Using the Equivalent Material Concept and the Average Strain Energy Density to Analyse the Fracture Behaviour of Structural Materials

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

- PA6 (Durethan, Lanxess, Germany), see [7,14] for details, with basically linear-elastic behaviour, even in the stress–strain curve of the tensile test, and fully linear behaviour in the presence of defects (for both crack and notch-type defects. SENB specimens). Tensile tests were performed according with [15], whereas fracture tests followed [16]. Both types of tests were completed at 20 ºC, with the thickness and the width being 4 and 10 mm, respectively, in all cases. Before being tested, the specimens were dried in an oven at 100 °C, to avoid any trace of moisture.

- SGFR-PA6 (Short Glass Fiber Reinforced PA6, see [7,14,15,16] for details), with 5 wt.% of fibre content. The short fibres were oriented in the longitudinal direction of the specimens, had an average length of 300 µm and a diameter of 10 µm, with their tensile strength, elastic modulus and density being 3450 MPa, 72.5 GPa and 2.6 gr/cm3, respectively. This material has a slightly nonlinear tensile curve, with the load–displacement curves of the fracture tests performed on SENB specimens (for both cracked and notched specimens) being fully linear. Again, the tests were completed at 20 °C, with the thickness and the width of the specimens being 4 and 10 mm, respectively. The specimens were also dried in an oven, at 10 °C to avoid any trace of moisture.

- SGFR-PA6 (Short Glass Fiber Reinforced PA6, see [7,14,15,16] for details), with 50 wt.% of fibre content. In this case, the tensile curve is clearly nonlinear, and the load–displacement curve of the fracture tests performed on SENB specimens is basically linear (fulfilling linear-elastic fracture mechanics conditions). The characteristics of the fibres and the specimens were analogous to those mentioned above.

- PMMA (see [10,15,16,17] for a wide description of experimental procedure, material properties and critical loads), with moderate nonlinear tensile curve and predominantly linear-elastic curves in notched conditions (with fully linear-elastic behaviour in cracked conditions. SENB specimens). Both tensile and fracture tests were performed at 20 °C in 4 mm thick specimens, with the width being 10 mm.

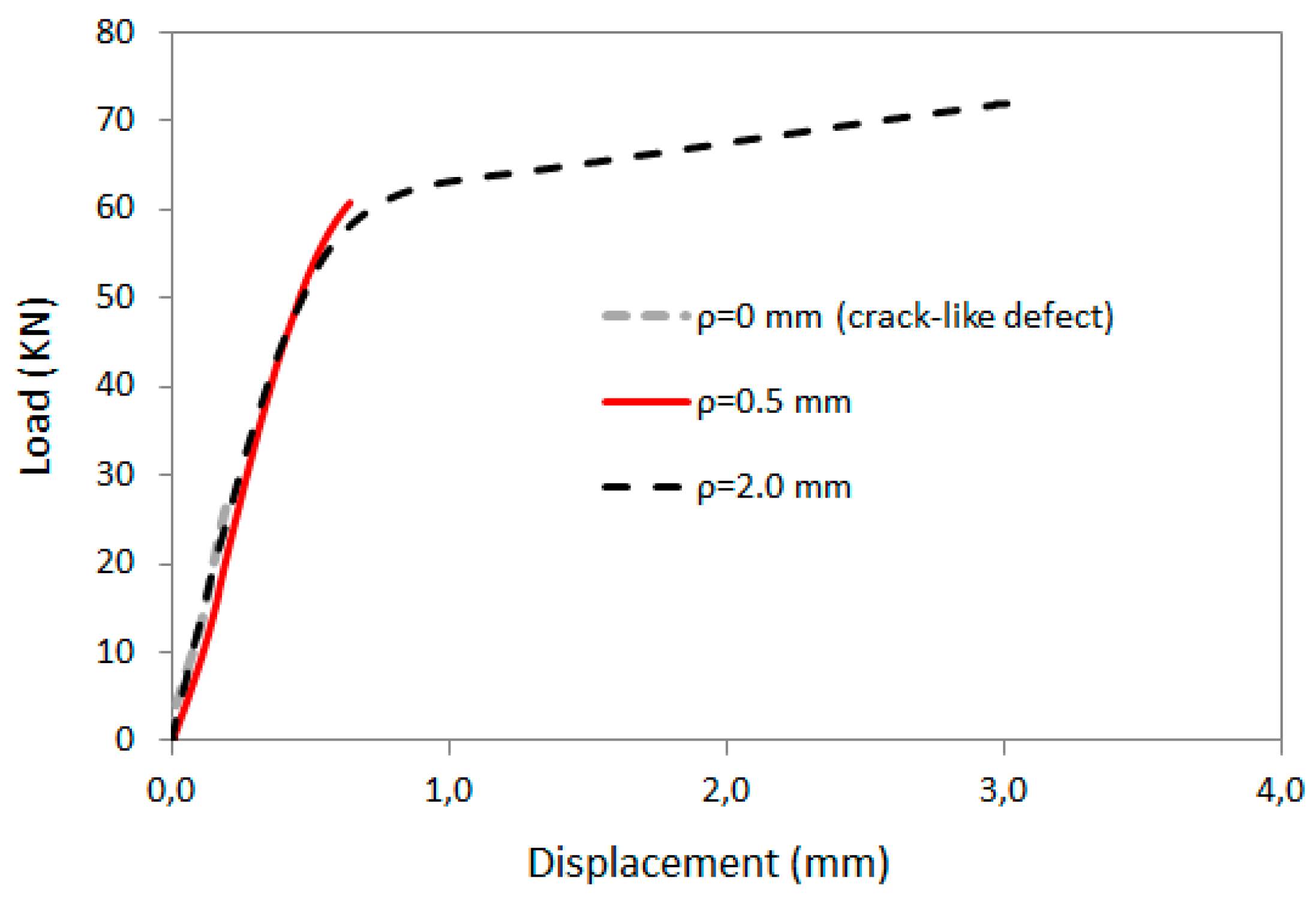

- Al7075-T651 (TL orientation) with linear-elastic behaviour in cracked conditions (CT specimens), moderate nonlinear behaviour in tensile behaviour and intermediate situations in the presence of notches. Details (material properties and experimental critical loads) may be found in [12,18], with the proper EMC–ASED criterion being applied in [13]. Tensile and fracture tests were performed by following [19] and [20], respectively. Fracture tests were performed at room temperature, with the width and the thickness of the specimens being 40 and 20 mm, respectively.

- Steel S275JR at −120 °C, operating within its Lower Shelf region (T0 = −26 °C [21]) and, thus, presenting dominant linear-elastic behaviour in cracked conditions. However, it develops significant nonlinear behaviour in tensile tests. Thus, this material is in an analogous situation of Al7075T651. The basic fracture (CT specimens) and tensile characterisation of this material, and the corresponding experimental critical loads, may be consulted in [8,19,20,22]. The thickness and the width of the fracture specimens were 25 and 50 mm, respectively.

- Steel S275JR at −50 °C (see [19,20,22] for details on experimental procedures, material properties and critical loads), operating within the Ductile-to-Brittle Transition Zone (DBTZ), below the corresponding Reference Temperature [21] (T0 = −26 °C). The material in such conditions is clearly nonlinear in tensile tests and moderately nonlinear in cracked conditions (CT specimens), with increasing nonlinear behaviour when the notch radius increases. Again, the thickness and the width of the fracture specimens were 25 and 50 mm, respectively. The fracture toughness results in cracked conditions do not fulfil KIC requirements and are qualified as KJc [20].

- Steel S275JR at −10 °C (see [19,20,22] for details), operating within the Ductile-to-Brittle Transition Zone (DBTZ), above the corresponding Reference Temperature [21] (T0 = −26 °C). The material in such conditions is, again and more noticeably, nonlinear in tensile tests, and moderately nonlinear in cracked conditions (CT specimens). The thickness and the width of the fracture specimens were 25 and 50 mm, respectively. Likewise, the fracture toughness results in cracked conditions do not fulfil KIC requirements and are qualified as KJc [20].

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sih, G.C. Strain-energy-density factor applied to mixed mode crack problems. Int. J. Fract. 1974, 10, 305–321. [Google Scholar] [CrossRef]

- Lazzarin, P.; Zambardi, R. A finite-volume-energy based approach to predict the static and fatigue behavior of components with sharp V-Shaped notches. Int. J. Fract. 2001, 112, 275–298. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P. A review of the volume-based strain energy density approach applied to V-noches and welded structures. Theor. App. Fract. Mech. 2009, 52, 183–194. [Google Scholar] [CrossRef]

- Berto, F.; Lazzarin, P. Recent developments in brittle and quasi-brittle failure assessment of engineering materials by means of local approaches. Mater. Sci. Eng. R Rep. 2014, 75, 1–48. [Google Scholar] [CrossRef]

- Lazzarin, P.; Berto, F. Some expressions for the strain energy in a finite volume surrounding the root of blunt V-notches. Int. J. Fract 2005, 135, 161–185. [Google Scholar] [CrossRef]

- Neuber, H. Theory of Notch Stresses; Springer-Verlag: Berlin, Germany, 1958. [Google Scholar]

- Ibáñez-Gutiérrez, F.T.; Cicero, S.; Madrazo, V.; Berto, F. Fracture loads prediction on notched short glass fibre reinforced polyamide 6 using the Strain Energy Density. Phys. Mesomech. 2018, 21, 165–172. [Google Scholar] [CrossRef]

- Cicero, S.; Berto, F.; Ibáñez-Gutiérrez, F.T.; Procopio, I.; Madrazo, V. SED criterion estimations of fracture loads in structural steels operating at lower shelf temperatures and containing u-notches. Theor. App. Fract. Mech. 2017, 90, 234–243. [Google Scholar] [CrossRef]

- Torabi, A.R. Estimation of tensile load-bearing capacity of ductile metallic materials weakened by a V-notch: The equivalent material concept. Mater. Sci. Eng. A. 2012, 536, 249–255. [Google Scholar] [CrossRef]

- Cicero, S.; Torabi, A.R.; Madrazo, V.; Azizi, P. Prediction of fracture loads in PMMA U-notched specimens using the Equivalent Material Concept and the theory of critical distances combined criterion. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 688–699. [Google Scholar] [CrossRef]

- Torabi, A.R.; Rahimi, A.S.; Ayatollahi, M.R. Elastic-plastic fracture assessment of CNT-reinforced epoxy/nanocomposite specimens weakened by U-shaped notches under mixed mode loading. Comp. Part B: Eng. 2019, 176, 107114. [Google Scholar] [CrossRef]

- Fuentes, J.D.; Cicero, S.; Berto, F.; Torabi, A.R.; Madrazo, V.; Azizi, P. Estimation of Fracture Loads in AL7075-T651 Notched Specimens Using the Equivalent Material Concept Combined with the Strain Energy Density Criterion and with the Theory of Critical Distances. Metals 2018, 8, 87. [Google Scholar] [CrossRef]

- Torabi, A.R.; Kamyab, M. The Fictitious Material Concept. Eng. Fract. Mech. 2019, 209, 17–31. [Google Scholar] [CrossRef]

- Ibáñez-Gutiérrez, F.T.; Cicero, S.; Carrascal, I.A.; Procopio, I. Effect of fibre content and notch radius in the fracture behaviour of short glass fibre reinforced polyamide 6: An approach from the Theory of Critical Distances. Comp. Part B Eng. 2016, 94, 299–311. [Google Scholar] [CrossRef]

- ASTM D638-10. Standard Test Method for Tensile Properties of Plastics; American Society for Testing and Materials: Philadelphia, PA, USA, 2010. [Google Scholar]

- ASTM D5045-99. Standard Test Methods for Plane-Strain Fracture Toughness and Strain Energy Release Rate of Plastic Materials; American Society for Testing and Materials: Philadelphia, PA, USA, 2007. [Google Scholar]

- Cicero, S.; Madrazo, V.; Carrascal, I.A. Analysis of notch effect in PMMA using the Theory of Critical Distances. Eng. Fract. Mech. 2012, 86, 56–72. [Google Scholar] [CrossRef]

- Madrazo, V.; Cicero, S.; Carrascal, I.A. On the Point Method and the Line Method notch effect predictions in Al7075-T651. Eng. Fract. Mech. 2012, 79, 363–379. [Google Scholar] [CrossRef]

- ASTM E8/E8M-09. Standard Test Method for Tension Testing of Metallic Materials; American Society of Testing and Materials: Philadelphia, USA, 2018. [Google Scholar]

- ASTM E1820-091. Standard Test Method for Measurement of Fracture Toughness; American Society of Testing and Materials: Philadelphia, PA, USA, 2009. [Google Scholar]

- ASTM E1921-05. Standard Test Method for Determination of Reference Temperature, T0. for Ferritic Steels in the Transition Range; American Society for Testing and Materials: Philadelphia, PA, USA, 2005. [Google Scholar]

- Cicero, S.; García, T.; Madrazo, V.; Carrascal, I.A.; Ruiz, E. Analysis of notch effect in load bearing capacity, apparent fracture toughness and fracture micromechanisms of ferritic–pearlitic steels. Eng. Fail. Anal. 2014, 44, 250–271. [Google Scholar] [CrossRef]

- Yosibash, Z.; Bussiba, A.R.; Gilad, I. Fracture criteria for brittle elastic materials. Int. J. Fract. 2004, 125, 47–64. [Google Scholar] [CrossRef]

- Creager, M.; Paris, P.C. Elastic Field Equations for Blunt Cracks with Reference to Stress Corrosion Cracking. Int. J. Fract. 1967, 3, 247–252. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Torabi, A.R. Tensile failure in blunt V-notched ductile members: A new formulation of the Equivalent Material Concept. Eng. Fract. Mech. 2017, 184, 1–13. [Google Scholar] [CrossRef]

- Torabi, A.R.; Kamyab, M. Notch ductile failure with significant strain-hardening: The modified equivalent material concept. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 439–453. [Google Scholar] [CrossRef]

| Material | E (MPa) | σy (MPa) | σu (MPa) | σf* (MPa) | εmax | Kmat (MPa·m1/2) |

|---|---|---|---|---|---|---|

| PA 6 | 2850 | 54.20 | 54.20 | 59.34 | 2.07 | 2.17 |

| SGFR PA 6 (5% wt.%) | 3300 | 66.90 | 72.05 | 86.30 | 2.66 | 1.84 |

| SGFR PA 6 (50% wt.%) | 12,600 | 161.1 | 192.8 | 282.1 | 2.47 | 8.59 |

| PMMA | 3420 | 48.5 | 71.95 | 115.8 | 4.05 | 2.04 |

| Al7075-T651 | 74,400 | 539.2 | 602.2 | 2727 | 9.90 | 26.6 |

| S275JR (−120 °C) | 218000 | 837.0 | 928.2 | 7208 | 13.71 | 31.3 |

| S275JR (−50 °C) | 209,000 | 349.1 | 564.7 | 5639 | 15.33 | 80.6 |

| S275JR (−10 °C) | 207,000 | 337.6 | 536.3 | 5853 | 17.15 | 122.8 |

| Material | Notch Radius, ρ (mm) | Pexp (kN) | PASED (kN) | PEMC–ASED (kN) | PASED/Pexp | PEMC–ASED/Pexp |

|---|---|---|---|---|---|---|

| PA6 | 0.25 | 0.1049 | 0.0683 | 0.0748 | 0.724 | 0.713 |

| 0.50 | 0.1330 | 0.0910 | 0.0890 | 0.714 | 0.669 | |

| 1.0 | 0.1309 | 0.0930 | 0.0968 | 0.718 | 0.739 | |

| 2.0 | 0.1389 | 0.1120 | 0.1182 | 0.862 | 0.850 | |

| SGFR-PA6 5 wt.% | 0.25 | 0.0821 | 0.0689 | 0.0730 | 0.839 | 0.889 |

| 0.50 | 0.0976 | 0.0792 | 0.0878 | 0.811 | 0.899 | |

| 1.0 | 0.1135 | 0.0986 | 0.1125 | 0.868 | 0.991 | |

| 2.0 | 0.1378 | 0.1291 | 0.1503 | 0.936 | 1.090 | |

| SGFR-PA6 50 wt.% | 0.25 | 0.3370 | 0.2431 | 0.3556 | 0.721 | 1.055 |

| 0.50 | 0.3714 | 0.3437 | 0.3960 | 0.925 | 1.066 | |

| 1.0 | 0.3944 | 0.3960 | 0.4472 | 1.004 | 1.133 | |

| 2.0 | 0.4262 | 0.4397 | 0.5491 | 1.031 | 1.288 | |

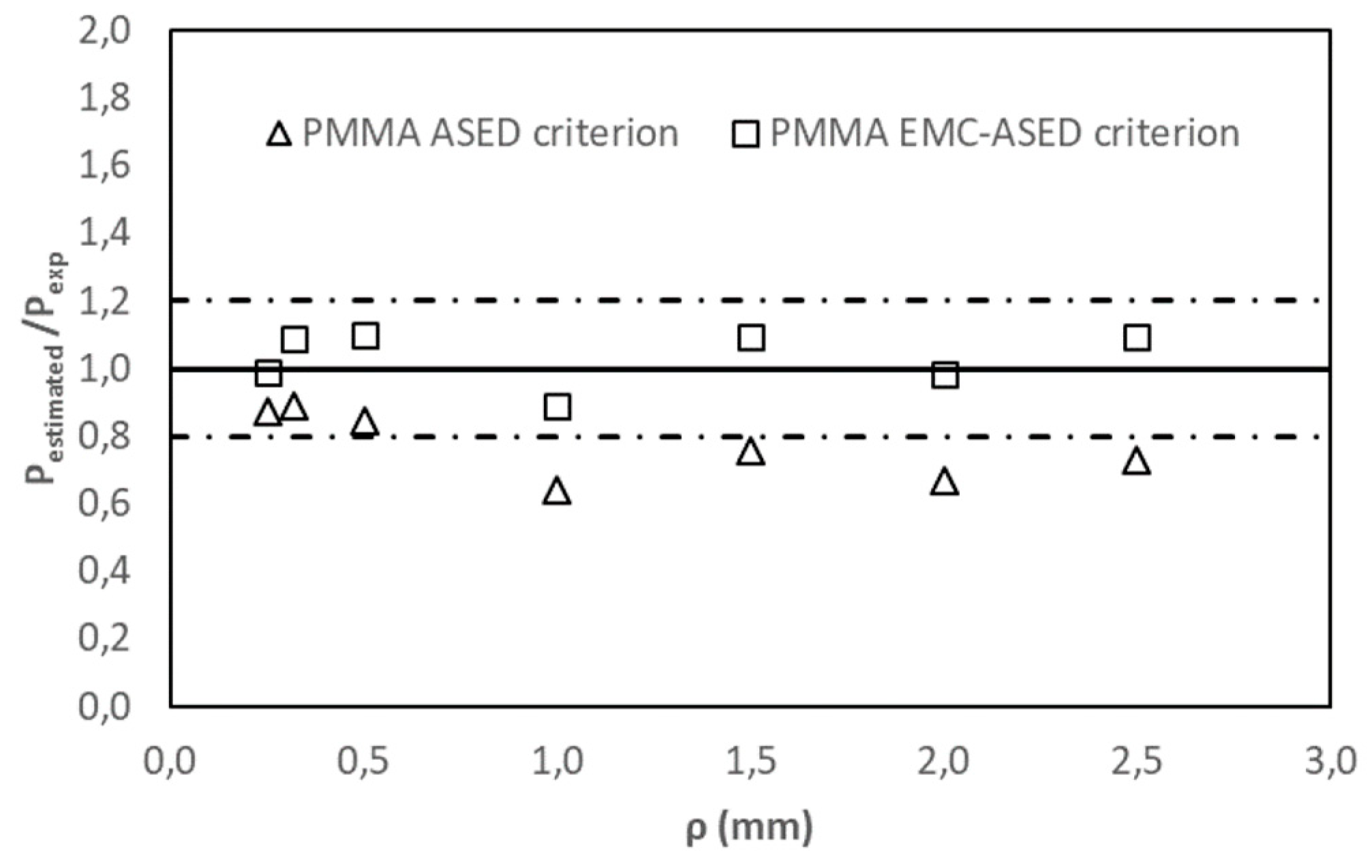

| PMMA | 0.25 | 0.1140 | 0.0993 | 0.1125 | 0.871 | 0.987 |

| 0.32 | 0.1103 | 0.0978 | 0.1202 | 0.888 | 1.090 | |

| 0.50 | 0.1270 | 0.1071 | 0.1400 | 0.843 | 1.102 | |

| 1.0 | 0.2073 | 0.1327 | 0.1848 | 0.641 | 0.891 | |

| 1.5 | 0.1996 | 0.1505 | 0.2183 | 0.754 | 1.094 | |

| 2.0 | 0.2525 | 0.1690 | 0.2491 | 0.669 | 0.986 | |

| 2.5 | 0.2517 | 0.1838 | 0.2751 | 0.730 | 1.093 | |

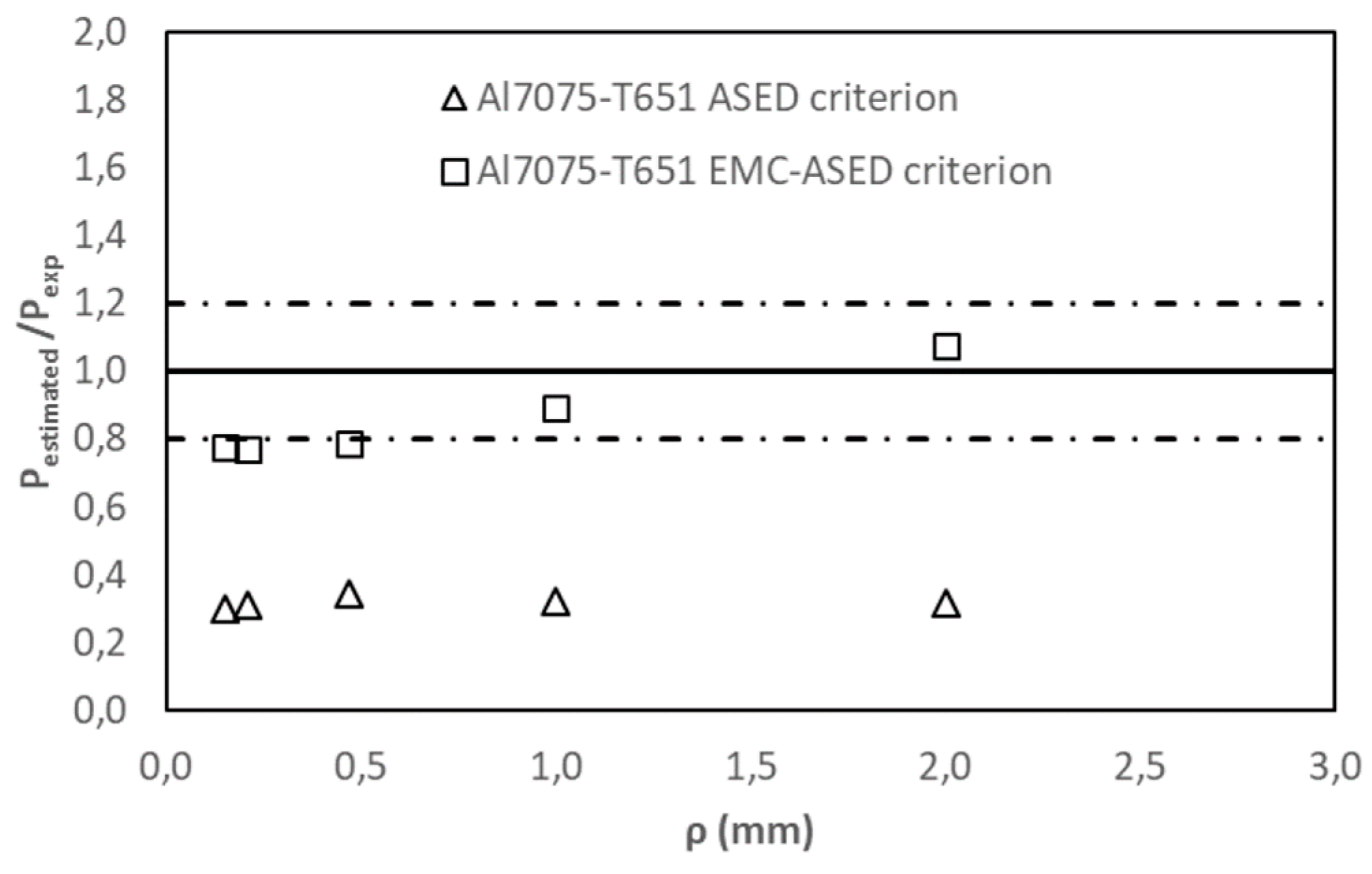

| Al7075-T651 | 0.15 | 20.36 | 6.09 | 15.74 | 0.299 | 0.773 |

| 0.21 | 23.04 | 7.20 | 17.76 | 0.312 | 0.770 | |

| 0.47 | 31.39 | 10.78 | 24.70 | 0.343 | 0.786 | |

| 1.0 | 38.93 | 12.48 | 34.77 | 0.320 | 0.893 | |

| 2.0 | 44.91 | 14.35 | 48.33 | 0.319 | 1.076 | |

| S275JR (−120 °C) | 0.15 | 49.25 | 8.61 | 52.16 | 0.174 | 1.059 |

| 0.25 | 50.90 | 11.11 | 64.31 | 0.218 | 1.263 | |

| 0.50 | 59.13 | 15.72 | 87.90 | 0.265 | 1.486 | |

| 1.0 | 64.33 | 22.23 | 121.8 | 0.345 | 1.894 | |

| 2.0 | 69.83 | 31.45 | 170.6 | 0.450 | 2.444 | |

| S275JR (−50 °C) | 0.15 | 62.00 | 7.70 | 56.85 | 0.124 | 0.916 |

| 0.25 | 56.52 | 9.94 | 64.03 | 0.175 | 1.132 | |

| 0.50 | 65.48 | 14.06 | 79.64 | 0.214 | 1.216 | |

| 1.0 | 65.53 | 19.89 | 104.3 | 0.303 | 1.591 | |

| 2.0 | 80.02 | 28.13 | 141.5 | 0.351 | 1.768 | |

| S275JR (−10 °C) | 0.15 | 65.04 | 7.41 | 82.74 | 0.114 | 1.272 |

| 0.25 | 65.80 | 9.56 | 83.99 | 0.145 | 1.276 | |

| 0.50 | 69.85 | 13.52 | 95.16 | 0.193 | 1.362 | |

| 1.0 | 72.63 | 19.13 | 118.2 | 0.263 | 1.627 | |

| 2.0 | 75.30 | 27.05 | 154.1 | 0.359 | 2.046 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cicero, S.; Fuentes, J.D.; Torabi, A.R. Using the Equivalent Material Concept and the Average Strain Energy Density to Analyse the Fracture Behaviour of Structural Materials. Appl. Sci. 2020, 10, 1601. https://doi.org/10.3390/app10051601

Cicero S, Fuentes JD, Torabi AR. Using the Equivalent Material Concept and the Average Strain Energy Density to Analyse the Fracture Behaviour of Structural Materials. Applied Sciences. 2020; 10(5):1601. https://doi.org/10.3390/app10051601

Chicago/Turabian StyleCicero, Sergio, Juan Diego Fuentes, and Ali Reza Torabi. 2020. "Using the Equivalent Material Concept and the Average Strain Energy Density to Analyse the Fracture Behaviour of Structural Materials" Applied Sciences 10, no. 5: 1601. https://doi.org/10.3390/app10051601

APA StyleCicero, S., Fuentes, J. D., & Torabi, A. R. (2020). Using the Equivalent Material Concept and the Average Strain Energy Density to Analyse the Fracture Behaviour of Structural Materials. Applied Sciences, 10(5), 1601. https://doi.org/10.3390/app10051601