Heat Transfer Enhancement of Falling Film Evaporation on a Horizontal Tube by Thermal Spray Coating

Abstract

:1. Introduction

2. Experimental Apparatus and Methods

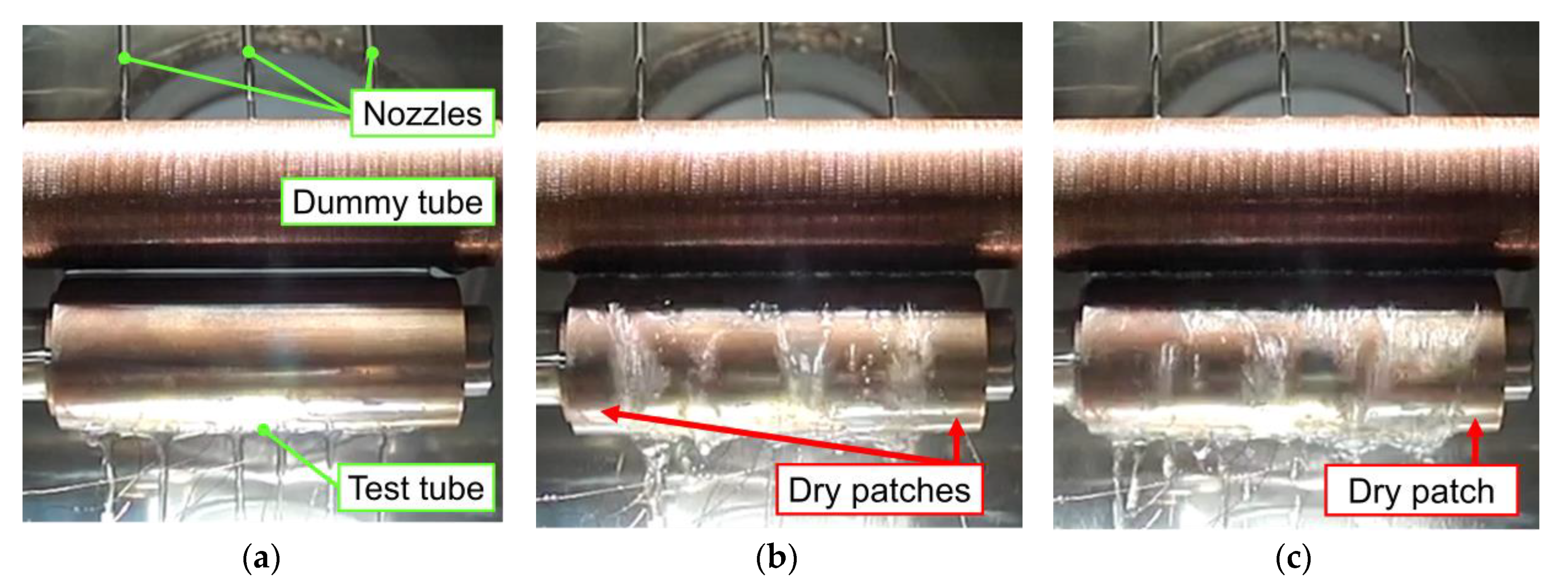

2.1. Experimental Apparatus

2.2. Tested Tubes

2.3. Data Reduction

3. Experimental Results and Discussion

3.1. Effect of Liquid Flow rate on Falling Film Evaporation

3.2. Effect of Heating Conditions on Falling Film Evaporation

3.3. Pool Boiling Heat Transfer Characteristics

4. Conclusions

- A high heat transfer enhancement factor up to 5.2 could be obtained by the thermal spray coating.

- The heat transfer coefficient increased with increasing liquid flow rate because of the spreading wetting area and then became saturated. The liquid flow rate for the saturation was lower for the coated tube than for the smooth tube due to the spreading easily through the porous structured surface.

- The hysteresis effect of the heating procedure, as seen in the pool boiling, was observed only for the coated tube. The heat flux decreasing process produced higher heat transfer coefficients due to the retention of the activated nucleation sites.

- In comparison with the results of pool boiling, for the smooth tube, heat transfer coefficients for falling film evaporation were slightly lower than those for pool boiling, especially in the high heat flux range, because of partial dry out. On the contrary, for the coated tube, the values for falling film evaporation were higher than those for pool boiling due to bubble agitation in the liquid film and increased evaporation from the liquid film surface.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fernández-Seara, J.; Pardiñas, Á.Á. Refrigerant falling film evaporation review: Description, fluid dynamics and heat transfer. Appl. Therm. Eng. 2014, 64, 155–171. [Google Scholar] [CrossRef]

- Ribatski, G.; Thome, J.R. Experimental study on the onset of local dryout in an evaporating falling film on horizontal plain tubes. Exp. Therm. Fluid Sci. 2007, 31, 483–493. [Google Scholar] [CrossRef]

- Christians, M.; Thome, J.R. Falling film evaporation on enhanced tubes, part 1: Experimental results for pool boiling, onset-of-dryout and falling film evaporation. Int. J. Refrig. 2012, 35, 300–312. [Google Scholar] [CrossRef]

- Chang, T.B.; Chiou, J.S. Spray evaporation heat transfer of R-141b on a horizontal tube bundle. Int. J. Heat Mass Transf. 1999, 42, 1467–1478. [Google Scholar] [CrossRef]

- Chien, L.H.; Tsai, Y.L. An experimental study of pool boiling and falling film vaporization on horizontal tubes in R-245fa. Appl. Therm. Eng. 2011, 31, 4044–4054. [Google Scholar] [CrossRef]

- Zheng, Y.; Ma, X.; Li, Y.; Jiang, R.; Wang, K.; Lan, Z.; Liang, Q. Experimental study of falling film evaporation heat transfer on superhydrophilic horizontal-tubes at low spray density. Appl. Therm. Eng. 2017, 111, 1548–1556. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Ji, W.T.; Jin, P.H.; Tao, W.Q. Heat transfer correlation of the falling film evaporation on a single horizontal smooth tube. Appl. Therm. Eng. 2016, 103, 177–186. [Google Scholar] [CrossRef]

- Jige, D.; Miyata, H.; Inoue, N. Falling film evaporation of R1234ze(E) and R245fa on a horizontal smooth tube. Exp. Therm. Fluid Sci. 2019, 105, 58–66. [Google Scholar] [CrossRef]

- McHale, J.P.; Garimella, S.V. Nucleate boiling from smooth and rough surfaces—Part 1: Fabrication and characterization of an optically transparent heater-sensor substrate with controlled surface roughness. Exp. Therm. Fluid Sci. 2013, 44, 456–467. [Google Scholar] [CrossRef] [Green Version]

- Bock, B.D.; Meyer, J.P.; Thome, J.R. Falling film boiling and pool boiling on plain circular tubes: Influence of surface roughness, surface material and saturation temperature on heat transfer and dryout. Exp. Therm. Fluid Sci. 2019, 109, 109–870. [Google Scholar] [CrossRef]

- Tehver, J.; Sui, H.; Temkina, V. Heat transfer and hysteresis phenomena in boiling on porous plasma-sprayed surface. Exp. Therm. Fluid Sci. 1992, 5, 714–727. [Google Scholar] [CrossRef]

- Asano, H.; Akita, K.; Inoue, M. Effect of gravity on pool boiling heat transfer on thermal spray coating. Microgravity Sci. Technol. 2007, 19, 90–92. [Google Scholar] [CrossRef]

- Dewangan, A.K.; Kumar, A.; Kumar, R. Experimental study of nucleate boiling heat transfer of R-134a and R-600a on thermal spray coating surfaces. Int. J. Therm. Sci. 2016, 110, 304–313. [Google Scholar] [CrossRef]

- Bogan, N.; Park, C. Influences of solution subcooling, wall superheat and porous-layer coating on heat transfer in a horizontal-tube, falling-film heat exchanger. Int. J. Heat Mass Transf. 2014, 68, 141–150. [Google Scholar] [CrossRef]

- Abed, A.M.; Alghoul, M.A.; Yazdi, M.H.; Al-Shamani, A.N.; Sopian, K. The role of enhancement techniques on heat and mass transfer characteristics of shell and tube spray evaporator: A detailed review. Appl. Therm. Eng. 2015, 75, 923–940. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Ver. 10.0; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018.

- Cooper, M.G. Heat Flow Rates in Saturated Nucleate Pool Boiling-A Wide-Ranging Examination Using Reduced Properties. Adv. Heat Transf. 1984, 16, 157–239. [Google Scholar] [CrossRef]

| Measured Physical Value | Uncertainty |

|---|---|

| Temperature | ±0.05 K |

| Pressure | ±4 × 103 Pa |

| Mass flow rate | ±4% R.D. |

| Heat input | ±5.5 W |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ubara, T.; Asano, H.; Sugimoto, K. Heat Transfer Enhancement of Falling Film Evaporation on a Horizontal Tube by Thermal Spray Coating. Appl. Sci. 2020, 10, 1632. https://doi.org/10.3390/app10051632

Ubara T, Asano H, Sugimoto K. Heat Transfer Enhancement of Falling Film Evaporation on a Horizontal Tube by Thermal Spray Coating. Applied Sciences. 2020; 10(5):1632. https://doi.org/10.3390/app10051632

Chicago/Turabian StyleUbara, Tsutomu, Hitoshi Asano, and Katsumi Sugimoto. 2020. "Heat Transfer Enhancement of Falling Film Evaporation on a Horizontal Tube by Thermal Spray Coating" Applied Sciences 10, no. 5: 1632. https://doi.org/10.3390/app10051632

APA StyleUbara, T., Asano, H., & Sugimoto, K. (2020). Heat Transfer Enhancement of Falling Film Evaporation on a Horizontal Tube by Thermal Spray Coating. Applied Sciences, 10(5), 1632. https://doi.org/10.3390/app10051632