Multi-Objective Optimization of Spatially Truss Structures Based on Node Movement

Abstract

:1. Introduction

2. MOEA Algorithm and Improvement

2.1. Basic Concept of MOEA

2.2. Improvement to MOEA

2.2.1. Mathematical Model

2.2.2. Pareto Dominate Relations

3. Numerical Method Verification

3.1. Function Test

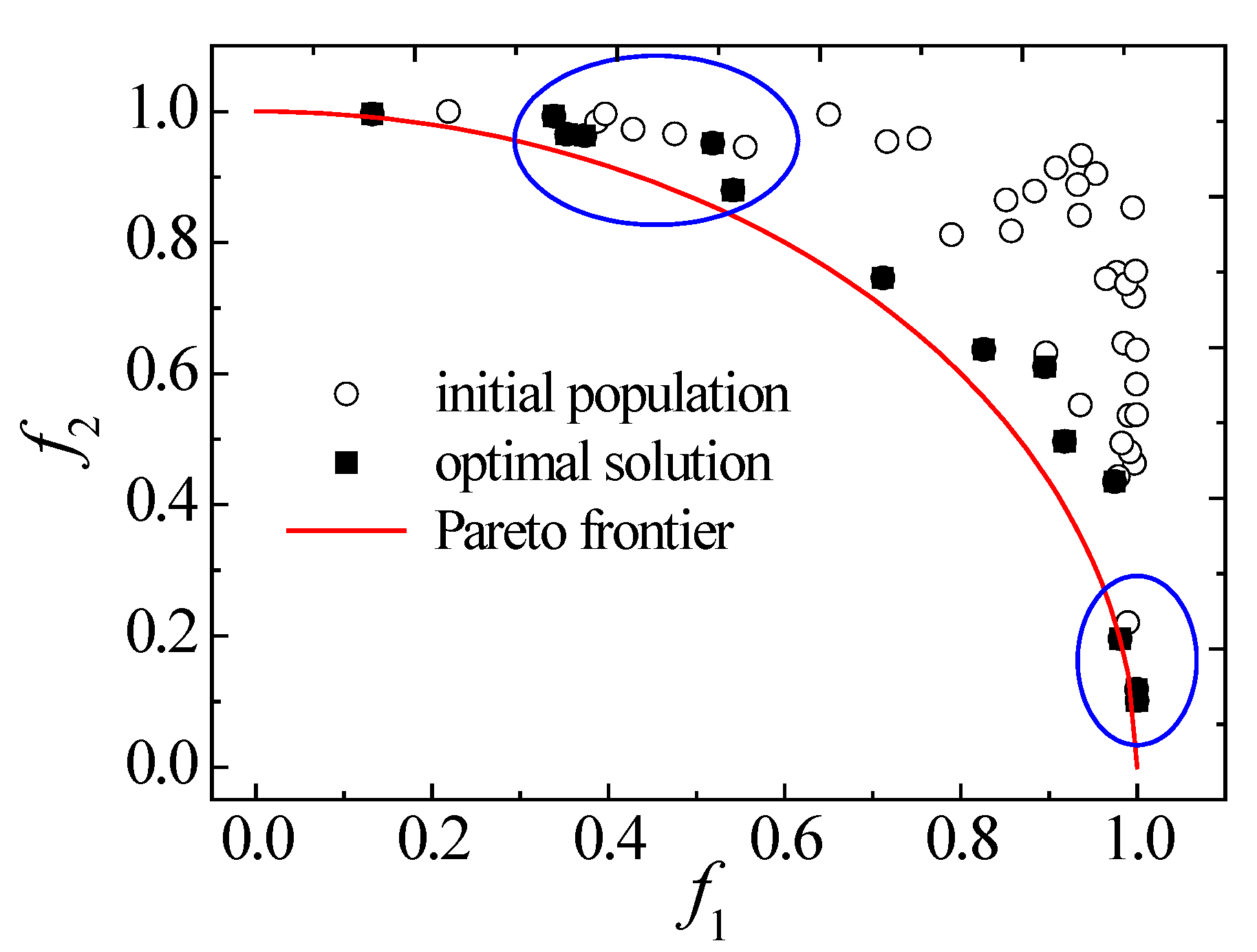

3.1.1. Test Function MOP1

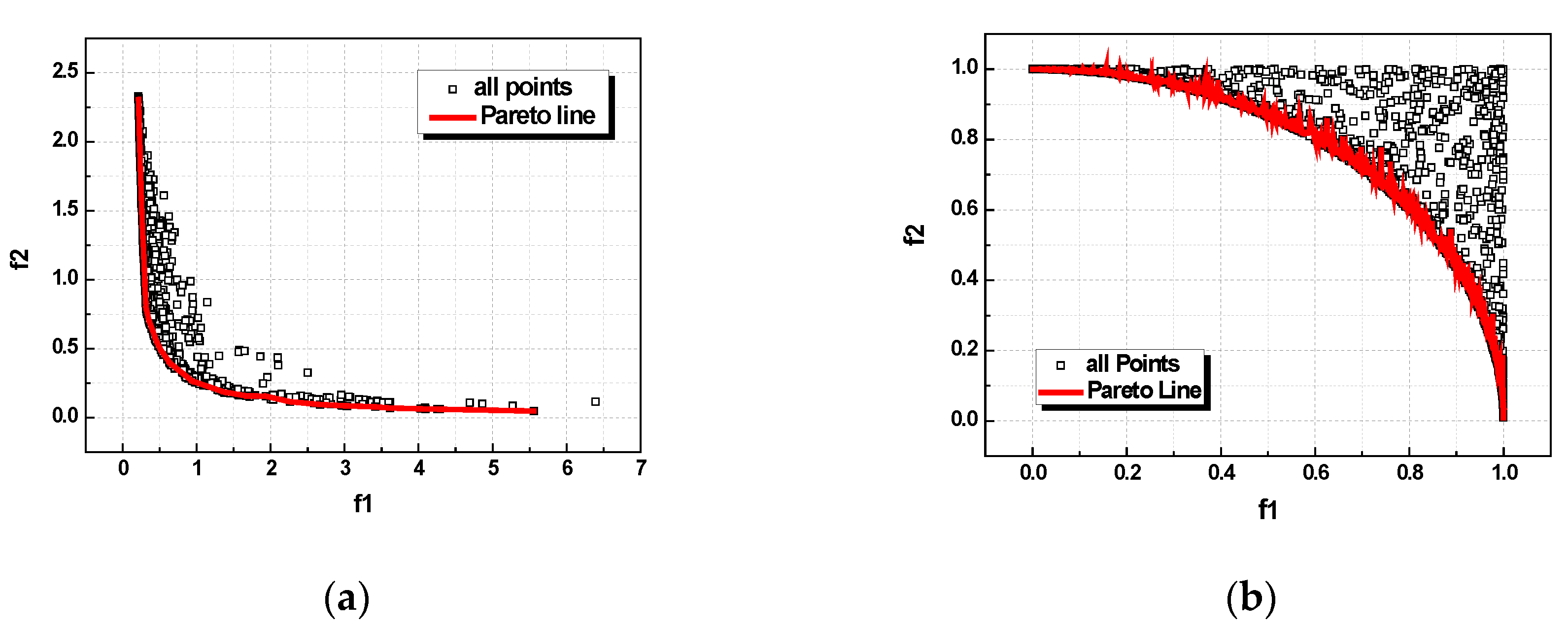

3.1.2. Test Function MOP2

3.2. Test Results

4. Analysis of Typical Discrete Structure Optimization

4.1. Space Truss Optimization

4.2. Space Tower Optimization

5. Conclusions

- (1)

- In this study, an improved MOEA optimization method was adopted to realize optimization of spatial discrete structures using moving bar node coordinates.

- (2)

- In contrast to the traditional optimization, which uses weight as the only object, the improved MOEA multi-objective optimization method is a combination of the structural weight and the maximum displacement of the spatially discrete structure. This method uses the strength rank idea and obtains a group of optimal solutions, not an individual value. Then, the optimal case can be confirmed according to other constraint conditions, such as the boundary value and the user’s preferences.

- (3)

- This algorithm was tested using standard mathematical functions, and the results indicate that the rate of convergence is fast and that no inferior solution evenly distributes in the solution space, which maintains good diversity without converging to a local part. Thus, we used the combination of this method with ANSYS to analyze a three-dimensional truss and tower structure, and the results confirmed that the modified MOEA algorithm appears to be feasible and superior with respect to the optimization of the discrete structure design.

Author Contributions

Funding

Conflicts of Interest

References

- Michell, A.G.M. The limits of economy of material in frame structures. Philos. Mag. 1904, 8, 589–597. [Google Scholar] [CrossRef] [Green Version]

- Prager, W. A note on discredited michell structures. Comput. Method Appl. Mech. 1974, 3, 349–355. [Google Scholar] [CrossRef]

- Dorn, W.S.; Gomory, R.E.; Greenberg, H.J. Automatic design of optimal structures. J. Mech. 1964, 3, 25–52. [Google Scholar]

- Sivapuram, R.; Picelli, R. Topology optimization of binary structures using Integer Linear Programming. Finite Elem. Anal. Des. 2018, 139, 49–61. [Google Scholar] [CrossRef]

- Tang, Z.F.; Sun, H.C. The modified simplex method for topology optimization of space truss structure with multiple loading conditions. Acta Mech. Sin. PRC 1994, 26, 90–96. [Google Scholar]

- Víctor, C.; Juan, L.C.; Abubakr, M.I. Optimization using the gradient and simplex methods. Talanta 2016, 148, 641–648. [Google Scholar]

- Sun, R.F.; Mou, Z.G.; Yan, M. Application of genetic algorithms design of truss structures. J. Build. Eng. 2004, 5, 75–79. [Google Scholar]

- Ioannis, N.T.; Lassi, L.; Toni, K.; Jarkko, N. Structural optimization employing isogeometric tools in particle swarm optimizer. J. Build. Eng. 2019, 24, 100761. [Google Scholar] [CrossRef]

- Ghannad, M.; Rahimi, G.H.; Nejad, M.Z. Elastic analysis of pressurized thick cylindrical shells with variable thickness made of functionally graded materials. Compos. Part B Eng. 2013, 45, 388–396. [Google Scholar] [CrossRef]

- Laumanns, M.; Thiele, L.; Deb, K.; Zitzler, E. Combining convergence and diversity in evolutionary multi-objective optimization. Evol. Comput. 2002, 10, 263–282. [Google Scholar] [CrossRef] [PubMed]

- Fonseca, C.; Fleming, P.J. Multi-objective optimization and multiple constraints handling with evolutionary algorithms Part 1: A Unified for mutation. IEEE Trans. Syst. Man Cybern. A 1998, 28, 26–37. [Google Scholar] [CrossRef] [Green Version]

- Srinivas, N.; Deb, K. Multi-objective optimization using non-dominated sorting in genetic algorithms. Evol. Comput. 1995, 2, 221–248. [Google Scholar] [CrossRef]

- San, B.; Waisman, H.; Harari, I. Analytical and Numerical Shape Optimization of a Class of Structures under Mass Constraints and Self-Weight. J. Eng. Mech. ASCE 2010, 146, 04019109. [Google Scholar] [CrossRef]

- Luis, M.J.; Alejandro, B.P.; Gutierrez, G.J.; Di, R.A. A selective genetic algorithm for multi objective optimization of cross sections in 3D trussed structures based on a spatial sensitivity analysis. Multidiscip. Model. Mater. Struct. 2016, 12, 423–435. [Google Scholar]

- Deb, K. Multi-Objective Optimization Using Evolutionary Algorithms; Wiley: Chichester, UK, 2001. [Google Scholar]

- Noilublao, N.; Bureerat, S. Simultaneous topology, shape and sizing optimization of a three-dimensional slender truss tower using multi objective evolutionary algorithms. Comput. Struct. 2011, 89, 2531–2538. [Google Scholar] [CrossRef]

- Galante, M. Genetic algorithms as an approach to optimize real-world trusses. Int. J. Numer. Methods Eng. 1996, 39, 361–382. [Google Scholar] [CrossRef]

- Kaveh, A.; Zolghadr, A. Democratic PSO for truss layout and size optimization with frequency. Comput. Struct. 2014, 130, 10–21. [Google Scholar] [CrossRef]

- Mokarram, V.; Banan, M. A new PSO-based algorithm for multi-objective optimization with continuous and discrete design variables. Struct. Multidiscip. Optim. 2018, 57, 509–533. [Google Scholar] [CrossRef]

- Deb, K.; Samir, A.; Amrit, P.; Meyarivan, T. A Fast and Elitist Multi-Objective Genetic Algorithm: NSGA-II. KanGal Report, 2000, 01; Indian Institute of Technology: KanPur, India, 2000; Volume 1. [Google Scholar]

- Hirad, A.; Ali, J.; Nader, N. Multi-objective sizing and topology optimization of truss structures using genetic programming based on a new adaptive mutant operator. Neural Comput. Appl. 2019, 31, 5729–5749. [Google Scholar]

| Population Size | Terminate Generation | Crossover Probability | Mutation Probability |

|---|---|---|---|

| 40 | 30 | 0.4 | 0.02 |

| Population Size | Terminate Generation | Crossover Probability | Mutation Probability |

|---|---|---|---|

| 50 | 50 | 0.4 | 0.02 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nan, B.; Bai, Y.; Wu, Y. Multi-Objective Optimization of Spatially Truss Structures Based on Node Movement. Appl. Sci. 2020, 10, 1964. https://doi.org/10.3390/app10061964

Nan B, Bai Y, Wu Y. Multi-Objective Optimization of Spatially Truss Structures Based on Node Movement. Applied Sciences. 2020; 10(6):1964. https://doi.org/10.3390/app10061964

Chicago/Turabian StyleNan, Bo, Yikui Bai, and Yue Wu. 2020. "Multi-Objective Optimization of Spatially Truss Structures Based on Node Movement" Applied Sciences 10, no. 6: 1964. https://doi.org/10.3390/app10061964