Development of a DSP Microcontroller-Based Fuzzy Logic Controller for Heliostat Orientation Control

Abstract

:1. Introduction

2. Heliostat Orientation Control

2.1. DC Motor Mathematical Model

2.2. Control Algorithms

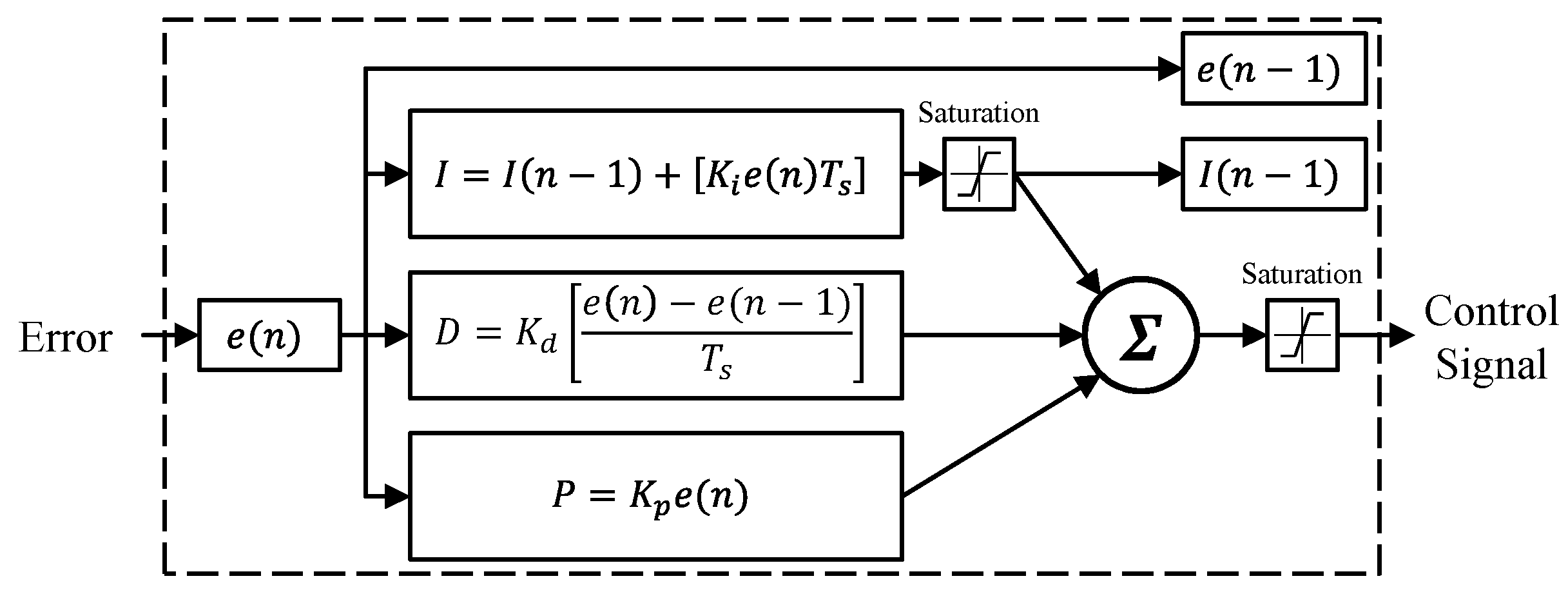

2.2.1. PID Controller

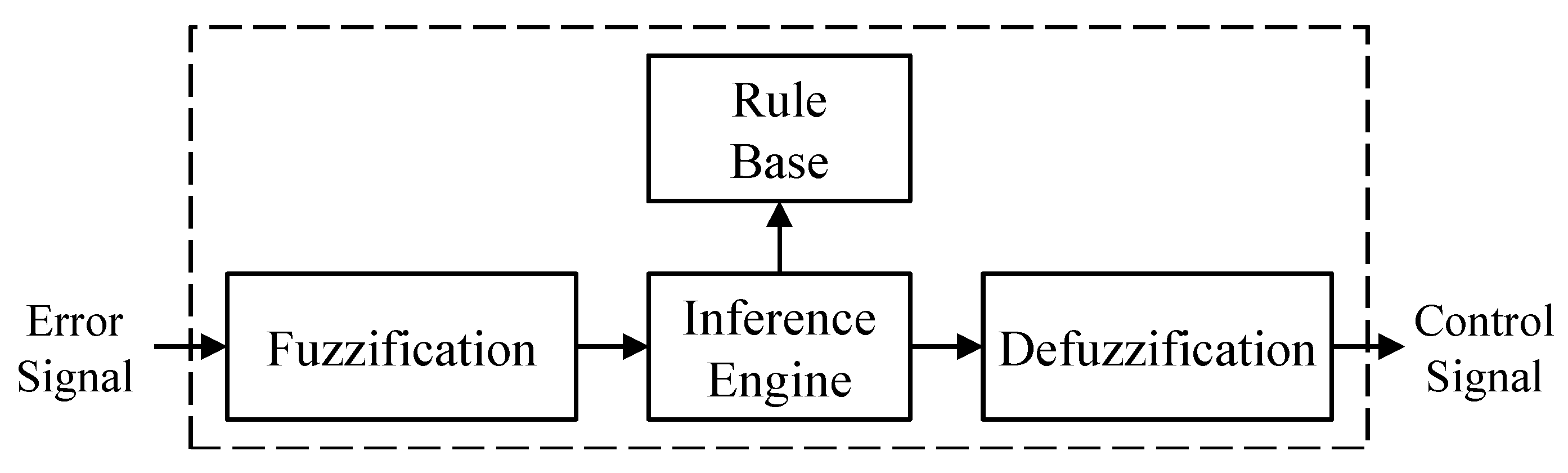

2.2.2. Fuzzy Logic Controller

2.3. Sun Position and Heliostat Angles

2.4. Embedded System

2.4.1. Controller Parameters

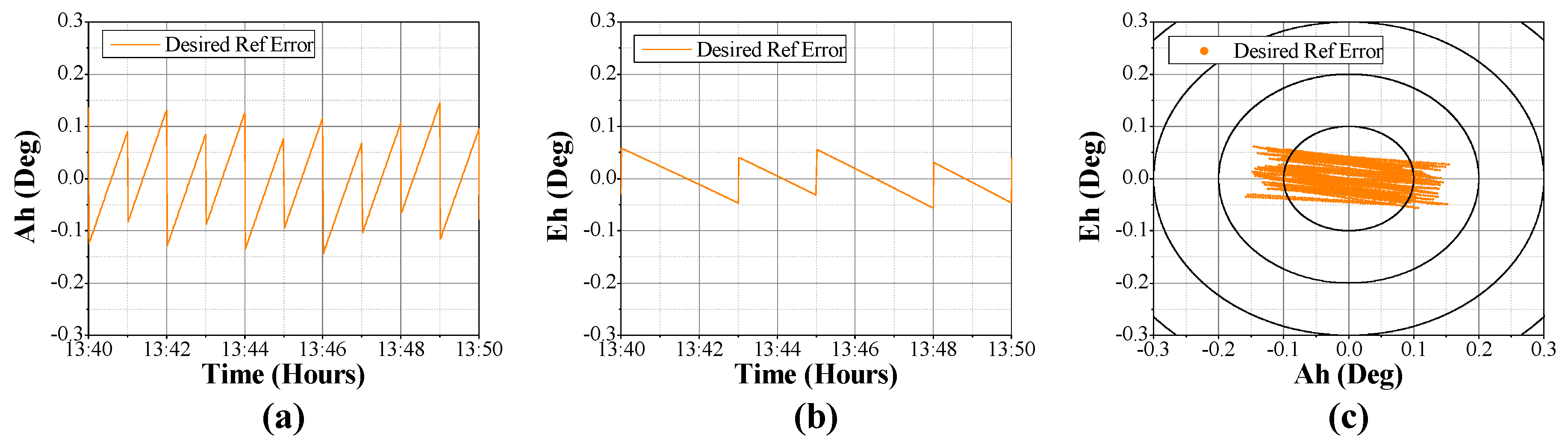

2.4.2. Setpoint Values

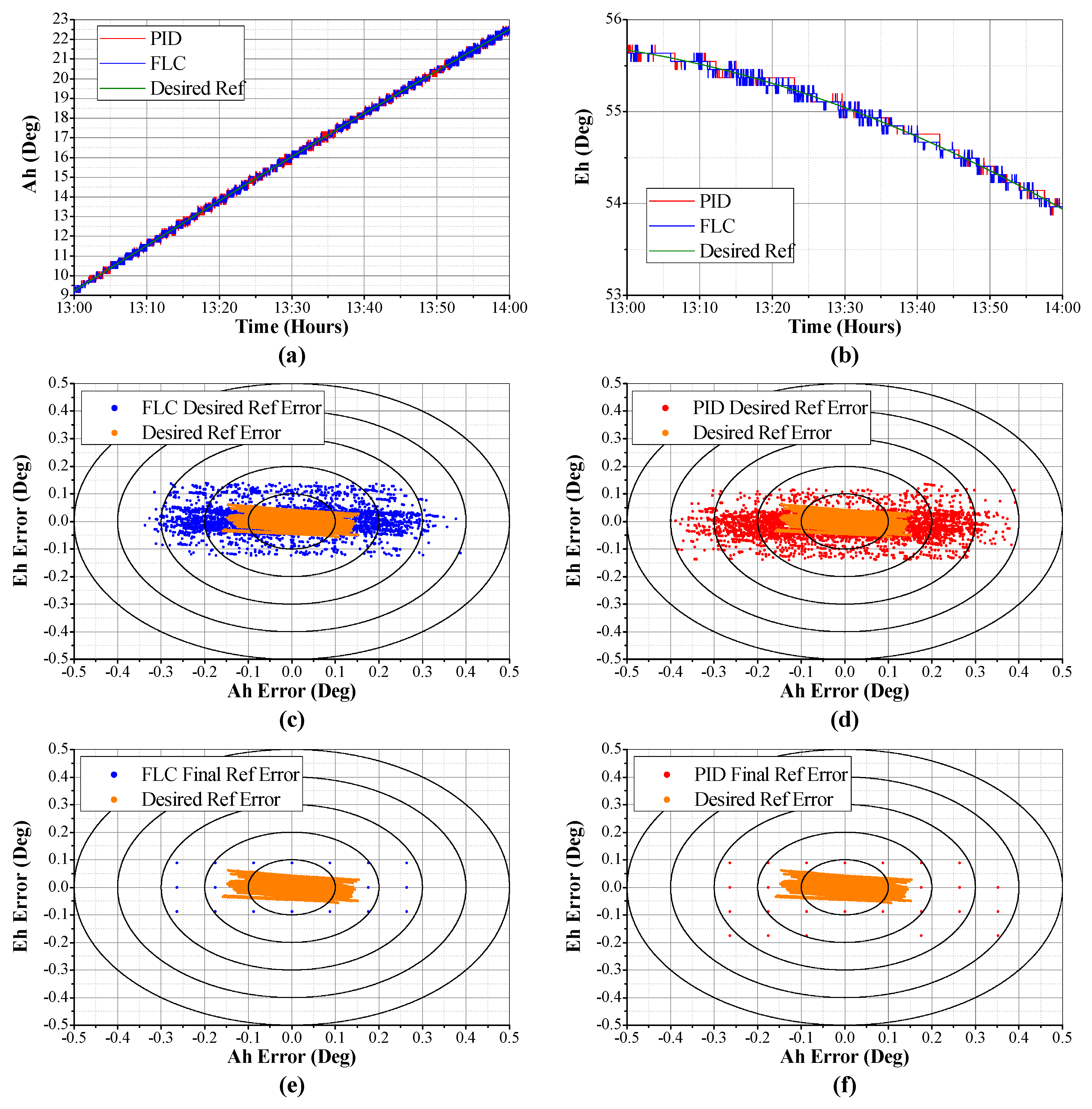

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| CoG | Center of Gravity |

| CoS | Center of Sums |

| DSP | Digital Signal Processor |

| FLC | Fuzzy Logic Controller |

| FPGA | Field-Programmable Gate Array |

| LCD | Liquid Crystal Display |

| MCU | Microcontroller Unit |

| MDS | Microprocessor Driver System |

| MSE | Mean Squared Error |

| PC | Personal Computer |

| PCB | Printed Circuit Board |

| PID | Proportional–Integral–Derivative |

| PV | Photo-Voltaic |

| PWM | Pulse Width Modulation |

| RTC | Real-Time Clock |

| SDS | Sensor Driver System |

| STS | Sun Tracking System |

| UART | Universal Asynchronous Receiver-Transmitter |

| Angular position of the DC motor | |

| Angular velocity of the DC motor | |

| Time constant of the system | |

| Steady-state gain of the system | |

| Controller error signal | |

| Controller change of error signal | |

| Controller output signal | |

| Controller sampling time | |

| Controller maximum output voltage | |

| Solar vector | |

| Target vector | |

| Normal vector of the heliostat | |

| Solar unit vector | |

| Target unit vector | |

| Solar vector azimuth angle | |

| Solar vector elevation angle | |

| Target vector azimuth angle | |

| Target vector elevation angle | |

| Heliostat azimuth angle | |

| Heliostat elevation angle |

References

- Camacho, E.F.; Berenguel, M.; Rubio, F.R.; Martínez, D. Control of Solar Energy Systems; Springer: London, UK, 2012; p. 414. [Google Scholar]

- Al-Rousan, N.; Isa, N.A.M.; Desa, M.K.M. Advances in solar photovoltaic tracking systems: A review. Renew. Sustain. Energy Rev. 2018, 82, 2548–2569. [Google Scholar] [CrossRef]

- Grena, R. Five new algorithms for the computation of sun position from 2010 to 2110. Sol. Energy 2012, 86, 1323–1337. [Google Scholar] [CrossRef]

- Soufi, N.J. Design and implementation of fuzzy position control system for tracking applications and performance comparison with conventional pid. IAES Int. J. Artif. Intell. (IJ-AI) 2012, 1, 31–44. [Google Scholar]

- Paul-l-Hai, L.; Sentai, H.; Chou, J. Comparison on fuzzy logic and pid controls for a dc motor position controller. In Proceedings of the 1994 IEEE Industry Applications Society Annual Meeting, Denver, CO, USA, 2–6 October 1994; pp. 1930–1935. [Google Scholar]

- Bal, G.; Bekiroǧlu, E.; Demirbaş, Ş.; Çolak, İ. Fuzzy logic based dsp controlled servo position control for ultrasonic motor. Energy Convers. Manag. 2004, 45, 3139–3153. [Google Scholar] [CrossRef]

- Wang, H.-P. Design of fast fuzzy controller and its application on position control of dc motor. In Proceedings of the 2011 International Conference on Consumer Electronics, Communications and Networks, XianNing, China, 16–18 April 2011; pp. 4902–4905. [Google Scholar]

- Chermitti, A.; Zeghoudi, A. A comparison between a fuzzy and pid controller for universal motor. Int. J. Comput. Appl. 2014, 104, 32–36. [Google Scholar]

- Meena, P.K.; Bhushan, B. Simulation for position control of dc motor using fuzzy logic controller. Int. J. Electron. Electr. Comput. Syst. 2017, 6, 188–191. [Google Scholar]

- Rahman, Z.-A.S.A. Design a fuzzy logic controller for controlling position of dc motor. Int. J. Comput. Eng. Res. Trends 2017, 4, 285–289. [Google Scholar]

- Lim, C.M. Implementation and experimental study of a fuzzy logic controller for dc motors. Comput. Ind. 1995, 26, 93–96. [Google Scholar] [CrossRef]

- Ko, J.S.; Youn, M.J. Simple robust position control of bldd motors using integral-proportional plus fuzzy logic controller. Mechatronics 1998, 8, 65–82. [Google Scholar] [CrossRef]

- Pravadalioglu, S. Single-Chip fuzzy logic controller design and an application on a permanent magnet dc motor. Eng. Appl. Artif. Intell. 2005, 18, 881–890. [Google Scholar] [CrossRef]

- Namazov, M.; Basturk, O. Dc motor position control using fuzzy proportional-derivative controllers with different defuzzification methods. Turk. J. Fuzzy Syst. 2010, 1, 36–54. [Google Scholar]

- Natsheh, E.; Buragga, K.A. Comparison between conventional and fuzzy logic pid controllers for controlling dc motors. Int. J. Comput. Sci. Issues 2010, 7, 128–134. [Google Scholar]

- Manikandan, R.; Arulmozhiyal, R. Position control of dc servo drive using fuzzy logic controller. In Proceedings of the 2014 International Conference on Advances in Electrical Engineering (ICAEE), Vellore, India, 9–11 January 2014; pp. 1–5. [Google Scholar]

- Yousef, H.A. Design and implementation of a fuzzy logic computer-controlled sun tracking system. In Proceedings of the IEEE International Symposium on Industrial Electronics, Bled, Slovenia, 12–16 July 1999; pp. 1030–1034. [Google Scholar]

- Belkasmi, M.; Bouziane, K.; Akherraz, M.; Sadiki, T.; Faqir, M.; Elouahabi, M. Improved dual-axis tracker using a fuzzy-logic based controller. In Proceedings of the 3rd International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 10–13 December 2015; pp. 1–5. [Google Scholar]

- Zakariah, A.; Jamian, J.J.; Yunus, M.A.M. Dual-Axis solar tracking system based on fuzzy logic control and light dependent resistors as feedback path elements. In Proceedings of the 2015 IEEE Student Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2015; pp. 139–144. [Google Scholar]

- Toylan, H. Performance of dual axis solar tracking system using fuzzy logic control a case study in Pinarhisar, Turkey. Eur. J. Eng. Nat. Sci. 2017, 2, 130–136. [Google Scholar]

- Ataei, E.; Afshari, R.; Pourmina, M.A.; Karimian, M.R. Design and construction of a fuzzy logic dual axis solar tracker based on dsp. In Proceedings of the 2nd International Conference on Control, Instrumentation and Automation, Shiraz, Iran, 27–29 December 2011; pp. 185–189. [Google Scholar]

- Batayneh, W.; Owais, A.; Nairoukh, M. An intelligent fuzzy based tracking controller for a dual-axis solar pv system. Autom. Constr. 2013, 29, 100–106. [Google Scholar] [CrossRef]

- Baran, N.; Sinha, D. Fuzzy logic-based dual axis solar tracking system. Int. J. Comput. Appl. 2016, 155, 13–18. [Google Scholar]

- Huang, C.-H.; Pan, H.-Y.; Lin, K.-C. Development of intelligent fuzzy controller for a two-axis solar tracking system. Appl. Sci. 2016, 6, 130. [Google Scholar] [CrossRef] [Green Version]

- Zeghoudi, A.; Hamidat, A.; Takilalte, A.; Debbache, M. Contribution to the control of a tracker solar using hybrid controller and artificial intelligence systems. In Proceedings of the 4th International Seminar on New and Renewable Energies, Ghardaïa, Algeria, 24–25 October 2016; pp. 1–9. [Google Scholar]

- Benzekri, A.; Azrar, A. FPGA-based design process of a fuzzy logic controller for a dual-axis sun tracking system. Arab. J. Sci. Eng. 2014, 39, 6109–6123. [Google Scholar] [CrossRef]

- Ardehali, M.M.; Emam, S.H. Development, design and experimental testing of fuzzy-based controllers for a laboratory scale sun-tracking heliostat. Fuzzy Inf. Eng. 2011, 3, 247–257. [Google Scholar] [CrossRef]

- Zeghoudi, A.; Chermitti, A. Speed control of a dc motor for the orientation of a heliostat in a solar tower power plant using artificial intelligence systems (flc and nc). Res. J. Appl. Sci. Eng. Technol. 2015, 10, 570–580. [Google Scholar] [CrossRef]

- Zeghoudi, A.; Chermitti, A.; Benyoucef, B. Contribution to the control of the heliostat motor of a solar tower power plant using intelligence controller. Int. J. Fuzzy Syst. 2015, 18, 741–750. [Google Scholar] [CrossRef]

- Bedaouche, F.; Gama, A.; Hassam, A.; Khelifi, R.; Boubezoula, M. Fuzzy pid control of a dc motor to drive a heliostat. In Proceedings of the 2017 International Renewable and Sustainable Energy Conference, Tangier, Morocco, 4–7 December 2017; pp. 1–6. [Google Scholar]

- Jirasuwankul, N.; Manop, C. A lab-scale heliostat positioning control using fuzzy logic based stepper motor drive with micro step and multi-frequency mode. In Proceedings of the 2017 IEEE International Conference on Fuzzy Systems (FUZZ-IEEE), Naples, Italy, 9–12 July 2017; pp. 1–6. [Google Scholar]

- Dorf, R.C.; Bishop, R.H. Modern Control Systems, 12th ed.; Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2011. [Google Scholar]

- Aguado, A.B.; Martínez, M.I. Identificación y Control Adaptativo; Pearson Educación, S.A.: Madrid, Spain, 2003. [Google Scholar]

- Lilly, J.H. Fuzzy Control and Identification, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; p. 231. [Google Scholar]

- Eminoğlu, İ.; Altaş, İ.H. The effects of the number of rules on the output of a fuzzy logic controller employed to a pm dc motor. Comput. Electr. Eng. 1998, 24, 245–261. [Google Scholar] [CrossRef]

- Abdalla, M.; Al-Jarrah, T. Optimal fuzzy controller: Rule base optimized generation. Control. Eng. Appl. Inform. 2018, 20, 76–86. [Google Scholar]

- Ross, T.J. Fuzzy Logic with Engineering Applications, 3rd ed.; John Wiley & Sons Ltd.: Chichester, UK, 2010; p. 585. [Google Scholar]

- Grena, R. An algorithm for the computation of the solar position. Sol. Energy 2008, 82, 462–470. [Google Scholar] [CrossRef]

| Kp | Ki | Kd |

|---|---|---|

| 2250.0 | 0.025 | 110.0 |

| Parameter | Value | Unit |

|---|---|---|

| Total height | 5.24 | m |

| Pedestal height | 2.85 | m |

| Elevation axis length | 4.43 | m |

| Gap between support frames | 0.70 | m |

| Number of facets | 16 | - |

| Mirror face size | 1.2 × 1.2 | m |

| Heliostat mirror area | 23 | |

| DC Motors Rated Voltage | 24 | V |

| DC Motors Rated Current | ≤5 | A |

| DC Motors Rated Torque | 100 | N·m |

| DC Motors No Load Speed | 5 | rpm |

| DC Motors Gear Ratio | 710.5 | - |

| Parameter | Value |

|---|---|

| Date | Friday, 13 September 2019 |

| Time | 13:00:00–14:00:00 |

| Latitude | 20.590636° N |

| Longitude | 100.413226° W |

| Monthly Mean Atmospheric Pressure | 819.795 mbar |

| Monthly Mean Temperature | 20.3 °C |

| Maximum Wind Speed | 8 m/s (28.8 km/h) |

| Target Height | 30.0 m |

| Heliostat Height | 2.85 m |

| East-West distance to the target | 15 m East |

| North-South distance to the target | 35 m North |

| Parameter | Final Ref MSE | Desired Ref MSE | |

|---|---|---|---|

| DC Motor at no load | PID Azimuth | 0.0° | 0.068610° |

| PID Elevation | 0.0° | 0.026349° | |

| FLC Azimuth | 0.0° | 0.068610° | |

| FLC Elevation | 0.0° | 0.026349° | |

| Heliostat | PID Azimuth | 0.153941° | 0.168669° |

| PID Elevation | 0.051032° | 0.048347° | |

| FLC Azimuth | 0.131647° | 0.146435° | |

| FLC Elevation | 0.039328° | 0.047251° | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salgado-Plasencia, E.; Carrillo-Serrano, R.V.; Toledano-Ayala, M. Development of a DSP Microcontroller-Based Fuzzy Logic Controller for Heliostat Orientation Control. Appl. Sci. 2020, 10, 1598. https://doi.org/10.3390/app10051598

Salgado-Plasencia E, Carrillo-Serrano RV, Toledano-Ayala M. Development of a DSP Microcontroller-Based Fuzzy Logic Controller for Heliostat Orientation Control. Applied Sciences. 2020; 10(5):1598. https://doi.org/10.3390/app10051598

Chicago/Turabian StyleSalgado-Plasencia, Eugenio, Roberto V. Carrillo-Serrano, and Manuel Toledano-Ayala. 2020. "Development of a DSP Microcontroller-Based Fuzzy Logic Controller for Heliostat Orientation Control" Applied Sciences 10, no. 5: 1598. https://doi.org/10.3390/app10051598