Durability of Fabric-Reinforced Cementitious Matrix (FRCM) Composites: A Review

Abstract

:1. Introduction

2. Test Methods

3. Conditioning Environments

3.1. Freeze–Thaw Cycles

3.2. Hygrothermal Environment

3.3. Concentrated Solutions

4. Durability of Composite

4.1. Durability of Composite Matrix

4.2. Durability of the Fibers

4.3. Durability of the Matrix–Fiber Interface Capacity

4.4. Durability of the Composite–Substrate Bond Capacity

5. Conclusions

- Various conditioning environments were utilized in the literature to simulate the effect of outdoor exposure. Some of them were proposed by researchers and some others taken from standards for different materials. Therefore, the results could not be easily compared. In order to standardize specific conditioning environments for durability tests of FRCM, a thorough comparison among these conditioning environments is needed.

- Studies reported contradictory results regarding the durability of FRCM lime-based matrices exposed to saline environments. The difference among the results was attributed to the variation in the porosity and pore radius. Further studies are required to correlate the physical properties of the matrix with its durability against various environments.

- Limited studies are available regarding the corrosion of steel cords embedded within inorganic matrices. Studies of the performance of steel cords in corrosive environments are required to gain information on the durability of SRG composites.

- The effect of wet–dry cycles on the durability of inorganic-matrix composites including glass fiber textiles can be influenced by the contrasting effects of hydration and densification. Therefore, more studies are needed to better understand the dominant effect.

- The durability of the bond between matrix and fiber and composite and substrate was not thoroughly investigated yet. Studies on the effect of freeze–thaw and wet–dry cycles, alkaline environments, sulfate attack, and other exposures are needed to gain a clear and reliable understanding of the long-term behavior of externally bonded inorganic-matrix composites.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

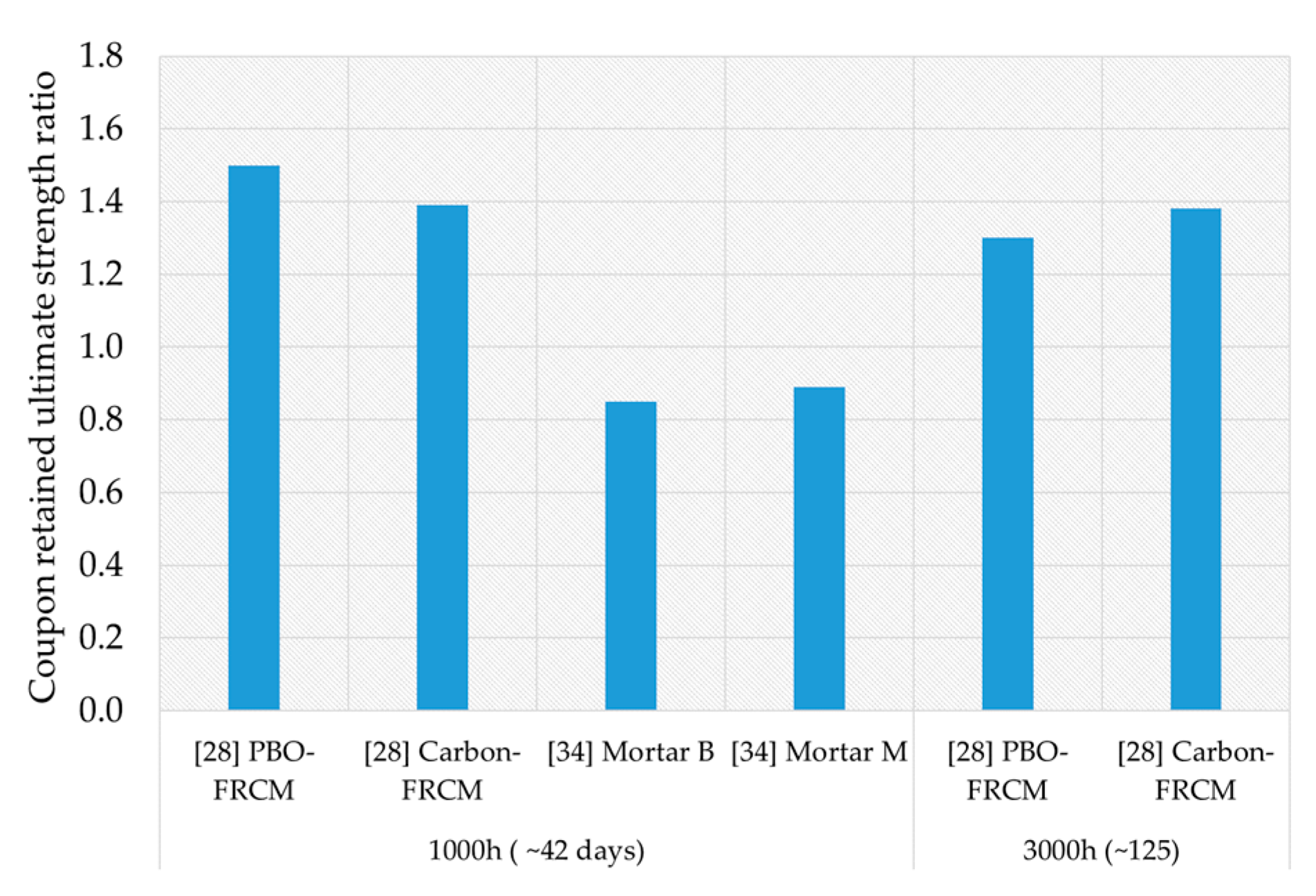

| Reference | Materials | Exposure Conditions | Tests | Average Retained Matrix Cracking Strength | Average Retained Tensile Strength of Fiber | Average Retained Ultimate Tensile Strength of Coupons |

|---|---|---|---|---|---|---|

| [28] |

|

|

|

|

|

|

| [22] |

|

|

|

|

|

|

| [21] |

|

|

|

|

|

|

| [35] |

|

|

|

|

|

|

| [26] |

|

|

|

|

|

|

| [33] |

|

|

|

|

|

|

| [53] |

|

|

|

|

|

|

| [34] |

|

|

|

|

|

|

| [51] |

|

|

|

|

|

|

| [47] |

|

|

|

|

|

|

| [14] |

|

|

|

|

|

|

| [36,43] |

|

|

|

|

|

|

References

- Abid, S.R.; Al-lami, K. Critical review of strength and durability of concrete beams externally bonded with FRP. Cogent Eng. 2018, 5, 1525015. [Google Scholar] [CrossRef]

- Breveglieri, M.; Aprile, A.; Barros, J.A.O. Shear strengthening of reinforced concrete beams strengthened using embedded through section steel bars. Eng. Struct. 2014, 81, 76–87. [Google Scholar] [CrossRef] [Green Version]

- Karbhari, V.M.; Chin, J.W.; Hunston, D.; Benmokrane, B.; Juska, T.; Morgan, R.; Lesko, J.J.; Sorathia, U.; Reynaud, D. Durability Gap Analysis for Fiber-Reinforced Polymer Composites in Civil Infrastructure. J. Compos. Constr. 2003, 7, 238–247. [Google Scholar] [CrossRef] [Green Version]

- Larson, K.H.; Peterman, R.J.; Rasheed, H.A. Strength-Fatigue Behavior of Fiber Reinforced Polymer Strengthened Prestressed Concrete T-Beams. J. Compos. Constr. 2005, 9, 313–326. [Google Scholar] [CrossRef]

- Micelli, F.; Mazzotta, R.; Leone, M.; Aiello, M.A. Review Study on the Durability of FRP-Confined Concrete. J. Compos. Constr. 2015, 19, 04014056. [Google Scholar] [CrossRef]

- Sen, R. Developments in the durability of FRP-concrete bond. Constr. Build. Mater. 2015, 78, 112–125. [Google Scholar] [CrossRef]

- Kouris, L.A.S.; Triantafillou, T.C. State-of-the-art on strengthening of masonry structures with textile reinforced mortar (TRM). Constr. Build. Mater. 2018, 188, 1221–1233. [Google Scholar] [CrossRef]

- Grace, N.F.; Grace, M. Effect of repeated loading and long term humidity exposure on flexural response of CFRP strengthened concrete beams. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures (BBFS 2005); Chen, J.F., Teng, J.G., Eds.; International Institute for FRP in Construction: Hong Kong, China, 2005; pp. 539–546. [Google Scholar]

- ACI Committee 440. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures; American Society of Civil Engineers: Farminton Hills, MI, USA, 2008; ISBN 9780870312854. [Google Scholar]

- Firmo, J.P.; Correia, J.R.; Pitta, D.; Tiago, C.; Arruda, M.R.T. Experimental characterization of the bond between externally bonded reinforcement (EBR) CFRP strips and concrete at elevated temperatures. Cem. Concr. Compos. 2015, 60, 44–54. [Google Scholar] [CrossRef]

- Ferrier, E.; Rabinovitch, O.; Michel, L. Mechanical behavior of concrete-resin/adhesive-FRP structural assemblies under low and high temperatures. Constr. Build. Mater. 2015, 127, 1017–1028. [Google Scholar] [CrossRef]

- De Santis, S.; Ceroni, F.; de Felice, G.; Fagone, M.; Ghiassi, B.; Kwiecień, A.; Lignola, G.P.; Morganti, M.; Santandrea, M.; Valluzzi, M.R.; et al. Round Robin Test on tensile and bond behaviour of Steel Reinforced Grout systems. Compos. Part B 2017, 127, 100–120. [Google Scholar] [CrossRef]

- D’Antino, T.; Carloni, C.; Sneed, L.H.; Pellegrino, C. Matrix–fiber bond behavior in PBO FRCM composites: A fracture mechanics approach. Eng. Fract. Mech. 2014, 117, 94–111. [Google Scholar] [CrossRef]

- Pekmezci, B.Y.; Arabaci, E.; Ustundag, C. Freeze–thaw Durability of Lime Based FRCM Systems for Strengthening Historical Masonry. Key Eng. Mater. 2019, 817, 174–181. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V.; Nanni, A. FRCM mechanical properties using carbon fabrics with different coating treatments. In ACI Special Publication; American Concrete Institute: Farmington Hills, MI, USA, 2015; pp. 8.1–8.12. [Google Scholar]

- Bencardino, F.; Condello, A.; Ashour, A.F. Single-lap shear bond tests on Steel Reinforced Geopolymeric Matrix-concrete joints. Compos. Part B Eng. 2017, 110, 62–67. [Google Scholar] [CrossRef] [Green Version]

- Bencardino, F.; Condello, A. Eco-friendly external strengthening system for existing reinforced concrete beams. Compos. Part B Eng. 2016, 93, 163–173. [Google Scholar] [CrossRef]

- Bencardino, F.; Condello, A. Structural behaviour of RC beams externally strengthened in flexure with SRG and SRP systems. Int. J. Struct. Eng. 2014, 5, 346–368. [Google Scholar] [CrossRef]

- D’Antino, T.; Carozzi, F.G.; Colombi, P.; Poggi, C. Out-of-plane maximum resisting bending moment of masonry walls strengthened with FRCM composites. Compos. Struct. 2018, 202, 881–896. [Google Scholar] [CrossRef]

- Koutas, L.N.; Tetta, Z.; Bournas, D.A.; Triantafillou, T.C. Strengthening of Concrete Structures with Textile Reinforced Mortars: State-of-the-Art Review. J. Compos. Constr. 2019, 23, 03118001. [Google Scholar] [CrossRef]

- Yin, S.; Jing, L.; Yin, M.; Wang, B. Mechanical properties of textile reinforced concrete under chloride wet–dry and freeze–thaw cycle environments. Cem. Concr. Compos. 2019, 96, 118–127. [Google Scholar] [CrossRef]

- Colombo, I.G.; Colombo, M.; Di Prisco, M. Tensile behavior of textile reinforced concrete subjected to freezing-thawing cycles in un-cracked and cracked regimes. Cem. Concr. Res. 2015, 73, 169–183. [Google Scholar] [CrossRef]

- International Code Council Evaluation Service (ICC-ES). Masonry and Concrete Strengthening Using Fabric-Reinforced Cementitious Matrix (FRCM) and Steel Reinforced Grout (SRG) Composite Systems AC434; International Code Council Evaluation Service: Whittier, CA, USA, 2018. [Google Scholar]

- CSLLPP—Servizio Tecnico Centrale. Linee Guida per la Identificazione, la Qualificazione ed il Controllo di Accettazione di Compositi Fibrorinforzati a Matrice Inorganica (FRCM) da Utilizzarsi per il Consolidamento Strutturale di Costruzioni Esistenti; CSLLPP: Rome, Italy, 2019. [Google Scholar]

- Carozzi, F.G.; Bellini, A.; D’Antino, T.; de Felice, G.; Focacci, F.; Hojdys, Ł.; Laghi, L.; Lanoye, E.; Micelli, F.; Panizza, M.; et al. Experimental investigation of tensile and bond properties of Carbon-FRCM composites for strengthening masonry elements. Compos. Part B Eng. 2017, 128, 100–119. [Google Scholar] [CrossRef]

- De Munck, M.; El Kadi, M.; Tsangouri, E.; Vervloet, J.; Verbruggen, S.; Wastiels, J.; Tysmans, T.; Remy, O. Influence of environmental loading on the tensile and cracking behaviour of textile reinforced cementitious composites. Constr. Build. Mater. 2018, 181, 325–334. [Google Scholar] [CrossRef]

- Butler, M.; Mechtcherine, V.; Hempel, S. Experimental investigations on the durability of fibre-matrix interfaces in textile-reinforced concrete. Cem. Concr. Compos. 2009, 31, 221–231. [Google Scholar] [CrossRef]

- Arboleda, D. Fabric Reinforced Cementitious Matrix (FRCM) Composites for Infrastructure Strengthening and Rehabilitation: Characterization Methods. Ph.D. Thesis, University of Miami, Coral Gables, FL, USA, 2014. [Google Scholar]

- Carozzi, F.G.; Poggi, C. Mechanical properties and debonding strength of Fabric Reinforced Cementitious Matrix (FRCM) systems for masonry strengthening. Compos. Part B 2015, 70, 215–230. [Google Scholar] [CrossRef]

- Focacci, F.; D’Antino, T.; Carloni, C. Analytical modelling of the tensile response of PBO-FRCM composites. In Proceedings of the twenty-fourth Italian Association of Theoretical and Applied Mechanics Convention (AIMETA 2019), Rome, Italy, 15–19 September 2019. [Google Scholar]

- ASTM International. Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials. ASTM D2344/D2344M-13; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- EN 1015-11 BSI Standards Publication Methods of Test for Mortar for Masonry; CEN: Bruxelles, Belgium, 2019.

- Donnini, J. Durability of glass FRCM systems: Effects of different environments on mechanical properties. Compos. Part B Eng. 2019, 174, 107047. [Google Scholar] [CrossRef]

- Nobili, A. Durability assessment of impregnated Glass Fabric Reinforced Cementitious Matrix (GFRCM) composites in the alkaline and saline environments. Constr. Build. Mater. 2016, 105, 465–471. [Google Scholar] [CrossRef] [Green Version]

- Ceroni, F.; Bonati, A.; Galimberti, V.; Occhiuzzi, A. Effects of environmental conditioning on the bond behavior of FRP and FRCM systems applied to concrete elements. J. Eng. Mech. 2018, 144, 1–15. [Google Scholar] [CrossRef]

- Franzoni, E.; Gentilini, C.; Santandrea, M.; Zanotto, S.; Carloni, C. Durability of steel FRCM-masonry joints: Effect of water and salt crystallization. Mater. Struct. Mater. Constr. 2017, 50, 201. [Google Scholar] [CrossRef]

- Cabral-fonseca, S.; Correia, J.R.; Custódio, J.; Silva, H.M.; Machado, A.M.; Sousa, J. Durability of FRP—Concrete bonded joints in structural rehabilitation: A review. Int. J. Adhes. Adhes. 2018, 83, 153–167. [Google Scholar] [CrossRef]

- BS EN 12467, E.S. Fibre-cement flat sheets—Product specification and test methods. Shock 2004, 2009, 1–8. [Google Scholar]

- ASTM International. Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM C666/C666M; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM International. Standard Test Method for Alkali Resistance of Fiber Reinforced Polymer (FRP) Matrix Composite Bars Used in Concrete Construction. ASTM D7705/D7705M; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- D’Antino, T.; Pisani, M.A.; Poggi, C. Effect of the environment on the performance of GFRP reinforcing bars. Compos. Part B 2018, 141, 123–136. [Google Scholar] [CrossRef]

- Micelli, F.; Nanni, A. Durability of FRP rods for concrete structures. Constr. Build. Mater. 2004, 18, 491–503. [Google Scholar] [CrossRef]

- Franzoni, E.; Gentilini, C.; Santandrea, M.; Carloni, C. Effects of rising damp and salt crystallization cycles in FRCM-masonry interfacial debonding: Towards an accelerated laboratory test method. Constr. Build. Mater. 2018, 175, 225–238. [Google Scholar] [CrossRef]

- Kabir, M.I.; Shrestha, R.; Samali, B.; Ikramul, M.; Shrestha, R.; Samali, B. Effects of applied environmental conditions on the pull-out strengths of CFRP-concrete bond. Constr. Build. Mater. 2016, 114, 817–830. [Google Scholar] [CrossRef]

- EN 12370:1999 Natural Stone Test Methods: Resistance to Salt Crystallization; CEN: Bruxelles, Belgium, 1999.

- RILEM TC 127-MS MS-A.1. Determination of the resistance of wallettes against sulphates and chlorides. Mat. Struct. 1998, 31, 2–9. [Google Scholar] [CrossRef]

- Butler, M.; Mechtcherine, V.; Hempel, S. Durability of textile reinforced concrete made with AR glass fibre: Effect of the matrix composition. Mater. Struct. Mater. Constr. 2010, 43, 1351–1368. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Y.M.; Yan, H.D.; Mu, R. Damage and damage resistance of high strength concrete under the action of load and freeze–thaw cycles. Cem. Concr. Res. 1999, 29, 1519–1523. [Google Scholar] [CrossRef]

- Lomboy, G.; Wang, K. Effects of strength, permeability, and air void parameters on freezing-thawing resistance of concrete with and without air entrainment. J. ASTM Int. 2009, 6, 1–14. [Google Scholar]

- Benzarti, K.; Chataigner, S.; Quiertant, M.; Marty, C.; Aubagnac, C. Accelerated aging behaviour of the adhesive bond between concrete specimens and CFRP overlays. Constr. Build. Mater. 2011, 25, 523–538. [Google Scholar] [CrossRef]

- Portal, W.N.; Flansbjer, M.; Johannesson, P.; Malaga, K.; Lundgren, K. Tensile behaviour of textile reinforcement under accelerated aging conditions. J. Build. Eng. 2016, 5, 57–66. [Google Scholar] [CrossRef]

- Scheffler, C.; Förster, T.; Mäder, E.; Heinrich, G.; Hempel, S.; Mechtcherine, V. Aging of alkali-resistant glass and basalt fibers in alkaline solutions: Evaluation of the failure stress by Weibull distribution function. J. Non Cryst. Solids 2009, 355, 2588–2595. [Google Scholar] [CrossRef]

- Hristozov, D.; Wroblewski, L.; Sadeghian, P. Long-term tensile properties of natural fibre-reinforced polymer composites: Comparison of flax and glass fibres. Compos. Part B Eng. 2016, 95, 82–95. [Google Scholar] [CrossRef]

- Roventi, G.; Bellezze, T.; Giuliani, G.; Conti, C. Corrosion resistance of galvanized steel reinforcements in carbonated concrete: Effect of wet–dry cycles in tap water and in chloride solution on the passivating layer. Cem. Concr. Res. 2014, 65, 76–84. [Google Scholar] [CrossRef]

- Fayala, I.; Dhouibi, L.; Nóvoa, X.R.; Ben Ouezdou, M. Effect of inhibitors on the corrosion of galvanized steel and on mortar properties. Cem. Concr. Compos. 2013, 35, 181–189. [Google Scholar] [CrossRef]

- Yadav, A.P.; Nishikata, A.; Tsuru, T. Degradation mechanism of galvanized steel in wet–dry cyclic environment containing chloride ions. Corros. Sci. 2004, 46, 361–376. [Google Scholar] [CrossRef]

- Carloni, C.; D’Antino, T.; Sneed, L.H.; Pellegrino, C. Three-Dimensional Numerical Modeling of Single-Lap Direct Shear Tests of FRCM-Concrete Joints Using a Cohesive Damaged Contact Approach. J. Compos. Constr. 2018, 22, 04017048. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Lami, K.; D’Antino, T.; Colombi, P. Durability of Fabric-Reinforced Cementitious Matrix (FRCM) Composites: A Review. Appl. Sci. 2020, 10, 1714. https://doi.org/10.3390/app10051714

Al-Lami K, D’Antino T, Colombi P. Durability of Fabric-Reinforced Cementitious Matrix (FRCM) Composites: A Review. Applied Sciences. 2020; 10(5):1714. https://doi.org/10.3390/app10051714

Chicago/Turabian StyleAl-Lami, Karrar, Tommaso D’Antino, and Pierluigi Colombi. 2020. "Durability of Fabric-Reinforced Cementitious Matrix (FRCM) Composites: A Review" Applied Sciences 10, no. 5: 1714. https://doi.org/10.3390/app10051714

APA StyleAl-Lami, K., D’Antino, T., & Colombi, P. (2020). Durability of Fabric-Reinforced Cementitious Matrix (FRCM) Composites: A Review. Applied Sciences, 10(5), 1714. https://doi.org/10.3390/app10051714