioners [34]. These positive effects of BIM technologies have overcome the status of constituting exclusively research topics. However, since BIM technology is evolving and access to BIM data is becoming increasingly convenient—even for non-IT specialists—also new research potential arises continuously.

1.4. Lean Construction Management and the Last Planner® System

The term lean construction management (LCM) is derived from lean principles being applied in the production industry and refers to the original concepts of the Toyota Production System (TPS). One of the core elements of lean management, in general, is the aim for maximization of value from the customer’s perspective by eliminating waste. Waste in the construction industry can e.g., be referred to as rework or waiting time [35].

The Last Planner® System has been developed for the construction industry as a production planning and controlling system. It aims at both increasing schedule reliability and smoothening flow of work [36], and is been considered as one of the most import lean methods in construction execution [10]. The LPS strives for the achievement of its purposes through collaboration, transparency, continuous improvement as well as reliable commitments from the responsible persons for actual work completion, the Last Planners [37].

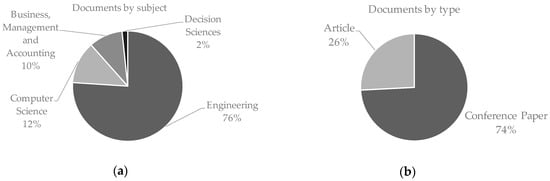

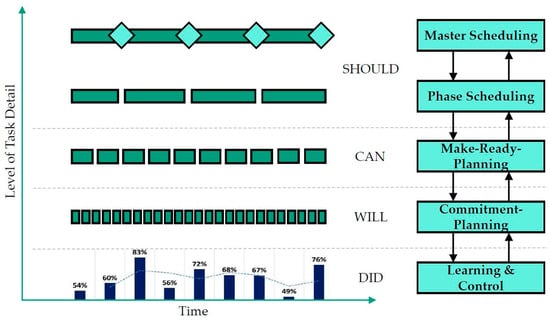

According to Ballard [36], every possibly occurring task, needed for the completion of a construction project, can be technically categorized into four groups during its execution phase: (1) SHOULD-tasks include in principal all tasks needed for achieving global milestones defined by an existing master schedule or client’s requirements. (2) CAN-tasks for a preliminarily defined project look-ahead window consist out of SHOULD-tasks, which are free of constraints and thus ready for immediate execution. (3) WILL-tasks are considered as CAN-tasks whose execution by a defined due date has been assured by consensus of all involved and explicitly by the responsible last planner. (4) DID-tasks in turn, are all accordingly completed WILL-tasks of the prevenient LPS-cycle. The latter ratio in LPS applications can be expressed as a percent planned complete value (PPC).

The SHOULD-CAN-WILL-DID (SCWD) logic is supposed to be applied in five consecutive steps which are characterized by corresponding plan phases with increasing level of detail: (1) master scheduling, (2) phase scheduling, (3) make-ready-planning, (4) commitment-planning and (5) learning and control [38]. This procedure is shown in Figure 2.

Figure 2.

Last Planner® System (LPS), adapted from Hamzeh and Bergstrom (2010).

The least mentioned step learning and control accounts for the analysis of completed tasks with respect to their commitment. Crucial at this point is a profound analysis of reasons for non-completion (RNC) of tasks that have not been completed as committed in terms of both quality and due date in order to avoid those mistakes to re-occur, as part of a continuous improvement process (CIP) [39].

Of equal importance is the social process going along with the implementation and application of the LPS in construction projects. These interpersonal matters are especially characterized by open and transparent discussions between involved trades represented by their last planners, increasing trust among them as well as collectively emerging learning cycle effects. The latter can be seen as an inherent consequence of the analysis of RNC [40,41].

According to Ballard [36], the main advantages of the LPS include the following points:

- Stabilization of project-based production systems

- Making control proactive

- Reduction of waiting times and project durations

- Decentralization of decision-making processes

- Early communication of insufficient project status

As with many lean-based process changes, the necessary commitment of all those involved and thus resistance to change can be stated as disadvantages. At the process level, it should be noted that the LPS does not offer any functionalities with regard to cost control and is therefore not sufficient as the sole method for holistic project management with regard to the optimization of the three target variables quality, time and budget.

1.5. BIM—Lean interaction matrix

As indicated above, we want to make use of the BIM–Lean interaction matrix by Sacks et al. [10] as a filter to find the most relevant literature within the scope of this review. This interaction matrix contains synergies between the Lean philosophy and the BIM approach as known as of the year 2010. Synergies in this context are referred to as interaction effects that could result when certain Lean principles are combined with BIM functionalities. Sacks et al. [10] elaborated originally a total of 56 interactions.

To have an even finer a-priori filter, we reduced this original interaction matrix to those Lean principles and BIM functionalities that refer directly or indirectly to production planning and control and the Last Planner® system. Additionally, and according to our hypothesis of newly appeared BIM functionalities over the last decade, new interactions with Lean principles have evolved too, which we also added to the reduced interaction matrix. It is true that the original interaction matrix has been already extended by Oskouie et al. [9]. However, most of the extensions mentioned deal with BIM functionalities for the operation and maintenance phase which is out of the scope of this paper. Nonetheless, we will consider the BIM functionalities mentioned in that work, which are dealing with production planning and control and have not been covered by the original interaction matrix yet: “Facilitating real-time construction tracking and reporting” [22]. All these elements together result in a specialized BIM-LPS interaction matrix which is given Table 1.

Table 1.

New BIM-LPS interaction matrix.

The resulting interactions of the new BIM-LPS interaction matrix are given in Appendix A.

We will use this list of interactions for eliminating those papers from the literature sample that should not be part of the final content analysis. More in detail, the topics of the here listed interactions will be condensed and abstracted to a high-level. This allows for deciding which of the found sub-clusters in the second literature screening round should not be considered in the qualitative content analysis. Furthermore, we are particularly interested in how the interactions that were considered as being negative back then (e.g., called “cannot be considered mature technology”) have developed over time.

2. Research Strategy

We have decided to conduct an integrative literature review on the integration of BIM and the Last Planner® System in construction execution. The rationale for this decision is that we would like to cover all the relevant literature in this field involving both quantitative and qualitative studies, which is the essence of an “integrative” review [42]. However, this review remains systematic in the sense that it follows a strict review protocol allowing for replication of the chosen procedure in line with the specifications for performing systematic reviews by Kitchenham [43].

In addition to that, integrative literature reviews analyze, criticize and integrate the considered literature sample in a way that new models or frameworks on the topic can be devised [44]. We will make use of this technique to formulate a new conceptual model for the integration of BIM and the Last Planner® System as a basis for improved production management systems in construction.

3. Review Protocol and Implementation

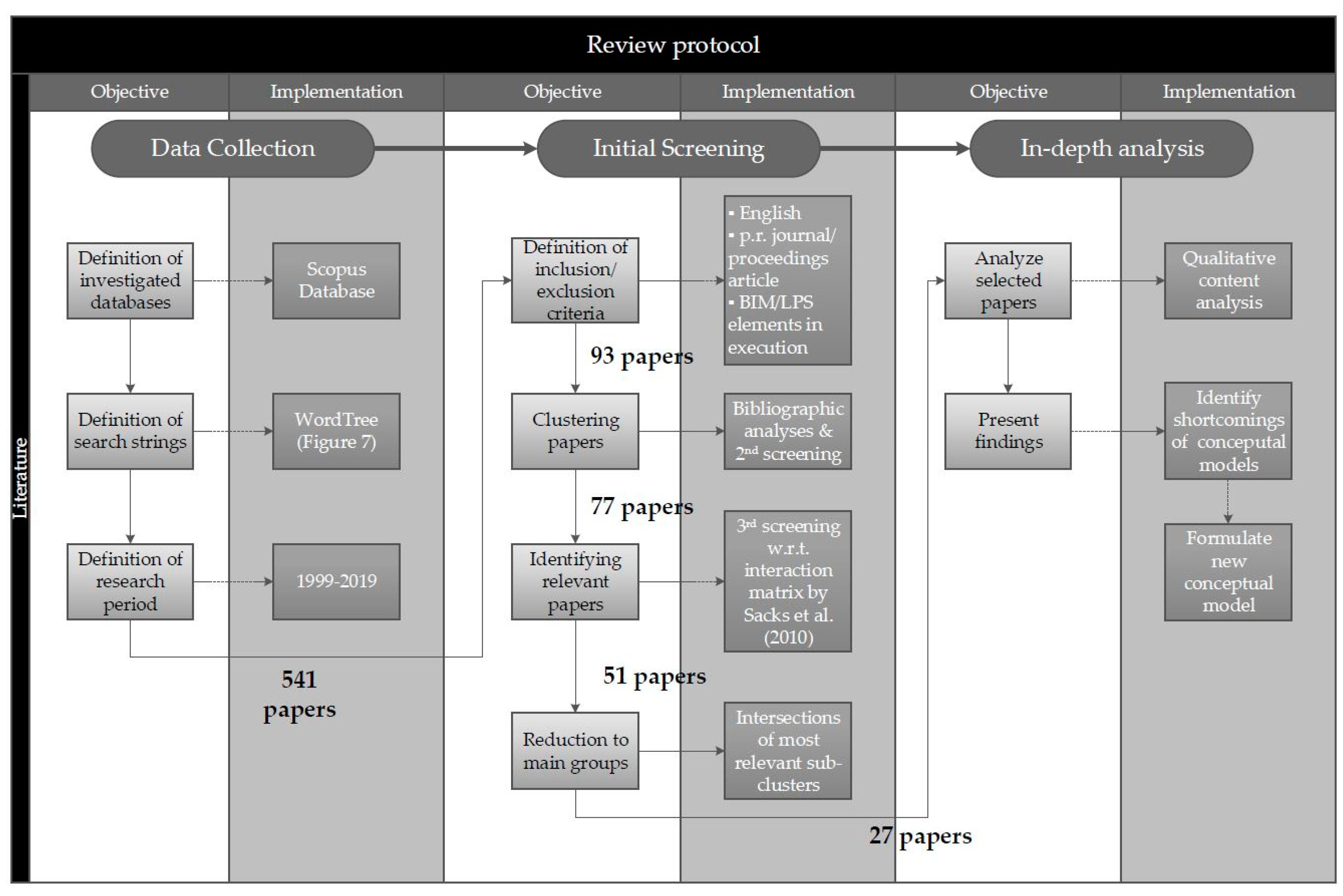

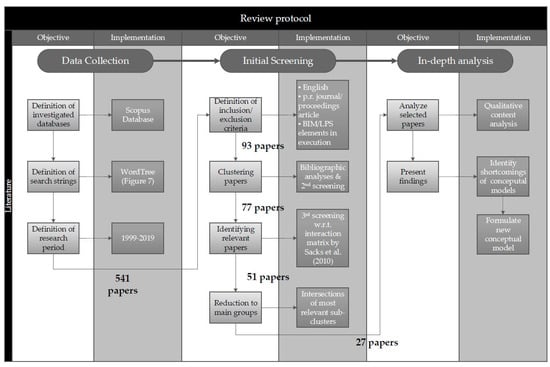

This review is divided into the parts of (i) data collection; (ii) initial screening and (iii) an in-depth analysis which is mainly characterized by a qualitative content analysis of the final sample literature. The review protocol is shown in Figure 3 and described in the following subsections.

Figure 3.

Review protocol.

3.1. Data collection

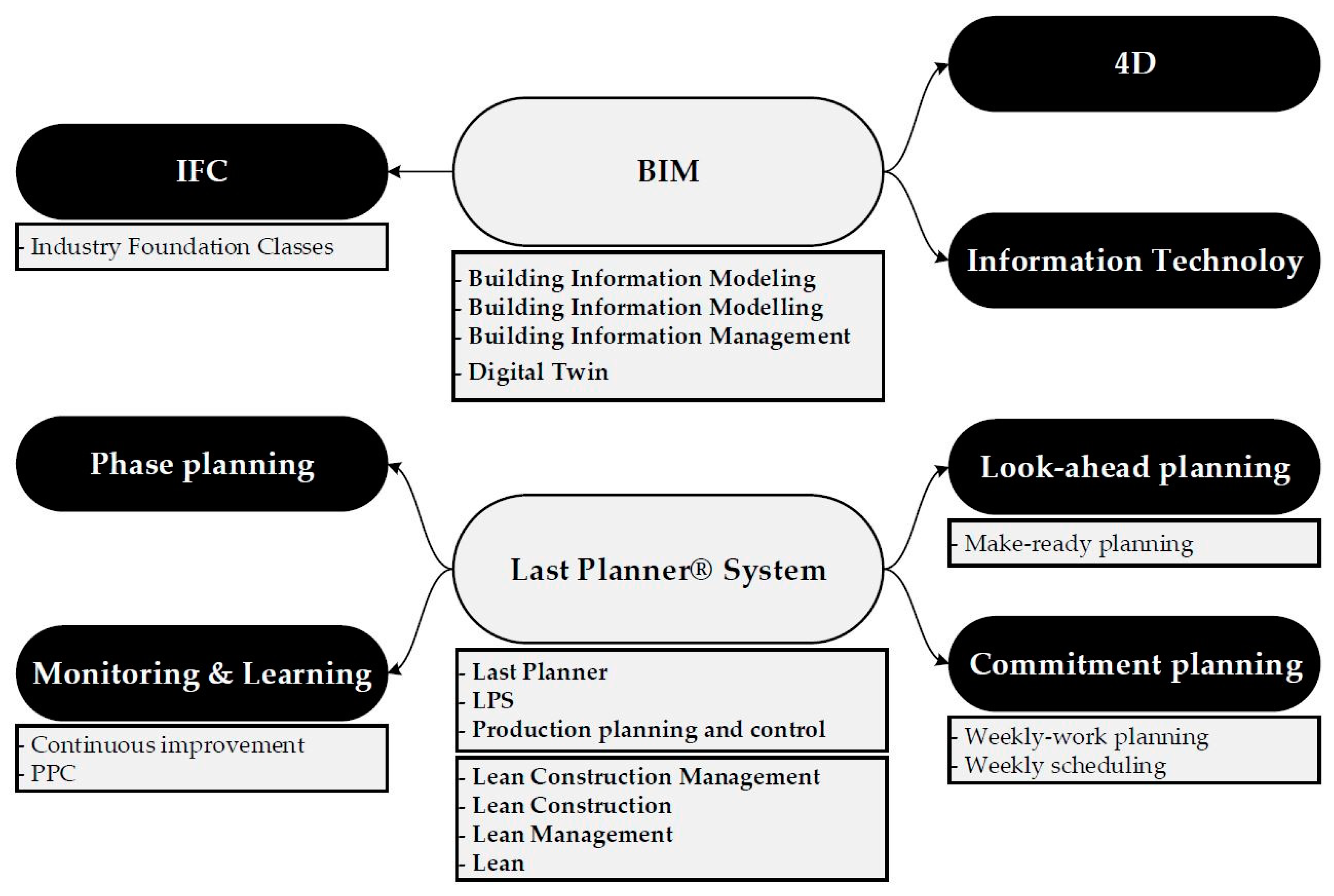

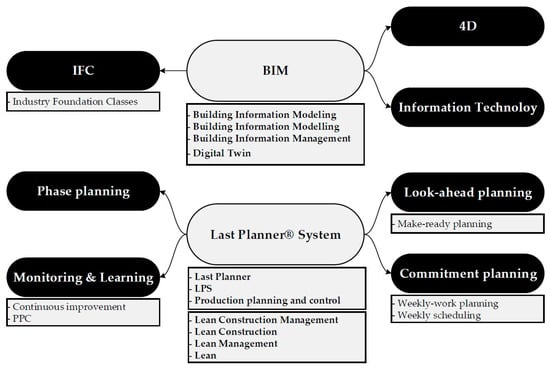

In line with Saunders et al. [45], we considered as reliable sources only peer-reviewed journal articles and conference proceedings for this literature review. We chose the Scopus database as a search engine and used as search string any combinations of the terms “BIM” and “Last Planner System”, their synonyms, as well as possible subsystems such as e.g., “Look-ahead planning” in the case of the LPS. These different terms are shown in the word tree in Figure 4, whilst Table 2 contains the resulting and full search string that has been entered into the database. Only title and keywords were considered in the search engine, since the search string contains many general terms and would output too many hits if the abstract field was also enabled. The resulting sample size would not be manageable with the procedure according to this review protocol. The data collection part comprises all entries in the research period from 1999 to 2019 in the Scopus database that were available until October 2019, when the database search was performed. The database search was performed by the first author of this review article. This first step of data collection resulted in a total of 541 papers.

Figure 4.

Search terms word tree.

Table 2.

Search string.

3.2. Initial Screening

3.2.1. Inclusion/Exclusion Criteria

Within the initial screening phase of 541 papers, which resulted from data collection, we first defined several inclusion and exclusion criteria to reduce the sample size and to narrow the considered literature down to the focus area of joint BIM-LPS applications in execution. The criteria for this purpose were defined as (i) written in English; (ii) peer-reviewed journal/conference papers; (iii); related to the phase of construction execution; (iv) the studies have to deal with at least partial elements of BIM and the LPS, such as e.g., look-ahead planning in the case of LPS (Table 3). The latter has been verified by reading the title and abstract (where necessary) of the papers within the initial sample. Applying these criteria reduced the sample size to 93 papers.

Table 3.

Inclusion and exclusion criteria.

3.2.2. Bibliometric Analyses and Paper Clustering

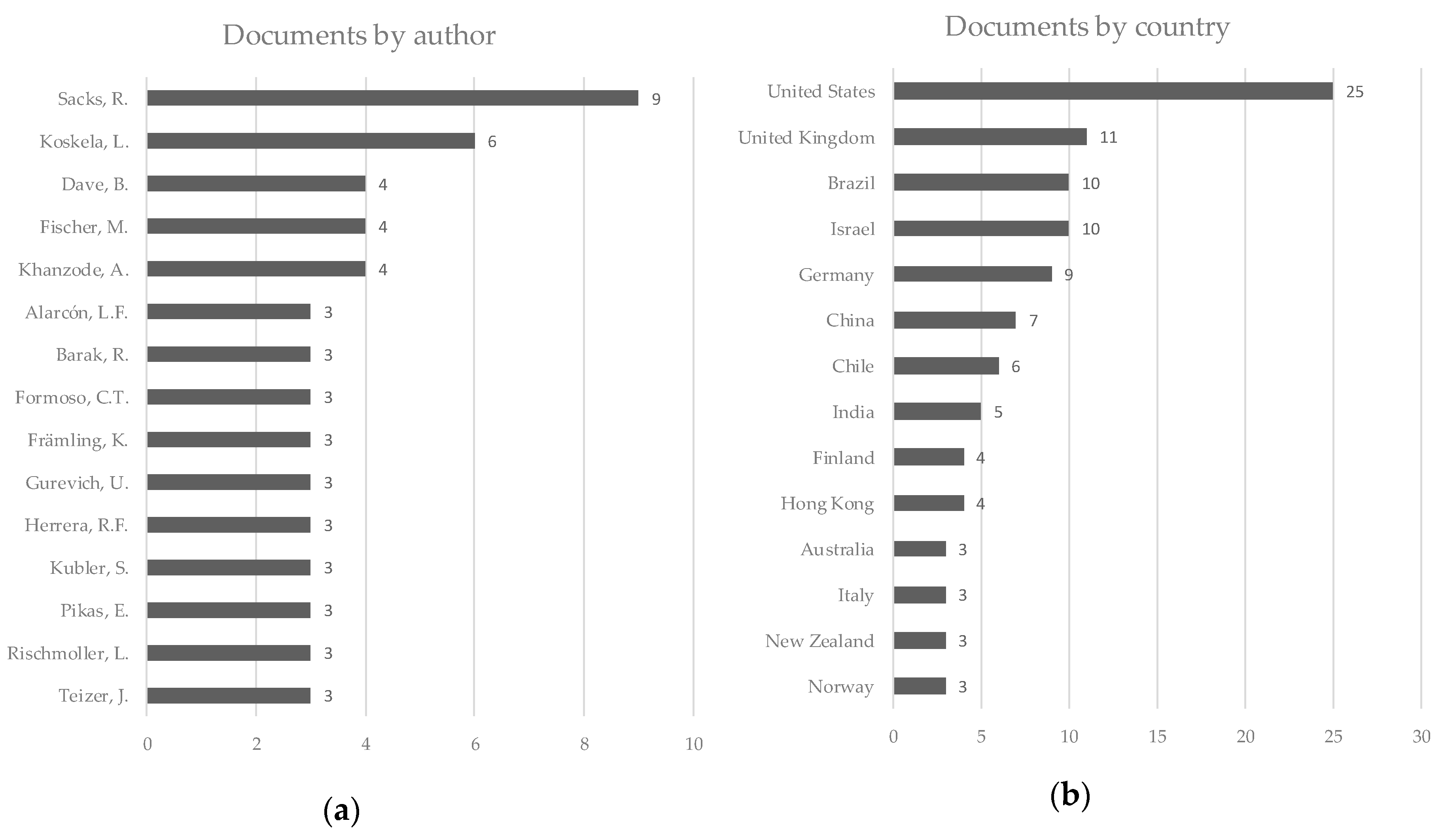

Bibliometric analyses of these remaining 93 papers comprise at this stage statistics about

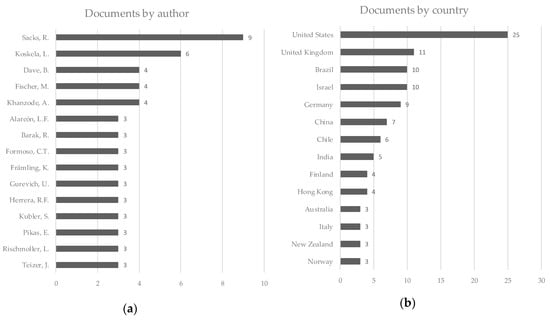

The bibliometric analysis shows in Figure 5b that most of the relevant documents were published by American researchers (25). Also, the United Kingdom (11), Brazil (10), Israel (10) and Germany (9) appear to be very active in the field of joint BIM-LPS applications.

Figure 5a presents the document distribution by authors. Here, Rafael Sacks is the author of the most publications. This underlines his significance in this field of research, who is already playing an important role in this review as the first author of the original BIM–Lean interaction matrix.

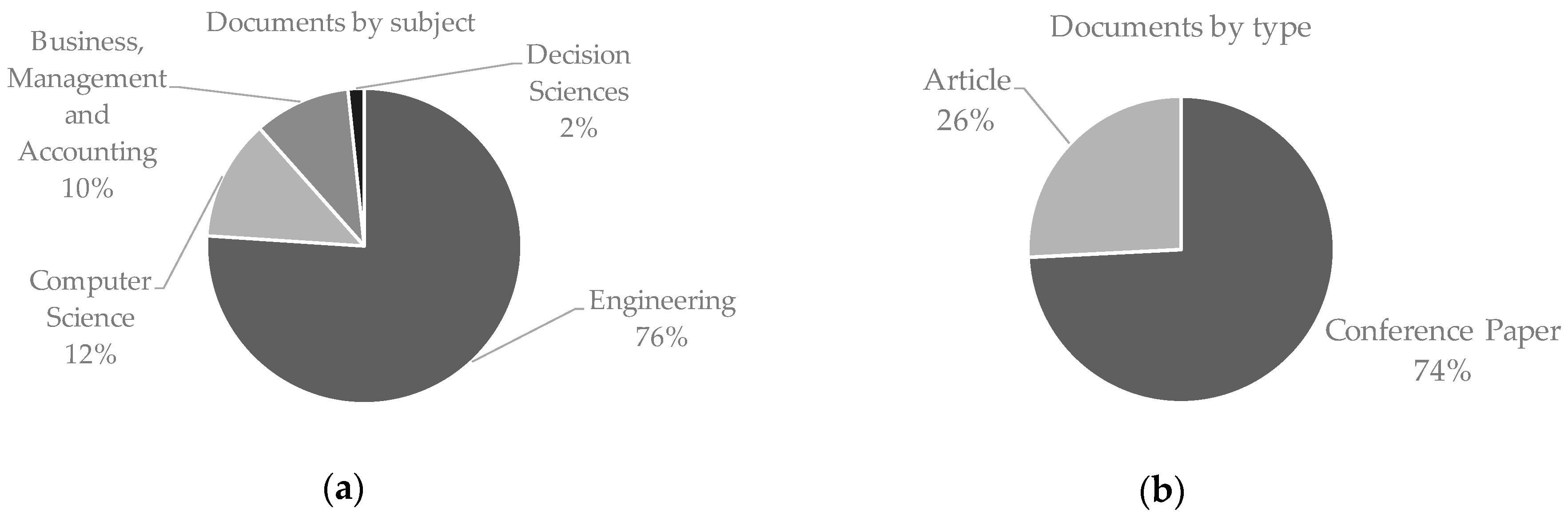

On the other hand, Figure 6 shows the document distribution by subject (a) and type (b). Especially the type distribution is noticeable as it reveals that the majority of publications are presented at research conferences. This could be an indication that many observations and considerations in this research area have not yet been consolidated and that, accordingly, there are not yet enough reliable findings for extensive publication in journals.

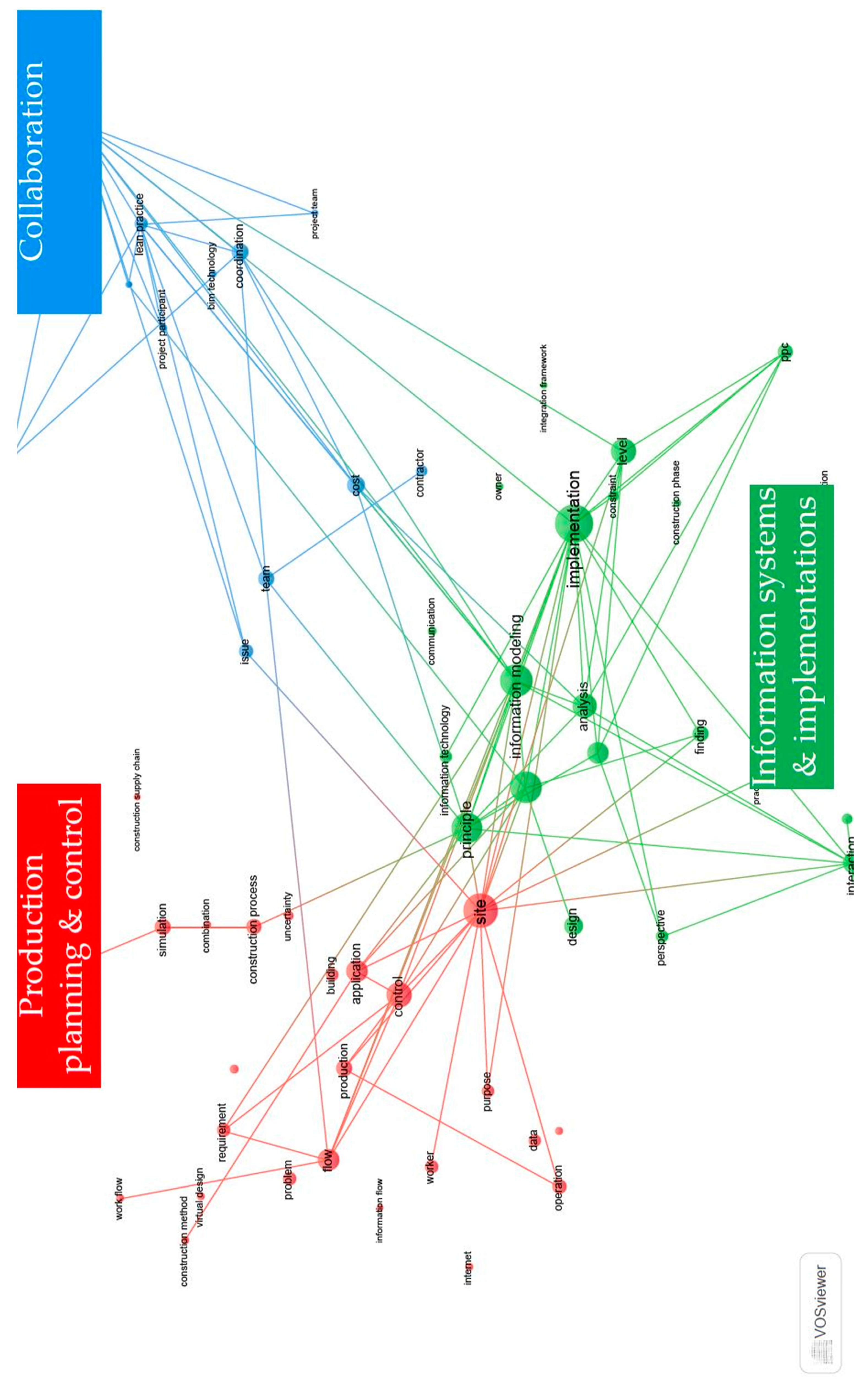

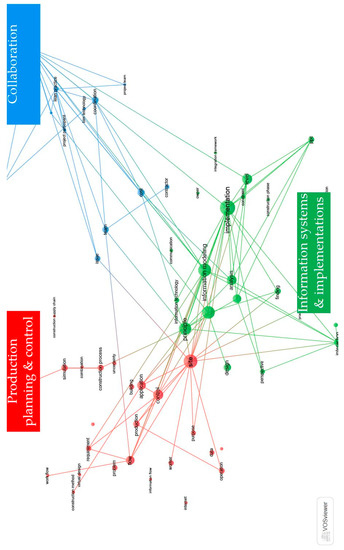

In addition to that, science mapping visualizations were conducted with VOSViewer software (Figure 7). VOSViewer is a freely usable software system based on text-mining algorithms and network clustering techniques which has been developed by van Eck and Waltman [46]. It allows for distance-based cluster visualization of bibliometric networks [47], where the size of the nodes in our settings renders absolute occurrences of analyzed terms in title and abstract fields of the literature sample. The distance between the nodes, on the other hand, visualizes how much related to each other the terms are, meaning how often they occur in the same paper. The clustering in different colors is done automatically by the software. However, the user can decide how many clusters the system should generate and by doing so, fine-tune clustering results. The detailed settings that we chose are summarized in Table 4.

Figure 7.

Science mapping using VOSViewer.

Table 4.

VOSViewer settings and found clusters.

The rationale for this clustering approach was to identify the most relevant macro topics that BIM-LPS co-applications in scientific studies deal with. The results of the cluster visualization are shown in Figure 7.

Figure 7 shows the most occurring terms in the considered literature sample of 93 papers, which have been grouped into three different clusters by the VOSViewer clustering algorithm:

- The red cluster contains characteristic terms such as e.g., site, construction process, production, control, operation, worker, workflow, so that we grouped these terms to the cluster of production planning and control.

- The green cluster contains characteristic terms such as e.g., information modeling, information technology, implementation, analysis, communication, so that we grouped these terms to the cluster of information systems and implementations.

- The blue cluster contains characteristic terms such as e.g., coordination, team, project participant, project team, so that we grouped these terms into the cluster of collaboration.

These found clusters are also indicated in Table 4 and represent the macro topics of the considered literature sample. Furthermore, the visual science mapping approach with VOSViewer software indicates also that the majority of the papers dealing with IT-systems and digitization advancements in construction (green cluster) are more often concerned with supporting production planning and control (red cluster) rather than supporting collaboration among the persons on site (blue cluster). This is evident in Figure 7 by the spatial proximity between the red and green cluster, while the blue cluster is more distant.

At this stage of the review procedure and following the review protocol (Figure 3), a second round of screening was conducted. This time also the main text body of the papers was considered where necessary. The aim was to filter out papers, that could not be grouped into one of the three identified main topics (clusters), since they were considered as dealing with less popular topics. This further reduction of the literature sample resulted in a total of 77 papers. We defined a total of 9 sub-clusters for these 77 papers based on their content as another result of the second literature screening round. These sub-clusters are presented in Table 5.

Table 5.

Sub-clusters after second screening.

3.2.3. Identifying Relevant Papers for Content Analysis

The remaining 77 papers were considered for identifying the really relevant papers for the content analysis within the scope of this review. At this point, the reduced BIM-LPS interaction matrix comes back into play for helping to define which of the sub-clusters are relevant for this review. Since the interactions of the BIM-LPS interaction matrix are mainly dealing with arguments regarding production planning and control supported by BIM, it has been decided to take over the sub-clusters of “BIM–lean interactions” and “Production” to the next step of detailed qualitative content analysis. In addition to that, we took also the cluster “4D simulation” into consideration since it helps practitioners to test different production strategies by means of visualization in the BIM model. For this reason, it is also in line with the introduced BIM-LPS interaction matrix filter. Lastly, we also considered the sub-cluster of “conceptual models and frameworks” within the next round to analyze the foundations in terms of theory in the area of BIM-LPS co-applications.

All the papers that are not part of one of these sub-clusters were removed from the literature sample which further reduced the sample size to 51 papers.

3.3. Final Sample Overview

The remaining sample contains 51 papers being published from 2009 to 2019. This sample is listed in Table 6.

Table 6.

Articles included in the content analysis.

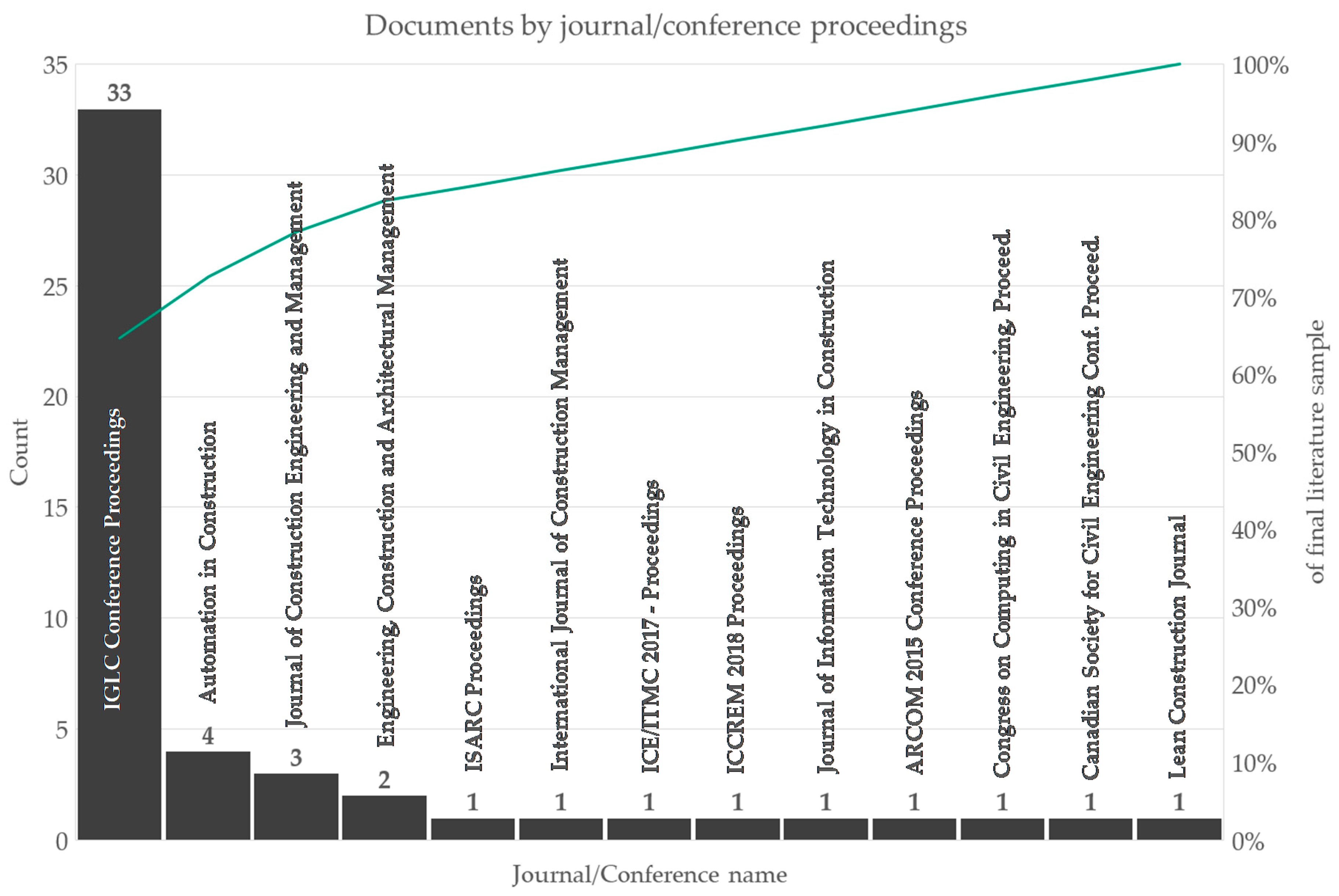

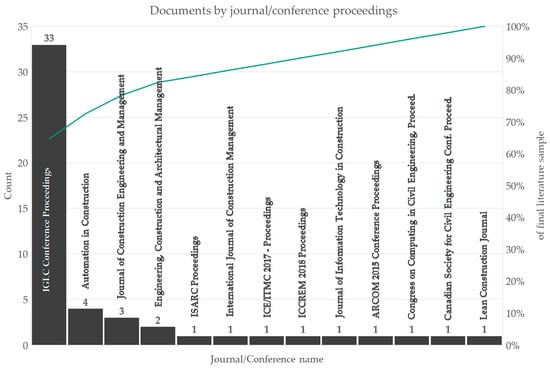

Most of the contributions (ca. 65%) were made through the annual conference of the International Group for Lean Construction (IGLC), which provides for a separate BIM and Lean track even though this conference is focusing on Lean Construction. None of the other mediums account for more than 8% of the papers in the final literature sample, which can be seen in the Pareto chart in Figure 8. The top journal to be mentioned here is Automation in Construction, which ranked second right after the IGLC proceedings.

Figure 8.

Documents by journal/conference proceedings.

A total of 37 of the papers of this sample deals with interactions of BIM and Lean (ca. 73%), whilst 19 papers of this subset focus in particular on BIM-supported production planning and control systems which accounts for ca. 37% of the entire sample. Another 16 papers of the sub-cluster BIM–Lean interactions have a strong focus on theory in terms of conceptual models or frameworks for BIM–Lean integration or new production (management) systems, which are highly relevant to this review with respect to the defined scope. The same is true for the earlier mentioned sub-set of “production planning and and control supported by BIM”, so that we decided to perform the qualitative content analysis on their elements. The sub-cluster of 4D simulations with only 10 papers was not considered there.

The remaining sub-clusters of this 51-papers-sample are presented in Table 7. These were further abstracted to the two groups of “production planning and control supported by BIM” and “theory of BIM-LPS integration”, as indicated above.

Table 7.

Relevant sub-clusters and abstract groups for content analysis.

The papers within these two groups—a total of 27 papers—became then the subject of qualitative content analysis as part of the in-depth analysis according to the review protocol.

4. In-Depth Analysis and Results

In this phase, we qualitatively analyze the remaining papers to provide the reader with a comprehensive summary of their main focus (Section 4.1) and resulting implications (Section 4.2), before we proceed with the discussion of the findings.

4.1. Qualitative Content Analysis

The in-depth analysis of the final literature sample was carried out by means of the research technique referred to as qualitative content analysis. In the scientific context, content analysis, in general, is an approach for identifying the most important characteristics of written research studies allowing for valid inferences [87]. It is a very useful technique to gather and organize information for obtaining insights into current trends and patterns in the considered literature sample [88]. The qualitative aspect, in particular, refers to sorting the content into groups and summarizing the key messages [87]. The results of the qualitative content analysis for the groups of (i) production planning and control supported by BIM and (ii) theory of BIM-LPS integration are presented in the next sub-sections.

4.1.1. Group 1: Production Planning and Control Supported by BIM

Group 1 refers to studies concerned with the management of construction processes according to Lean principles that are also supported by BIM technology. Thanks to the a-priori BIM-LPS interaction matrix filter and the rigorous focalization of this review procedure, most of such comprise BIM-LPS co-applications in construction execution. Several authors developed so-called “Lean IT-tools” which support one or many aspects of the LPS and provide a link to BIM models [22,23,49,55,84,86,89]. However, none of them supports the Last Planner® System to its full extent, since the tools either support only collaborative phase planning [55], even neglect the collaborative aspects such as hand-offs discussion among last planners [22,23,49] or systematic task-breakdown [84,86,90] as stipulated in the current LPS process benchmark [91].

Besides methodological insufficiencies with respect to LPS, this literature sample reveals that the BIM integrations are also not fully developed up to the data processing level: Either, only 3D-representations of BIM models are considered [84,86,90] in case of some integrated IT-systems, LPS elements were included in a non-digital fashion in regular BIM coordination meetings [83], or lean production philosophy was applied in parallel with BIM models but not truly integrated [27,50,70].

This literature sample is also characterized by case studies in the construction execution phase of different project types to find and demonstrate evidence of the described BIM–Lean synergies [54,70,73,74]. Examples here are engineer-to-order (EtO) projects [50,73] or areas of mechanical, electrical, and plumbing (MEP) works [70,80,83].

Another aspect of this literature sample deals with BIM models made available at the construction site to support the implementation of lean principles, which are referred to as BIM-stations [29].

4.1.2. Group 2: Theory of BIM-LPS Integration

Besides the fundamental theoretical work of BIM–Lean interactions of Sacks and his co-authors [10,85], the second group of the final literature sample regarding the theory of BIM-LPS integrations contains two main aspects (i) conceptual models and frameworks for integrations [1,52,64,68,76], and (ii) findings of applications in case studies of such [1,53,75,92]. Some of the analyzed papers cover both aspects [1,52,82].

Regarding the first aspect, we found examples for BIM–lean frameworks [68,83], that propose to “better use BIM models together with LPS” [68]. These kinds of frameworks are basically instructions on where and when to take a look at the BIM model during the Last Planner® process to improve the process itself. In this very example, an Autodesk Revit® BIM model is used, which does not constitute an integrated BIM-LPS IT-system, but requires the use of external, purchasable software.

Another piece of research of this aspect deals with the digital transformation on construction sites by means of mobile applications that enable simultaneously BIM practices and lean principles [52]. Here, the focus is on the delivery of BIM data on-site through tablets according to lean production principles. Also, here the framework is leaning towards commercial BIM software products. Other frameworks focus on prefabrication [64], the integration of BIM, Lean and Green concepts providing for the identification of operational and tactical relations [76] or the maturity of BIM adaption from stakeholder’s perspective and its role on BIM–Lean interactions [82].

Findings of BIM-LPS co-applications, on the other hand, indicate among other things that both Lean and BIM approaches are inextricably linked. However, this link is not fully explored yet [92]. BIM can support LPS decision-making processes thanks to the availability of the right information at the right time [75] and the level of BIM maturity plays a significant role in enabling Lean principles on construction sites [82].

4.2. Findings and Implications

In the following, the central claims from the qualitative content analysis are evaluated and the subsequent implications are presented. The main points listed below both represent shortcomings of current BIM-LPS applications in practice and theory and the resulting motivation to propose a new conceptual model for integration.

4.2.1. Shortcomings and Gaps

As it has become evident in the previous qualitative content analysis, insufficiencies in current attempts of linking the Last Planner® System and the BIM approach conceptually consist mainly of three points:

- Parallel applications rather than true integration which would need provision for detailed insights on how to capitalize BIM data systematically and in a software-vendor independent way and vice versa: how to retrieve BIM data for the LPS process and how to store and potentially visualize LPS process information within a BIM model. In addition to that, a sound conceptual model for integration should also cover BIM functionalities other than 3D representations and automated clash detections, especially when striving for new, BIM-based production management systems in construction.

- There is a lot of scientific evidence focusing on traditional, “stand-alone” LPS that describes its implementation as less successful when not implemented to its full extent in terms of methodology [93,94,95]. Current attempts of implementing the LPS together with BIM show the same methodological inappropriateness which might lead to the same non-satisfactory results. This could be avoided if an accepted reference framework that guides future users through correct methodological implementations in a BIM environment was established.

- Combinations of BIM and LPS in both frameworks and practical implementations in case studies are infrequently connected to solid theory, other than the nowadays known BIM–lean interactions themselves. As claimed by Kasanen et al. [96], this connection is especially needed in the case of frameworks or conceptual models, which often derive from constructive research based on a design science research (DSR) approach.

As for gaps and the combination of digital technology such as BIM with the Last Planner® System, also digital representations of the LPS entities should be considered in a conceptual model for making a link of these entities to BIM objects possible. Thus, LPS being conceptually a Kanban system [97], intuitively brings up the suggestion of digital Kanban systems, where traditional sticky notes could become digital on a touch-whiteboard.

We further think that clear roles with distinct responsibilities could add value to a framework for BIM-LPS integrations in order to improve process compliance in terms of methodology and to avoid the omission of important LPS steps. We will consider this when devising a new conceptual model for integration in the next section.

4.2.2. Devising a New Conceptual Model

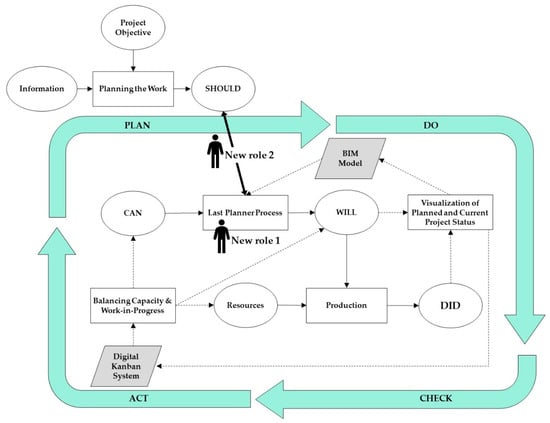

Given the results of the integrative literature review, we take both the lack of a complete conceptual model that is accepted by the scientific and practitioner community and the shortcomings mentioned above as an opportunity to propose a new conceptual model for BIM-LPS integration. This new conceptual model aims to account for the BIM-LPS interactions presented in Table 1 and the above-mentioned needs of adding new functionalities. These new functionalities are:

- Establishing clear roles (e.g., similar to the Scrum framework)

- Deploying on (digital) Kanban boards → Enhancing visualization, emphasizing LPS’ pull-system characteristics, adhering to digitization [97,98,99]

This addition is intended to give the model on a conceptual level the properties that make it possible to derive holistic, IT-oriented production management systems based on BIM and LPS. These could become the source of new information systems. For this purpose, the proposed model also highlights a software-neutral information flow from BIM to the LPS process steps and vice versa.

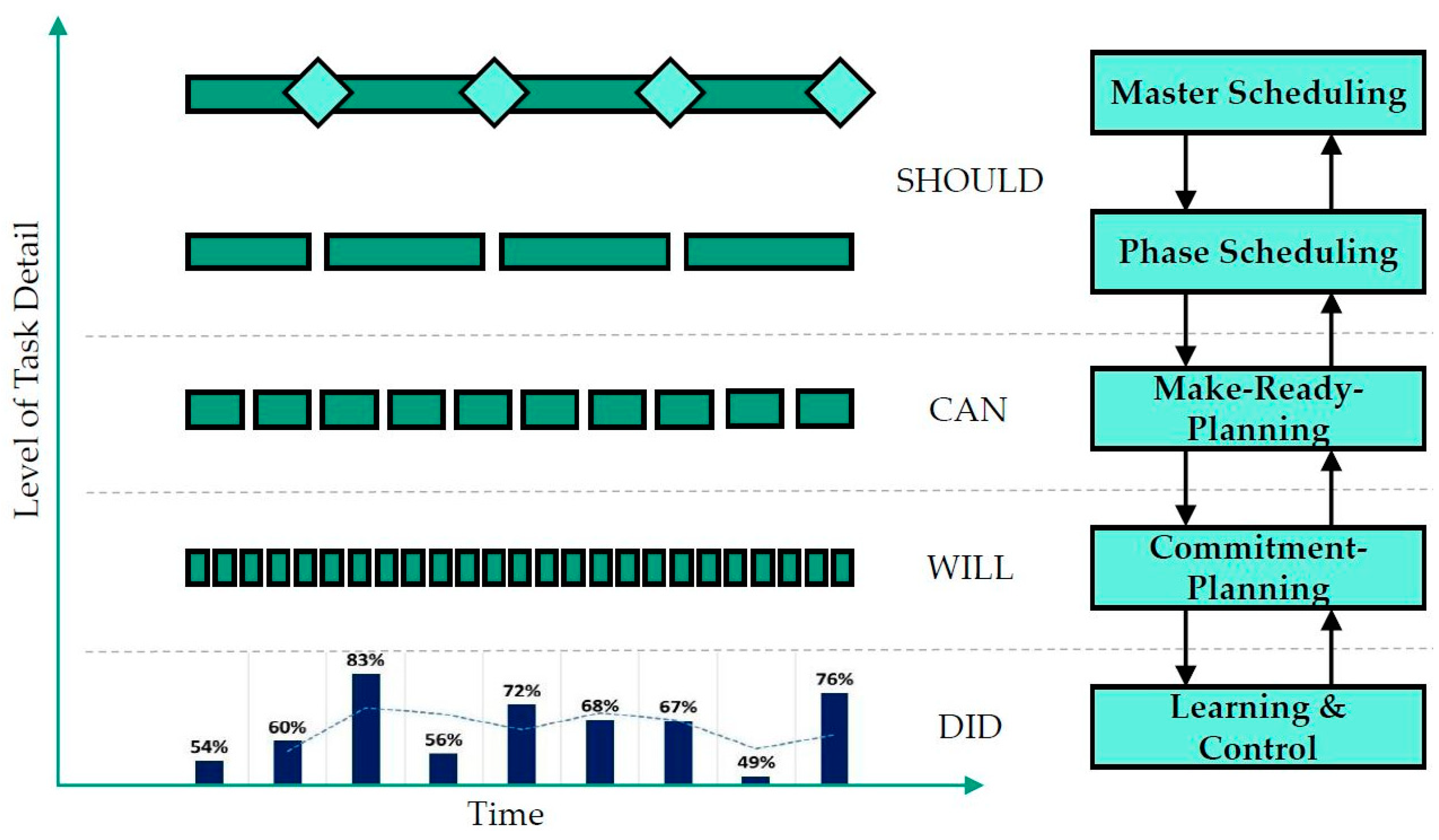

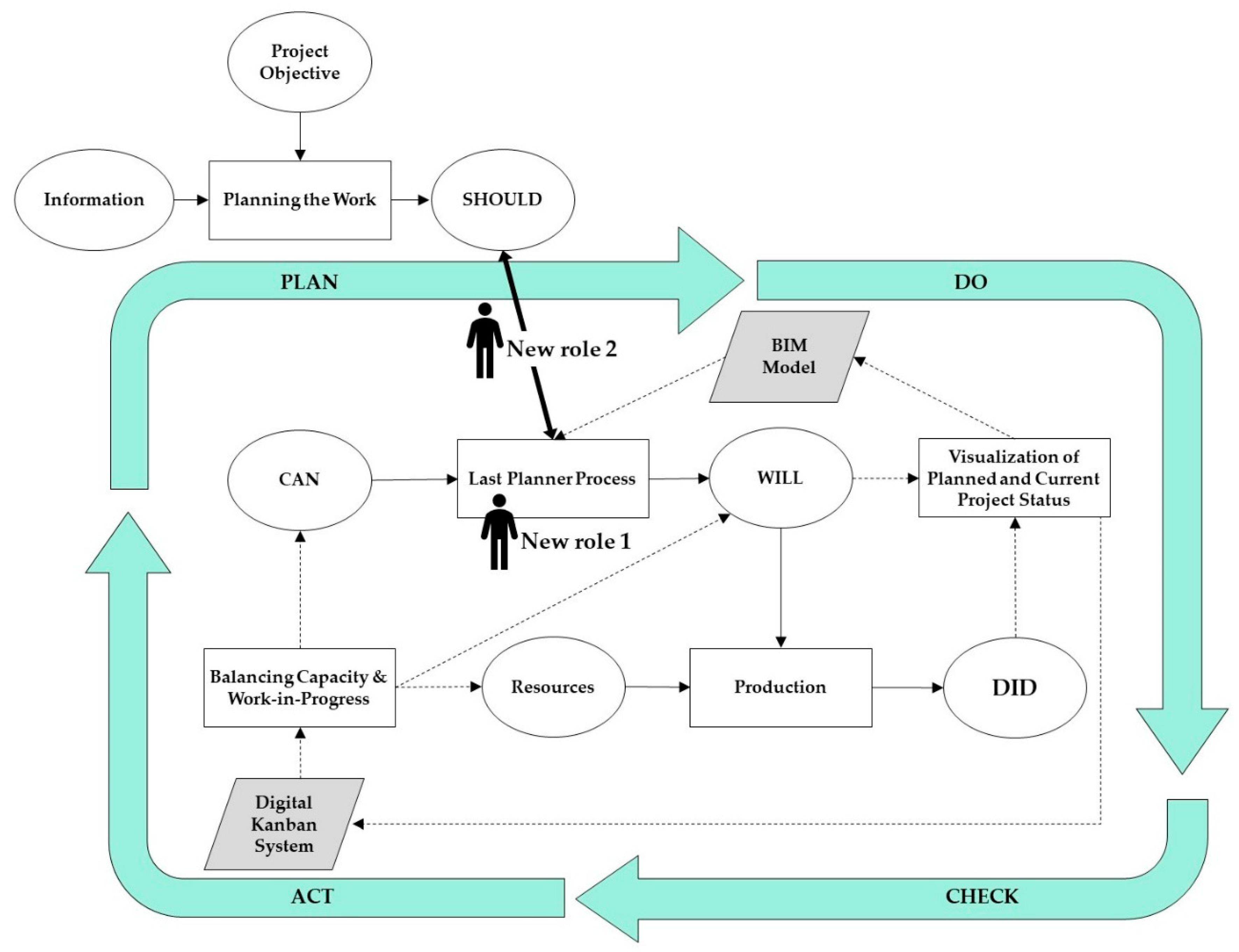

In order to establish a connection to existing theory, and thus meeting the requirements of the DSR approach, our model (Figure 9) is based on the original LPS model by Ballard [36]. Our model refers to the definition of Greca and Moreira [100], who stated that a conceptual model comprises an “external representation created by researchers, teachers, engineers, etc., that facilitates the comprehension or the teaching of systems or states of affairs in the world”.

Figure 9.

Conceptual model for BIM-LPS integration.

On the one hand, this original model is extended by the BIM part which serves both as input and output/visualization instrument. On the other hand, a (digital) Kanban system should help to balance load to capacity [36], to optimize flow through limited Work-in-Progress (WIP) [101], and to improve visual management [98,102]. What is more, Kanban, being a system to provide information as pull signals along value-adding-chains, applied to the LPS, it could help to release new work, when tasks are completed as demanded by Ballard [103].

Lastly, we introduce new roles for enhanced process compliance and customer satisfaction in the style of Scrum. We need a role (“new role 1”) that precisely implements the LPS methodology in conjunction with BIM to prevent partial implementations as we have seen in pure LPS implementations. Besides that, we want to introduce another role (“new role 2”) that ensures that process planning and construction execution according to this model is in line with the customer requirements. Of course, both roles could also be filled by the same person, for example, the site manager in a general contractor environment or an external project manager.

As a consequence, using LPS terminology, the new role 2 is responsible for aligning what SHOULD be done to what WILL be and to what was done (DID) from the customer perspective. The new role 1 has been introduced to define a person who moderates the combined BIM–Last Planner® process according to this conceptual model. The BIM model serves as an information input source for the planning process according to the LPS and for status visualization. The latter can also be visualized by means of a digital Kanban system. Furthermore, the Kanban system can be capitalized for defining what CAN be done when load is visually balanced to capacity (will). Comprising a circular process, this model can be interpreted as being embedded in the plan–do–check–act (PDCA) cycle by Deming [104].

5. Discussion

Drawing a line to the initially stated research questions, it can be said, that—to our best knowledge—there is currently no sufficient conceptual model for the integration of BIM and the Last Planner® System in construction execution. The findings of this integrative literature review demonstrated this and led eventually to the formulation of a new conceptual model for integration as a response to the discovered shortcomings of current integration attempts.

This new conceptual model is intended to serve as an inspiration for future joint BIM and LPS implementations in construction processes, and also—but not exclusively—to develop new integrated information systems that make these implementations possible. These implementations shall be independent of commercial software solutions, such as the selected BIM modeling and scheduling software. A special role is played here by the open BIM exchange format Industry Foundation Classes (IFC):

Even though this conceptual model foresees the use of BIM data as input information for the LPS process planning and the subsequent visualization of the process parameters, it is inevitable for actual practical implementations—as also claimed by Toledo et al. [68]—that this becomes actually feasible in practical, real-world tools. In other words, it has to be made sure, that process parameters can be actually represented in the IFC data structure or that IFC entities and/or attributes can be linked to digital LPS entities, such as e.g., quantity take-off information. With the emergence of new, open BIM toolkits and binding libraries based on higher programming languages [105], and new IFC entities—from IFC version 4 onwards—such as e.g., IfcTaskTime, both becomes possible at the present time. In addition, it is possible to extend the IFC data structure in accordance with official standards according to buildingSMART [106]. Also, so-called model view definitions (MVD), as defined by buildingSMART could be used to create valid IFC sub-sets [107], which allow for BIM-LPS data exchange. All this was not possible at the time of the formulation of the original BIM-Lean interaction matrix. Thus, these new possibilities can be interpreted as new BIM functionalities in line with the hypothesis presented at the beginning of this paper.

Logically, these functionalities were not listed in the original interaction matrix and their absence may have contributed to the lack of robust conceptual models for integration that we have encountered in this review. The same applies to the negative interactions that have been entitled e.g., “cannot be considered mature technology” back then. Now and with the help of new software solutions following this conceptual model, they could be potentially transformed into actual positive synergies. Eventually, this justifies our formulation of a new conceptual model and, at the same time, links our work to the previous body of knowledge in this field of research.

6. Conclusions

This integrative literature review provides for a comprehensive overview of the joint application of BIM and the Last Planner® System in the area of both practical case studies and theoretical contributions. Furthermore, this study reveals gaps at the conceptual level of BIM-LPS integrations and makes a proposal on how to fill these gaps. Concrete results of this study and their conclusions are:

- A specialized BIM-LPS interaction matrix as an update of the general BIM-Lean interaction matrices by Sacks et al. [10] and Oskouie et al. [9] has been formulated.

- On overview of the existing literature in the area of BIM-LPS co-applications in the phase of construction execution from the perspective of both theory and practice has been presented.

- The content of this literature has been condensed and key findings have been elaborated. Among them:

- ○

- When BIM and the LPS are implemented together, they are often not entirely implemented (e.g., only parts of the LPS such as look-ahead planning). We know from past, pure LPS implementations, that this way of implementation can become less successful.

- ○

- BIM and LPS are mainly used in parallel, but not truly integrated as e.g., in the form of an integrated information system.

- ○

- Lack of a comprehensive and holistic framework or conceptual model for BIM-LPS integration in construction execution.

- ○

- Software support is not treated thoroughly.

- A new conceptual model for BIM-LPS integration has been devised based on the findings of the integrative literature review.

The latter could be a reference within the existing body of knowledge to point out new “ways-of-doing” related to the fruition of BIM technology in the practice of construction execution. Future steps could foresee to actually take this theoretical conceptual model to develop new IT-tools that are based on BIM data and support the production on-site in line with LPS principles. These tools should be compliant to current BIM–lean theory and thoroughly tested under real conditions on pilot construction sites to evaluate robustness, applicability and especially utility in practice, since many important concepts—e.g., in lean production—have been erected based on findings in practical analyses [108]. In addition, the conceptual model itself does not claim to be complete or perfectly mature. Improvements based on real-implementation experiences should be continuously incorporated. Also, other aspects of production management might be interesting for assessment and potential integration into this conceptual model. For example, the role of cost control could be examined given that the LPS itself does not support this function.

Author Contributions

Conceptualization, C.P.S., C.M.; methodology, C.P.S.; investigation, C.P.S.; writing—original draft preparation, C.P.S.; supervision, C.M., G.P.M., D.T.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Open Access Publishing Fund of the Free University of Bozen-Bolzano.

Acknowledgments

This work is part of BIM Simulation Lab—FESR 1086, a research project financed by the European Development Fund (ERDF) Südtirol/Alto Adige. Special thanks are directed to Stefania Benedicti for proofreading.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

BIM-LPS interactions according to the matrix presented in Table 1.

Table A1.

BIM-LPS interactions according to the matrix presented in Table 1.

| Authors | Index * | Explanation |

|---|---|---|

| Sacks et al. [10] | 12 | “Use of software capable of model integration (such as Solibri/Navisworks/Tekla) to merge models, identify clashes, and resolve them through iterative refinement of the different discipline specefic model results in almost error free installation on site.” |

| 22 | “Quick turnaround of structural, thermal, and acoustic performance analyses; of cost estimation; and of evaluation of conformance to client program, all enable collaborative design, collapsing cycle times for building design, and detailing.” | |

| 25 | “All three functions serve to reduce cycle time during construction itself because they result in optimized operational schedules, with fewer conflicts.” | |

| 26 | “Where process status is visualized through a BIM model, such as in the KanBIM system, series of consecutive activities required to complete a building space can be performed one after the other with little delay between them. This shortens cycle time for any given space or assembly.” | |

| 30 | “Online visualization and management of process can help implement production strategies designed to reduce work-in-process inventories and production batch sizes (number of spaces in process by a specific trade at any given time), as in the KanBIM approach.” | |

| 34 | “Process visualization and online communication of process status are key elements in allowing production teams to prioritize their subsequent work locations in terms of their potential contribution to ensuring a continuous subsequent flow of work that completes spaces, thus implementing a pull flow. This is central to the KanBIM approach, which extends the last planner system.” | |

| 38 | “Online access to production standards, product data, and company protocols helps institutionalize standard work practices by making them readily available and, within context, to work teams at the work face. This relies, however, on provision of practical means for workers to access online information.” | |

| 40 | “BIM provides an ideal visualization environment for the project throughout the design and construction stage and enables simulation of production methods, temporary equipment, and processes. Modeling and animation of construction sequences in “4D” tools provide a unique opportunity to visualize construction processes for identifying resource conflicts in time and space and resolving constructability issues. This enables process optimization improving efficiency and safety and can help identify bottlenecks and improve flow.” | |

| −41 | “Detailed planning and generation of multiple fine-grained alternatives can be said to increase complexity rather than simplify management.” | |

| −42 | “These applications cannot be considered mature technology.” | |

| 54 | “Automated drawing generation improves engineering capacity when compared with 2D drafting, and it is a more reliable technology because it produces properly coordinated drawing sets.” | |

| Authorship of this study | 57 | Having reliable information for construction components in terms of quantities and materials immediately available, (through a BIM viewer connected to Last Planner® process design) allows for more accurate estimation of duration and resource demand as well as better leveling of production. When correctly modelled, these information are more reliable than manual estimates from 2D plans. |

| 58 | Quantity/material take offs and the visualization of information origin in terms of BIM objects, can help to establish pull systems and understand intuitively downstream demand | |

| 59 | First Run Studies for operation design according to the Last Planner® System could be done by making use of local 4D simulations operations that are linked to BIM objects | |

| 60 | Visualization of completed BIM components, can support the pull planning requisite of task-completion releasing new work Thanks to the BIM-based information visualization, task specifications and sequencing are clearly visible to workers or respectively to Last Planners. | |

| Oskouie et al. [9] | 61 | “With BIM interfaces, real- time productivity can be measured, so that any defects in terms of production in workstations can be rapidly detected and resolved in early stages of work. This will result in learning from experience and consequently improves future methods of implementation” |

| 62 | “Comparing generated As- Built model with As- Planned, discrepancies between these two can be easier detected. In addition, quality assurance and control can be accelerated through this procedure resulting in a better product to the owner.” |

* We have taken the indices from the original BIM-Lean interaction matrix by Sacks et al. [10] and continued the counter accordingly.

References

- Tezel, A.; Aziz, Z. From conventional to it based visual management: A conceptual discussion for lean construction. J. Inf. Technol. Constr. 2017, 22, 220–246. [Google Scholar]

- Ratajczak, J.; Riedl, M.; Matt, D.T. BIM-based and AR Application Combined with Location-Based Management System for the Improvement of the Construction Performance. Buildings 2019, 9, 118. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the Construction Industry—How Ready Is the Industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- Dallasega, P.; Rauch, E.; Matt, D.T.; Fronk, A. Increasing productivity in ETO construction projects through a lean methodology for demand predictability. In Proceedings of the IEOM 2015—5th International Conference on Industrial Engineering and Operations Management, Dubai, UAE, 3–5 March 2015. [Google Scholar]

- Matthews, O.; Howell, G.A. Integrated Project Delivery An Example Of Relational Contracting. Lean Constr. J. 2005, 2, 46–61. [Google Scholar]

- Koskela, L.; Howell, G.; Ballard, G.; Tommelein, I.D. The foundations of lean construction. In Design and Construction: Building in Value; Butterworth-Heinemann: Oxford, UK, 2002; pp. 211–226. [Google Scholar]

- Matt, D.T. Template based production system design. J. Manuf. Technol. Manag. 2008, 19, 783–797. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T. Lean Thinking: Banish Waste and Create Wealth in Your Corporation, 1st ed.; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Oskouie, P.; Gerber, D.J.; Alves, T.; Becerik-Gerber, B. Extending the interaction of building information modeling and lean construction. In Proceedings of the IGLC 2012—20th Conference of the International Group for Lean Construction, San Diego, CA, USA, 18 July 2012. [Google Scholar]

- Sacks, R.; Koskela, L.; Dave, B.A.; Owen, R. Interaction of lean and building information modeling in construction. J. Constr. Eng. Manag. 2010, 136, 968–980. [Google Scholar] [CrossRef]

- Kröger, S. BIM und Lean Construction—Synergien zweier Arbeitsmethodiken; Beuth: Berlin, Germany, 2018; ISBN 9783410267416. [Google Scholar]

- Saieg, P.; Sotelino, E.D.; Nascimento, D.; Caiado, R.G.G. Interactions of Building Information Modeling, Lean and Sustainability on the Architectural, Engineering and Construction industry: A systematic review. J. Clean. Prod. 2018, 174, 788–806. [Google Scholar] [CrossRef]

- Li, J.; Hou, L.; Wang, X.; Wang, J.; Guo, J.; Zhang, S.; Jiao, Y. A project-based quantification of BIM benefits. Int. J. Adv. Robot. Syst. 2014, 11, 1–13. [Google Scholar] [CrossRef]

- Schimanski, C.P.; Monizza, G.P.; Marcher, C.; Matt, D.T. Pushing digital automation of configure-to-order services in small and medium enterprises of the construction equipment industry: A design science research approach. Appl. Sci. 2019, 9, 3780. [Google Scholar] [CrossRef]

- Bolpagni, M.; Burdi, L.; Luigi, A.; Ciribini, C. The implementation of building information modelling and lean construction in design firms in Massachusetts. In Proceedings of the 25th Ann. Conf. of the Int’l. Group for Lean Construction, At Haifa, Israel, 9 July 2017; Volume II, pp. 235–242. [Google Scholar]

- Arokiaprakash, A.; Kannan, S.; Manikanda Prabhu, S. Formulize construction and operation management by integrating BIM and lean. Int. J. Civ. Eng. Technol. 2017, 8, 991–1001. [Google Scholar]

- Mollasalehi, S.; Fleming, A.; Talebi, S.; Underwood, J. Development of an Experimental Waste Framework Based on Bim / Lean Concept in Construction Design. In Proceedings of the 24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18 July 2016; pp. 193–202. [Google Scholar]

- Junior, J.S.; Baldauf, J.P.; Formoso, C.T.; Tzortzopoulos, P. Using BIM and Lean for Modelling Requirements in the Design of Healthcare Projects. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction (IGLC), Chennai, India, 16–22 July 2018; pp. 571–581. [Google Scholar]

- Al Hattab, M.; Hamzeh, F. Using social network theory and simulation to compare traditional versus BIM-lean practice for design error management. Autom. Constr. 2015, 52, 59–69. [Google Scholar] [CrossRef]

- Sacks, R.; Radosavljevic, M.; Barak, R. Requirements for building information modeling based lean production management systems for construction. Autom. Constr. 2010, 19, 641–655. [Google Scholar] [CrossRef]

- Gurevich, U.; Sacks, R. Examination of the effects of a KanBIM production control system on subcontractors’ task selections in interior works. Autom. Constr. 2014, 37, 81–87. [Google Scholar] [CrossRef]

- Dave, B.; Kubler, S.; Främling, K.; Koskela, L. Addressing information flow in lean production management and control in construction. In Proceedings of the 22nd Annual Conference International Group for Lean Construction IGLC, Oslo, Norway, 4 June 2014; pp. 581–592. [Google Scholar]

- Dave, B.; Boddy, S.; Koskela, L. Visilean: Designing a production management system with lean and BIM. In Proceedings of the 19th Annual Conference of the International Group for Lean Construction, Lima, Peru, 1 January 2011; pp. 514–524. [Google Scholar]

- Tezel, A.; Taggart, M.; Koskela, L.; Tzortzopoulos, P.; Hanahoe, J.; Kelly, M. Lean Construction and BIM in Small and Medium-Sized Enterprises (SMEs) in Construction: A Systematic Literature Review. Can. J. Civ. Eng. 2019. [Google Scholar] [CrossRef]

- Franco, J.V.; Picchi, F.A. Lean design in building projects: Guiding principles and exploratory collection of good practices. In Proceedings of the IGLC 2016—24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 13 August 2016; pp. 113–122. [Google Scholar]

- Harris, B.N.; Alves, T.D.C.L. Building information modeling: A report from the field. In Proceedings of the IGLC 2016—24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016; pp. 13–22. [Google Scholar]

- Spitler, L.; Feliz, T.; Wood, N.; Sacks, R. Constructible Bim Elements: A Root Cause Analysis Of Work Plan Failures. In Proceedings of the International Group for Lean Construction, Perth, Norway, 29–31 July 2015; pp. 351–360. [Google Scholar]

- De Vargas, F.B.; Bataglin, F.S.; Formoso, C.T. Guidelines to develop a BIM model focused on construction planning and control. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; Volume 2, pp. 744–753. [Google Scholar]

- Vestermo, A.; Murvold, V.; Svalestuen, F.; Lohne, J.; Lædre, O. BIM-stations: What it is and how it can be used to implement lean principles. In Proceedings of the IGLC 2016-24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016; pp. 33–42. [Google Scholar]

- Murvold, V.; Vestermo, A.; Svalestuen, F.; Lohne, J.; Lædre, O. Experiences from the use of BIM-stations. In Proceedings of the IGLC 2016-24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24 July 2016; pp. 23–32. [Google Scholar]

- Eastman, C.M.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors, 1st ed.; Wiley: Hoboken, NJ, USA, 2008; ISBN 9780470541371. [Google Scholar]

- NBS National BIM Report, Building Information Modelling. Available online: https://www.thenbs.com/about-nbs/ (accessed on 20 October 2019).

- Azhar, S.; Nadeem, A.; Mok, J.Y.N.; Leung, B.H.Y. Building Information Modeling (BIM): A New Paradigm for Visual Interactive Modeling and Simulation for Construction Projects. In Proceedings of the First International Conference on Construction in Developing Countries (ICCIDC-I), Karachi, Pakistan, 4 August 2008; pp. 435–446. [Google Scholar]

- Mirshokraei, M.; De Gaetani, C.I.; Migliaccio, F. A web-based BIM-AR quality management system for structural elements. Appl. Sci. 2019, 9, 3984. [Google Scholar] [CrossRef]

- Kalsaas, B.T. Measuring waste and workflow in construction. In Proceedings of the Annual Conference of the International Group for Lean Construction, Fortaleza, Brazil, 29 July–2 August 2013; pp. 33–42. [Google Scholar]

- Ballard, G. The Last Planner System of Production Control; University of Birmingham: Birmingham, UK, 2000. [Google Scholar]

- Schimanski, C.P.; Monizza, G.P.; Marcher, C.; Matt, D.T. Conceptual Foundations for a New Lean BIM-Based Production System in Construction. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction, Dublin, Ireland, 1–7 July 2019; pp. 877–888. [Google Scholar]

- Hamzeh, F.; Bergstrom, E. The Lean Transformation: A Framework for Successful Implementation of the Last Planner TM System in Construction. In Proceedings of the International 46th Annual Conference Associated Schools of Construction, Boston, MA, USA, 7–10 April 2010; p. 8. [Google Scholar]

- Daniel, E.I.; Pasquire, C.; Dickens, G. Exploring the implementation of the last planner® system through iglc community: Twenty one years of experience. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction: Global Knowledge-Global Solutions, Perth, Australia, 28 July 2015; Volume 23, pp. 153–162. [Google Scholar]

- Hamzeh, F.R. The Lean Journey: Implementing The Last Planner® System in Construction. In Proceedings of the 19th Annual Conference of the International Group for Lean Construction, Lima, Peru, 13–15 July 2011; pp. 379–390. [Google Scholar]

- Gao, S.; Low, S.P. The Last Planner System in China’s construction industry—A SWOT analysis on implementation. Int. J. Proj. Manag. 2014, 32, 1260–1272. [Google Scholar] [CrossRef]

- Whitehead, D. Searching and reviewing the research literature. In Nursing & Midwifery Research: Methods and Appraisal for Evidence-Based Practice; Schneider, Z., Whitehead, D., LoBiondo-Wood, G., Habe, R.J., Eds.; Elsevier: Sidney, Australia, 2013; pp. 35–56. [Google Scholar]

- Kitchenham, B. Procedures for Performing Systematic Reviews; Joint Technical Report TR/SE-0401; Computer Science Department, Keele University: Keele, UK, 2004; Volume 33. [Google Scholar]

- Torraco, R.J. Writing Integrative Literature Reviews: Guidelines and Examples. Hum. Resour. Dev. Rev. 2005, 4, 356–367. [Google Scholar] [CrossRef]

- Saunders, A.; Lewis, P.; Thornhill, A. Research Methods for Business Students; Pearson Education Limited: Harlow, UK, 2012. [Google Scholar]

- Van Eck, J.N.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef]

- Jin, R.; Yuan, H.; Chen, Q. Science mapping approach to assisting the review of construction and demolition waste management research published between 2009 and 2018. Resour. Conserv. Recycl. 2019, 140, 175–188. [Google Scholar] [CrossRef]

- Lagos, C.I.; Herrera, R.F.; Alarcón, L.F. Assessing the Impacts of an IT LPS Support System on Schedule Accomplishment in Construction Projects. J. Constr. Eng. Manag. 2019, 145, 04019055. [Google Scholar] [CrossRef]

- Heigermoser, D.; de Soto, B.; Abbott, E.L.S.; Chua, D.K.H. BIM-based Last Planner System tool for improving construction project management. Autom. Constr. 2019, 104, 246–254. [Google Scholar] [CrossRef]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site logistics planning and control for engineer-to-order prefabricated building systems using BIM 4D modeling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Melzner, J. BIM-based takt-time planning and takt control: Requirements for digital construction process management. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction, Banff, AB, Canada, 21–24 May 2019; pp. 50–56. [Google Scholar]

- Koseoglu, O.; Nurtan-Gunes, E.T. Mobile BIM implementation and lean interaction on construction site: A case study of a complex airport project. Eng. Constr. Arch. Manag. 2018, 25, 1298–1321. [Google Scholar] [CrossRef]

- Koseoglu, O.; Sakin, M.; Arayici, Y. Exploring the BIM and lean synergies in the Istanbul Grand Airport construction project. Eng. Constr. Arch. Manag. 2018, 25, 1339–1354. [Google Scholar] [CrossRef]

- Zhang, X.; Azhar, S.; Nadeem, A.; Khalfan, M. Using Building Information Modelling to achieve Lean principles by improving efficiency of work teams. Int. J. Constr. Manag. 2017, 18, 293–300. [Google Scholar] [CrossRef]

- Guerriero, A.; Kubicki, S.; Berroir, F.; Lemaire, C. BIM-enhanced collaborative smart technologies for LEAN construction processes. In Proceedings of the 2017 International Conference on Engineering, Technology and Innovation: Engineering, Technology and Innovation Management Beyond 2020: New Challenges, New Approaches, ICE/ITMC 2017, Piscataway, NJ, USA, 27–29 June 2017; pp. 1023–1030. [Google Scholar]

- Surendhra Babu, P.R.; Hayath Babu, N. Using technology to achieve lean objectives. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; pp. 1069–1078. [Google Scholar]

- Mollasalehi, S.; Aboumoemen, A.A.; Rathnayake, A.; Fleming, A.; Underwood, J. Development of an integrated BIM and lean maturity model. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; pp. 1217–1228. [Google Scholar]

- Singhal, N.; Ahuja, R. CAN BIM furnish lean benefits—An Indian case study. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; pp. 90–100. [Google Scholar]

- Antunes, R.; Poshdar, M. Envision of an integrated information system for project-driven production in construction. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; pp. 134–143. [Google Scholar]

- Häringer, P.; Borrmann, A. Evaluation of a case study to design a BIM-based cycle planning concept. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; pp. 58–67. [Google Scholar]

- Elmaraghy, A.; Voordijk, H.; Marzouk, M. An exploration of BIM and lean interaction in optimizing demolition projects. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; pp. 112–122. [Google Scholar]

- Matta, G.; Herrera, R.F.; Baladrón, C.; Giménez, Z.; Alarcón, L.F. Using BIM-Based sheets as a visual management tool for on-site instructions: A case study. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; pp. 144–154. [Google Scholar]

- Vrijhoef, R.; Dijkstra, J.T.; Koutamanis, A. Modelling and simulating time use of site workers with 4d BIM. In Proceedings of the 26th Annual Conference of the International Group for Lean Construction: Evolving Lean Construction Towards Mature Production Management Across Cultures and Frontiers, Chennai, India, 16–22 July 2018; pp. 155–165. [Google Scholar]

- Goyal, M.; Gao, Z. Integration of Building Information Modeling (BIM) and Prefabrication for Lean Construction. In Proceedings of the ICCREM 2018: Innovative Technology and Intelligent Construction-Proceedings of the International Conference on Construction and Real Estate Management 2018, Charleston, SC, USA, 9–10 August 2018; pp. 78–84. [Google Scholar]

- Fosse, R.; Ballard, G.; Fischer, M. Virtual design and construction: Aligning BIM and lean in practice. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017; pp. 499–506. [Google Scholar]

- Lagos, C.I.; Herrera, R.F.; Alarcón, L.F. Contributions of information technologies to last planner system implementation. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017; pp. 87–94. [Google Scholar]

- Von Heyl, J.; Teizer, J. Lean production controlling and tracking using digital methods. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction, Heraklion, Greece, 9–12 July 2017; pp. 127–134. [Google Scholar]

- Toledo, M.; Olivares, K.; González, V. Exploration of a lean-BIM planning framework: A last planner system and BIM-based case study. In Proceedings of the IGLC 2016-24th Annual Conference of the International Group for Lean Construction, Boston, MA, USA, 18–24, July 2016; pp. 3–12. [Google Scholar]

- Haiati, O.; von Heyl, J.; Schmalz, S. Bim and Sequence Simulation in Structural Work—Development of a Procedure for Automation. In Proceedings of the 24th Annual Conference of the International for Lean Construction, Boston, MA, USA, 18–24, July 2016; pp. 73–82. [Google Scholar]

- Tillmann, P.; Sargent, Z. Last Planner & Bim Integration: Lessons From a Continuous Improvement Effort. In Proceedings of the International Group for Lean Construction, Boston, MA, USA, 18–24, July 2016; pp. 113–122. [Google Scholar]

- Ben-Alon, L.; Sacks, R. Simulating and vizualising emergent production in construction (Epic)using agents and BIM. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction: Global Knowledge—Global Solutions, Perth, Australia, 29–31 July 2015; pp. 371–380. [Google Scholar]

- Dave, B.; Kubler, S.; Pikas, E.; Holmström, J.; Singh, V.; Främling, K.; Koskela, L.; Peltokorp, A. Intelligent Products: Shifting the Production Control Logic in Construction (With Lean and BIM). In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction, Perth, Australia, 29–31 July 2015; pp. 341–350. [Google Scholar]

- Tillmann, P.; Viana, D.; Sargent, Z.; Tommelein, I.; Formoso, C. Bim and lean in the design-production interface of eto components in complex projects. In Proceedings of the 23rd Annual Conference of the International Group for Lean Construction: Global Knowledge-Global Solutions, Perth, Australia, 29–31 July 2015; pp. 331–340. [Google Scholar]

- Tallgren, M.V.; Roupé, M.; Johansson, M. An empowered collaborative planning method in a swedish construction company-a case study. In Proceedings of the 31st Annual Association of Researchers in Construction Management Conference, ARCOM 2015, Lincoln, UK, 7–9 September 2015; pp. 793–802. [Google Scholar]

- Garrido, M.C.; Mendes, R.; Scheer, S.; Campestrini, T.F. Using BIM for last planner system: Case studies in Brazil. In Proceedings of the Congress on Computing in Civil Engineering, Austin, TX, USA, 21–23 June 2015; pp. 604–611. [Google Scholar]

- Ahuja, R.; Sawhney, A.; Arif, M. Bim based conceptual framework for lean and green integration. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction: Understanding and Improving Project Based Production, Oslo, Norway, 25–27 June 2014; pp. 123–132. [Google Scholar]

- Toledo, M.; González, V.A.; Villegas, A.; Mourgues, C. Using 4D models for tracking project progress and visualizing the owner’s constraints in fast-track retail renovation projects. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction: Understanding and Improving Project Based Production, Oslo, Norway, 25–27 June 2014; pp. 969–980. [Google Scholar]

- Biotto, C.; Mota, B.; Araújo, L.; Barbosa, G.; Andrade, F. Adapted use of andon in a horizontal residential construction project. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction: Understanding and Improving Project Based Production, Oslo, Norway, 25–27 June 2014; pp. 1295–1305. [Google Scholar]

- Bouguessa, A.; Forgues, D.; Doré, S. Complementarity between the Building Information Modeling (BIM) and Product Life Cycle Management (PLM) through the Lean Construction (LC). In Proceedings of the Proceedings, Annual Conference-Canadian Society for Civil Engineering, Montreal, QC, Canada, 29 May–1 June 2013; pp. 1139–1148. [Google Scholar]

- Clemente, J.; Cachadinha, N. BIM-lean synergies in the management on MEP works in public facilities of intensive use-A case study. In Proceedings of the 21st Annual Conference of the International Group for Lean Construction 2013, Fortaleza, Brazil, 29 July–2 August 2013; pp. 70–79. [Google Scholar]

- Sacks, R.; Barak, R.; Belaciano, B.; Gurevich, U.; Pikas, E. KanBIM workflow management system: Prototype implementation and field testing. Lean Constr. J. 2013, 2013, 19–35. [Google Scholar]

- Hamdi, O.; Leite, F. BIM and Lean interactions from the bim capability maturity model perspective: A case study. In Proceedings of the IGLC 2012-20th Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Bhatla, A.; Leite, F. Integration Framework of BIM with the Last Planner System. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction, San Diego, CA, USA, 18–20 July 2012; p. 10. [Google Scholar]

- Sacks, R.; Barak, R.; Belaciano, B.; Gurevich, U.; Pikas, E. Field tests of the KanBIM lean production management system. In Proceedings of the 19th Annual Conference of the International Group for Lean Construction 2011, Lima, Peru, 13–15 July 2011; pp. 465–476. [Google Scholar]

- Sacks, R.; Dave, B.A.; Koskela, L.; Owen, R. Analysis framework for the interaction between lean construction and Building Information Modelling. In Proceedings of the 17th Annual Conference of the International Group for Lean Construction, Taipei, Taiwan, 15–17 July 2019; pp. 221–234. [Google Scholar]

- Sacks, R.; Treckmann, M.; Rozenfeld, O. Visualization of work flow to support lean construction. J. Constr. Eng. Manag. 2009, 135, 1307–1315. [Google Scholar] [CrossRef]

- Siraj, N.B.; Fayek, A.R. Risk Identification and Common Risks in Construction: Literature Review and Content Analysis. J. Constr. Eng. Manag. 2019, 145, 03119004. [Google Scholar] [CrossRef]

- Shelley, M.; Krippendorff, K. Content Analysis: An Introduction to its Methodology. J. Am. Stat. Assoc. 1984, 79, 240. [Google Scholar] [CrossRef]

- Sacks, R.; Radosavljevic, M.; Barak, R. A Building Information Modelling Based Production Control System for Construction. In Proceedings of the W078-Special Track 18th CIB World Building Congress May 2010, Salford, UK, 10–13 May 2010; p. 1. [Google Scholar]

- Khan, S.; Tzortzopoulos, P. Effects of the interactions between lps and bim on workflow in two building design projects. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 933–944. [Google Scholar]

- Ballard, G.; Tommelein, I. Current Process Benchmark for the Last Planner System; Project Production Systems Laboratory, UC Berkeley: Berkeley, CA, USA, 2016. [Google Scholar]

- Gerber, D.J.; Becerik-Gerber, B. Building Information Modeling and Lean Construction: Technology, Methodology and Advances From Practice. In Proceedings of the 18th Annual Conference, International Group for Lean Construction, Haifa, Israel, 14–16 July 2010. [Google Scholar]

- Bortolazza, R.; Formoso, C.T. A quantitative analysis of data collected from the last planner system in brazil. In Proceedings of the 14th International Group for Lean Construction, Santiago de Chile, Chile, 25–27 July 2006; pp. 625–635. [Google Scholar]

- Alarcón, L.F.; Diethelm, S.; Rojo, O.; Calderon, R. Assessing the impacts of implementing lean construction. In Proceedings of the 13th Annual Conference of the International Group for Lean Construction, Sydney, Australia, 19–21 July 2005; pp. 387–393. [Google Scholar]

- Friblick, F.; Olsson, V.; Reslow, J. Prospects for implementing Last Planner in the construction industry. In Proceedings of the 17th Annual Conference of the International Group for Lean Construction, Taipei, Taiwan, 15–17 July 2019; pp. 197–206. [Google Scholar]