Application of Zero Average Dynamics and Fixed Point Induction Control Techniques to Control the Speed of a DC Motor with a Buck Converter

Abstract

:1. Introduction

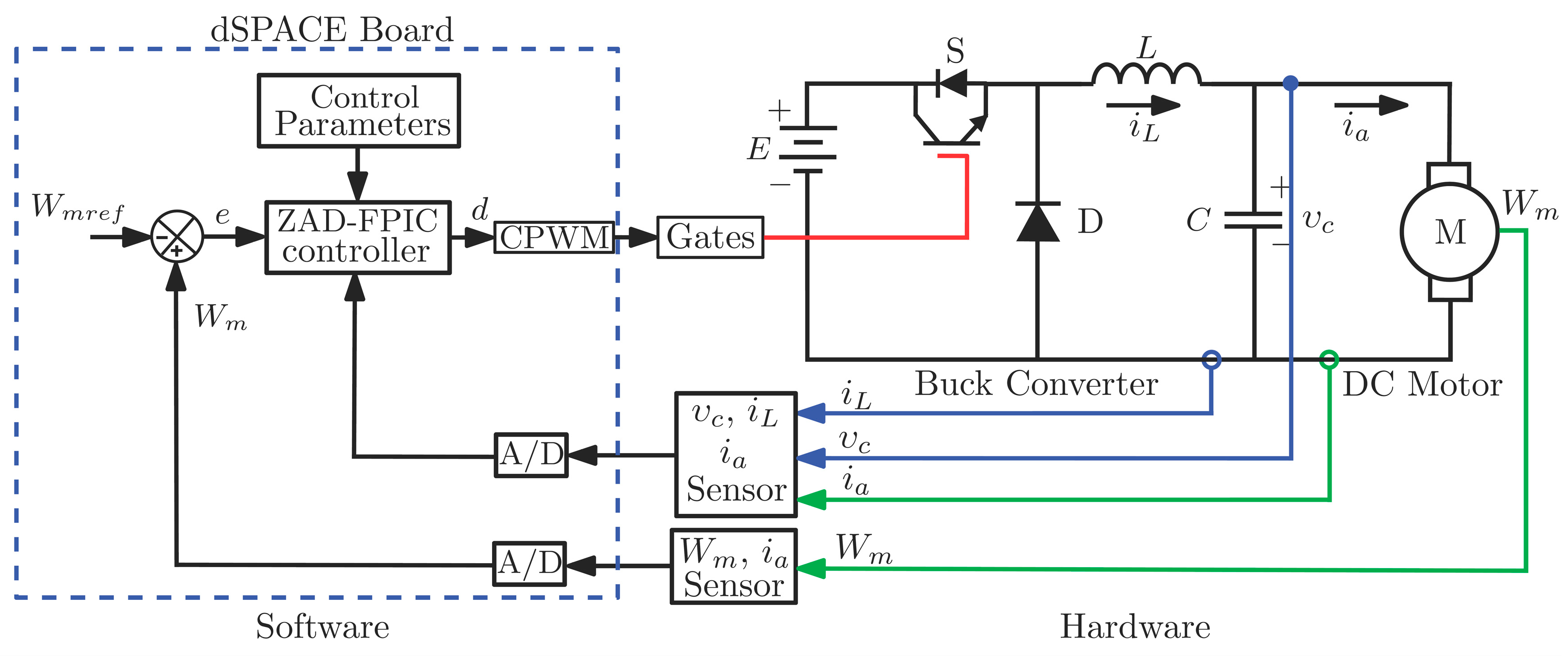

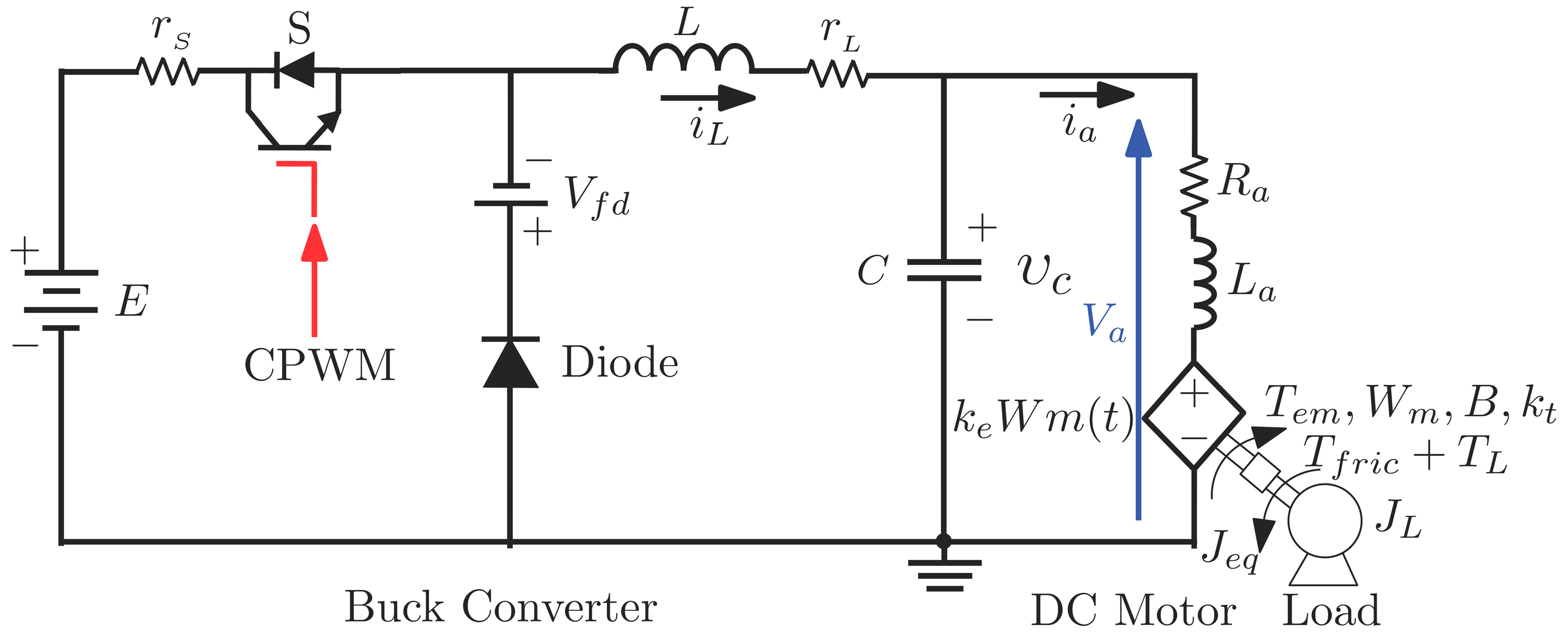

2. Materials and Methods

2.1. Model of the Buck Converter with a DC Motor

2.2. Speed Control of a DC Motor

3. Results and Analysis

3.1. Transient-State Results

3.2. Steady-State Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ADC | Analog-to-digital converter |

| AC | Alternating current |

| CPWM | Centered pulse width modulation |

| DC | Direct current |

| DPWM | Digital pulse width modulation |

| DSP | Digital signal processor |

| FPGA | Field-programmable gate array |

| FPIC | Fixed point induction control |

| LC | Inductive-capacitive |

| MOSFET | Metal–oxide–semiconductor field-effect transistor |

| OS | Overshoot |

| PID | Proportional integral derivative |

| PWM | Pulse-width modulation |

| SISO | Single-input and single-output |

| SMC | Sliding mode control |

| SSError | Steady-state error |

| ST | Settling time |

| SVPWM | Space vector pulse width modulation |

| ZAD | Zero average dynamics |

| ZAD-FPIC | Zero average dynamics and fixed point induction control |

References

- Cuong, N.D.; Van Lanh, N.; Dinh, G.T. An Adaptive LQG Combined With the MRAS—Based LFFC for Motion Control Systems. J. Autom. Control Eng. 2015, 3, 130–136. [Google Scholar] [CrossRef]

- Sankardoss, V.; Geethanjali, P. PMDC Motor Parameter Estimation Using Bio-Inspired Optimization Algorithms. IEEE Access 2017, 5, 11244–11254. [Google Scholar] [CrossRef]

- Guerrero, E.; Linares, J.; Guzman, E.; Sira, H.; Guerrero, G.; Martinez, A. DC Motor Speed Control through Parallel DC/DC Buck Converters. IEEE Lat. Am. Trans. 2017, 15, 819–826. [Google Scholar] [CrossRef]

- Hoyos Velasco, F.; Candelo-Becerra, J.; Rincón Santamaría, A. Dynamic Analysis of a Permanent Magnet DC Motor Using a Buck Converter Controlled by ZAD-FPIC. Energies 2018, 11, 3388. [Google Scholar] [CrossRef] [Green Version]

- Jia, N.; Wang, T. Chaos control and hybrid projective synchronization for a class of new chaotic systems. Comput. Math. Appl. 2011, 62, 4783–4795. [Google Scholar] [CrossRef] [Green Version]

- Hoyos Velasco, F.E.; Toro-García, N.; Garcés Gómez, Y.A. Adaptive Control for Buck Power Converter Using Fixed Point Inducting Control and Zero Average Dynamics Strategies. Int. J. Bifurc. Chaos 2015, 25, 1550049. [Google Scholar] [CrossRef]

- Lascu, C.; Trzynadlowski, A.M. Combining the Principles of Sliding Mode, Direct Torque Control, and Space-Vector Modulation in a High-Performance Sensorless AC Drive. IEEE Trans. Ind. Appl. 2004, 40, 170–177. [Google Scholar] [CrossRef]

- Lascu, C.; Boldea, I.; Blaabjerg, F. Direct Torque Control of Sensorless Induction Motor Drives: A Sliding-Mode Approach. IEEE Trans. Ind. Appl. 2004, 40, 582–590. [Google Scholar] [CrossRef]

- Orlowska-Kowalska, T.; Dybkowski, M.; Szabat, K. Adaptive Sliding-Mode Neuro-Fuzzy Control of the Two-Mass Induction Motor Drive Without Mechanical Sensors. IEEE Trans. Ind. Electron. 2010, 57, 553–564. [Google Scholar] [CrossRef]

- Wu, J.; Pu, D.; Ding, H. Adaptive robust motion control of SISO nonlinear systems with implementation on linear motors. Mechatronics 2007, 17, 263–270. [Google Scholar] [CrossRef]

- Huang, A.-C.; Kuo, Y.-S. Sliding control of non-linear systems containing time-varying uncertainties with unknown bounds. Int. J. Control 2001, 74, 252–264. [Google Scholar] [CrossRef]

- Yazdanpanah, R.; Soltani, J.; Arab Markadeh, G.R. Nonlinear torque and stator flux controller for induction motor drive based on adaptive input–output feedback linearization and sliding mode control. Energy Convers. Manag. 2008, 49, 541–550. [Google Scholar] [CrossRef]

- Leva, A.; Piroddi, L.; Di Felice, M.; Boer, A.; Paganini, R. Adaptive relay-based control of household freezers with on–off actuators. Control Eng. Pract. 2010, 18, 94–102. [Google Scholar] [CrossRef]

- Di Felice, M.; Piroddi, L.; Leva, A.; Boer, A. Adaptive temperature control of a household refrigerator. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 889–894. [Google Scholar]

- Hilairet, M.; Auger, F. Speed sensorless control of a DC-motor via adaptive filters. IET Electr. Power Appl. 2007, 1, 601. [Google Scholar] [CrossRef]

- Hu, H.; Yousefzadeh, V.; Maksimovic, D. Nonuniform A/D Quantization for Improved Dynamic Responses of Digitally Controlled DC-DC Converters. IEEE Trans. Power Electron. 2008, 23, 1998–2005. [Google Scholar] [CrossRef]

- Fung, C.W.; Liu, C.P.; Pong, M.H. A Diagrammatic Approach to Search for Minimum Sampling Frequency and Quantization Resolution for Digital Control of Power Converters. In Proceedings of the 2007 IEEE Power Electronics Specialists Conference, Orlando, FL, USA, 17–21 June 2007; pp. 826–832. [Google Scholar]

- Taborda, J.A.; Angulo, F.; Olivar, G. Estimation of parameters in Buck converter with Digital-PWM control based on ZAD strategy. In Proceedings of the 2011 IEEE Second Latin American Symposium on Circuits and Systems (LASCAS), Bogata, Colombia, 23–25 February 2011; pp. 1–4. [Google Scholar]

- Maksimovic, Z. Erickson Impact of digital control in power electronics. In Proceedings of the 16th International Symposium on Power Semiconductor Devices & IC’s, Kitakyushu, Japan, 24–27 May 2004; pp. 13–22. [Google Scholar]

- Peterchev, A.V.; Sanders, S.R. Quantization resolution and limit cycling in digitally controlled PWM converters. IEEE Trans. Power Electron. 2003, 18, 301–308. [Google Scholar] [CrossRef] [Green Version]

- Peng, H.; Maksimovic, D.; Prodic, A.; Alarcon, E. Modeling of quantization effects in digitally controlled DC-DC converters. IEEE 2004, 4312–4318. [Google Scholar] [CrossRef]

- Angulo, F.; Hoyos, F.; Olivar, G. Experimental results on the quantization in the ADC device for a ZAD-strategy controlled DC-DC buck converter. In Proceedings of the 7th European Nonlinear Dynamics Conference, Rome, Italy, 24–29 July 2011; pp. 1–6. [Google Scholar]

- Tirandaz, H.; Ahmadnia, M.; Tavakoli, H. Adaptive Projective Lag Synchronization of T and Lu Chaotic Systems. Int. J. Electr. Comput. Eng. 2017, 7, 3446–3453. [Google Scholar] [CrossRef] [Green Version]

- Corradini, L.; Mattavelli, P. Analysis of Multiple Sampling Technique for Digitally Controlled dc-dc Converters. In Proceedings of the 37th IEEE Power Electronics Specialists Conference, Jeju, Korea, 18–22 June 2006; pp. 1–6. [Google Scholar]

- Hoyos, F.E.; Burbano, D.; Angulo, F.; Olivar, G.; Toro, N.; Taborda, J.A. Effects of Quantization, Delay and Internal Resistances in Digitally ZAD-Controlled Buck Converter. Int. J. Bifurc. Chaos 2012, 22, 1250245. [Google Scholar] [CrossRef]

- Hoyos, F.E.; Rincón, A.; Taborda, J.A.; Toro, N.; Angulo, F. Adaptive Quasi-Sliding Mode Control for Permanent Magnet DC Motor. Math. Probl. Eng. 2013, 2013, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Hoyos, F.E.; Candelo-Becerra, J.E.; Toro, N. Numerical and experimental validation with bifurcation diagrams for a controlled DC–DC converter with quasi-sliding control. TecnoLógicas 2018, 21, 147–167. [Google Scholar] [CrossRef] [Green Version]

- Fossas, E.; Griño, R.; Biel, D. Quasi-Sliding control based on pulse width modulation, zero averaged dynamics and the L2 norm. In Proceedings of the Advances in Variable Structure Systems—6th IEEE International Workshop on Variable Structure Systems, Orlando, FL, USA, 4–7 December 2001; pp. 335–344. [Google Scholar]

- Biel, D.; Fossas, E.; Ramos, R.; Sudria, A. Programmable logic device applied to the quasi-sliding control implementation based on zero averaged dynamics. In Proceedings of the Proceedings of the 40th IEEE Conference on Decision and Control (Cat. No.01CH37228), Orlando, FL, USA, 4–7 December 2001; Volume 2, pp. 1825–1830. [Google Scholar]

- Ramos, R.R.; Biel, D.; Fossas, E.; Guinjoan, F. A fixed-frequency quasi-sliding control algorithm: Application to power inverters design by means of FPGA implementation. IEEE Trans. Power Electron. 2003, 18, 344–355. [Google Scholar] [CrossRef]

- Angulo, F.; Olivar, G.; Taborda, J.; Hoyos, F. Nonsmooth dynamics and FPIC chaos control in a DC-DC ZAD-strategy power converter. In Proceedings of the ENOC, Saint Petersburg, Rusia, 30 June–4 July 2008; pp. 1–6. [Google Scholar]

- Hoyos, F.E.; Candelo, J.E.; Taborda, J.A. Selection and validation of mathematical models of power converters using rapid modeling and control prototyping methods. Int. J. Electr. Comput. Eng. 2018, 8, 1551. [Google Scholar] [CrossRef]

- Hoyos, F.E.; Candelo-Becerra, J.E.; Hoyos Velasco, C.I. Model-Based Quasi-Sliding Mode Control with Loss Estimation Applied to DC–DC Power Converters. Electronics 2019, 8, 1086. [Google Scholar] [CrossRef] [Green Version]

- Hernandez Marquez, E.; Silva Ortigoza, R.; Garcia Sanchez, J.R.; Garcia Rodriguez, V.H.; Alba Juarez, J.N. A New “DC/DC Buck-Boost Converter-DC Motor” System: Modeling and Experimental Validation. IEEE Lat. Am. Trans. 2017, 15, 2043–2049. [Google Scholar] [CrossRef]

- Silva Ortigoza, R.; Alba Juarez, J.N.; Garcia Sanchez, J.R.; Hernandez Guzman, V.M.; Sosa Cervantes, C.Y.; Taud, H. A Sensorless Passivity-Based Control for the DC/DC Buck Converter-Inverter-DC Motor System. IEEE Lat. Am. Trans. 2016, 14, 4227–4234. [Google Scholar] [CrossRef]

- Department of Electrical and Computer Engineering University of Minnesota. DSP Based Electric Drives Laboratory: User Manual; Department of Electrical and Computer Engineering University of Minnesota: Minneapolis, MN, USA, 2012.

| Parameter | Description | Value |

|---|---|---|

| Total resistance at the source | ||

| Power supply voltage | 40.086 V | |

| Forward voltage | 1.1 V | |

| Inductance | mH | |

| Total resistance in the inductor | ||

| Capacitance | F | |

| Armature resistance | ||

| Armature inductance | mH | |

| Viscosity friction coefficient | 0.000138 (N·m/(rad/s)) | |

| Inertia moment | 0.000115 (kg) | |

| Motor torque constant | 0.0663 (N·m/A) | |

| Motor voltage constant | 0.0663 (V/rad/s) | |

| Friction constant | 0.0284 (N·m) | |

| Load torque | Variable (N·m) | |

| Speed reference | Variable (rad/s) | |

| Speed of the DC motor | Variable (rad/s) | |

| Control parameter of the FPIC | 1 | |

| Switching frequency | 6 kHz | |

| Sampling frequency | 6 kHz | |

| Delay period | s | |

| Control parameter | 2 | |

| Control parameter | 2 | |

| Control parameter | Variable |

| Index | Simulation Test | Experimental Test |

|---|---|---|

| OS (%) | 0.57 | 0 |

| ST (seg) | 0.1473 | 0.1859 |

| SSError (%) | −0.1645 | 0.4245 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hoyos, F.E.; Candelo-Becerra, J.E.; Hoyos Velasco, C.I. Application of Zero Average Dynamics and Fixed Point Induction Control Techniques to Control the Speed of a DC Motor with a Buck Converter. Appl. Sci. 2020, 10, 1807. https://doi.org/10.3390/app10051807

Hoyos FE, Candelo-Becerra JE, Hoyos Velasco CI. Application of Zero Average Dynamics and Fixed Point Induction Control Techniques to Control the Speed of a DC Motor with a Buck Converter. Applied Sciences. 2020; 10(5):1807. https://doi.org/10.3390/app10051807

Chicago/Turabian StyleHoyos, Fredy E., John E. Candelo-Becerra, and Carlos I. Hoyos Velasco. 2020. "Application of Zero Average Dynamics and Fixed Point Induction Control Techniques to Control the Speed of a DC Motor with a Buck Converter" Applied Sciences 10, no. 5: 1807. https://doi.org/10.3390/app10051807