Methodology of Employing Exoskeleton Technology in Manufacturing by Considering Time-Related and Ergonomics Influences

Abstract

:1. Introduction

2. Problem Statement and Motivation

3. Methodology for the Integration of Exoskeleton Technology in Manufacturing Workplaces

3.1. Challenges and Specific Requirements for Integration of Exoskeletons in Industry

3.2. Classification of Smart Adaptive Exoskeletons for Their Deployment in Manufacturing

- General: number, priority, state of experience, etc.;

- Technical features: active/passive, power support, weight, size, material, storage, etc.;

- Compatibility: scratching, hygiene, etc.;

- Legal: conformity, occupational safety, instructions, etc.;

- Specific pro and cons: cheap, light, robust, etc.;

- Costs: acquirement, maintenance, service, training, etc.

- Project state: number, priority, processing state, etc.;

- Workplace: description, contact, location, additional tasks, required tools, etc.;

- Ergonomics: load, weight (time and attitude), etc.;

- Environment: organization, division, access ways, escape exits, stairs, etc.

3.3. Holistic Impacts by Integrating Exoskeleton Technology in Manufacturing

4. Ergonomic Assessment of Human-Centred Workplaces with Integrated Exoskeleton Technology

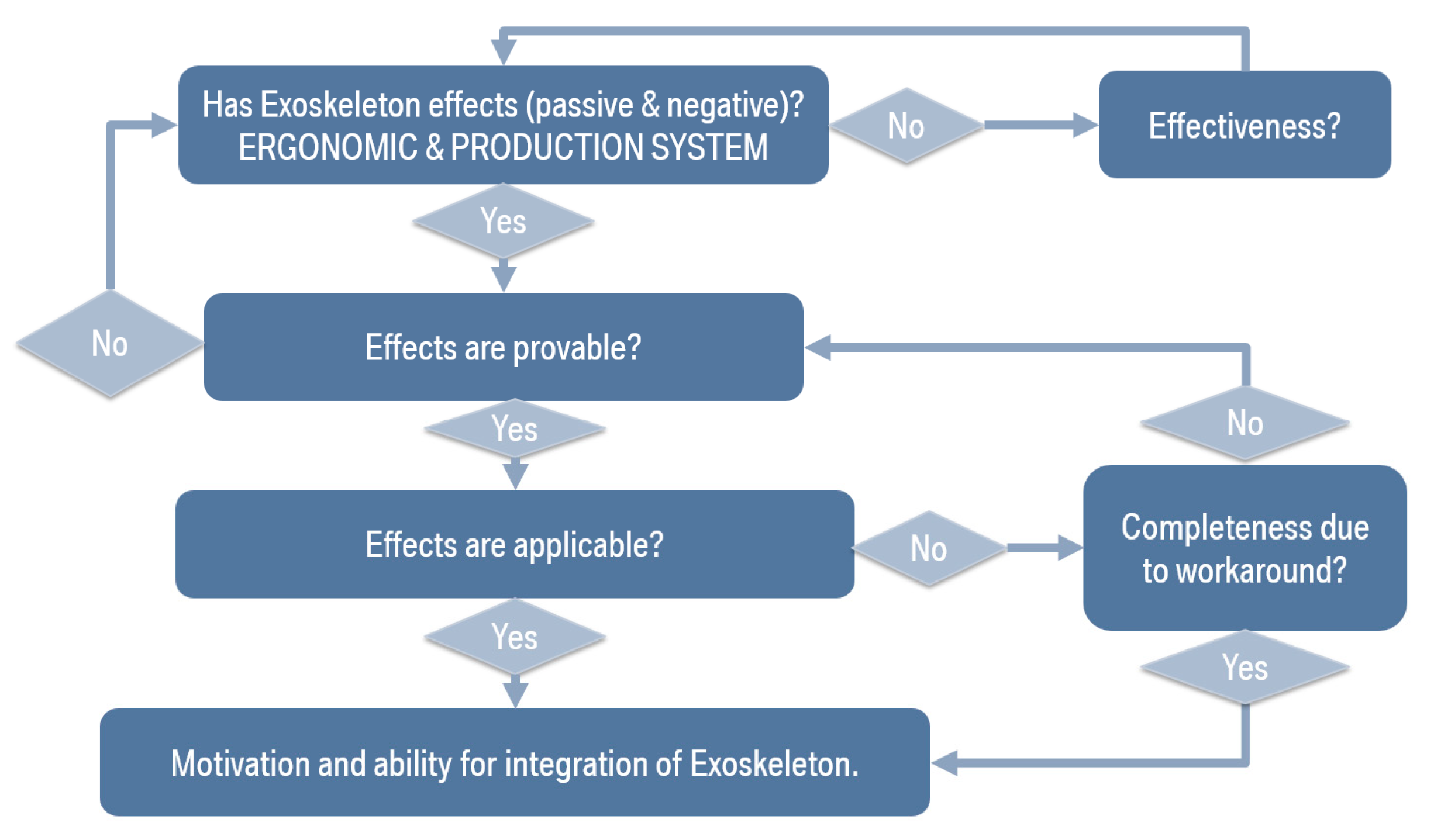

4.1. Chain of Reasoning of Ergonomic Assessment

4.2. Review of Studies Regarding Exoskeleton Ergonomics

4.3. Assessment Requirements and Selected Methods Based on Manufacturing Needs

4.4. Exemplarily Workplace with Integrated Exoskeleton

5. Production Impacts of Exoskeletons in Manufacturing, Especially “Time Management”

5.1. Impact from Time-Management Perspective

5.2. Exoskeleton “Wear/Unwear” Times Experiments and Evaluation

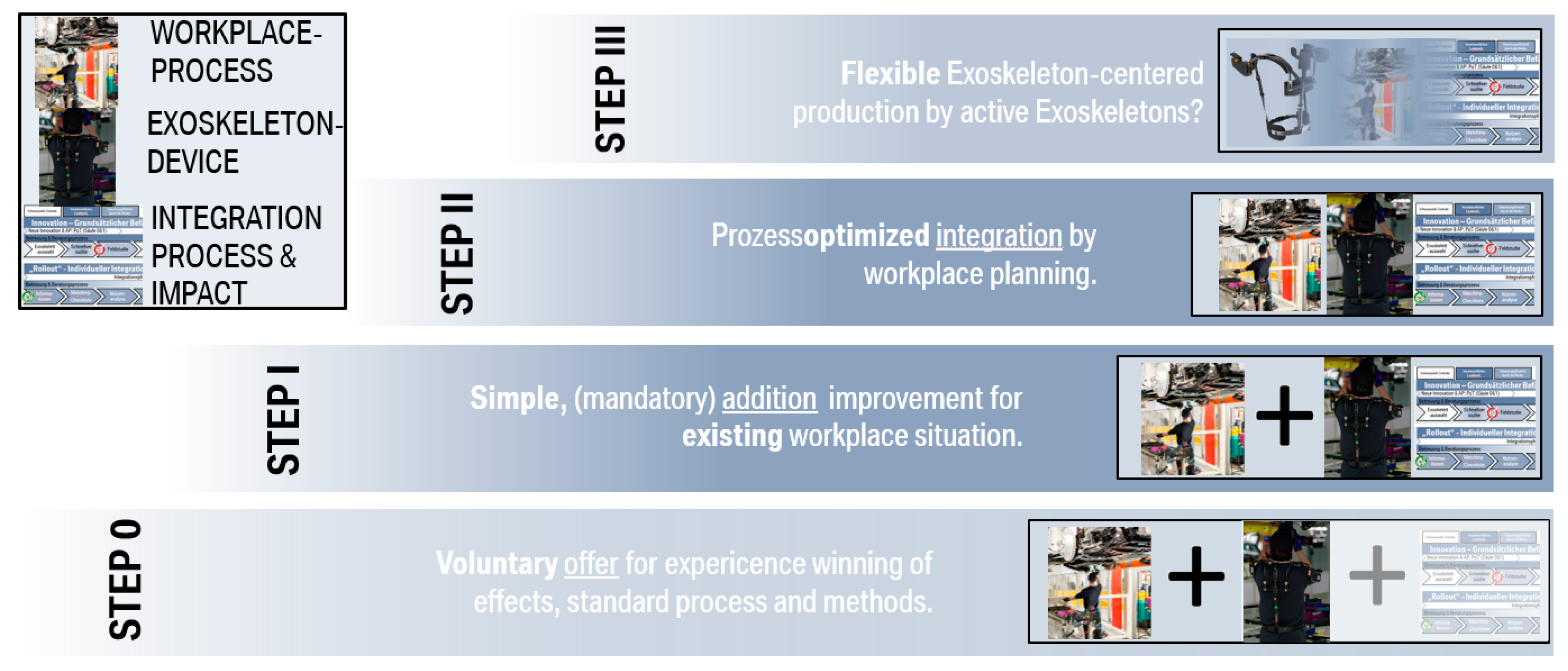

6. Roadmap for Optimized Integration of Exoskeleton

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dahmen, C.; Wöllecke, F.; Constantinescu, C. Challenges and Possible Solutions for Enhancing the Workplaces of the Future by Integrating Smart and Adaptive Exoskeletons. In Proceedings of the 11th CIRP Conference on Intelligent Computation in Manufacturing Engineering—CIRP ICME 17, Naples, Italy, 19–21 July 2017. [Google Scholar]

- Dahmen, C.; Hölzel, C.; Wöllecke, F.; Constantinescu, C. Approach of Optimized Planning Process for Exoskeleton Centered Workplace Design. In Proceedings of the 51st CIRP Conference on Manufacturing Systems, Stockholm, Sweden, 16–18 May 2018. [Google Scholar]

- Dahmen, C.; Hefferle, M. Application of Ergonomic Assessment Methods on an Exoskeleton Centered Workplace. In Proceedings of the XXXth Annual Occupational Ergonomics and Safety Conference, Pittsburgh, PA, USA, 7–8 June 2018. [Google Scholar]

- Dahmen, C.; Constantinescu, C. Methodology for Evaluation of the Time-Management impact of Exoskeleton-centred workplaces. Tech. Univ. Cluj Napoca Acta Tech. Napoc. 2018, 55–58. [Google Scholar]

- Marinov, B.; Dao, T. Exoskeleton Report. Available online: http://exoskeletonreport.com/ (accessed on 8 March 2017).

- Bräunig, D.; Kohstall, T. Berechnung des internationalen “Return on Prevention” für Unternehmen—Kosten und Nutzen von Investitionen in den betrieblichen Arbeits- und Gesundheitsschutz. DGUV Rep. 2013, 1, 34–38. [Google Scholar]

- Bungard, S.; Hertle, D.; Kliner, K.; Lüken, F.; Tewes, C.; Trümmer, A. Gesundheit in Bewegung—Gesundheit in Bewegung: Schwerpunkt Muskel- und Skeletterkrankungen. BKK Gesundh. 2013, 1, 16–22. [Google Scholar]

- Bevan, S.; Davies, C. The Impact of Back Pain on Sickness Absence in Europe. Work Found. 2012, 1, 3–4. [Google Scholar]

- Accelopment AG. RoboMate. Available online: http://www.robo-mate.eu/ (accessed on 8 March 2017).

- Constantinescu, C.; Mureșan, P.C.; Gînța, S.M.; Todorovic, O. Modelling and simulation of advanced factory environments integrating intelligent exoskeleton. Int. Conf. Prod. Res. 2014, 3, 109–114. [Google Scholar]

- Constantinescu, C.; Muresan, P.-C.; Simon, G.-M. JackEx: The New Digital Manufacturing Resource for Optimization of Exoskeleton-based Factory Environments. Procedia CIRP 2016, 26, 508–511. [Google Scholar] [CrossRef]

- Chase, B. The LevitateTM Difference—Analysis of the LevitateTM Personal Lift Assist Device (PLAD) During Various Physical Work-Related Tasks. White Pap. 2015, 1, 1–11. [Google Scholar]

- Constantinescu, C.; Popescu, D.; Muresan, P.-C.; Stana, S.-I. Exoskeleton-centered Process Optimization in Advanced Factory Environments. Procedia CIRP 2015, 48, 740–745. [Google Scholar] [CrossRef]

- Constantinescu, C.; Popescu, D.; Muresan, P.; Todorovic, O. Optimisation of advanced manufacturing environments with integrated intelligent Exoskeletons. Int. Conf. Prod. Res. 2016, 4, 1–6. [Google Scholar]

- Weidner, R.; Redlich, T.; Wulfsberg, J.P. Technische Unterstützungssysteme, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- Westkämper, E.; Constantinescu, C.; Lentes, J.; Spath, D. Digitale Produktion, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Østergaard, E.H. Human-robot collaboration in the age of industry 4.0—How process automation becomes a child’s play for SMEs. Präsentation 2015, 1, 8–32. [Google Scholar]

- VDI Wissensforum. Assistenzroboter in der Produktion 2015—Mensch-Roboter-Kollaboration im Industriealltag—Mensch, Roboter & Sicherheit: Wie Industrieroboter gefahrlos mit dem Menschen kollaborieren. VDI Wissensforum 2015, 2, 1–4. [Google Scholar]

- Deutsche Gesetzliche Unfallversicherung e.V. Fragen und Antworten zum Thema Exoskelette. Available online: http://www.dguv.de/fbhl/sachgebiete/physische-belastungen/faq_exo/index.jsp (accessed on 18 April 2017).

- Becker, T. Prozesse in Produktion und Supply Chain Optimieren, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Levitate Technologies Inc. Levitate Device—Personal-body worn—Performance enhancement. Technol. Overv. 2016, 1, 1–4. [Google Scholar]

- Stadler, K.S.; Elspass, W.J.; van de Venn, H.W. Mobile Service Robotics: CLAWAR 2014—Robo-Mate: Exoskeleton to Enhance Industrial Production, 1st ed.; World Scientific Publishing Co. Pte. Ltd.: Singapore, 2014. [Google Scholar]

- De Looze, M.P.; Bosch, T.; Krause, F.; Stadler, K.S.; O’Sullivan, L.W. Exoskeletons for industrial application and their potential effects on physical work load. Ergonomics 2016, 59, 671–681. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sylla, N.; Bonnet, V.; Colledani, F.; Fraisse, P. Ergonomic contribution of ABLE exoskeleton in automotive industry. Int. J. Ind. Ergon. 2014, 44, 475–481. [Google Scholar] [CrossRef]

- Ulrey, B.L.; Fathallah, F.A. Subject-specific, whole-body models of the stooped posture with a personal weight transfer device. J. Electromyogr. Kinesiol. 2013, 23, 206–215. [Google Scholar] [CrossRef]

- Weston, E.B.; Alizadeh, M.; Knapik, G.G.; Wang, X.; Marras, W.S. Biomechanical evaluation of exoskeleton use on loading of the lumbar spine. Appl. Ergon. 2018, 68, 101–108. [Google Scholar] [CrossRef]

- Spada, S.; Ghibaudo, L.; Gilotta, S.; Gastaldi, L.; Cavatorta, M.P. Analysis of Exoskeleton Introduction in Industrial Reality: Main Issues and EAWS Risk Assessment. Adv. Phys. Ergon. Hum. Factors 2017, 1, 236–244. [Google Scholar]

- Rashedi, E.; Kim, S.; Nussbaum, M.A.; Agnew, M.J. Ergonomic evaluation of a wearable assistive device for overhead work. Ergonomics 2014, 57, 1864–1874. [Google Scholar] [CrossRef]

- Peter, F.; Tropschuh, B.H. Taktgeber für Arbeitsplatzergonomie in der Industrie; UmweltDialog—Wirtschaft; Verantwortung; Nachhaltigkeit. 2015. Available online: https://www.umweltdialog.de/de/wirtschaft/arbeitsbedingungen/2018/Taktgeber-fuer-Arbeitsplatzergonomie-in-der-Industrie.php (accessed on 20 January 2020).

- Rosemarie, P. Mit klassischen gesundheitsfördernden Maßnahmen und neuesten Technologien ist das BMW Group Werk Steyr für den demografischen Wandel gerüstet. In Sichere Arbeit: Internationales Fachmagazin für Prävention in der Arbeitswelt; 2017; Available online: http://www.sicherearbeit.at/cms/X04/X04_1.8.6.a/1342585867168/archiv/html-archiv-2017/sichere-arbeit-6-2017/bmw-vorsorge-heute-fuer-morgen (accessed on 20 January 2020).

- Butler, T. Exoskeleton Technology—Making Workers Safer and More Productive. Am. Soc. Saf. Eng. ASSE 2016, 61, 32–36. [Google Scholar]

- Bosch, T.; van Eck, J.; Knitel, K.; Looze, M. The effects of a passive exoskeleton on muscle activity, discomfort and endurance time in forward bending work. Appl. Ergon. 2016, 1, 212–217. [Google Scholar] [CrossRef]

- Spada, S.; Ghibaudo, L.; Gilotta, S.; Gastaldi, L.; Cavatorta, M.P. Investigation into the Applicability of a Passive Upper-limb Exoskeleton in Automotive Industry. Procedia Manuf. 2017, 27, 1255–1262. [Google Scholar] [CrossRef]

- BGHM. Einsatz von passiven Exoskeletten an (gewerblichen) Arbeitsplätzen der Automobilindustrie. In Fach-Information: BGHM FAQ-Liste 05/2017; BGHM: Mainz, Germany, 2017; pp. 1–5. [Google Scholar]

- Abdoli-E, M.; Agnew, M.J.; Stevenson, J.M. An on-body personal lift augmentation device (PLAD) reduces EMG amplitude of erector spinae during lifting tasks. Clin. Biomech. 2006, 5, 456–465. [Google Scholar] [CrossRef] [PubMed]

- Godwin, A.A.; Stevenson, J.M.; Agnew, M.J.; Twiddy, A.L.; Abdoli-Eramaki, M.; Lotz, C.A. Testing the efficacy of an ergonomic lifting aid at diminishing muscular fatigue in women over a prolonged period of lifting. Int. J. Ind. Ergon. 2009, 1, 121–126. [Google Scholar] [CrossRef]

- REFA Bundesverband E.V. Leistungsgradbeurteilung—Lehrunterlage zu Modul 3210248, 1st ed.; REFA: Darmstadt, Germany, 2003. [Google Scholar]

- REFA. Durchführen und Auswerten von Zeitaufnahmen—Lehrunterlage zu Modul 3210251, 1st ed.; REFA-Fachbuchreihe Unternehmensentwicklung: Darmstadt, Germany, 2006. [Google Scholar]

- PR—Prävention Aktuell. Das STOP-PRINZIP. Available online: https://praevention-aktuell.de/das-stop-prinzip/ (accessed on 5 July 2018).

| Method | Without Exoskeleton | With Exoskeleton |

|---|---|---|

| EAWS TB | 61: High risk—Design measures are necessary. | 66: High—Design measures |

| EAWS UB | 78: High risk—Design measures are necessary | 44.5: Potential risk—Design measures. |

| KIM MA | 72.5: very high strain: measures are necessary. | 67.5: High strain: design measures |

| REBA | 4: Medium risk. Further, investigate. | 3: Low risk. Change may be needed. |

| RULA | 7: Very high risk, implement change now | 6: Medium risk, further investigation |

| Exo | Type | Wear/Unwear | Standard Deviation | Relative Confidence Interval |

|---|---|---|---|---|

| 1 | Overhead V1 | 37 s | 1.19 s | 2.3 |

| 2 | Overhead V2 | 87 s | 5.5 s | 4.4 |

| 3 | Bending V1 | 20.3 s | 1.19 s | 4 |

| 4 | Bending V2 | 66.3 s | 4.98 s | 7 |

| 5a | Sitting V1 | 52.6 s | 3.07 s | 4.1 |

| 5b | Sitting V2 | 37.8 s | 3.26 s | 6.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dahmen, C.; Constantinescu, C. Methodology of Employing Exoskeleton Technology in Manufacturing by Considering Time-Related and Ergonomics Influences. Appl. Sci. 2020, 10, 1591. https://doi.org/10.3390/app10051591

Dahmen C, Constantinescu C. Methodology of Employing Exoskeleton Technology in Manufacturing by Considering Time-Related and Ergonomics Influences. Applied Sciences. 2020; 10(5):1591. https://doi.org/10.3390/app10051591

Chicago/Turabian StyleDahmen, Christian, and Carmen Constantinescu. 2020. "Methodology of Employing Exoskeleton Technology in Manufacturing by Considering Time-Related and Ergonomics Influences" Applied Sciences 10, no. 5: 1591. https://doi.org/10.3390/app10051591

APA StyleDahmen, C., & Constantinescu, C. (2020). Methodology of Employing Exoskeleton Technology in Manufacturing by Considering Time-Related and Ergonomics Influences. Applied Sciences, 10(5), 1591. https://doi.org/10.3390/app10051591