5.2.1. The Comparative Experiment of the Improved Artificial Potential Field Method and the Rapidly-Exploring Random Tree* Method

Create a work environment for the pickup manipulator, set the initial point of the end-effector

= [1 cm, 18 cm], target point

= [60 cm, 60 cm], and the center of obstacle M = [50 cm, 50 cm] to conduct the simulation experiment in MATLAB. The improved artificial potential field method is adopted for obstacle avoidance planning to obtain the path points of the end-effector, and the results are showed in

Table 2. The rapidly-exploring Random Tree* (RRT*) method is adopted for obstacle avoidance planning to obtain the path points of the end-effector, and the results are showed in

Table 3.

Figure 12 shows the path point obtained by the improved artificial potential field method for obstacle avoidance planning. When the end-effector is not affected by obstacles, the improved artificial potential field method can plan a straight-line trajectory to reduce the running distance and improve the working efficiency of the pickup manipulator. When the manipulator is affected by obstacles, the improved artificial potential field method can plan the obstacle avoidance path and make the pickup manipulator successfully reach the target point. The minimum obstacle avoidance radius is 2.873 cm, and it can be found in

Table 2 at

P20.

Figure 13 shows the trajectory of the end-effector obtained by RRT* method for obstacle avoidance planning. Due to the randomness of the sampling of RRT* method, the generated path is often not the optimal path, which makes the manipulator run a longer distance. When the manipulator is affected by obstacles, the minimum obstacle avoidance radius is 11.566 cm, shown in

Table 2 at

P6 and is much higher than the improved artificial potential field method. That reduces the working efficiency of the manipulator.

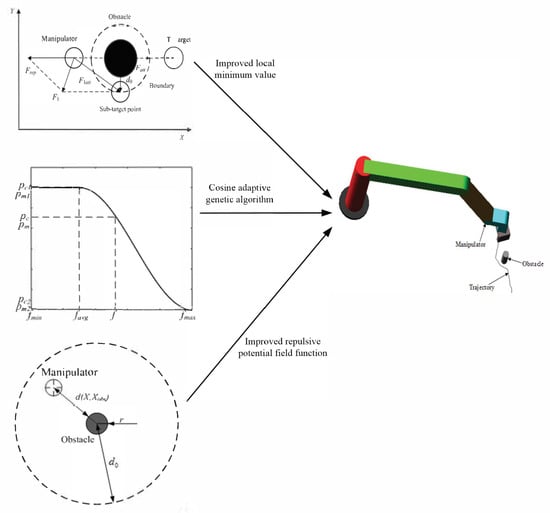

5.2.2. Simulation Experiment of the Improved Artificial Potential Field Method and Cosine Adaptive Genetic Algorithm

(1) General Obstacle Environment

Create a work environment for the pickup manipulator, set the initial point of the end-effector

= [59 cm, 0 cm, 15 cm], target point

= [45 cm, 20 cm, 0 cm], and the center of obstacle M = [53 cm, 10 cm, 20 cm] to conduct the simulation experiment in MATLAB. The improved artificial potential field method is adopted for obstacle avoidance planning to obtain the path points of the end-effector, and the results are showed in

Table 4. The established Kinematics model is used to calculate the joint angle, and the results are shown in

Table 5.

The primary selection of the running time between the path points is 2 s, and the established cosine adaptive genetic algorithm is used to optimize the time of the trajectory planning. The time optimization results of each joint at each path point are shown in

Table 6.

In order to ensure that every joint reaches the joint position, the longest running time of the joints is taken as the running time of the pickup manipulator. The time optimization results in the obstacle environment are shown in

Table 7.

According to the time optimization results in

Table 7, the running time of the pickup manipulator in each stage is shortened by 6.1%, 26.1%, 51.6%, 38.4%, 51.6%, 67.7%, 67.7%, 67.7%, and 70.6%, respectively. The overall time is shortened by 51.6%, and the optimization effect is obvious. Combine the joint angles in

Table 5 and the time optimization results of each path point in

Table 7 to conduct the motion simulation in ADAMS(Adams 2016, MSC, LA, America and 1963). Set the simulation time t = 8.72 s and the simulation step size = 200 for the simulation, and the results are shown in

Figure 14 and

Figure 15.

Figure 14 depicts the overall motion state of the pickup manipulator under the obstacle environment.

Figure 14a shows the initial state of the pickup manipulator under the obstacle environment. If the pickup manipulator moves in a straight line without obstacle avoidance planning, it will collide with the cylindrical obstacle.

Figure 14b shows the end state of the pickup manipulator. The running curve of the pickup manipulator is obtained by using the improved artificial potential field to avoid an obstacle in the obstacle environment and then using the cosine adaptive genetic algorithm to optimize the trajectory. It can be seen from the trajectory curve that the pickup manipulator can successfully avoid the obstacle and smoothly reach the target point along the path of the obstacle avoidance planning, and the trajectory optimization.

Figure 15 shows the displacement curve of the end-effector along each coordinate axes. It can be seen from

Figure 15 that the trajectory of the end-effector along the coordinate axes during the movement is continuous, without a large fluctuation phenomenon, and the motion law is reasonable. It proves the correctness of the theoretical derivation of the improved artificial potential field method and the cosine adaptive genetic algorithm.

(2) Obstacle Environment with the Problems of Local Minimum Value and Unreachable Target

Create a work environment with the problems of local minimum value and unreachable target for the pickup manipulator, set the initial point of the end-effector

= [60 cm, 0 cm, 15 cm], target point

= [45 cm, 10 cm, 15 cm], and the center of obstacle M = [49 cm, 6 cm, 16 cm] to conduct the simulation experiment in MATLAB. The improved artificial potential field method is adopted for obstacle avoidance planning to obtain the path points of the end-effector, and the results are showed in

Table 8.

The primary selection of the running time between the path points is 2 s, and the established cosine adaptive genetic algorithm is used to optimize the time of the trajectory planning. In order to ensure every joint reaches the joint position in the same time, the longest-running time of the joints is taken as the pickup manipulator running time. The time optimization results in the obstacle environment are shown in

Table 9.

According to the time optimization results in

Table 9, the running time of the pickup manipulator in each path point is respectively shortened by 27.11%, 37.38%, 51.08%, 58.42%, 52.52%, 50.59%, 68.69%, 54.5%, and 84.35%. The overall running time is shortened by 53.85%, and the optimization effect is obvious. Combine the path points in

Table 6 and the time optimization results of each path point in

Table 9 to conduct the motion simulation in ADAMS. Set the simulation time t = 8.31 s and the simulation step size = 200 for simulation, and the result is shown in

Figure 16.

Figure 16 shows the end state of the pickup manipulator. The running curve of the pickup manipulator is obtained by using an improved artificial potential field to avoid an obstacle in the obstacle environment and then using the cosine adaptive genetic algorithm to optimize the trajectory. It can be seen from the trajectory curve that the pickup manipulator can successfully avoid the obstacle and smoothly reach the target point along the path of obstacle avoidance planning and trajectory optimization.

Figure 17 shows the displacement curve of the end-effector along each coordinate axes. It can be seen from

Figure 17 that the trajectory of the end-effector along the coordinate axes is continuous, without large fluctuation. The issues of local minimum values and unreachable targets are solved, and the motion law is reasonable. It proves the correctness of the theoretical derivation of the the improved artificial potential field method and the cosine adaptive genetic algorithm.

According to the above two experimental results, the pickup manipulator can successfully avoid the obstacle and smoothly reach the target point along the path of obstacle avoidance planning and trajectory optimization. When the obstacle point is close to the target point, the improved artificial potential field method can avoid the end-effector swing between the obstacle point and the target point and solve the problem of the unreachable target. When the end-effector is in local minimum value, the improved artificial potential field method can make the end-effector jump out of the local minimum value quickly and solve the problem of the local minimum value of the artificial potential field method. Combining with the improved artificial potential field method and cosine adaptive genetic algorithm, the overall running time of the pickup manipulator is, respectively, reduced by 51.6% and 53.85%. During the movement, the trajectory of the end-effector is continuous, without large fluctuations.