Figure 1.

Flowchart of the study.

Figure 1.

Flowchart of the study.

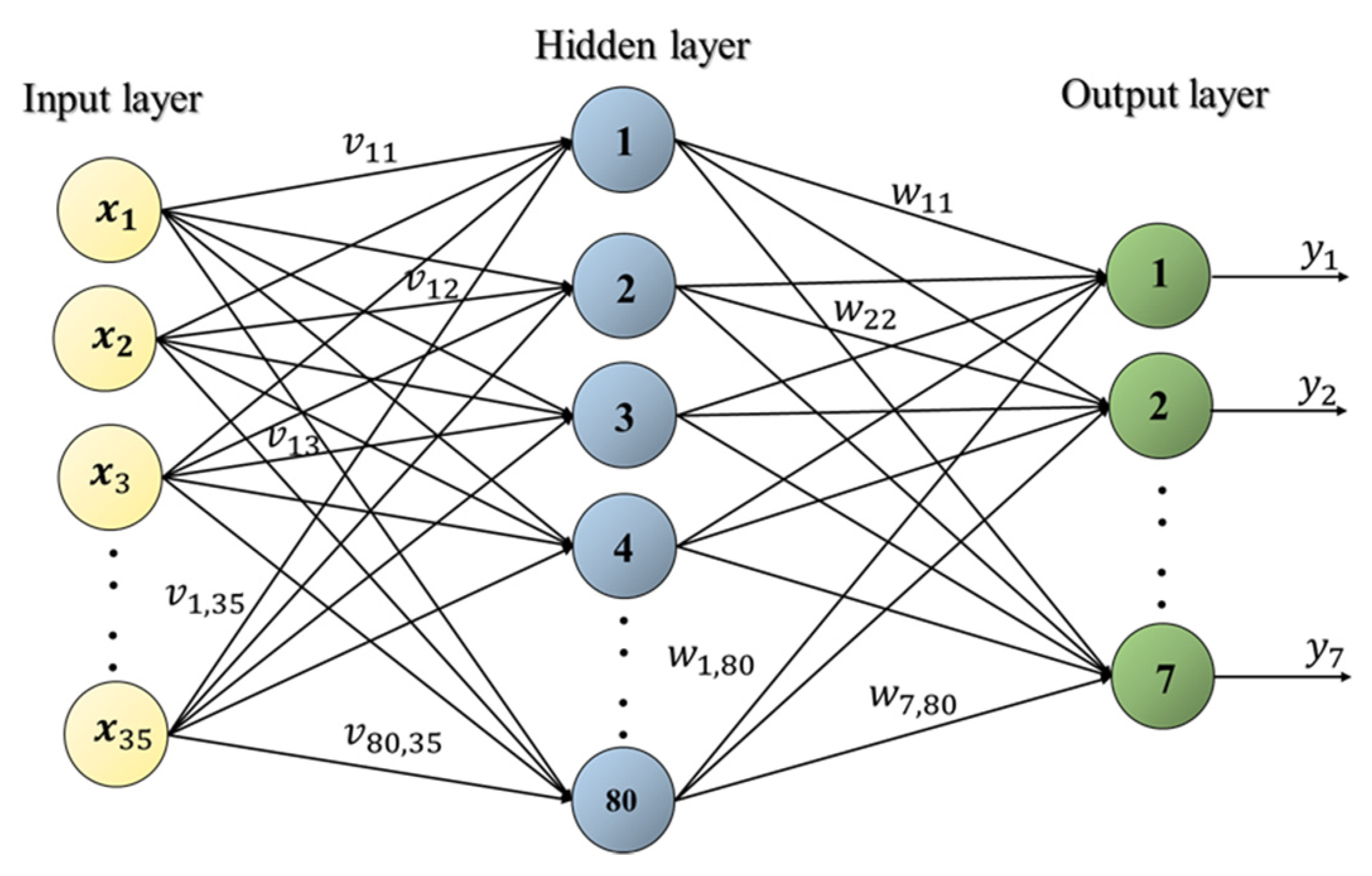

Figure 2.

The structure of BPN.

Figure 2.

The structure of BPN.

Figure 3.

(a) The finite element model. (b) The damaged scenario (the bracings was removed from the red circle).

Figure 3.

(a) The finite element model. (b) The damaged scenario (the bracings was removed from the red circle).

Figure 4.

Detailed structure of the artificial neural network (ANN).

Figure 4.

Detailed structure of the artificial neural network (ANN).

Figure 5.

(a) The training state. (b) Regression distribution of the training, test.

Figure 5.

(a) The training state. (b) Regression distribution of the training, test.

Figure 6.

Health index of damage on the first floor.

Figure 6.

Health index of damage on the first floor.

Figure 7.

Health index of damage on the sixth floor.

Figure 7.

Health index of damage on the sixth floor.

Figure 8.

Health index of damage for the third floor and the fourth floor.

Figure 8.

Health index of damage for the third floor and the fourth floor.

Figure 9.

Health index of damage from the first floor to the third floor.

Figure 9.

Health index of damage from the first floor to the third floor.

Figure 10.

Health index of damage from the fourth floor to the seventh floor.

Figure 10.

Health index of damage from the fourth floor to the seventh floor.

Figure 11.

Health index of damage on the low floors.

Figure 11.

Health index of damage on the low floors.

Figure 12.

Health index of damage on the middle floors.

Figure 12.

Health index of damage on the middle floors.

Figure 13.

Health index of damage on the high floor.

Figure 13.

Health index of damage on the high floor.

Figure 14.

A seven-story scale-down benchmark structure.

Figure 14.

A seven-story scale-down benchmark structure.

Figure 15.

Arrangement of velocity meter and mass block.

Figure 15.

Arrangement of velocity meter and mass block.

Figure 16.

The damage simulation: (a) the healthy condition; (b) the damaged condition.

Figure 16.

The damage simulation: (a) the healthy condition; (b) the damaged condition.

Figure 17.

(a) The training state; (b) Regression distribution of the training, test.

Figure 17.

(a) The training state; (b) Regression distribution of the training, test.

Figure 18.

Health index of damage on the second floor.

Figure 18.

Health index of damage on the second floor.

Figure 19.

Health index of damage on the fourth floor.

Figure 19.

Health index of damage on the fourth floor.

Figure 20.

Health index of damage on the fifth floor and the sixth floor.

Figure 20.

Health index of damage on the fifth floor and the sixth floor.

Figure 21.

Health index of damage from the first floor to the third floor.

Figure 21.

Health index of damage from the first floor to the third floor.

Figure 22.

Health index of damage from the fourth floor to the seventh floor.

Figure 22.

Health index of damage from the fourth floor to the seventh floor.

Table 1.

Damage cases and modal analysis.

Table 1.

Damage cases and modal analysis.

| Damage Group | Damage Floors | Frequency (Hz) |

|---|

| Undamaged | None | 3.25 |

| One-story damage | 1F | 2.98 |

| 2F | 2.18 |

| 3F | 1.9 |

| 4F | 2.08 |

| 5F | 2.34 |

| 6F | 2.76 |

| 7F | 3.54 |

| Two-story damage | 1&2F | 1.79 |

| 3&4F | 1.51 |

| 5&6F | 2.01 |

| Three-story damage | 1&2&3F | 1.22 |

| 4&5&6F | 1.56 |

| Multistory damage | 1&2&3&4F | 2.5 |

| 4&5&6&7F | 1.54 |

Table 2.

Relationship between stiffness loss and health index.

Table 2.

Relationship between stiffness loss and health index.

| Stiffness K | Health Index |

|---|

| K*1 (Health) | 1 |

| K*0.7 | 0.7 |

| K*0.35 | 0.35 |

| K*0 | 0 |

Table 3.

Parameters applied for training.

Table 3.

Parameters applied for training.

| Training Parameters |

|---|

| Number of neurons | 80 |

| Number of hidden layers | 1 |

| Transfer function | Logsig |

| Epoch | 30,000 |

| Max failure number | 0 |

| Time | Infinite |

| Goal | 0 |

| Min gradient | 1 × 10−7 |

| mu | 0.005 |

| mu_decrement | 0.1 |

| mu_increment | 10 |

| Max mu | 1 × 1010 |

Table 4.

Diagnosis result of damage on the first floor (case 1).

Table 4.

Diagnosis result of damage on the first floor (case 1).

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | ✓ | 0 | 0.026 | 2.6% |

| 2F | | 1 | 0.744 | 25.6% |

| 3F | | 1 | 0.796 | 20.4% |

| 4F | | 1 | 0.812 | 18.8% |

| 5F | | 1 | 0.975 | 2.5% |

| 6F | | 1 | 0.936 | 6.4% |

| 7F | | 1 | 0.98 | 2% |

Table 5.

Diagnosis result of damage on the sixth floor (case 2).

Table 5.

Diagnosis result of damage on the sixth floor (case 2).

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | | 1 | 0.983 | 1.7% |

| 2F | | 1 | 1.037 | 3.7% |

| 3F | | 1 | 0.982 | 1.8% |

| 4F | | 1 | 0.988 | 1.2% |

| 5F | | 1 | 1.019 | 1.9% |

| 6F | ✓ | 0 | 0.014 | 1.4% |

| 7F | | 1 | 0.923 | 7.7% |

Table 6.

Diagnosis result of damage for the third floor and the fourth floor (case 3).

Table 6.

Diagnosis result of damage for the third floor and the fourth floor (case 3).

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | | 1 | 0.996 | 0.4% |

| 2F | | 1 | 0.958 | 4.2% |

| 3F | ✓ | 0 | 0.006 | 0.6% |

| 4F | ✓ | 0 | 0.004 | 0.4% |

| 5F | | 1 | 0.835 | 16.5% |

| 6F | | 1 | 0.977 | 2.3% |

| 7F | | 1 | 0.997 | 0.3% |

Table 7.

Diagnosis result of damage from the first floor to the third floor (case 4).

Table 7.

Diagnosis result of damage from the first floor to the third floor (case 4).

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | ✓ | 0 | 0.03 | 3% |

| 2F | ✓ | 0 | 0.018 | 1.8% |

| 3F | ✓ | 0 | 0.047 | 4.7% |

| 4F | | 1 | 0.932 | 6.8% |

| 5F | | 1 | 1.009 | 0.9% |

| 6F | | 1 | 1.05 | 5% |

| 7F | | 1 | 0.987 | 1.3% |

Table 8.

Diagnosis result of damage from the fourth floor to the seventh floor (case 5).

Table 8.

Diagnosis result of damage from the fourth floor to the seventh floor (case 5).

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | | 1 | 0.986 | 1.4% |

| 2F | | 1 | 0.994 | 0.6% |

| 3F | | 1 | 1.002 | 0.2% |

| 4F | ✓ | 0 | 0.002 | 0.2% |

| 5F | ✓ | 0 | 0.005 | 0.5% |

| 6F | ✓ | 0 | -0.009 | 0.9% |

| 7F | ✓ | 0 | -0.002 | 0.2% |

Table 9.

Diagnosis result of damage on the low floors (case 6).

Table 9.

Diagnosis result of damage on the low floors (case 6).

| | Stiffness Reduction | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | k*0.7 | 0.7 | 0.785 | 8.5% |

| 2F | k*0.7 | 0.7 | 0.881 | 18.1% |

| 3F | k*0.35 | 0.35 | 0.401 | 5.1% |

| 4F | k | 1 | 1.046 | 4.6% |

| 5F | k | 1 | 0.9 | 10% |

| 6F | k | 1 | 0.986 | 1.4% |

| 7F | k | 1 | 1.029 | 2.9% |

Table 10.

Diagnosis result of damage on the middle floors (case 7).

Table 10.

Diagnosis result of damage on the middle floors (case 7).

| | Stiffness Reduction | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | k | 1 | 0.98 | 2% |

| 2F | k | 1 | 0.981 | 1.9% |

| 3F | k*0.7 | 0.7 | 0.733 | 3.3% |

| 4F | k*0.35 | 0.35 | 0.35 | 0% |

| 5F | k*0.35 | 0.35 | 0.331 | 1.9% |

| 6F | k | 1 | 1.011 | 1.1% |

| 7F | k | 1 | 0.988 | 1.2% |

Table 11.

Diagnosis result of damage on the high floors (case 8).

Table 11.

Diagnosis result of damage on the high floors (case 8).

| | Stiffness Reduction | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | k | 1 | 0.984 | 1.6% |

| 2F | k | 1 | 1.044 | 4.4% |

| 3F | k | 1 | 0.988 | 1.2% |

| 4F | k | 1 | 1 | 0% |

| 5F | k*35 | 0.35 | 0.371 | 2.1% |

| 6F | k*0.7 | 0.7 | 0.689 | 1.1% |

| 7F | k*0.35 | 0.35 | 0.361 | 1.1% |

Table 12.

Damage cases and modal analysis.

Table 12.

Damage cases and modal analysis.

| Damage Group | Damage Floors | Frequency (Hz) |

|---|

| Undamaged | None | 3.34 |

| One-story damage | 1F | 2.08 |

| 2F | 2.13 |

| 3F | 2.12 |

| 4F | 2.29 |

| 5F | 2.61 |

| 6F | 2.88 |

| 7F | 3.2 |

| Two-story damage | 1&2F | 1.64 |

| 3&4F | 1.83 |

| 5&6F | 2.32 |

| Three-story damage | 1&2&3F | 1.44 |

| 4&5&6F | 1.88 |

| Multistory damage | 1&2&3&4F | 1.33 |

| 4&5&6&7F | 1.86 |

Table 13.

Parameters applied for training.

Table 13.

Parameters applied for training.

| Training Parameters |

|---|

| Number of neurons | 50 |

| Number of hidden layers | 1 |

| Transfer function | Logsig |

| Epoch | 30,000 |

| Max failure number | 0 |

| Time | Infinite |

| Goal | 0 |

| Min gradient | 1 × 10−7 |

| mu | 0.005 |

| mu_decrement | 0.1 |

| mu_increment | 10 |

| Max mu | 1 × 1010 |

Table 14.

Diagnosis result of damage on the second floor.

Table 14.

Diagnosis result of damage on the second floor.

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | | 1 | 1 | 0% |

| 2F | ✓ | 0 | 0.257 | 25.7% |

| 3F | | 1 | 1 | 0% |

| 4F | | 1 | 1 | 0% |

| 5F | | 1 | 1 | 0% |

| 6F | | 1 | 0.887 | 11.3% |

| 7F | | 1 | 0.957 | 4.3% |

Table 15.

Diagnosis result of damage on the fourth floor.

Table 15.

Diagnosis result of damage on the fourth floor.

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | | 1 | 0.811 | 18.9% |

| 2F | | 1 | 0.744 | 25.6% |

| 3F | | 1 | 0.99 | 1% |

| 4F | ✓ | 0 | 0.548 | 54.8% |

| 5F | | 1 | 0.627 | 37.3% |

| 6F | | 1 | 1 | 0% |

| 7F | | 1 | 1 | 0% |

Table 16.

Diagnosis result of damage on the fifth floor and the sixth floor.

Table 16.

Diagnosis result of damage on the fifth floor and the sixth floor.

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | | 1 | 1 | 0% |

| 2F | | 1 | 1 | 0% |

| 3F | | 1 | 1 | 0% |

| 4F | | 1 | 1 | 0% |

| 5F | ✓ | 0 | 0 | 0% |

| 6F | ✓ | 0 | 0 | 0% |

| 7F | | 1 | 0.467 | 53.3% |

Table 17.

Diagnosis result of damage from the first floor to the third floor.

Table 17.

Diagnosis result of damage from the first floor to the third floor.

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | ✓ | 0 | 0.417 | 41.7% |

| 2F | ✓ | 0 | 0.056 | 5.6% |

| 3F | ✓ | 0 | 0.338 | 33.8% |

| 4F | | 1 | 0.747 | 25.3% |

| 5F | | 1 | 0.953 | 4.7% |

| 6F | | 1 | 0.949 | 5.1% |

| 7F | | 1 | 1 | 0% |

Table 18.

Diagnosis result of damage from the fourth floor to the seventh floor.

Table 18.

Diagnosis result of damage from the fourth floor to the seventh floor.

| | Damaged Floor | Health Index | Evaluated Health Index | Error (%) |

|---|

| 1F | | 1 | 1 | 0% |

| 2F | | 1 | 1 | 0% |

| 3F | | 1 | 0.688 | 31.2% |

| 4F | ✓ | 0 | 0.206 | 20.6% |

| 5F | ✓ | 0 | 0.062 | 6.2% |

| 6F | ✓ | 0 | 0 | 0% |

| 7F | ✓ | 0 | 0.015 | 1.5% |

Table 19.

The results of confusion matrix for the experimental verification.

Table 19.

The results of confusion matrix for the experimental verification.

| Damaged Floors | RCMCSE |

|---|

| TP | FP | TN | FN |

|---|

| 1F | 5 | 0 | 1 | 1 |

| 2F | 6 | 0 | 1 | 0 |

| 3F | 4 | 0 | 1 | 2 |

| 4F | 6 | 1 | 0 | 0 |

| 5F | 5 | 0 | 1 | 1 |

| 6F | 5 | 0 | 1 | 1 |

| 7F | 5 | 0 | 1 | 1 |

| 1&2F | 5 | 0 | 2 | 0 |

| 3&4F | 5 | 0 | 2 | 0 |

| 5&6F | 4 | 0 | 2 | 1 |

| 1&2&3F | 4 | 1 | 2 | 0 |

| 4&5&6F | 4 | 0 | 3 | 0 |

| 1&2&3&4F | 3 | 1 | 3 | 0 |

| 4&5&6&7F | 3 | 0 | 4 | 0 |

| Total | 64 | 3 | 24 | 7 |

| Accuracy | 89.8% |

| Precision | 95.5% |

| Recall | 90% |