Numerical Investigation of the Combustion Characteristics of an Internal Combustion Engine with Subcritical and Supercritical Fuel

Abstract

Featured Application

Abstract

1. Introduction

2. Numerical Simulation Method

2.1. Fuel Injection and Turbulent Combustion Models

2.2. Emission Model

3. Establishment and Verification of the Engine Model

3.1. Establishment of the Engine Model

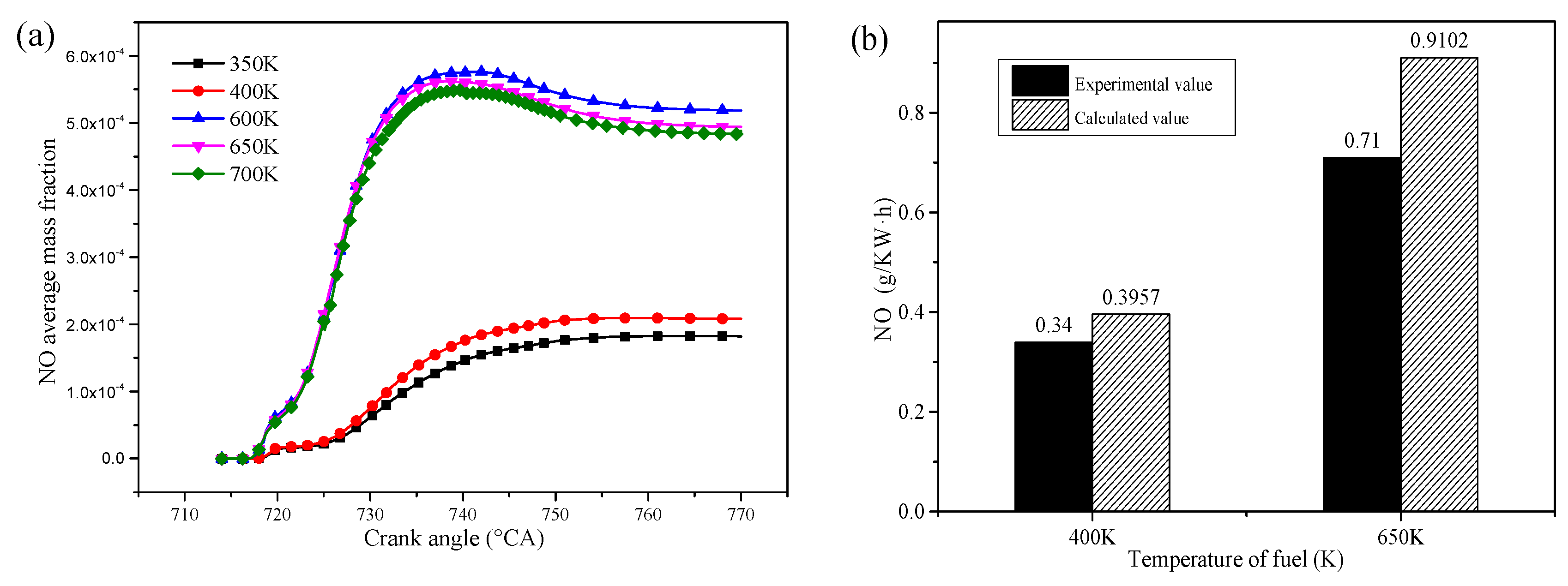

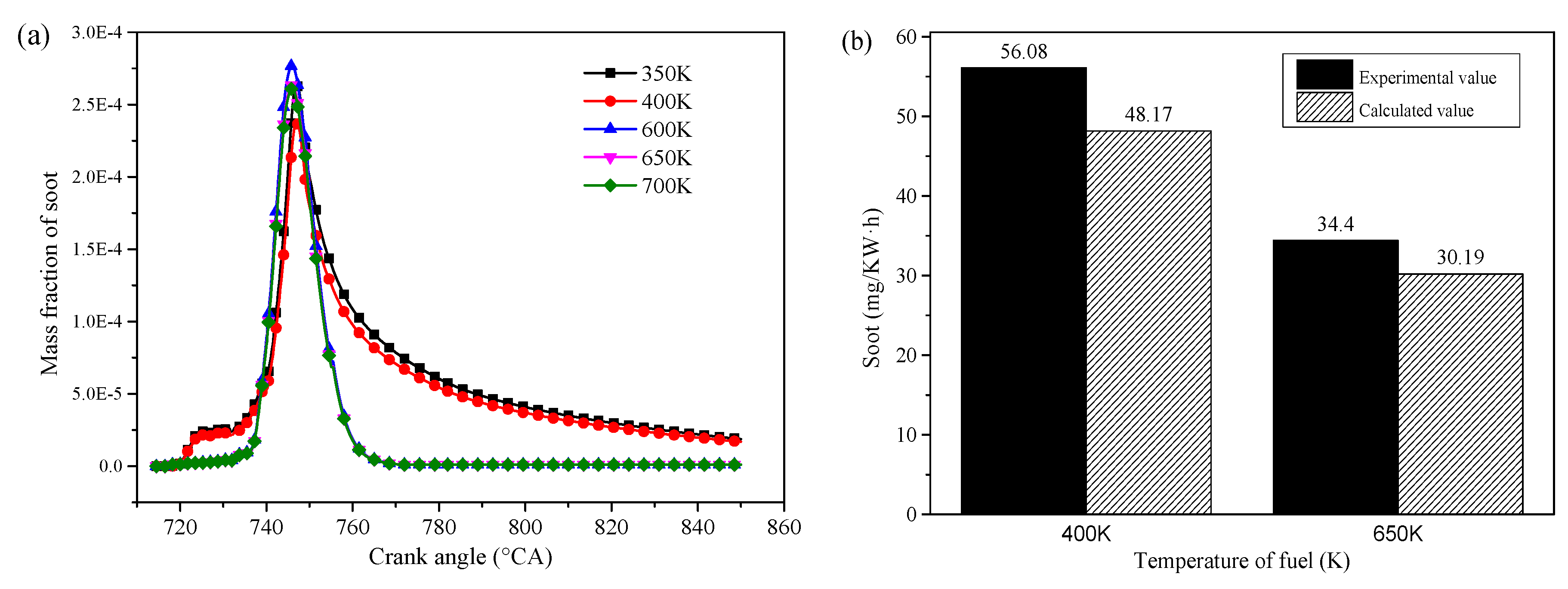

3.2. Verification of the Engine Model

4. Results

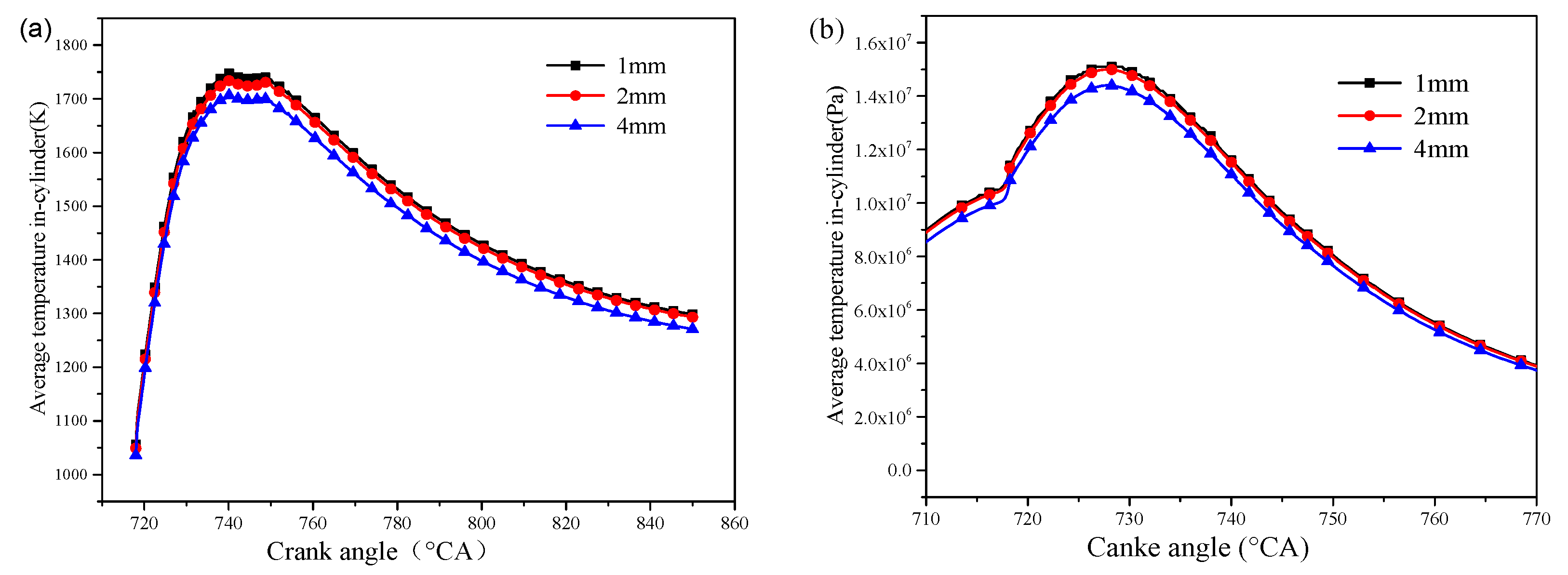

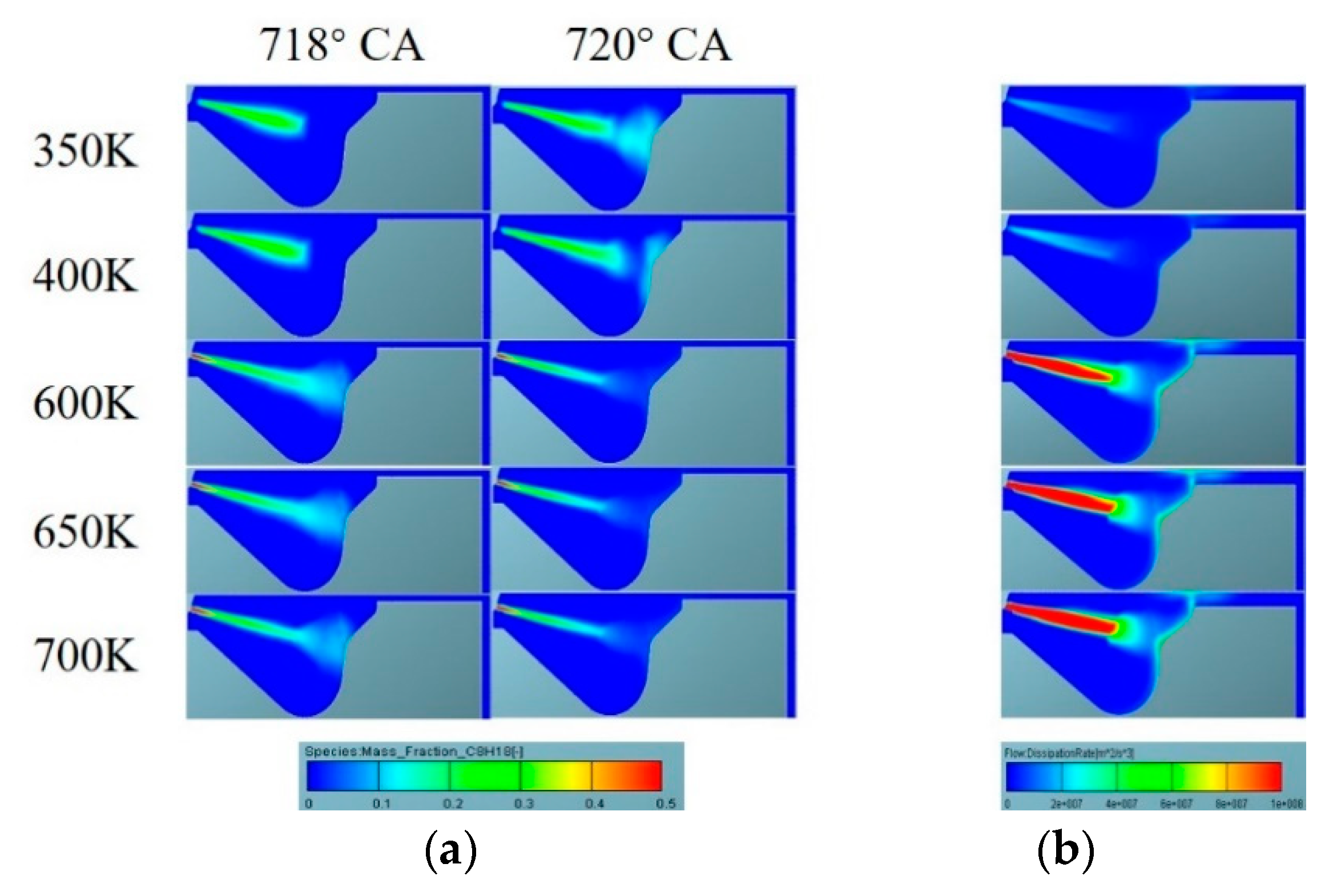

4.1. Comparison of In-Cylinder Temperature and Pressure

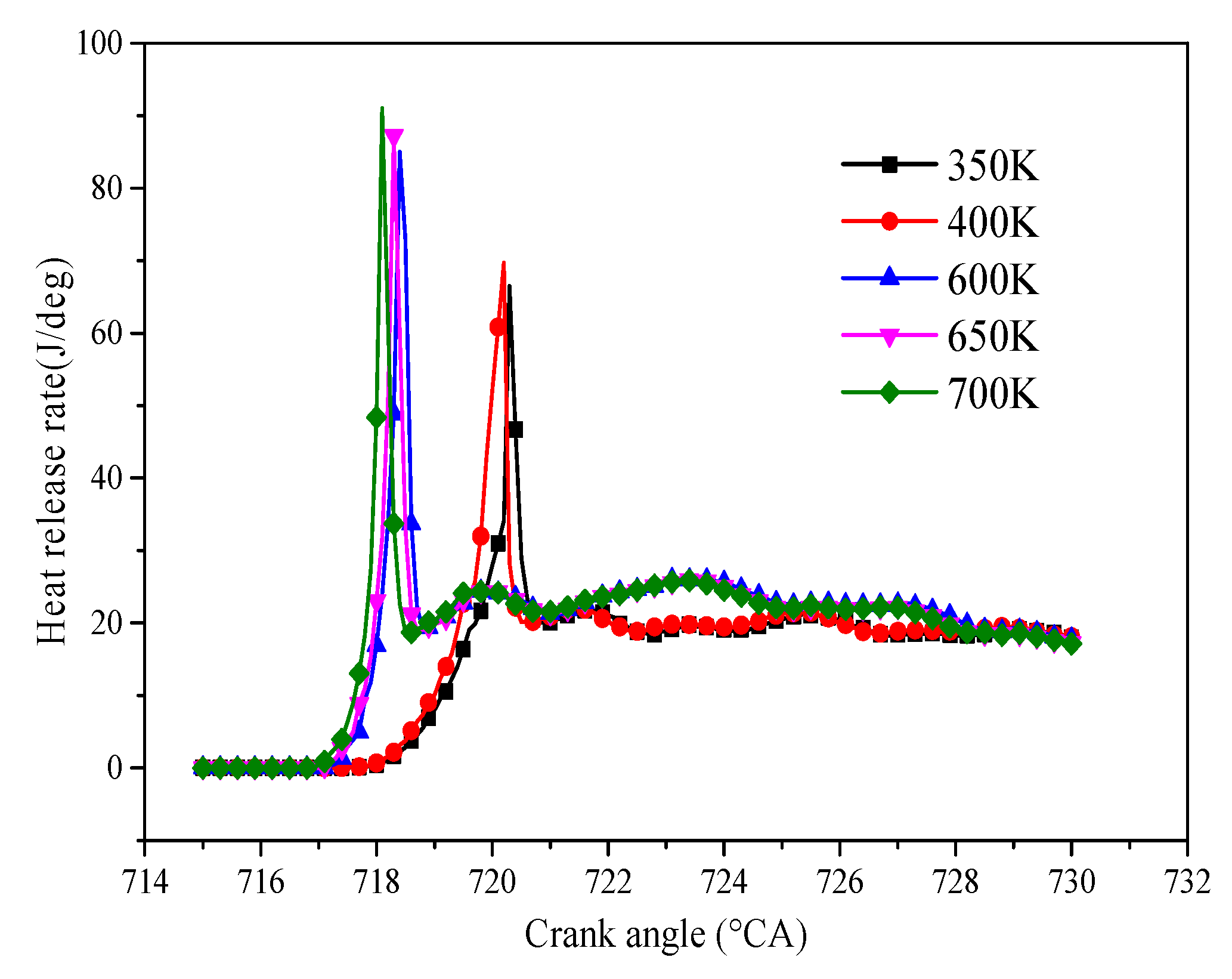

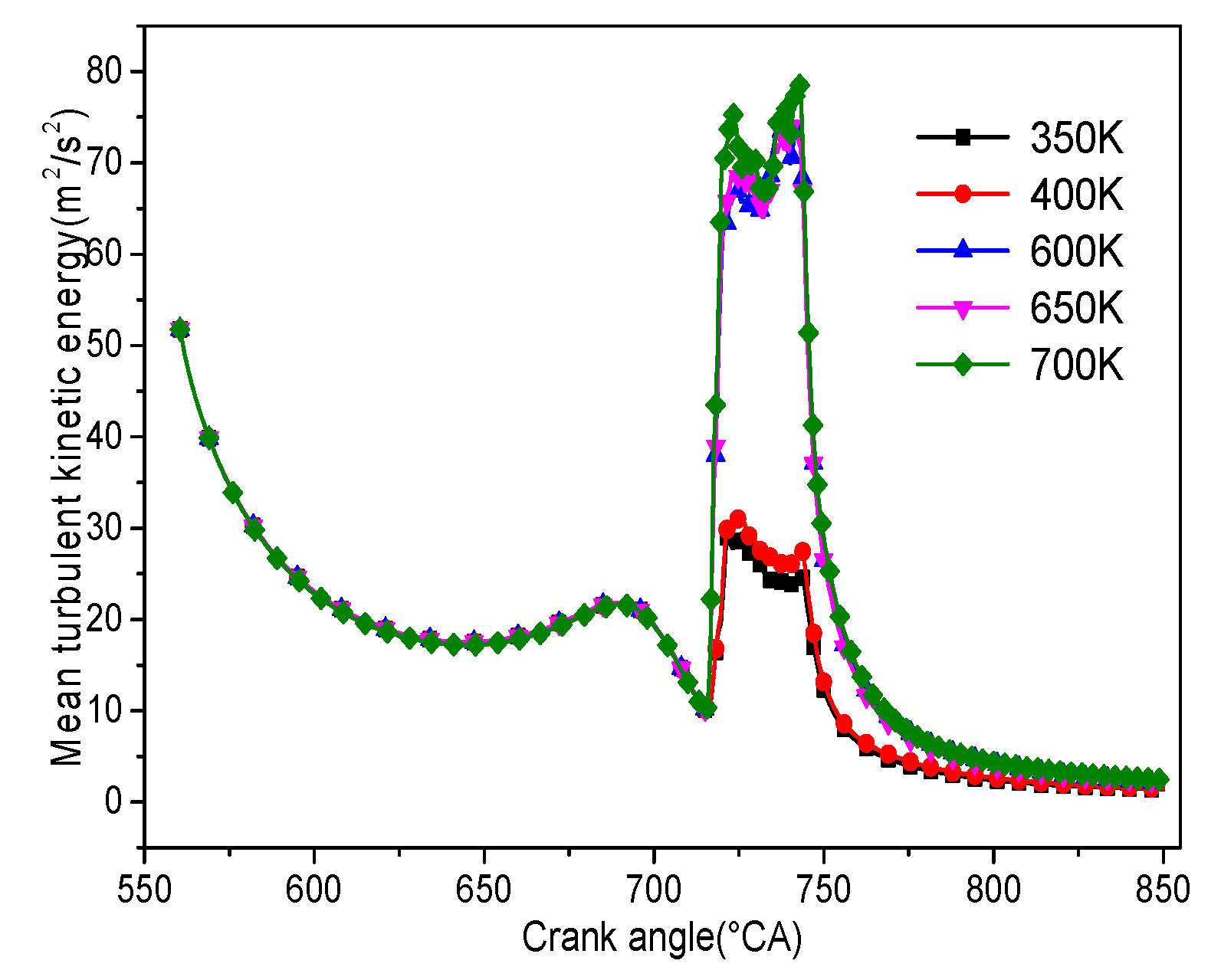

4.2. Comparison of In-Cylinder Turbulent Kinetic Energy under Engine Operation

4.3. Emission Performance Analysis

5. Conclusions

- (1)

- The ignition time is shorter and the peak temperature in the cylinder is achieved earlier in the supercritical fuel injection condition compared with the subcritical fuel injection condition. The rate of pressure increase and the peak value of the average pressure of the supercritical state fuel are significantly higher than those of the subcritical fuel.

- (2)

- The time to release heat in the supercritical fuel injection condition is shorter than that in the subcritical condition. The rate of heat release in the premixed combustion stage decreases, whereas that in the diffusion combustion stage increases with the increase in the fuel temperature in both conditions.

- (3)

- The velocity of the fluid is high in the supercritical state fuel injection condition. Hence, the eddy current of high-velocity flow is formed in the local area of the cylinder, resulting in a significant increase in turbulent energy after the fuel is injected into the cylinder.

- (4)

- NO emission increases and soot emission decreases under the supercritical condition compared with the subcritical condition.

Author Contributions

Funding

Conflicts of Interest

References

- SAE-China. Proceedings of the annual meeting of China automotive engineering society. SAECCE 2018, 6–8. [Google Scholar]

- Elfasakhany, A. Experimental study on emissions and performance of an internal combustion engine fueled with gasoline and gasoline/n-butanol blends. Energy Convers. Manag. 2014, 88, 277–283. [Google Scholar] [CrossRef]

- Buckeridge, D.L.; Glazier, R.; Harvey, B.J.; Escobar, M.; Amrhein, C.; Frank, J. Effect of motor vehicle emissions on respiratory health in an urban area. Environ. Health Perspect. 2002, 110, 293. [Google Scholar] [CrossRef] [PubMed]

- Iwamoto, Y.; Noma, K.; Nakayama, O.; Yamauchi, T.; Ando, H. Development of Gasoline Direct Injection Engine. SAE Tech. Pap. Ser. 1997, 106, 777–793. [Google Scholar]

- Katashiba, H.; Honda, T.; Kawamoto, M.; Sumida, M.; Fukutomi, N.; Kawajiri, K. Improvement of Center Injection Spray Guided DISI Performance. SAE Tech. Pap. Ser. 2006. [Google Scholar] [CrossRef]

- Binder, A.; Ecker, R.; Glaser, A.; Müller, K. Gasoline direct injection. In Gasoline Engine Management; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2015; pp. 110–111. [Google Scholar]

- Mohr, M.; Forss, A.-M.; Steffen, D. Particulate Emissions of Gasoline Vehicles and Influence of the Sampling Procedure. SAE Tech. Pap. Ser. 2000. [Google Scholar] [CrossRef]

- Zong, N.; Meng, H.; Hsieh, S.-Y.; Yang, V. A numerical study of cryogenic fluid injection and mixing under supercritical conditions. Phys. Fluids 2004, 16, 4248. [Google Scholar] [CrossRef]

- Piock, W.; Hoffmann, G.; Berndorfer, A.; Salemi, P.; Fusshoeller, B. Strategies Towards Meeting Future Particulate Matter Emission Requirements in Homogeneous Gasoline Direct Injection Engines. SAE Int. J. Engines 2011, 4, 1455–1468. [Google Scholar] [CrossRef]

- Mayer, W.; Schik, A.; Sch-aring, M.; Tamura, H. Injection and Mixing Processes in High-Pressure Liquid Oxygen/Gaseous Hydrogen Rocket Combustors. J. Propuls. Power 2012, 16, 823–828. [Google Scholar] [CrossRef]

- Anitescu, G.; Bruno, T.J.; Tavlarides, L.L. Dieseline for Supercritical Injection and Combustion in Compression-Ignition Engines: Volatility, Phase Transitions, Spray/Jet Structure, and Thermal Stability. Energy Fuels 2012, 26, 6247–6258. [Google Scholar] [CrossRef]

- Lin, R.; Tavlarides, L.L. Thermophysical properties needed for the development of the supercritical diesel combustion technology: Evaluation of diesel fuel surrogate models. J. Supercrit. Fluids 2012, 71, 136–146. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, V.; Dondapati, R.S.; Usurumarti, P.R. Analytical approximations for temperature dependent thermophysical properties of supercritical diesel fuel surrogates used in combustion modeling. Recent Adv. Fundam. Appl. Sci. 2017, 1860, 20056. [Google Scholar]

- Dondapati, R.S.; Usurumarti, P.R.; Kumar, A. Development of correlations for combustion modelling with supercritical surrogate jet fuels. Eng. Sci. Technol. Int. J. 2014, 20, 1676–1679. [Google Scholar] [CrossRef]

- Zheng, Z.; Liu, B.; Chen, Y. The physical properties of supercritical gasoline fuels and their alternative mixtures. J. Intern. Combust. Engines 2016, 1, 61–67. [Google Scholar]

- Song, Y.; Zheng, Z.; Xiao, J. Development and validation of a reduced chemical kinetic mechanism for supercritical gasoline of GDI engine. Fuel 2019, 241, 676–685. [Google Scholar] [CrossRef]

- Anitescu, G. Supercritical Fluid Technology Applied to the Production and Combustion of Diesel and Biodiesel Fuels. Ph.D. Thesis, Syracuse University, New York, NY, USA, 2008. [Google Scholar]

- Anitescu, G.; Tavlarides, L.L.; Geană, D. Phase Transitions and Thermal Behavior of Fuel−Diluent Mixtures. Energy Fuels 2009, 23, 3068–3077. [Google Scholar] [CrossRef]

- Tavlarides, L.L.; Antiescu, G. Supercritical Diesel Fuel Composition, Combustion Process and Fuel System. US Patent 7,488,357, 10 February 2009. [Google Scholar]

- De Boer, C.; Bonar, G.; Sasaki, S.; Shetty, S. Application of Supercritical Gasoline Injection to a Direct Injection Spark Ignition Engine for Particulate Reduction. SAE Tech. Pap. Ser. 2013. [Google Scholar] [CrossRef]

- Boer, C.D.; Chang, J.; Shetty, S. Transonic Combustion-A Novel Injection-Ignition System for Improved Gasoline Engine Efficiency. In Proceedings of the SAE 2010 Powertrains Fuels & Lubricants Meeting, Rio de Janeiro, Brazil, 25 October 2010; pp. 559–561. [Google Scholar]

- Zoldak, P.; De Boer, C.; Shetty, S. Transonic Combustion—Supercritical Gasoline Combustion Operating Range Extension for Low Emissions and High Thermal Efficiency. SAE Tech. Pap. Ser. 2012. [Google Scholar] [CrossRef]

- Canter, N. Tech Beat: Catalyst eliminates diesel NOx emissions. Tribol. Lubr. 2010, 63, 12–14. [Google Scholar]

- Le, J.; Wei, F.; Fan, Z. Numerical study on the influence of environmentand jet parameters on supercritical injection. Aerosp. Power 2014, 29, 1323–1329. [Google Scholar]

- Fan, Z.; Fan, W. Numerical simulation of the effects of flow parameters on supercritical injection. Aeronaut 2012, 34, 1018–1027. [Google Scholar]

- Fan, Z.; Fan, W.; Jin, L. Application of PR equation of state in the supercritical injection model. Aircr. Engine 2012, 41, 12–17. [Google Scholar]

- Zheng, Z.; Yang, Z. Numerical simulation of the influence of environmental and jet parameters on supercritical injection. Appl. Eng. 2017, 127, 925–932. [Google Scholar] [CrossRef]

- Polifke, W. Fundamental and Practical Limitations of NOX Reduction in Lean-Premixed Combustion. In Euro-Conference Premixed Turbulent Combustion: Introduction to the State of the Art; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Zeldovich, Y.B.; Sadovnikov, P.Y.; Frank-Kamenetskii, D.A. Oxidation of Nitrogen in Combustion; Publishing House of the Acad of Sciences of USSR: Leningrad, Russian, 1947. [Google Scholar]

- Nagle, J.; Strickland-Constable, R. Oxidation of Carbon between 1000–2000°C. In Proceedings of the Fifth Conference on Carbon; Elsevier BV: Amsterdam, The Netherlands, 1962; Volume 1, pp. 154–164. [Google Scholar]

- Zheng, Q. Experimental Study on Combustion Fundamental Theory and Control Strategy of Diesel Low-Temperature Combustion; Tianjin University: Tianjin, China, 2010. [Google Scholar]

- Shioji, M.; Kitazaki, M.; Mohammadi, A.; Kawasaki, K.; Eguchi, S. Knock Characteristics and Performance in an SI Engine with Hydrogen and Natural-Gas Blended Fuels. SAE Tech. Pap. Ser. 2004, 1–8. [Google Scholar] [CrossRef]

- Hua, Y.; Wang, Y.; Meng, H. Numerical Study on Turbulent Convective Heat Transfer with n-heptane Under Supercritical Pressures. J. Aeronaut. 2010, 1324–1330. [Google Scholar]

- Somers, M.L.; Mcclaine, J.W.; Wornat, M.J. The formation of polycyclic aromatic hydrocarbons from the supercritical pyrolysis of 1-methylnaphthalene. Proc. Combust. Inst. 2007, 31, 501–509. [Google Scholar] [CrossRef]

- Ren, B.; Wang, P.; Li, C. Chemical reaction technology and application on supercritical. Chem. Technol. 2003, 11, 45–48. [Google Scholar]

| Parameters | Values |

|---|---|

| Cylinder diameter × cylinder stroke, mm | 115 × 115 |

| Compression ratio | 16:1 |

| Connecting rod length, mm | 210 |

| Displacement, L | 1.2 |

| Combustion chamber shape | ω |

| Rotating speed, r·min−1 | 1800 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, Y.; Zheng, Z.; Peng, T.; Yang, Z.; Xiong, W.; Pei, Y. Numerical Investigation of the Combustion Characteristics of an Internal Combustion Engine with Subcritical and Supercritical Fuel. Appl. Sci. 2020, 10, 862. https://doi.org/10.3390/app10030862

Song Y, Zheng Z, Peng T, Yang Z, Xiong W, Pei Y. Numerical Investigation of the Combustion Characteristics of an Internal Combustion Engine with Subcritical and Supercritical Fuel. Applied Sciences. 2020; 10(3):862. https://doi.org/10.3390/app10030862

Chicago/Turabian StyleSong, Yukun, Zhaolei Zheng, Tao Peng, Zhanfeng Yang, Weidong Xiong, and Yiqiang Pei. 2020. "Numerical Investigation of the Combustion Characteristics of an Internal Combustion Engine with Subcritical and Supercritical Fuel" Applied Sciences 10, no. 3: 862. https://doi.org/10.3390/app10030862

APA StyleSong, Y., Zheng, Z., Peng, T., Yang, Z., Xiong, W., & Pei, Y. (2020). Numerical Investigation of the Combustion Characteristics of an Internal Combustion Engine with Subcritical and Supercritical Fuel. Applied Sciences, 10(3), 862. https://doi.org/10.3390/app10030862