Optimization of the Secondary Optical Element of a Hybrid Concentrator Photovoltaic Module Considering the Effective Absorption Wavelength Range

Abstract

:1. Introduction

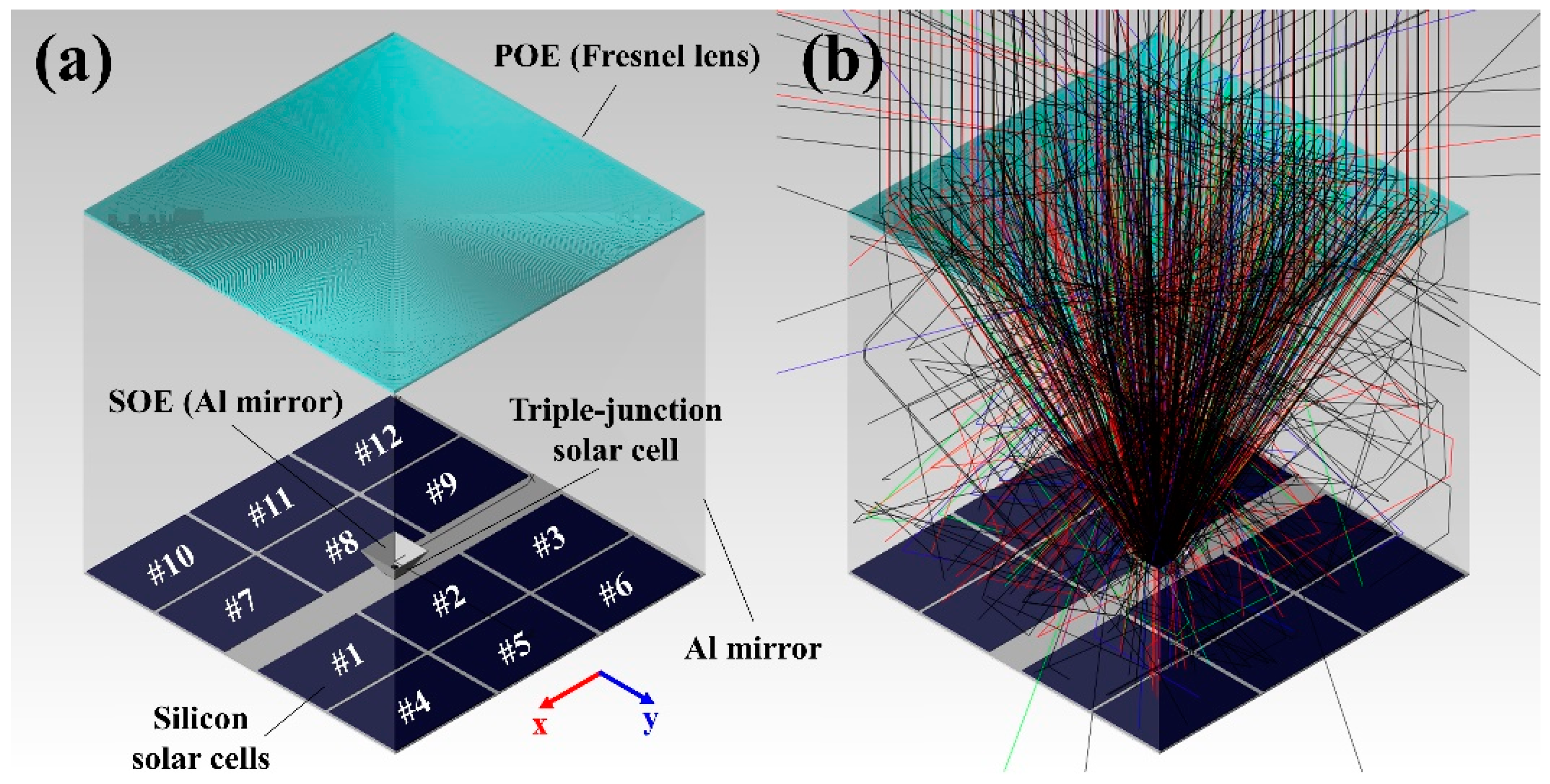

2. Simulation Setup

3. Simulations

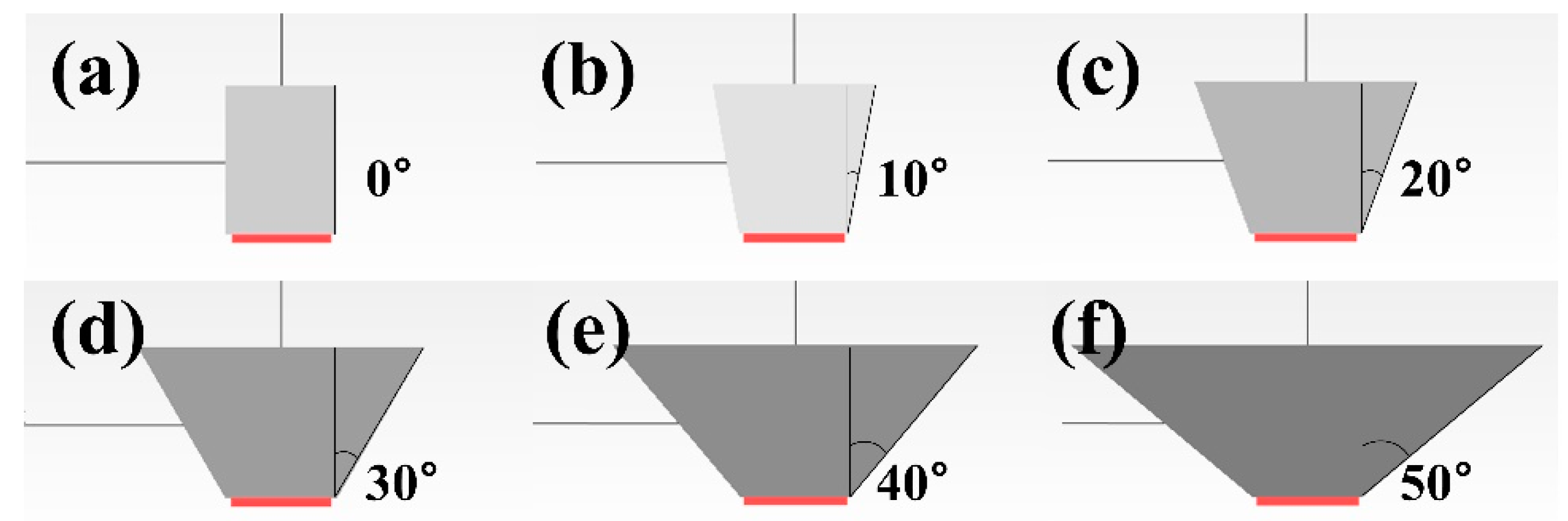

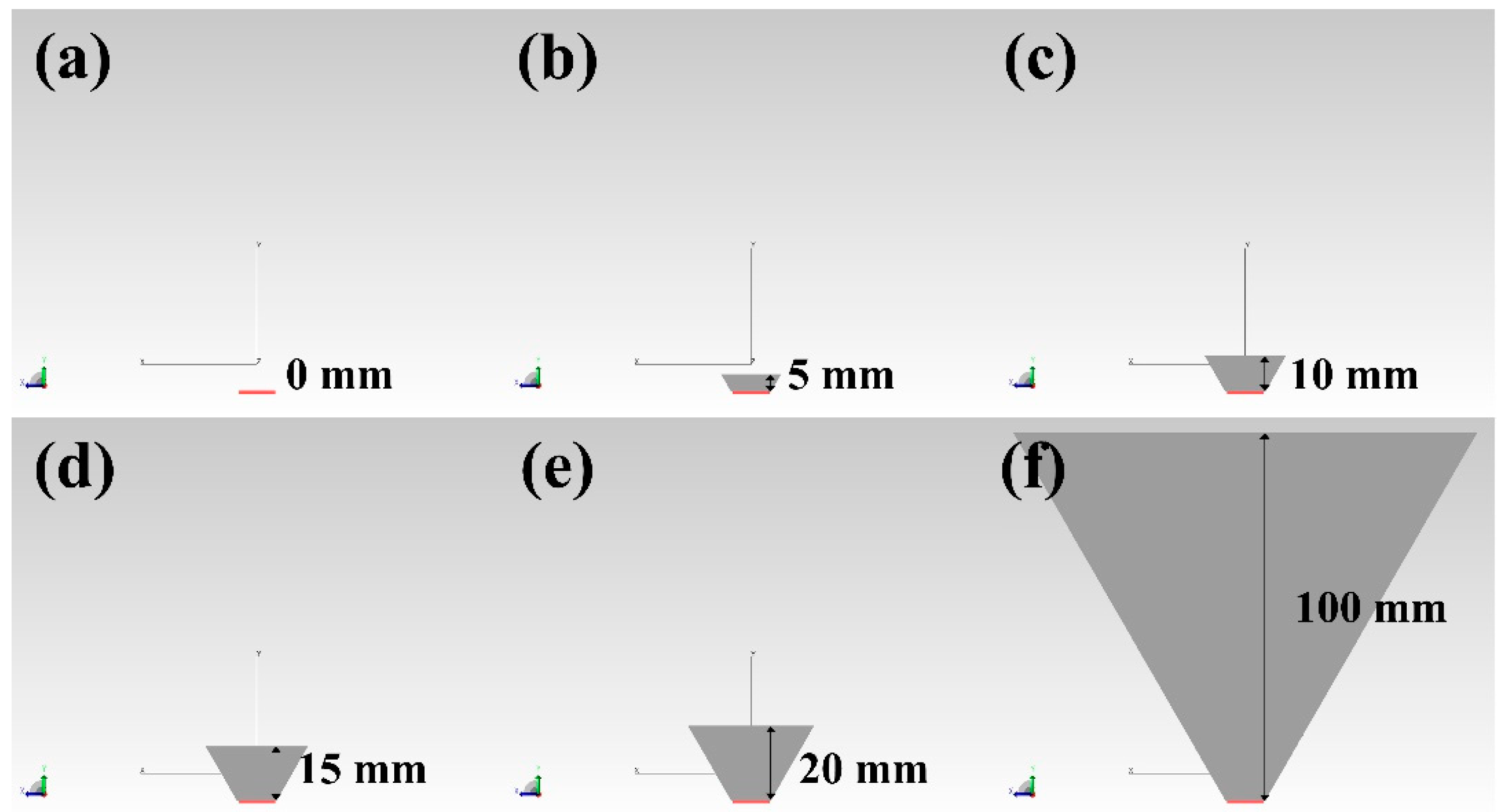

3.1. Optimization of SOE Design

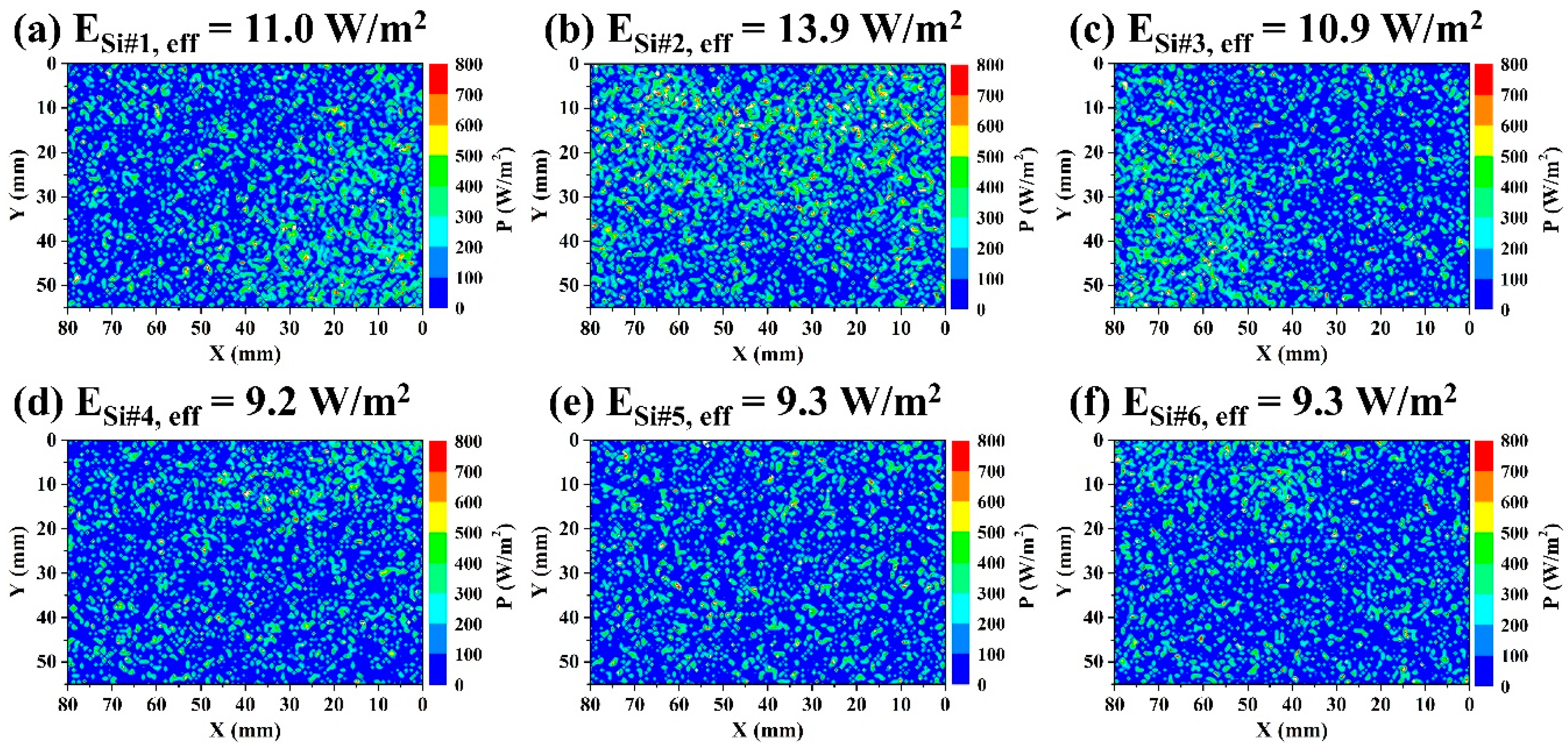

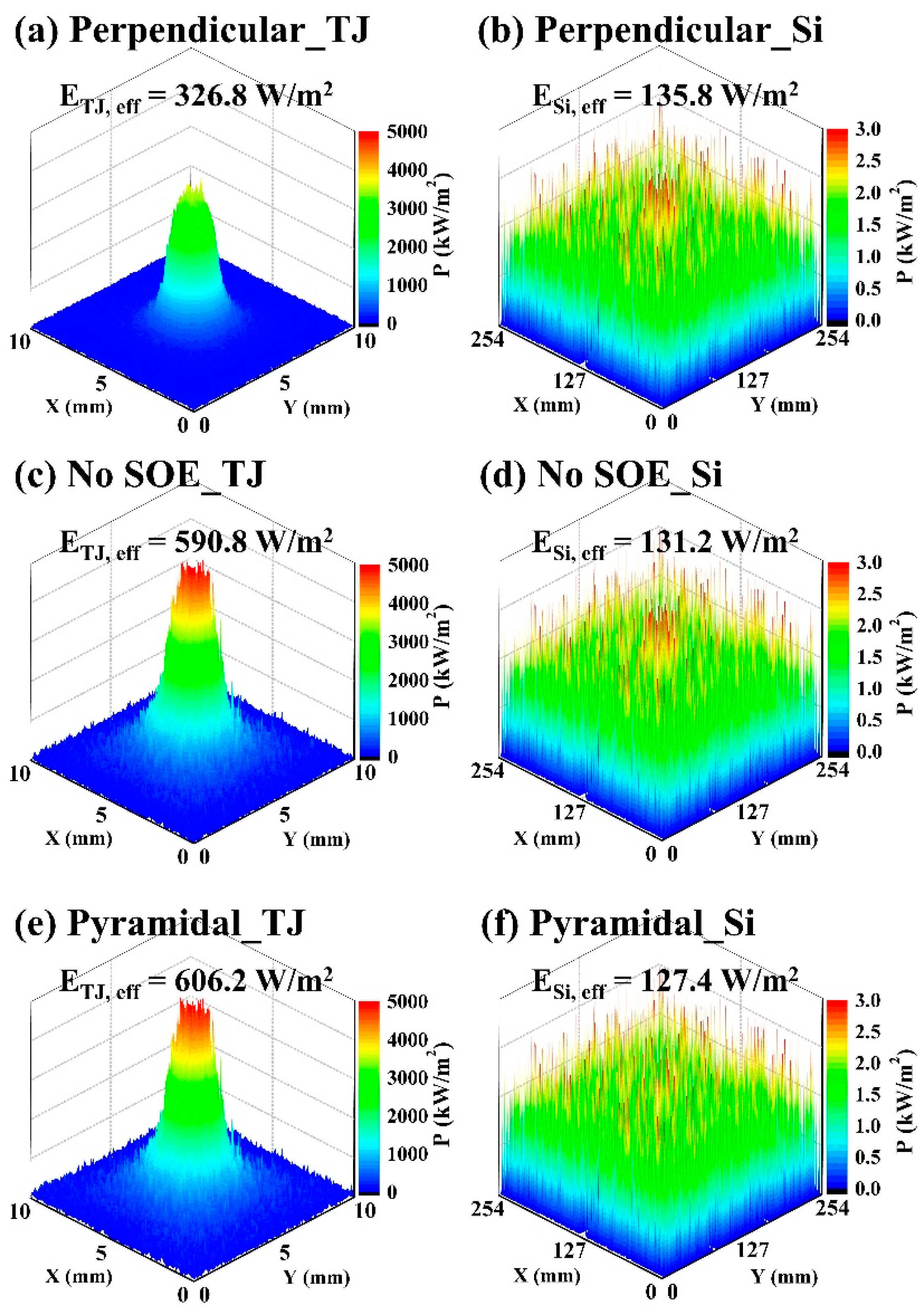

3.2. Irradiance Distributions

4. Experimental Measurements

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- McDaniels, D.K.; Lowndes, D.H.; Mathew, H.; Reynolds, J.; Gray, R. Enhanced solar energy collection using reflector-solar thermal collector combinations. Sol. Energy 1975, 17, 277–283. [Google Scholar] [CrossRef]

- Baker, S.; McDaniels, D.K.; Kaehn, H.D.; Lowndes, D.H. Time integrated calculation of the insolation collected by a reflector-collector system. Sol. Energy 1978, 20, 415–417. [Google Scholar] [CrossRef]

- Armenta, C.; Vorobieff, P.; Mammoli, A. Summer off-peak performance enhancement for rows of fixed solar thermal collectors using flat reflective surfaces. Sol. Energy 2011, 85, 2041–2052. [Google Scholar] [CrossRef]

- Sharaf, O.Z.; Orhan, M.F. Concentrated photovoltaic thermal (CPVT) solar collector systems: Part I—Fundamentals, design considerations and current technologies. Renew. Sustain. Energy Rev. 2015, 50, 1500–1565. [Google Scholar] [CrossRef]

- Herrero, R.; Victoria, M.; Domínguez, C.; Askins, S.; Antón, I.; Sala, G. Concentration photovoltaic optical system irradiance distribution measurements and its effect on multi-junction solar cells. Prog. Photovolt. Res. Appl. 2012, 20, 423–430. [Google Scholar] [CrossRef] [Green Version]

- Gordon, J.M.; Feuermann, D.; Young, P. Unfolded aplanats for high-concentration photovoltaics. Opt. Lett. 2008, 33, 1114–1116. [Google Scholar] [CrossRef]

- Sansoni, P.; Fontani, D.; Francini, F.; Jafrancesco, D.; Pierucci, G.; Lucia, M.D. Technique for outdoor test on concentrating photovoltaic cells. Int. J. Photoenergy 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Y.; Zhu, L.; Yin, B.; Xiang, H.; Huang, Q. Direct liquid-immersion cooling of concentrator silicon solar cells in a linear concentrating photovoltaic receiver. Energy 2014, 65, 264–271. [Google Scholar] [CrossRef]

- Narasimman, K.; Selvarasan, I. Design construction and analysis of solar ridge concentrator photovoltaic (PV) system to improve battery charging performance. Ecotoxicol. Environ. Saf. 2016, 127, 187–192. [Google Scholar] [CrossRef] [PubMed]

- Wei, A.; Chen, Z.; Sze, J. Planar solar concentrator with a v-groove array for a side-absorption concentrated photovoltaic system. Optik 2016, 127, 10858–10867. [Google Scholar] [CrossRef]

- Chen, Y.; Chiang, H. Design of the secondary optical elements for concentrated photovoltaic units with Fresnel Lenses. Appl. Sci. 2015, 5, 770–786. [Google Scholar] [CrossRef] [Green Version]

- Nakatani, M.; Yamada, N. Characterization of core-shell spherical lens for microtracking concentrator photovoltaic system. Energies 2019, 12, 3517. [Google Scholar] [CrossRef] [Green Version]

- Yamada, N.; Hirai, D. Maximization of conversion efficiency based on global normal irradiance using hybrid concentrator photovoltaic architecture. Prog. Photovolt. Res. Appl. 2016, 24, 846–854. [Google Scholar] [CrossRef]

- Lee, K.T.; Yao, Y.; He, J.; Fisher, B.; Sheng, X.; Lumb, M.; Xu, L.; Anderson, M.A.; Scheiman, D.; Han, S.; et al. Concentrator photovoltaic module architectures with capabilities for capture and conversion of full global solar radiation. Proc. Natl. Acad. Sci. USA 2016, 113, E8210–E8218. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yamada, N.; Okamoto, K. Experimental measurements of a prototype high concentration Fresnel lens CPV module for the harvesting of diffuse solar radiation. Opt. Express 2014, 22, A28–A34. [Google Scholar] [CrossRef] [PubMed]

- Araki, K.; Ota, Y.; Lee, K.; Nishioka, K.; Yamaguchi, M. Is It CPV? Yes, But It Is a Partial CPV. In Proceedings of the 13th Conference on Concentrator Photovoltaic Systems, Ottawa, ON, Canada, 1–3 May 2017; Volume 1881, p. 080001. [Google Scholar]

- Kreske, K. Optical design of a solar flux homogenizer for concentrator photovoltaics. Appl. Opt. 2002, 41, 2053–2058. [Google Scholar] [CrossRef] [PubMed]

- Fontani, D.; Sansoni, P.; Francini, F.; DeLucia, M.; Pierucci, G.; Jafrancesco, D. Optical tests on a curve Fresnel Lens as secondary optics for solar troughs. Int. J. Photoenergy 2017, 2017, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Benítez, P.; Miñano, J.C.; Zamora, P.; Mohedano, R.; Cvetkovic, A.; Buljan, M.; Chaves, J.; Hernández, M. High performance Fresnel-based photovoltaic concentrator. Opt. Express 2010, 18, A25–A40. [Google Scholar] [CrossRef]

- Cotal, H.; Fetzer, C.; Boisvert, J.; Kinsey, G.; King, R.; Hebert, P.; Yoon, H.; Karam, N. III–V multijunction solar cells for concentrating photovoltaics. Energy Environ. Sci. 2009, 2, 174–192. [Google Scholar] [CrossRef]

- Zhang, L.; Niu, P.; Li, Y.; Song, M.; Zhang, J.; Ning, P.; Chen, P. Investigation on high-efficiency Ga0.51In0.49P/In0.01Ga0.99As/Ge triple-junction solar cells for space applications. AIP Adv. 2017, 7, 125217. [Google Scholar] [CrossRef] [Green Version]

- Hayashi, N.; Inoue, D.; Matsumoto, M.; Matsushita, A.; Higuchi, H.; Aya, Y.; Nakagawa, T. High-efficiency thin and compact concentrator photovoltaics with micro-solar cells directly attached to a lens array. Opt. Express 2015, 23, A594–A603. [Google Scholar] [CrossRef] [PubMed]

| SOE Angle | ETJ,eff (W/m2) | ETJ,loss (W/m2) | ETJ,loss/ETJ,eff ratio (%) | ESi,eff (W/m2) | ESi,loss (W/m2) |

|---|---|---|---|---|---|

| 0° (Perpendicular) | 326.8 | 7.2 | 2.2 | 135.8 | 7.3 |

| 10° | 495.6 | 15.1 | 3.1 | 130.6 | 7.1 |

| 20° | 588.6 | 24.1 | 4.1 | 129.8 | 13.5 |

| 30° | 606.2 | 34.5 | 5.7 | 127.4 | 9.9 |

| 40° | 604.7 | 41.7 | 6.9 | 125.8 | 10.2 |

| 50° | 603.4 | 26.1 | 4.3 | 125.1 | 5.2 |

| SOE Height (mm) | ETJ,eff (W/m2) | ETJ,loss (W/m2) | ETJ, loss/ETJ,eff Ratio (%) | ESi,eff (W/m2) | ESi,loss (W/m2) |

|---|---|---|---|---|---|

| 0 (No SOE) | 590.8 | 20.4 | 3.5 | 131.2 | 7.1 |

| 5 | 601.8 | 26.1 | 4.3 | 131.5 | 9.8 |

| 10 | 605.2 | 30.9 | 5.1 | 130.3 | 10.4 |

| 15 | 606.2 | 34.5 | 5.7 | 127.4 | 9.9 |

| 20 | 608.3 | 37.9 | 6.2 | 124.8 | 9.3 |

| 100 | 609.7 | 47.4 | 7.8 | 85.4 | 1.6 |

| SOE Configuration | Cell | PMAX (W/m2) | VOC (V) | ISC (A) | Fill factor | Area (cm2) |

|---|---|---|---|---|---|---|

| Perpendicular (θ = 0°, h = 15 mm) | Triple-junction | 149.0 | 3.04 | 3.78 | 83.61 | 645.2 |

| silicon | 5.67 (sum of #1–12) | - | - | - | 645.2 | |

| No SOE | Triple-junction | 181.5 | 3.03 | 4.73 | 81.8 | 645.2 |

| silicon | 5.99 (sum of #1–12) | - | - | - | 645.2 | |

| Pyramidal (θ = 30°, h = 15 mm) | Triple-junction | 212.8 | 3.04 | 5.57 | 81.16 | 645.2 |

| silicon | 5.14 (sum of #1–12) | - | - | - | 645.2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, W.-L.; Kim, K.-P.; Min, J.-H.; Lee, J.-Y.; Mun, S.-H.; Park, J.-H.; Han, J.-H.; Park, W.-K.; Yoon, S.; Lee, D.-S. Optimization of the Secondary Optical Element of a Hybrid Concentrator Photovoltaic Module Considering the Effective Absorption Wavelength Range. Appl. Sci. 2020, 10, 2051. https://doi.org/10.3390/app10062051

Jeong W-L, Kim K-P, Min J-H, Lee J-Y, Mun S-H, Park J-H, Han J-H, Park W-K, Yoon S, Lee D-S. Optimization of the Secondary Optical Element of a Hybrid Concentrator Photovoltaic Module Considering the Effective Absorption Wavelength Range. Applied Sciences. 2020; 10(6):2051. https://doi.org/10.3390/app10062051

Chicago/Turabian StyleJeong, Woo-Lim, Kyung-Pil Kim, Jung-Hong Min, Jun-Yeob Lee, Seung-Hyun Mun, Jeong-Hwan Park, Jang-Hwan Han, Won-Kyu Park, Sewang Yoon, and Dong-Seon Lee. 2020. "Optimization of the Secondary Optical Element of a Hybrid Concentrator Photovoltaic Module Considering the Effective Absorption Wavelength Range" Applied Sciences 10, no. 6: 2051. https://doi.org/10.3390/app10062051