Study on Properties of Waste Concrete Powder by Thermal Treatment and Application in Mortar

Abstract

:1. Introduction

2. Materials, Methods, and Procedure

3. Results

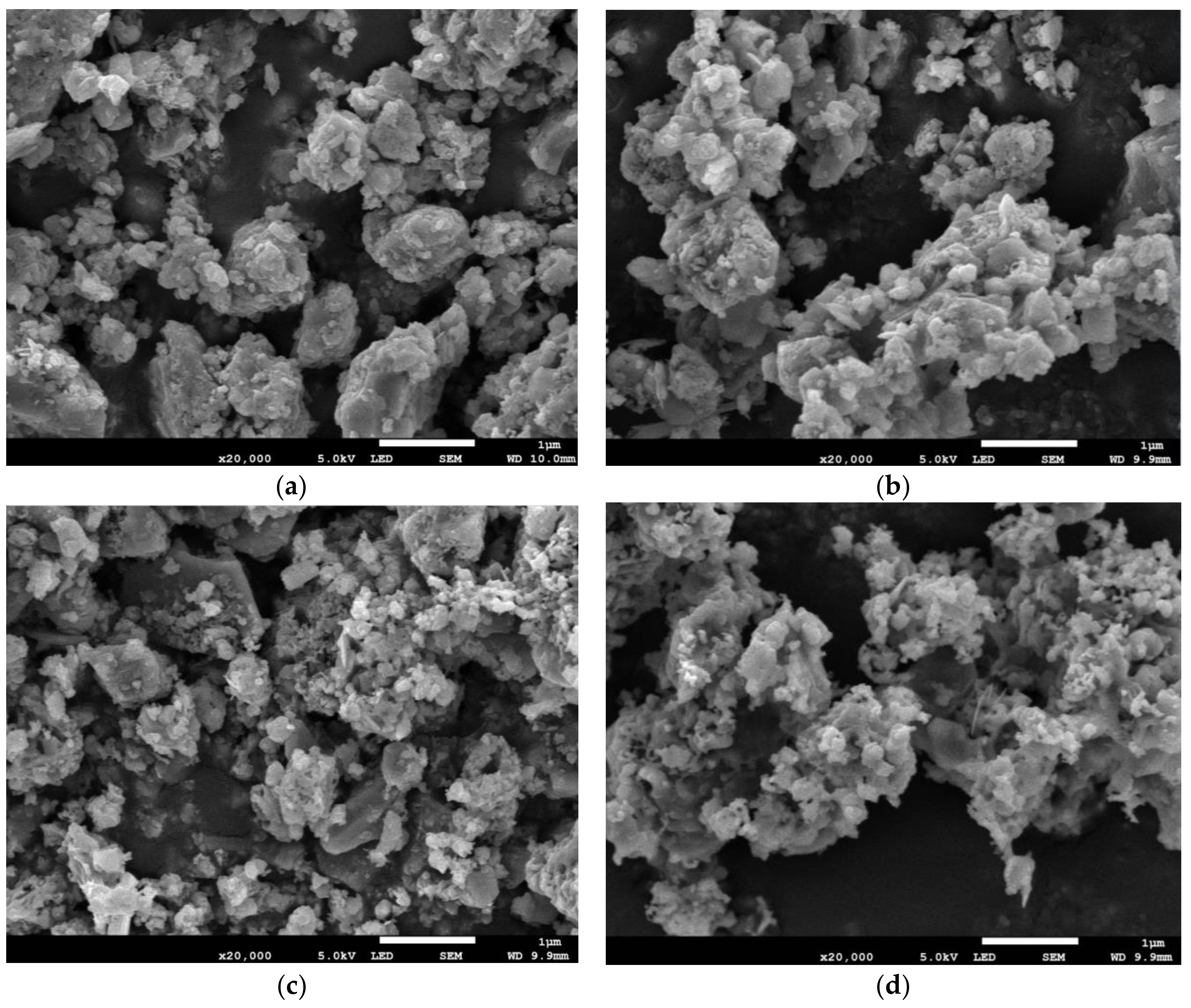

3.1. Properties of WCP by Thermal Treatment

3.2. Change of Activity Materials in WCP by the Thermal Treatment

3.3. Application of WCP in Mortar with the Replacement of Cement

4. Discussion

5. Conclusions

- (1)

- The particle size of waste concrete powder changed after heat treatments of 200 ℃, 400 ℃, 600 ℃, 700 ℃, and 800 ℃; the treatment of 700 ℃ decreased the particle size of WCP; and its D90 size was reduced by 55% with comparison to the original WCP.

- (2)

- More mass loss and free calcium oxide generation in WCP occurred after the heat treatment in 800 ℃; furthermore, some active materials in WCP treated at 800 ℃ were determined by XRD detection.

- (3)

- The activity index (AI), which was measured by the ratio of mechanical strengths between the mortar with 30% replacement of cement by WCP to those of the original mortar, demonstrated that the WCP treated at 700 ℃ could be used in concrete as an admixture.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Linss, E. Untersuchungen zur Leistung Schallimpulszerkleinerung fuer die selective Aufbereitung von Beton. Master’s Thesis, Bauhaus-Universität Weimar, Weimar, Germany, 2008. [Google Scholar]

- Sáez del Bosque, I.F.; van den Heede, P.; de Belie, N.; Sánchez de Rojas, M.I.; Medina, C. Carbonation of concrete with construction and demolition waste based recycled aggregates and cement with recycled content. Constr. Build. Mater. 2020, 234, 117336. [Google Scholar] [CrossRef]

- Bendimerad, A.Z.; Delsaute, B.; Rozière, E.; Staquet, S.; Loukili, A. Advanced techniques for the study of shrinkage-induced cracking of concrete with recycled aggregates at early age. Constr. Build. Mater. 2020, 233, 117340. [Google Scholar] [CrossRef]

- Sui, Y.; Mueller, A. Development of thermo-mechanical treatment for recycling of used concrete. Mater. Struct. 2012, 45, 1487–1495. [Google Scholar] [CrossRef]

- Lu, B.; Shi, C.; Zhang, J.; Wang, J. Effects of carbonated hardened cement paste powder on hydrationand microstructure of Portland cement. Constr. Build. Mater. 2018, 186, 699–708. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, J.; Cao, D.; Dang, H.; Ding, B. Comparison of recycled aggregate treatment methods on the performance for recycled concrete. Constr. Build. Mater. 2020, 234, 117366. [Google Scholar] [CrossRef]

- Wang, J.; Mu, M.; Liu, Y. Recycled cement. Constr. Build. Mater. 2018, 190, 1124–1132. [Google Scholar] [CrossRef]

- Xuan, D.X.; Shui, Z.H. Rehydration activity of hydrated cement paste exposed to high temperature. Fire Mater. 2011, 35, 481–490. [Google Scholar] [CrossRef]

- Shui, Z.; Xuan, D.; Chen, W.; Yu, R.; Zhang, R. Cementitious characteristics of hydrated cement paste subjected to various dehydration temperatures. Constr. Build. Mater. 2009, 23, 531–537. [Google Scholar] [CrossRef]

- Splittgerber, F.; Mueller, A. Identification of the Type of Cement in Hardened Concrete and Mortars. In International Conference on Construction Hong Kong 2001; Conference Proceeding Volume One; Institution of Civil Engineers: London, UK, 2001; pp. 143–154. [Google Scholar]

- Farzam, H.; Bolin, G.; Hove, R.H.; Marin, J.; Erlin, B.J.; Isabelle, H.L.; Mather., B.; Gibbe, F.K.; Kaetzel, H.L.; Meseguer, A.G.; et al. Cement and Concrete Terminology Reported by ACI Committee 116; American Concrete Institute: Farmington Hills, MI, USA, 2000. [Google Scholar]

- Mateusz, P.; Lukasz, S. Selected physical properties of concrete modified using mineral powders. Procedia Eng. 2017, 172, 891–896. [Google Scholar]

- JG/T 486. Compound Mineral Admixtures for Concrete; Ministry of Housing and Urban-Rural Construction of the People’s Republic of China: Beijing, China, 2016. (In Chinese) [Google Scholar]

- Aliabdo, A.A.; Elmoaty, M.A.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Donatello, S.; Cheeseman, M.; Tyrer, C.R. Comparison of test methods to assess pozzolanic activity. Cem. Conc. Comp. 2010, 32, 121–127. [Google Scholar] [CrossRef] [Green Version]

- BS EN 196-5:2011. Methods of Testing Cement-Part 5: Pozzolanicity Test for Pozzolanic Cement; British Standards Institution: London, UK, 2011. [Google Scholar]

- Kim, Y.J.; Choi, Y.W. Utilization of waste concrete powder as a substitution material for cement. Constr. Build. Mater. 2012, 30, 500–504. [Google Scholar] [CrossRef]

- Bordy, A.; Younsi, A.; Aggoun, S.; Fiorio, B. Cement substitution by a recycled cement paste fine: Role of the residual anhydrous clinker. Constr. Build. Mater. 2017, 132, 1–8. [Google Scholar] [CrossRef]

- Zhu, P.; Mao, X.; Qu, W.; Li, Z.; Ma, Z.J. Investigation of using recycled powder from waste of clay bricks and cement solids in reactive powder concrete. Constr. Build. Mater. 2016, 113, 246–254. [Google Scholar] [CrossRef]

- Schneider, U.; Herbst, H.-J. Permeabilitaet und Porositaet von Beton bei hohen Temperaturen. In Deutscher Ausschuss fuer Stahlbeton; Beuth Verlag GmbH: Berlin, Germany, 1989. [Google Scholar]

- Schneider, U. Verhalten von Beton bei hohen Temperaturen. Deutscher Ausschuss fuer Stahlbeton; Verlag von Wilhelm & Sohn: Berlin, Germany, 1982. [Google Scholar]

- Wolf, G. Untersuchung Ueber das Temperaturverhalten eines Tunnelbetons mit spezieller Gesteinskoenung. Master’s Thesis, Technische Universitaet Wien, Vienna, Austria, 2004. [Google Scholar]

- GB/T17671. Method of Testing Cements-Determination of Strength; Chinese national bureau of quality supervision: Beijing, China, 1999. [Google Scholar]

- GB/T 21372. Portland Cement Clinker; Chinese National Bureau of Quality Supervision: Beijing, China, 2008. [Google Scholar]

- Dora, B. Hydraulisch Erhaertende Baustoffe Aus Betonbrechsand, Phasenaenderung Durch Temperaturebehandlung Und Einsatzmoeglichkeit. In Master’s Thesis; TU Braunschweig: Braunschweig, Germany, 2001. [Google Scholar]

- Zhang, Q.; Guang, Y.; Eduard, K. Investigation of the structure of heated Portland cement paste by using various techniques. Constr. Build. Mater. 2013, 38, 1040–1050. [Google Scholar] [CrossRef]

- Berodier, E.; Scrivener, K. Understanding the Filler Effect on the Nucleation and Growth of C-S-H. J. Am. Ceram. Soc. 2014, 97, 3764–3773. [Google Scholar] [CrossRef]

| CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | Na2O | SO3 | P2O5 | Loss | |

|---|---|---|---|---|---|---|---|---|---|---|

| WCP | 56.75 | 20.50 | 8.42 | 3.99 | 3.84 | 1.08 | 0.49 | 3.49 | 0.13 | 1.04 |

| Cement | 58.14 | 20.65 | 8.62 | 3.13 | 3.33 | 0.63 | 0.21 | 3.95 | 0.18 | 1.16 |

| Samples | Cement | WCP | Standard Sand | Water | W/C | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| g | g | g | g | / | ||||||

| Thermal Treatment (℃) | ||||||||||

| 0 | 200 | 400 | 600 | 700 | 800 | |||||

| E-0 | 450 | 1350 | 225 | 0.5 | ||||||

| E-1 | 315 | 135 | ||||||||

| E-2 | 135 | |||||||||

| E-3 | 135 | |||||||||

| E-4 | 135 | |||||||||

| E-5 | 135 | |||||||||

| E-6 | 135 | |||||||||

| Day | Activity of Compound Mineral Admixtures for Concrete | |||

|---|---|---|---|---|

| Class Ⅰ | Class Ⅱ | Class Ⅲ | ||

| AI (%) | 7 | ≥80 | ≥70 | ≥65 |

| 28 | ≥90 | ≥75 | ≥70 | |

| Day | Reference Mortar | Replacement 30% | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 ℃ | 200 ℃ | 400 ℃ | 600 ℃ | 700 ℃ | 800 ℃ | |||

| Flexible strength (MPa) | 3 | 5.44 | 3.58 | 3.33 | 3.66 | 3.81 | 4.91 | 3.96 |

| 7 | 7.27 | 4.43 | 5.72 | 6.52 | 5.15 | 6.42 | 5.36 | |

| 28 | 8.79 | 4.63 | 6.18 | 7.06 | 5.89 | 6.83 | 6.23 | |

| Compressive strength (MPa) | 3 | 29.41 | 17.68 | 14.34 | 14.97 | 16.68 | 23.71 | 17.53 |

| 7 | 46.82 | 25.16 | 26.20 | 29.92 | 23.16 | 33.43 | 28.44 | |

| 28 | 55.34 | 41.91 | 38.98 | 42.64 | 39.82 | 47.71 | 36.98 | |

| Day | Reference Mortar | Replacement 30% | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 ℃ | 200 ℃ | 400 ℃ | 600 ℃ | 700 ℃ | 800 ℃ | |||

| AI of flexible strength (%) | 3 | 100 | 65.8 | 61.2 | 67.3 | 70.0 | 90.0 | 72.8 |

| 7 | 100 | 60.9 | 78.7 | 89.7 | 70.8 | 88.3 | 73.7 | |

| 28 | 100 | 52.7 | 70.3 | 80.3 | 67.0 | 77.7 | 70.9 | |

| AI of compressive strength (%) | 3 | 100 | 60.1 | 48.8 | 50.9 | 56.7 | 80.6 | 59.6 |

| 7 | 100 | 53.7 | 56.0 | 63.9 | 49.5 | 71.4 | 60.7 | |

| 28 | 100 | 75.7 | 70.4 | 73.5 | 72.0 | 86.2 | 66.8 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sui, Y.; Ou, C.; Liu, S.; Zhang, J.; Tian, Q. Study on Properties of Waste Concrete Powder by Thermal Treatment and Application in Mortar. Appl. Sci. 2020, 10, 998. https://doi.org/10.3390/app10030998

Sui Y, Ou C, Liu S, Zhang J, Tian Q. Study on Properties of Waste Concrete Powder by Thermal Treatment and Application in Mortar. Applied Sciences. 2020; 10(3):998. https://doi.org/10.3390/app10030998

Chicago/Turabian StyleSui, Yuwu, Chuping Ou, Shu Liu, Jinshuai Zhang, and Qingbo Tian. 2020. "Study on Properties of Waste Concrete Powder by Thermal Treatment and Application in Mortar" Applied Sciences 10, no. 3: 998. https://doi.org/10.3390/app10030998

APA StyleSui, Y., Ou, C., Liu, S., Zhang, J., & Tian, Q. (2020). Study on Properties of Waste Concrete Powder by Thermal Treatment and Application in Mortar. Applied Sciences, 10(3), 998. https://doi.org/10.3390/app10030998