Lightning Protection Methods for Wind Turbine Blades: An Alternative Approach

Abstract

1. Introduction

2. Lightning Discharges and Existing Lightning Protection Systems for Wind Turbine

Mechanism of Lightning Discharge

3. Wind Turbine Blades and Its Protection Methods

3.1. Wind Turbines and Blades

3.2. Lightning Protection in General

3.3. Protection Methods for Blades

- (a)

- receptors placed in the tip and an internal wire (i.e., conductor) is used to carry the current to the hub

- (b)

- metallic conductor placed around the edges to serve as termination and down conductor

- (c)

- metal mesh used on the side of the blade

- -

- Successful attachment of the lightning strike to a designated or preferred air termination or down conductor system to conduct the current safety without damaging the blades;

- -

- Provide passage for the lightning current through sufficient cross-section conductors, diverters, and air terminators to earth. Preventing damage to the system and minimizing the high level magnetic and electric field due to high currents;

- -

- Minimizing the high level of voltages induced and observed inside and outside of the turbine.

3.4. Lightning Damage to Wind Turbines and Blades

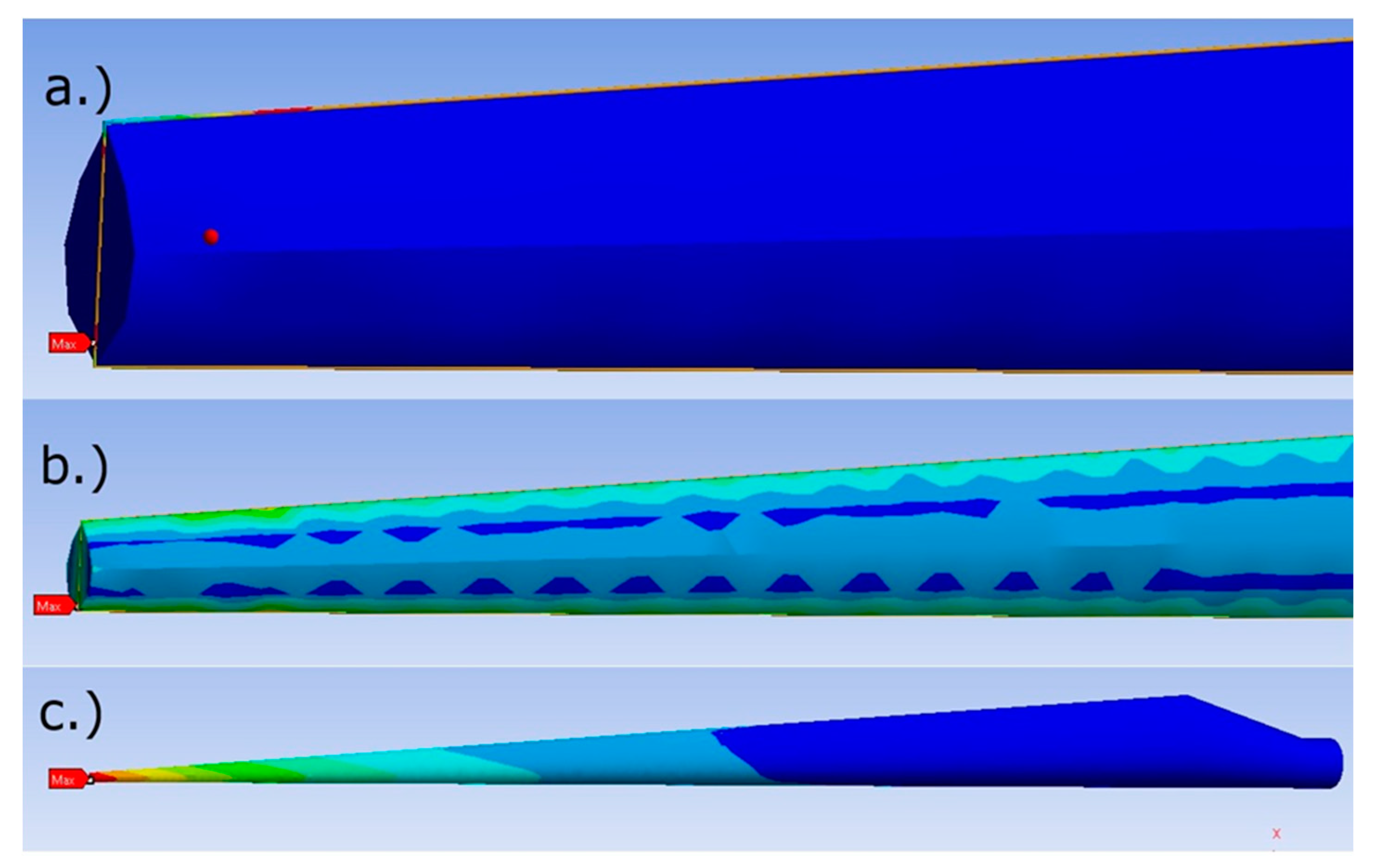

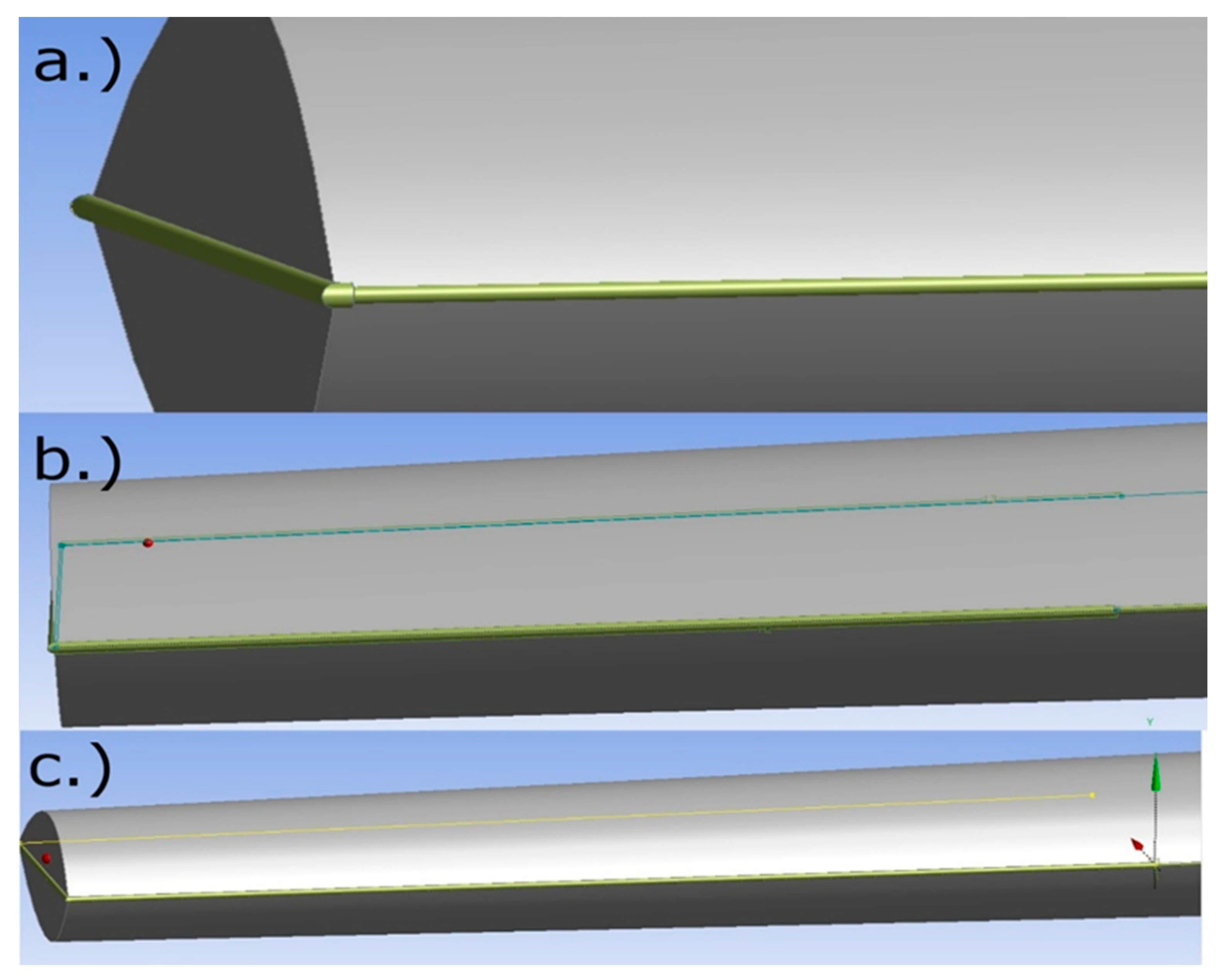

3.5. Blade Model for Investigation

4. ANSYS Workbench Implementation

4.1. ANSYS Workbench

4.2. Blade and Protection Implementation

4.3. Simulation Setup

- Conventional:

- A: Minimal protection level with 50 mm2 conductor cross-section area;

- B: 100 mm2 conductor cross-section area;

- C: 200 mm2 conductor cross-section area.

- Hybrid:

- D: Hybrid conductor design for tip;

- E: Hybrid conductor design, 2 m on sides;

- F: Hybrid conductor design, 5 m on sides.

- Voltage at the attachment point (V);

- Maximum value of Joule heating in the conductor (MW/m3);

- Current density at the attachment point (kA/m2);

- Maximum temperature generated by Joule heating in the conductor (°C);

- Total deformation caused on the blade due to the heating effect (mm);

- 6.

- Current density at joint (kA/m2).

5. Simulation Results and Discussion

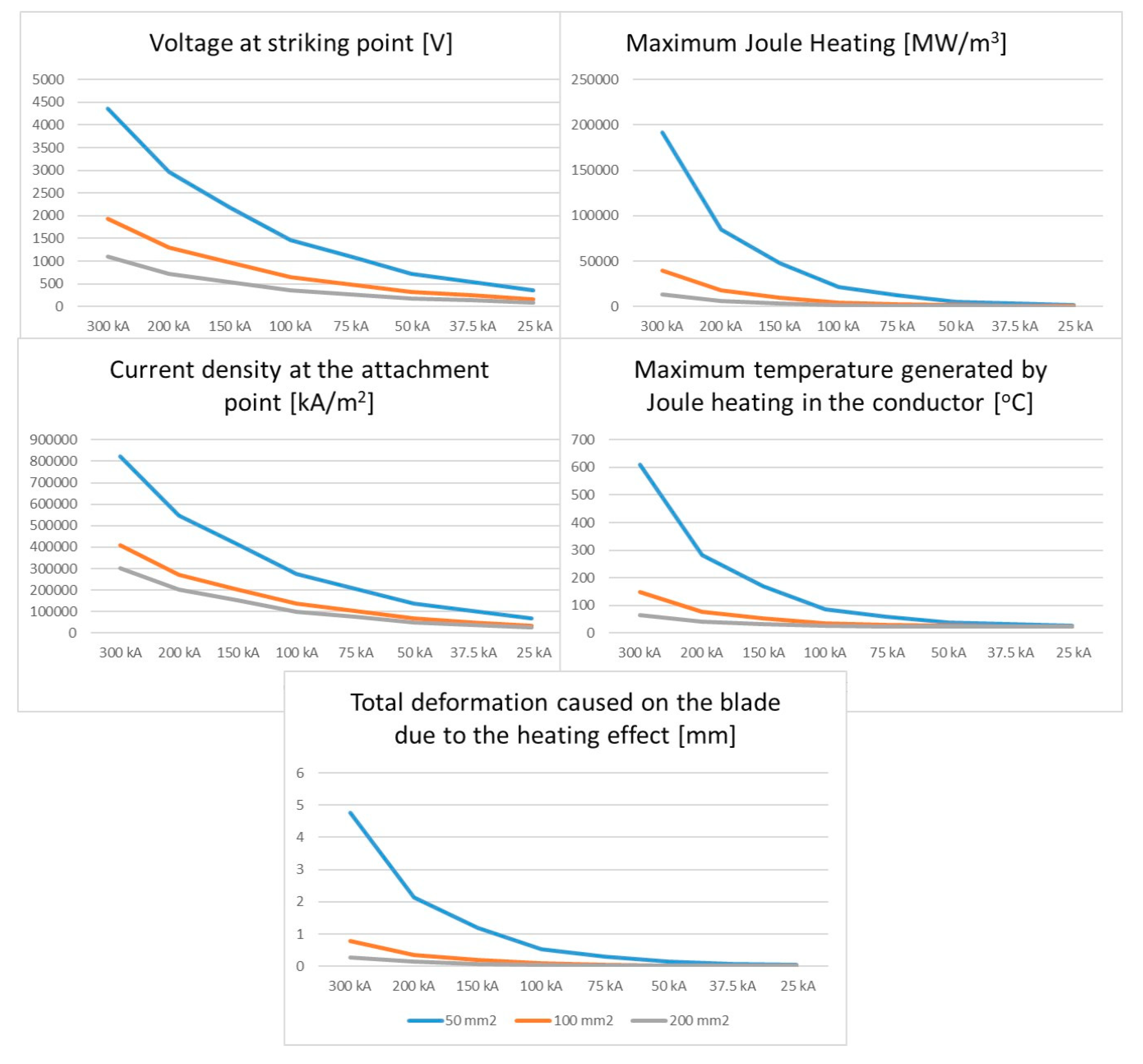

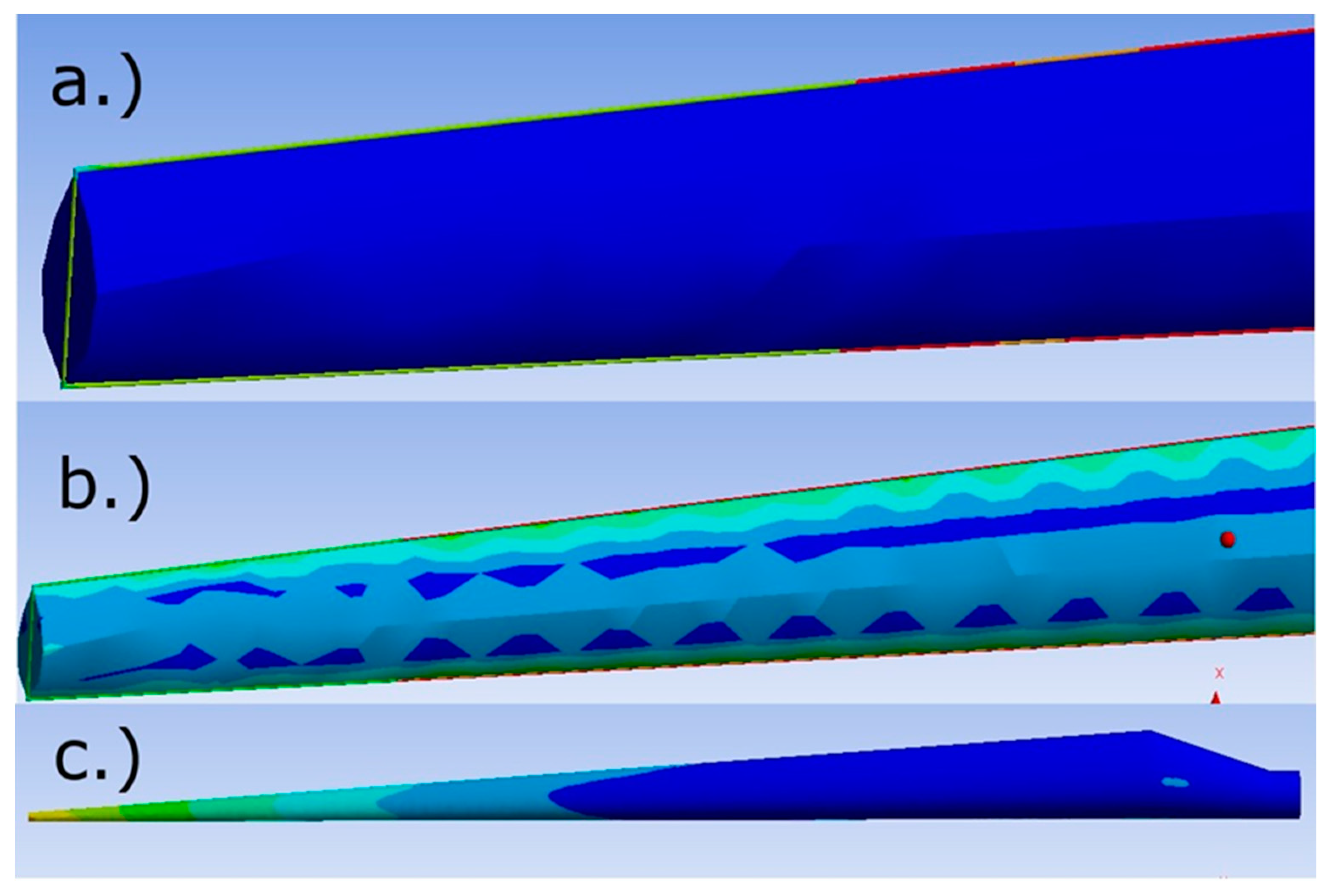

5.1. Results from Conventional Case Studies

- Current density in the conductor;

- Temperature generated by current;

- Deformation caused by temperature.

5.1.1. Case Study A: Minimal Protection Level with 50 mm2 Conductor Cross-Section Area

5.1.2. Case Study B: 100 mm2 Conductor Cross-Section Area

5.1.3. Case Study C: 200 mm2 Conductor Cross-Section Area

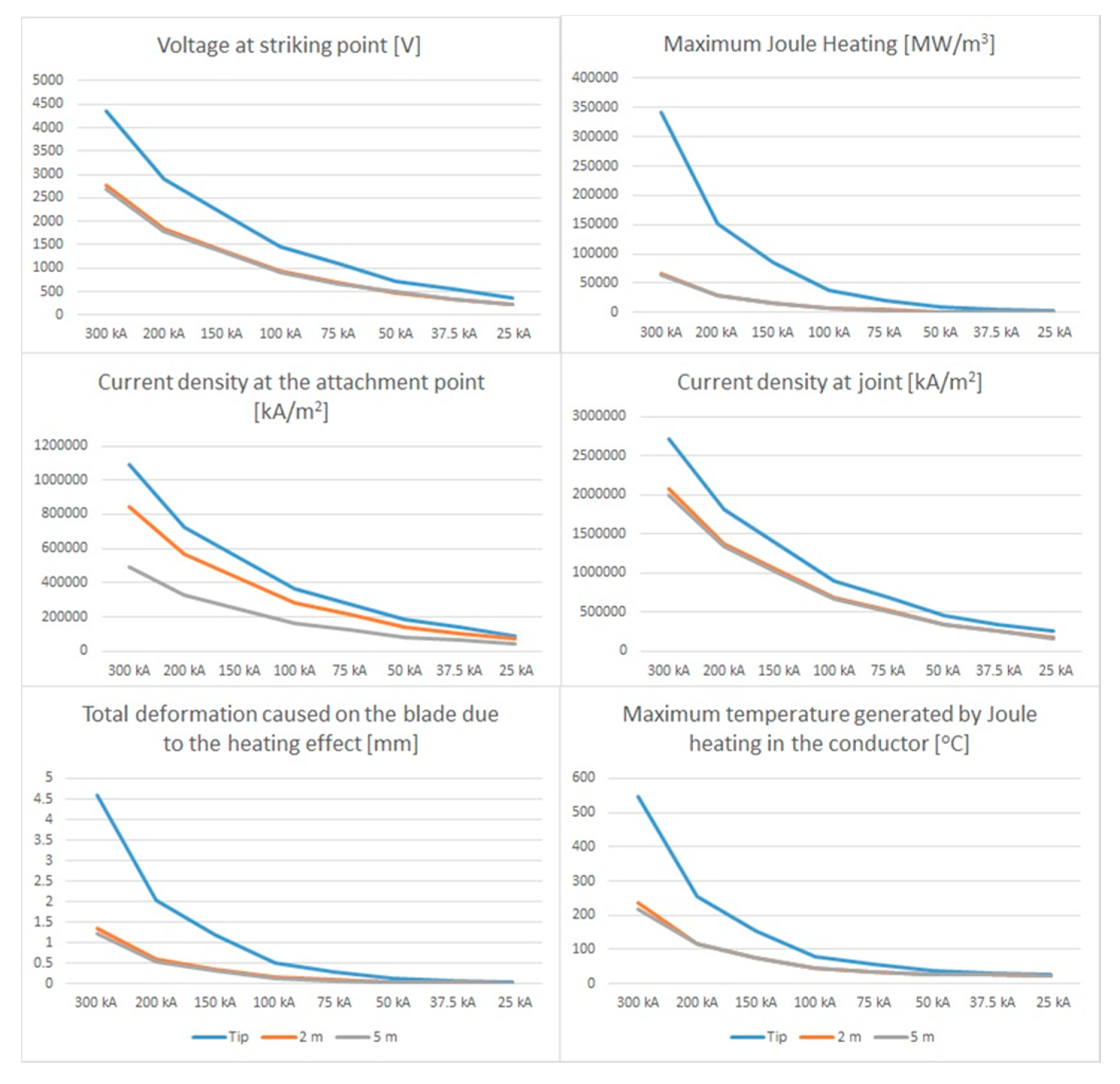

5.2. Results from Hybrid Case Studies

5.2.1. Case Study D: Hybrid Conductor Design for Tip

5.2.2. Case Study E: Hybrid Conductor Design, 2 m Sides

5.2.3. Case Study F: Hybrid Conductor Design, 5 m Sides

5.3. Discussion

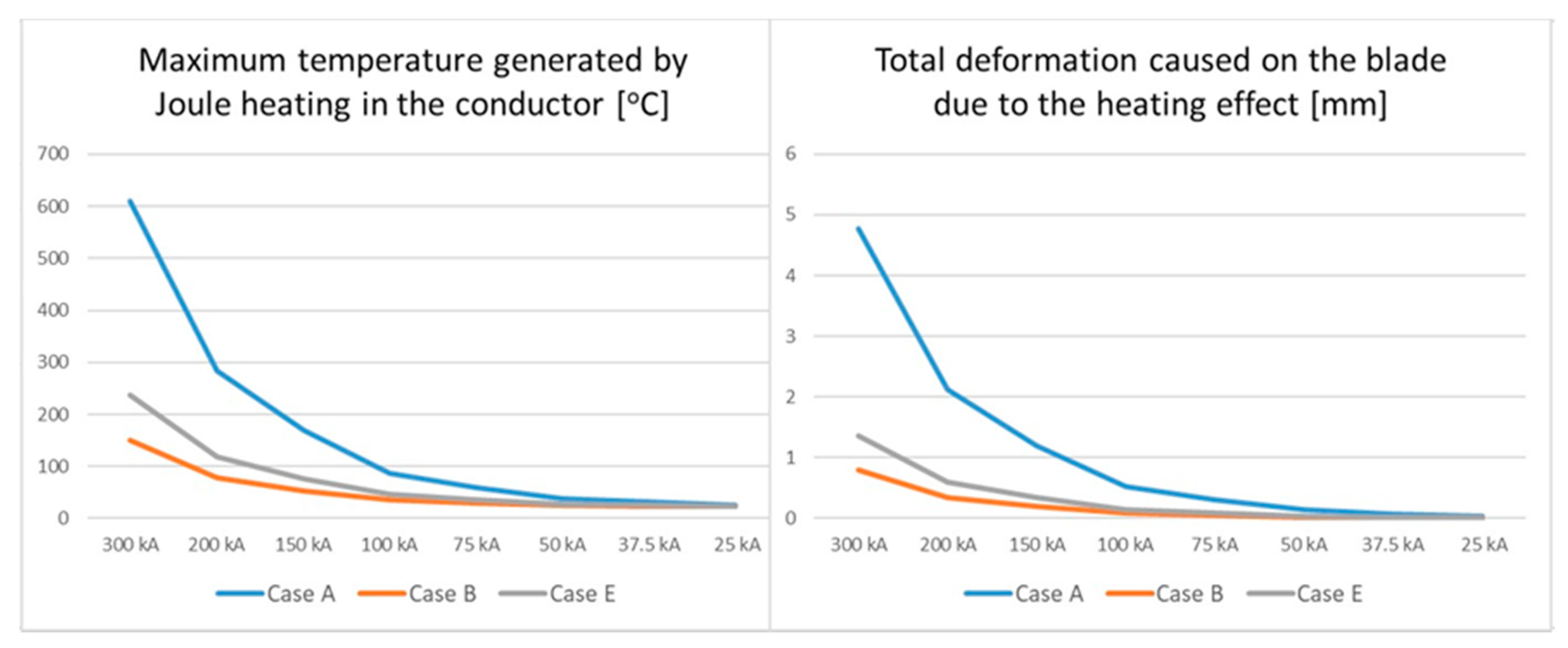

5.3.1. Conventional Cases (A, B, and C)

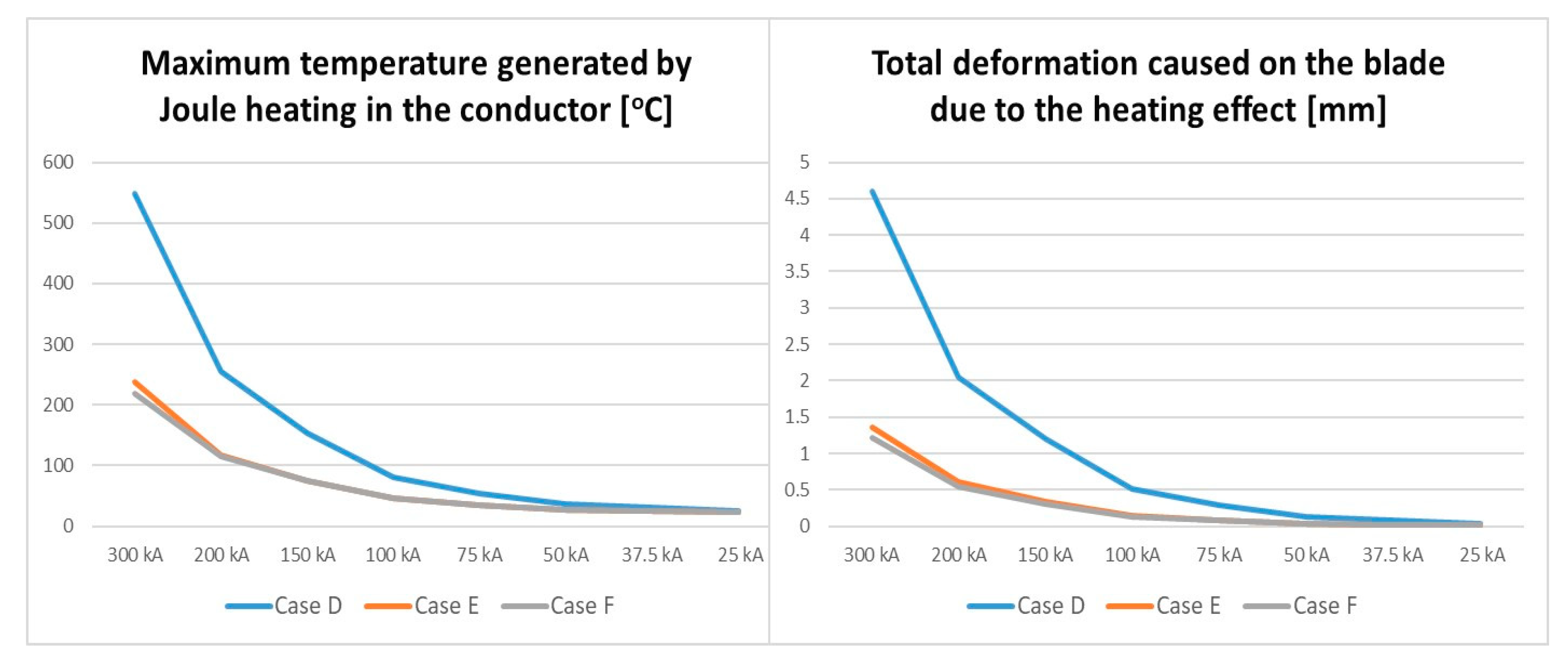

5.3.2. Hybrid Cases (D, E, and F)

5.3.3. Conventional and Hybrid

5.3.4. Summary

6. Conclusions, Recommendations for Future Works

6.1. Conclusions

6.2. Recommendations for Future Work

- One possible future work could include the examination of electromagnetic forces and waves generated by the current, since those were excluded from the simulation due to missing Mechanical APDL functions (electromagnetic analysis system).

- There are possible incorrect, unrealistic values presented in this work due to the potential misconfiguration of simulation physics in the absence of relatable guide.

- The software used had limited solver size due to academic license; therefore, the mesh of the objects had to be left coarse, meaning less accurate and possible differences in expected and real life values.

- The design and therefore the investigation could be extended to model a complete turbine to see the effects on the whole structure.

- The exact length of the increased diameter conductor could be evaluated in the ratio of the size of the blade; therefore, the proposed design could be implemented on various size blades with maximum efficiency.

- A comparison could be made with existing blade LPS what is used on large blades nowadays to estimate the efficiency of both designs.

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Cooray, V. An Introduction to Lightning; Springer: Heidelberg, Germany, 2015. [Google Scholar]

- NSSDC. Sun Fact Sheet. Available online: https://nssdc.gsfc.nasa.gov/planetary/factsheet/sunfact.html (accessed on 2 October 2018).

- Rakov, V.A.; Uman, M.A. Lightning: Physics and Effects; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Cooray, V. Lightning Protection; The Institution of Engineering and Technology: London, UK, 2010. [Google Scholar]

- The Weather Channel. Where Almost 9 Billion Lightning Strikes in 5 Years Have Happened on Earth. Available online: https://weather.com/safety/thunderstorms/news/2018-05-07-world-lightning-strikes-map-vaisala-2013-2017 (accessed on 2 February 2019).

- Anderson, G.; Klugmann, D. European lightning density analysis using 5 years of ATDnet data. Nat. Hazards Earth Syst. Sci. 2014, 14, 815–829. [Google Scholar] [CrossRef]

- Technical Committee PEL/88. Wind Turbines Part. 24: Lightning Protection, BS EN 61400-24:2019; The British Standards Institution: London, UK, 2019. [Google Scholar]

- Uman, M.A. The Lightning Discharge; Dover Publications, Inc.: Mineola, NY, USA, 2001. [Google Scholar]

- HMI Vestas Offshore Wind. The World’s Most Powerful Available Wind Turbine Gets Major Power Boost. Available online: http://www.mhivestasoffshore.com/worlds-most-powerful-available-wind-turbine-gets-major-power-boost/ (accessed on 5 February 2019).

- Hu, W. Advanced Turbine Wind Technology; Springer: Ithaca, NY, USA, 2018. [Google Scholar]

- Czeshop. Wind Turbine Blade Cross Section. Available online: http://czeshop.info/2017/wind-turbine-blade-cross-section.html (accessed on 10 February 2019).

- Technical Committee GEL/81. Protection against Lightning Part. 1: General Principles, BS EN 62305-1:2011; The British Standards Institution: London, UK, 2017. [Google Scholar]

- Cooray, V. Lightning Protection; Athenaeum Press Ltd.: Gateshead, UK, 2010. [Google Scholar]

- Barwise, A. Lightning and Surge Protection for Wind Turbines. Available online: https://www.ee.co.za/article/lightning-surge-protection-wind-turbines-2.html (accessed on 21 February 2019).

- Wilson, N.; Myers, J.; Cummins, K.L.; Hutchinson, M.; Nag, A. Lightning attachment to wind turbines in Central Kansas: Video observations, correlation with the NLDN and in-situ peak current measurements. In Proceedings of the European Wind Energy Conference Exhibition EWEC 2013, Vienna, Austria, 4–7 February 2013. [Google Scholar]

- Cummins, K.L.; Zhang, D.; Quick, M.G.; Garolera, A.C.; Myers, J. Overview of the Kansas Windfarm2013 Field Program. In Proceedings of the 23rd International Lightning Detection Conference (ILDC), Tucson, AZ, USA, 18–19 March 2014. [Google Scholar]

- Wang, D.; Takagi, N.; Watanabe, T.; Sakurano, H.; Hashimoto, M. Observed characteristics of upward leaders that are initiated from a windmill and its lighting protection tower. Geophys. Res. Lett. 2008, 35. [Google Scholar] [CrossRef]

- Ishii, M.; Saito, M.; Natsuno, D.; Sugita, A. Lighting current observed at wind turbines at winter in Japan. In Proceedings of the International Conference on Lightning & Static Electricity ICLOSE 2013, Seattle, WA, USA, 18–20 September 2013. [Google Scholar]

- Yasuda, Y.; Yokoyama, S.; Minowa, M. Classification of Lightning Damage to Wind Turbine Blades. IEEJ Trans. Electr. Electr. Eng. 2012, 7, 559–566. [Google Scholar] [CrossRef]

- Sorensen, T.; Jensen, F.V.; Raben, N. Lightning protection for offshore wind turbines. In Proceedings of the 16th International Conference & Exhibition on Electricity Distribution, Amsterdam, The Netherlands, 18–21 June 2001. [Google Scholar]

- Solacity. Lightning Protection. Available online: https://www.solacity.com/lightning-protection/ (accessed on 30 March 2019).

- Yasuda, Y.; Yokoyama, S. Proposal of Lightning Damage Classification to Wind Turbine Blades. In Proceedings of the 7th Asia Pacific International Conference on Lightning (APL), Chengdu, China, 1–4 November 2011; pp. 368–371. [Google Scholar]

- GlobalBladeService. Lightning Damage. Available online: https://www.globalbladeservice.eu/blade-service/lightning-damage (accessed on 31 March 2019).

- Gorgeouswithattitude. 1st Blade Wends Way to Wind Farm. Available online: http://gorgeouswithattitude.blogspot.com/2010/09/1st-blade-wends-way-to-wind-farm.html (accessed on 31 March 2019).

- EPSRC, Lightning Protection of Wind Turbine. Available online: https://community.dur.ac.uk/supergen.wind/docs/presentations/2010-04-25_1425_EWEC%202010_SideEvent_Lightning_VP.pdf (accessed on 31 March 2019).

- Garolera, A.C.; Madsen, S.F.; Nissim, M.; Myers, J.D.; Holboell, J. Lightning Damage to Wind Turbine Blades From Wind Farms in the U.S. IEEE Trans. Power Deliv. 2016, 31, 1043–1049. [Google Scholar] [CrossRef]

- MHI Vestas Offshore Wind A/S. V164-9.5 MW. Available online: http://www.mhivestasoffshore.com/category/v164-9-5-mw/ (accessed on 24 February 2019).

- Schubel, P.J. Technical cost modelling for a generic 45-m wind turbine blade producedby vacuum infusion (VI). Renew. Energy 2010, 35, 183–189. [Google Scholar] [CrossRef]

- Alawadhi, E.M. Finite Element Simulations Using ANSYS, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- AZoNetwork. E-Glass Fibre. Available online: https://www.azom.com/properties.aspx?ArticleID=764 (accessed on 25 February 2019).

- MatWeb. Glass Fiber Summary List. Available online: http://www.matweb.com/search/DataSheet.aspx?MatGUID=5c6df0ae272e41808562d3374d7b4f5a&ckck=1 (accessed on 28 February 2019).

- ANSYS, Inc. Analysis Types. Available online: https://www.sharcnet.ca/Software/Ansys/18.2.2/en-us/help/wb_sim/ds_simulation_types.html (accessed on 2 March 2019).

- Heidler, F.; Flisowski, Z.; Zischank, W.; Bouquegneau, C. Parameters of lightning current given in IEC 62305–Background, experience and outlook. In Proceedings of the 29th International Conference on Lightning Protection ICLP 2008, Uppsala, Sweden, 23–26 June 2008. [Google Scholar]

- Guo, Z.; Li, Q.; Ma, Y. Experimental study on lightning attachment manner to wind turbine blades with lightning protection system. IEEE Trans. Plasma Sci. 2019, 47, 635–646. [Google Scholar] [CrossRef]

- Arif, W.; Li, Q.; Guo, Z.; Ellahi, M.; Wang, G.; Siew, W.H. Experimental study on lightning discharge attachment to the modern wind turbine blade with lightning protection system. In Proceedings of the 13th International Conference on Emerging Technologies (ICET), Islamabad, Pakistan, 27–28 December 2017; pp. 1–6. [Google Scholar]

- Young, J.H. Steady state Joule heating with temperature dependent conductivities. Appl. Sci. Res. 1986, 43, 55–65. [Google Scholar] [CrossRef]

| Type of Stroke | Test Parameter | Unit | LPL |

|---|---|---|---|

| Extreme (0) | |||

| First | i | kA | 300 |

| t | s | 10 | |

| Subsequent | i | kA | 75 |

| t | s | 0.25 |

| First Strokes | LPL 0 | LPL I | LPL II | LPL III-IV |

|---|---|---|---|---|

| 300 kA | 200 kA | 150 kA | 100 kA | |

| Voltage at striking point (V) | 4360.3 | 2969.9 | 2180.2 | 1453.4 |

| Maximum joule heating (MW/m3) | 191,420 | 85,070 | 47,855 | 21,269 |

| Current density at striking point (kA/m2) | 823,240 | 548,830 | 411,620 | 274,410 |

| Maximum temperature (°C) | 608.98 | 282.88 | 168.74 | 87.22 |

| Total deformation (mm) | 47.725 | 2.1232 | 1.196 | 5.337 |

| Subsequent Strokes | LPL 0 | LPL I | LPL II | LPL III-IV |

| 75 kA | 50 kA | 37.5 kA | 25 kA | |

| Voltage at striking point (V) | 1090.1 | 726.72 | 545.04 | 363.36 |

| Maximum joule heating (MW/m3) | 11,964 | 5317.2 | 2991 | 1329.3 |

| Current density at striking point (kA/m2) | 205,810 | 137,210 | 102,910 | 68,604 |

| Maximum temperature (°C) | 58.686 | 38.305 | 31.172 | 26.076 |

| Total deformation (mm) | 0.3019 | 0.13632 | 0.078379 | 0.037002 |

| First Strokes | LPL0 | LPL I | LPL II | LPL III-IV |

|---|---|---|---|---|

| 300 kA | 200 kA | 150 kA | 100 kA | |

| Voltage at striking point (V) | 1937.9 | 1292 | 968.97 | 645.98 |

| Maximum joule heating (MW/m3) | 39,689 | 17,639 | 9922.1 | 4409.8 |

| Current density at striking point (kA/m2) | 407,620 | 271,700 | 203,810 | 135,870 |

| Maximum temperature (°C) | 149.31 | 78.583 | 53.828 | 36.146 |

| Total deformation (mm) | 0.79158 | 0.35234 | 0.19862 | 0.08883 |

| Subsequent Strokes | LPL 0 | LPL I | LPL II | LPL III-IV |

| 75 kA | 50 kA | 37.5 kA | 25 kA | |

| Voltage at striking point (V) | 484.49 | 322.99 | 242.24 | 161.5 |

| Maximum joule heating (MW/m3) | 2480.5 | 1102.5 | 620.13 | 276.1 |

| Current density at striking point (kA/m2) | 101,900 | 68,936 | 50,952 | 33,968 |

| Maximum temperature (°C) | 29.957 | 25.536 | 23.989 | 23.081 |

| Total deformation (mm) | 0.0504 | 0.02311 | 0.01364 | 0.00714 |

| First Strokes | LPL0 | LPL I | LPL II | LPL III-IV |

|---|---|---|---|---|

| 300 kA | 200 kA | 150 kA | 100 kA | |

| Voltage at striking point (V) | 1090 | 726.66 | 545 | 363.33 |

| Maximum joule heating (MW/m3) | 13,389 | 5950.8 | 3347.3 | 1487.7 |

| Current density at striking point (kA/m2) | 302,270 | 201,510 | 151,130 | 100,760 |

| Maximum temperature (°C) | 65.017 | 41.118 | 32.754 | 26.78 |

| Total deformation (mm) | 0.27567 | 0.13922 | 0.079422 | 0.036739 |

| Subsequent strokes | LPL 0 | LPL I | LPL II | LPL III-IV |

| 75 kA | 50 kA | 37.5 kA | 25 kA | |

| Voltage at striking point (V) | 181.67 | 136.25 | 90.833 | 181.67 |

| Maximum joule heating (MW/m3) | 371.93 | 209.21 | 92.982 | 371.93 |

| Current density at striking point (kA/m2) | 50,378 | 37,784 | 25,189 | 50,378 |

| Maximum temperature (°C) | 23.195 | 23.08 | 23.069 | 23.195 |

| Total deformation (mm) | 0.01129 | 0.00769 | 0.00523 | 0.01129 |

| First Strokes | LPL0 | LPL I | LPL II | LPL III-IV |

|---|---|---|---|---|

| 300 kA | 200 kA | 150 kA | 100 kA | |

| Voltage at striking point (V) | 4354.3 | 2902.8 | 2177.7 | 1451.4 |

| Maximum joule heating (MW/m3) | 341,640 | 151,840 | 85,411 | 37,961 |

| Current density at striking point (kA/m2) | 1,091,100 | 727,370 | 545,530 | 363,690 |

| Maximum temperature (°C) | 547.52 | 255.56 | 153.38 | 80.391 |

| Total deformation (mm) | 4.5937 | 2.043 | 1.502 | 0.5125 |

| Current density at joints (kA/m2) | 2,715,500 | 1,810,400 | 1,357,800 | 905,180 |

| Subsequent Strokes | LPL 0 | LPL I | LPL II | LPL III-IV |

| 75 kA | 50 kA | 37.5 kA | 25 kA | |

| Voltage at striking point (V) | 1088.6 | 725.71 | 544.28 | 362.85 |

| Maximum joule heating (MW/m3) | 21,353 | 9490.1 | 5338.2 | 2372.5 |

| Current density at striking point (kA/m2) | 272,760 | 181,840 | 136,380 | 90,922 |

| Maximum temperature (°C) | 54.845 | 36.598 | 30.211 | 25.649 |

| Total deformation (mm) | 0.2893 | 0.1299 | 0.0741 | 0.0343 |

| Current density at joints (kA/m2) | 678,890 | 452,590 | 339,440 | 263,000 |

| First Strokes | LPL0 | LPL I | LPL II | LPL III-IV |

|---|---|---|---|---|

| 300 kA | 200 kA | 150 kA | 100 kA | |

| Voltage at striking point (V) | 2773.4 | 1848.9 | 1386.7 | 924.45 |

| Maximum joule heating (MW/m3) | 66,067 | 29,363 | 16,517 | 7340.8 |

| Current density at striking point (kA/m2) | 844,930 | 563,290 | 422,470 | 281,640 |

| Maximum temperature (°C) | 237.15 | 117.62 | 75.788 | 45.906 |

| Total deformation (mm) | 1.355 | 0.6034 | 0.3404 | 0.1525 |

| Current density at joints (kA/m2) | 2,072,100 | 1,381,400 | 1,036,100 | 690,700 |

| Subsequent Strokes | LPL 0 | LPL I | LPL II | LPL III-IV |

| 75 kA | 50 kA | 37.5 kA | 25 kA | |

| Voltage at striking point (V) | 693.34 | 462.23 | 346.67 | 23.11 |

| Maximum joule heating (MW/m3) | 4129.2 | 1631.3 | 1032.3 | 458.8 |

| Current density at striking point (kA/m2) | 211,230 | 140,820 | 105,620 | 70,411 |

| Maximum temperature (°C) | 35.447 | 27.978 | 25.362 | 23.494 |

| Total deformation (mm) | 0.0867 | 0.0398 | 0.0234 | 0.0118 |

| Current density at joints (kA/m2) | 518,030 | 345,350 | 259,010 | 172,680 |

| First Strokes | LPL0 | LPL I | LPL II | LPL III-IV |

|---|---|---|---|---|

| 300 kA | 200 kA | 150 kA | 100 kA | |

| Voltage at striking point (V) | 2691.2 | 1794.1 | 1345.6 | 897.06 |

| Maximum joule heating (MW/m3) | 64,236 | 28,549 | 16,059 | 7137.3 |

| Current density at striking point (kA/m2) | 495,610 | 330,410 | 247,800 | 165,200 |

| Maximum temperature (°C) | 218.42 | 115.85 | 74.788 | 45.461 |

| Total deformation (mm) | 1.216 | 0.5420 | 0.3061 | 0.1376 |

| Current density at joints (kA/m2) | 1,999,800 | 1,333,200 | 999,910 | 666,610 |

| Subsequent Strokes | LPL 0 | LPL I | LPL II | LPL III-IV |

| 75 kA | 50 kA | 37.5 kA | 25 kA | |

| Voltage at striking point (V) | 672.8 | 488.53 | 336.4 | 224.27 |

| Maximum joule heating (MW/m3) | 4014.7 | 1784.3 | 1003.7 | 446.08 |

| Current density at striking point (kA/m2) | 123,900 | 82,601 | 61,951 | 41,301 |

| Maximum temperature (°C) | 35.197 | 27.865 | 25.299 | 23.466 |

| Total deformation (mm) | 0.0787 | 0.0366 | 0.0218 | 0.0114 |

| Current density at joints (kA/m2) | 499,960 | 333,300 | 249,980 | 166,650 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mucsi, V.; Ayub, A.S.; Muhammad-Sukki, F.; Zulkipli, M.; Muhtazaruddin, M.N.; Mohd Saudi, A.S.; Ardila-Rey, J.A. Lightning Protection Methods for Wind Turbine Blades: An Alternative Approach. Appl. Sci. 2020, 10, 2130. https://doi.org/10.3390/app10062130

Mucsi V, Ayub AS, Muhammad-Sukki F, Zulkipli M, Muhtazaruddin MN, Mohd Saudi AS, Ardila-Rey JA. Lightning Protection Methods for Wind Turbine Blades: An Alternative Approach. Applied Sciences. 2020; 10(6):2130. https://doi.org/10.3390/app10062130

Chicago/Turabian StyleMucsi, Viktor, Ahmad Syahrir Ayub, Firdaus Muhammad-Sukki, Muhammad Zulkipli, Mohd Nabil Muhtazaruddin, Ahmad Shakir Mohd Saudi, and Jorge Alfredo Ardila-Rey. 2020. "Lightning Protection Methods for Wind Turbine Blades: An Alternative Approach" Applied Sciences 10, no. 6: 2130. https://doi.org/10.3390/app10062130

APA StyleMucsi, V., Ayub, A. S., Muhammad-Sukki, F., Zulkipli, M., Muhtazaruddin, M. N., Mohd Saudi, A. S., & Ardila-Rey, J. A. (2020). Lightning Protection Methods for Wind Turbine Blades: An Alternative Approach. Applied Sciences, 10(6), 2130. https://doi.org/10.3390/app10062130